Академический Документы

Профессиональный Документы

Культура Документы

Executive Shir Inc Solution

Загружено:

Abhishek KumarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Executive Shir Inc Solution

Загружено:

Abhishek KumarАвторское право:

Доступные форматы

Harvard Business School

9-696-071

Rev. March 11, 1996

Executive Shirt Co!an"

Case #nal"sis-$he Executive Shirt Co!an" %&rou! 'ro(ect)

'art #

Calculations

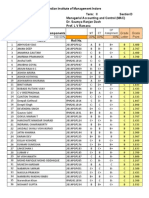

Current Process Mike's Plan Ike's Plan

Regular Shirts

Regular & Custom

Shirts

Regular Shirts Custom Shirts

A) Actual Cycle Time

(Min/shirt)

2 minutes per

cuff / 4 workers

= 0.5

2! minutes for

cutting / 4"! shirts

worth = !#2$ %

la&or content of

cuffs at 0.5 CT

'll la&or content /

one less worker for

each categor(

while cutting is still

!#2$)

Cuffs is still the

&ottleneck at 2

la&or content / *

workers = 0.67

mins/shirt

2#$ / $ = !#$ la&or

content for cutting#

+ith e,er(thing

-i,i-e- &( . collar

is new &ottleneck

at 3.90 CT

B) Manufacturing ea!

Time (!ays)

(WIP * Cycle Time) /

Minutes in a working day

./0! 1 !#$ / 4"!

minutes = "#.#5

!#$ 1 2"! / 4"!

=#.06 !ays

32!0! 1 !#004 /

4"! = "#.5$ !ays

3$! 1 *#24 / 4"!

=0.%" !ays

C) &'( 'n)ent*ry

(shirts)

Average WIP * Batc si!e

20 1 0! =""+760

*20 1 $ =

"9$0 shirts

0! 1 $ sum of

a,g# +IP =

9+060 shirts

*! units at sewing

5 $ units &eing cut

5 $ units &eing

finishe- = 50

&'(3gi,en in

case4

,) (r*!ucti*n Ca-acity

(shirts/!ay)

Minutes availa"le / CT

" hours 1 0!

minutes / !#$ =

960 shirts / !ay

" hours 1 0!

mins / !#$ = 960

shirts/!ay

4"! / !#000 =

7#0 shirts/!ay

" 1 0! / *#2 =

"#3 shirts/!ay

.) Ca-acity /tili0ati*n

Actual Produced / Wat

could "e #roduced

!.!!! / 320! 1 2!

-a(s4 = $31

30.!!! 5 2!!!4 /

320! 1 2!4

=93.751

0.!!! / 3/2! 1

2!4 = """.""1

2* 1 2! -a(s =

240! monthl(

pro-uction capacit(

2!!! / 240!

=$".#51

2) ,irect a3*r C*ntent

(min/shirt)

32! 5 *!

minutes /"hr 1 0!

30.!!! / ".!!!4

1 !#2$ = !#2/// 5

32! minutes /

4"! total minutes4

!#$ -irect la&or for

cutting 5 *#2 5 2

Current Process Mike's Plan Ike's Plan

Regular Shirts

Regular & Custom

Shirts

Regular Shirts Custom Shirts

Time s#ent cutting $

%irect la"or &or one sirt

mins4 5 *#2 5 2 5

!#0$ 5 2#$ 5 #/

5 !#00 5 #0$ 5

#$$ 5 !#0$ 5 #"

5 #$$ 5 #/ 5

#$ 5 #2$ 5 #/$

= #5.76

32.!!! / ".!!! 1

!#$4 = !#2/// =

weighte- a,g#

cutting time for

regular an-

custom

2$#/0 6 !#2$ =

2$#$ sum of

stan-ar- station

time

2$#$ 5 !#2///

=#5.79

5 *#2 5 2 5 !#0$

5 2#$ 5 #/ 5

!#00 5 #0$ 5

#$$ 5 !#0$ 5 #"

5 #$$ 5 #/ 5

#$ 5 #2$ 5 #/$

= #5.76

5 !#0$ 5 2#$ 5 #/

5 !#00 5 #0$ 5

#$$ 5 !#0$ 5 #"

5 #$$ 5 #/ 5 #$

5 #2$ 5 #/$

=#5.0"

4) ,irect a3*r

/tili0ati*n

('irts #er day * %irect

la"or content / (%irect

la"or * minutes

availa"le)

3"!! shirts 1

2$#/0 7irect la&or

content4 / 0414"!

= 67.0$1

32!! 1 2$#/24 /

30$ -irect workers

1 4"! minutes

a,aila&le4= 2*.2

/ *.2!!

=7%.391

3"!! per -a( 1

2$#/04 / 304 6 $4

1 4"!4 = 2!.0!" /

2*.$2! = $7.6#1

!! 1 20#! / 30

1 4"!4 = 33.$71

5) ,irect a3*r C*st

(6/shirt)

%irect la"or ('alary *

ours worked) / sirts

#roduced

04 30 1 "4 / "!!

=63.$%

0$ 3 80 1

"hours4 / 2!! =

*2!! / 2!!

= 63.%7

/2! shirts / -a( on

normal salar() 42

1 0 1 " = 82.*$2

"! remaining

shirts 1 !#0/ =

$*#0 minutes

$*#0 / 0! 1 2 =

"#!4

42 1 "#!4 =

*2*#20

9otal) 3*2*#20 5

2*$24 / "!! =3.%3

0 380 1 " hours4 /

!! = 7.6$

Ex!lanation

1. Regular shirt production process without custom shirt fabrication.

a. C"cle tie *or each station + total station tie , - o* .or/ers at station

i. C"cle tie *or s"ste + lon0est station c"cle tie

ii. Cu1s station + S"ste C$ + 2.0 inutes , 3 .or/ers + 0.5 minutes

4. Manu*acturin0 5ead $ie %M5$) + C"cle $ie %C$) 6 7or/s in 'ro0ress %78')

i. C$ + 0.9 inutes

ii. 78' individual shirts + %196 4atches 6 60 shirts , 4atch) + 11,760

iii. M5$ in da"s + %0.9 6 11,760) , 3:0 inutes !er da" + 12.25 days

c. $otal individual shirts as 78' + Su o* avera0e 4atches 6 60 shirts !er 4atch

i. 78' shirts + 196 4atches 6 60 shirts !er 4atch + 11,760 shirts as W!

d. 'roduction ca!acit" o* s"ste at continuous 100; utili<ation %inutes)

i. 'roduction ca!acit" + inutes !er da" , C$ o* s"ste

ii. 'roduction ca!acit" + 3:0 , 0.9 + "60 units per day = continuous 100;

utili<ation

e. 'roduction ca!acit" utili<ation + onthl" !roduction , onthl" !roduction

ca!acit"

i. Current onthl" !roduction is 16,000 %0iven in case)

ii. $otal onthl" ca!acit" + 19,200 %920 !er da" 6 20 da"s !er onth)

iii. 'roduction utili<ation + 16,000 , 19,200 + #$%

*. >irect 5a4or content + su o* tie at all stations ? tie !er shirt *or cuttin0

i. Su o* tie at all stations + 29.91 inutes !er shirt

ii. # sin0le cuttin0 o* : !atterns on 60 la"ers o* cloth !roduces %60 6 :) + 3:0

shirts

iii. $otal cuttin0 tie + %1.9 inutes 6 60 la"ers) ? %@0 inutes cuttin0) + 120

inutes

iv. Cuttin0 tie !er shirt + 120 inutes , 3:0 shirts + 0.29 inutes !er shirt

v. $otal la4or content %tie) !er shirt + 29.91 ? 0.29 + 25.76 minutes per

shirt

0. >irect 5a4or Atili<ation + $otal used la4or tie , $otal la4or tie availa4le

i. $otal la4or tie availa4le + 63 .or/ers 6 3:0 inutes !er da" + @0,720

inutes

ii. $otal tie used + tie !er shirt 6 dail" !roduction %16,000 !er onth , 20

da"s)

iii. $otal tie used + 29.76 inutes 6 :00 shirts !er da" + 20,60: inutes

iv. >irect 5a4or Atili<ation + 20,60: inutes used , @0,720 inutes availa4le

+ 67.0#%

h. $otal >irect 5a4or Cost !er shirt + %- .or/ers 6 : hours !er da" 6 B6 !er

hour) , :00

i. $otal >irect la4or cost + %63 6 : 6 6) , :00 %total dail" !roduction + 16,000 ,

20 da"s)

ii. $otal >irect 5a4or Cost + &$.#' ( shirt

2. )i*e+s plan for production of regular and custom shirts using

e,isting facilities with the addition of a new cutting machine and one

wor*er.

a. S"ste C$ reains unchan0ed + 0.9 %the cu1s station still has the lon0est

station C$)

4. Manu*acturin0 5ead $ie %M5$) + C"cle $ie %C$) 6 7or/s in 'ro0ress %78')

i. C$ + 0.9 inutes

ii. 78' individual shirts + %@96 4atches 6 9 shirts , 4atch) + 1,9:0

iii. M5$ in da"s + %0.9 6 1,9:0) , 3:0 inutes !er da" + 2.06 days

c. $otal individual shirts as 78' + Su o* avera0e 4atches 6 9 shirts !er 4atch

i. 78' shirts + @96 4atches 6 9 shirts !er 4atch + 1,"#0 shirts as W!

d. 'roduction ca!acit" o* s"ste at continuous 100; utili<ation %inutes)

i. 'roduction ca!acit" + inutes !er da" , C$ o* s"ste

ii. 'roduction ca!acit" + 3:0 , 0.9 + 960 units !er da" = continuous 100;

utili<ation

e. 'roduction ca!acit" utili<ation + onthl" !roduction , onthl" !roduction

ca!acit"

i. Current onthl" !roduction is 16,000 re0ular ? 2000 custo shirts %0iven in

case)

ii. $otal onthl" ca!acit" + 1:,000 %900 !er da" 6 20 da"s !er onth)

iii. 'roduction utili<ation + 1:,000 , 19,200 + "$.#%

*. >irect 5a4or content + su o* tie at all stations ? tie !er shirt *or cuttin0

i. Su o* tie at all stations + 29.91 inutes !er shirt

ii. Ce. achine can cut 1 !attern on Dve la"ers in 2.9 inutes

ii.Custo cuttin0 tie + 9 shirts , 2.9 inutes + 0.9 inutes !er custo shirt

iii. $otal cuttin0 tie + 7ei0hted avera0e o* old E ne. achine cuttin0 ties

iii.%16,000 re0 , 1:000 total) 6 0.29 ? %2000 , 1:000) 6 0.9 + 0.27: in,shirt

iv. $otal la4or content %tie) !er shirt + 29.91 ?0.2: + 25.7" minutes per

shirt

0. >irect 5a4or Atili<ation + $otal used la4or tie , $otal la4or tie availa4le

i. $otal la4or tie availa4le + 69 .or/ers 6 3:0 inutes !er da" + @1,200

inutes

ii. $otal tie used + tie !er shirt 6 dail" !roduction %1:000 !er onth , 20

da"s)

iii. $otal tie used + 29.79 inutes 6 900 shirts !er da" + 2@,211 inutes

iv. >irect 5a4or Atili<ation + 2@,211 inutes used , @1,200 inutes availa4le

+ 7'.$"%

h. $otal >irect 5a4or Cost !er shirt + %- .or/ers 6 : hours !er da" 6 B6 !er

hour) , 900

i. $otal >irect la4or cost + %69 6 : 6 6) , 900 %total dail" !roduction + 1:,000 ,

20 da"s)

ii. $otal >irect 5a4or Cost + &$.'7 ( shirt

$. *e+s plan for shifting labor from the regular assembly -oor to

create a separate assembly line dedicated to custom shirts, thus

separating the two streams of production.

(A) Regular Shirt Production:

a. S"ste C$ + 0.67 %the cu1s station still has the lon0est station C$ = 2.0 in

, @ .or/ers )

4. Manu*acturin0 5ead $ie %M5$) + C"cle $ie %C$) 6 7or/s in 'ro0ress %78')

i. C$ + 0.67 inutes

ii. 78' individual shirts + %191 4atches 6 60 shirts , 4atch) + 9,060

iii. M5$ in da"s + %0.67 6 9,060) , 3:0 inutes !er da" + 12.5# days %*or re0ular

shirts)

c. $otal individual shirts as 78' + Su o* avera0e 4atches 6 60 shirts !er 4atch

i. 78' shirts + 191 4atches 6 60 shirts !er 4atch + ",060 shirts as W!

d. 'roduction ca!acit" o* s"ste at continuous 100; utili<ation %inutes)

i. 'roduction ca!acit" + inutes !er da" , C$ o* s"ste

ii. 'roduction ca!acit" + 3:0 , 0.67 + 720 units per day = continuous 100;

utili<ation

e. 'roduction ca!acit" utili<ation + onthl" !roduction , onthl" !roduction

ca!acit"

i. Current onthl" !roduction is 16,000 re0ular shirts %0iven in case)

ii. $otal onthl" ca!acit" + 13,300 %720 !er da" 6 20 da"s !er onth)

iii. 'roduction utili<ation + 16,000 , 13,300 + 111%

*. >irect 5a4or content + su o* tie at all stations ? tie !er shirt *or cuttin0

i. Su o* tie at all stations + 29.91 inutes !er shirt

ii. # sin0le cuttin0 o* : !atterns on 60 la"ers o* cloth !roduces %60 6 :) + 3:0

shirts

iii. $otal cuttin0 tie + %1.9 inutes 6 60 la"ers) ? %@0 inutes cuttin0) + 120

inutes

iv. Cuttin0 tie !er shirt + 120 inutes , 3:0shirts + 0.29 inutes !er shirt

v. $otal la4or content %tie) !er shirt + 29.91 ? 0.29 + 25.76 minutes per

shirt

0. >irect 5a4or Atili<ation + $otal used la4or tie , $otal la4or tie availa4le

i. Ce. direct la4or availa4le + 63 F 19 + 39

ii. $otal la4or tie availa4le + 39 .or/ers 6 3:0 inutes !er da" + 20,60:

inutes

iii. $otal tie used + tie !er shirt 6 dail" !roduction %16000 !er onth , 20

da"s)

iv. $otal tie used + 29.76 inutes 6 :00 shirts !er da" + 2@,211 inutes

v. >irect 5a4or Atili<ation + 20,60: inutes used , 2@,920 inutes availa4le

+ #7.62%

h. $otal >irect 5a4or Cost !er shirt + %- .or/ers 6 : hours !er da" 6 B6 !er

hour) , :00

i. Gvertie is incurred *or all e!lo"ees in order to reach excess o* noral

hour !roduction levels %calculated a4ove = 11; a4ove ca!acit")

ii. Gvertie !roduction + dail" !roduction F dail" ca!acit" + :00 F 720 + :0

shirts

ii.G$ %inutes) + :0 6 C$ + :0 6 0.67 + 9@.60 extra inutes !er .or/er

ii.G$ cost + %9@.60 , 60) 6B6 , hour 6 nu4er o* .or/ers + %9@.60 , 60) 6 6 6 39

ii.G$ cost + B@9@.96

iii. $otal >irect la4or cost + %39 6 : 6 6) ? @9@.96 , :00 %total dail" !roduction +

1:,000 , 20 da"s)

iv. $otal >irect 5a4or Cost + &$.'$ ( regular shirt

(B) Custom shirt production on separate assembly line (1 !or"ers # 1

ne! hire):

a. C"cle tie *or each station + total station tie , - o* .or/ers at station

i. C"cle tie *or s"ste + lon0est station c"cle tie

ii. Cu1s station + S"ste C$ + @.90 inutes , 1 .or/er + $."0 minutes %collar

station)

4. Manu*acturin0 5ead $ie %M5$) + C"cle $ie %C$) 6 7or/s in 'ro0ress %78')

i. C$ + 0.9 inutes

ii. 78' individual shirts + %10 4atches 6 9 shirts , 4atch) + 90 shirts

iii. M5$ in da"s + %@.90 6 90) , 3:0 inutes !er da" + 0.31 da"s

c. $otal individual shirts as 78' + Su o* avera0e 4atches 6 9 shirts !er 4atch

i. 78' shirts + @0 shirts in se.in0 ? 9 shirts in cuttin0 ? 19 shirts in Dnishin0

+ 50 shirts as W! %0iven in case)

d. 'roduction ca!acit" o* s"ste at continuous 100; utili<ation %inutes)

i. 'roduction ca!acit" + inutes !er da" , C$ o* s"ste

ii. 'roduction ca!acit" + 3:0 , @.90 + 12$ units per day = continuous 100;

utili<ation

e. 'roduction ca!acit" utili<ation + onthl" !roduction , onthl" !roduction

ca!acit"

i. Current onthl" !roduction is 2,000 %0iven in case)

ii. $otal onthl" ca!acit" + 2360 %12@ !er da" 6 20 da"s !er onth)

iii. 'roduction utili<ation + 2000 , 2360 + #1.25%

*. >irect 5a4or content + su o* tie at all stations ? tie !er shirt *or cuttin0

i. Su o* tie at all stations + 29.91 inutes !er shirt

ii. # sin0le cuttin0 o* 1 !attern on 9 la"ers o* cloth !roduces 9 shirts

iii. $otal cuttin0 tie + 2.9 inutes

iv. Cuttin0 tie !er shirt + 2.9 inutes , 9 shirts + 0.90 inutes !er shirt

v. $otal la4or content %tie) !er shirt + 29.91 ? 0.90 + 26.01 minutes per

shirt

0. >irect 5a4or Atili<ation + $otal used la4or tie , $otal la4or tie availa4le

i. $otal la4or + 12 se.ers ? @ Dnishers ? 1 cutter + 16

ii. $otal la4or tie availa4le + 16 .or/ers 6 3:0 inutes !er da" + 76:0

inutes

iii. $otal tie used + tie !er shirt 6 dail" !roduction %2000 !er onth , 20 da"s)

iv. $otal tie used + 26.01 inutes 6 100 shirts !er da" + 2601 inutes

v. >irect 5a4or Atili<ation + 2601 inutes used , 76:0 inutes availa4le

+ $$.#7%

h. $otal >irect 5a4or Cost !er shirt + %- .or/ers 6 : hours !er da" 6 B6 !er

hour) , 200

i. $otal >irect la4or cost + %16 6 : 6 6) , 200 %total dail" !roduction + 2000 , 20

da"s)

ii. $otal >irect 5a4or Cost + &7.6# ( custom shirt

'art B

Recoendation to Mana0eent

Asin0 the calculations in Part A it is !ossi4le to evaluate each o* the t.o !ro!osals

in ters o* their cost and eHcienc". Iirstl", to deduce the total cost *or the custo

shirts each onth, the >irect 5a4our Cost *ro each !lan can 4e ulti!lied 4" 2000

%the desired Juantit" !roduced). B" doin0 this .e learn that 8/eKs total cost *or

custo shirts is B7.6: x 2000 + B19,@60, co!ared to Mi/eKs B@.37 x 2000 +

B6,930. $his results in an B:,320 cost di1erence in *avour o* Mi/eKs !lan. 'roduction

o* re0ular shirts on the other hand are chea!er usin0 8/eKs !rocess, that is 8/eKs

la4our costs are B@.3@ x 16,000 %desired Juantit" o* re0ular shirts) + B93,::0

co!ared .ith Mi/eKs la4our costs o* B@.37 x 16,000 + B99,920. $he di1erence

4et.een the t.o is onl" B630, .hich is *airl" insi0niDcant, and leaves the total cost

di1erence 4et.een the t.o !lans at B7,7:0 in *avour o* Mi/e.

$he 0reat dis!arit" in cost 4et.een the t.o is ainl" due to the eHcienc" o* each

!ro!osal. 7hilst Mi/e increases the eHcienc" o* 4oth ca!acit" and la4our utili<ation

in the *actor" %a4sor4in0 excess ca!acit" and increasin0 eHcienc" *ro :@; to

9@.79; as .ell as i!rovin0 la4our eHcienc" 4" 7.@1;), 8/e over-utili<es ca!acit"

in his re0ular shirt !roduction line and severel" under-utili<es ca!acit" in his custo

shirts !roduction line. $he result o* this is that he has to !a" the .or/ers on the

re0ular shirt line overtie .hilst the .or/ers on the custo shirt line are *reJuentl"

starved and sittin0 idle.

Iurtherore, .hen considerin0 the lo0istics o* each !roduction line la"out, Mi/eKs

!ro!osal is *avoura4le over 8/eKs 4ecause it allo.s *or ore Lexi4ilit". 7hilst Mi/e

retains the existin0 M!rocess la"outK in the 4atch sho! !rocess, .here siilar

o!erations are !er*ored in coon *unctional areas, 8/e instead ado!ts a M!roduct

la"outK structure, .here the o!erations are located accordin0 to the !ro0ressive

ste!s involved in a/in0 a shirt. Havin0 onl" one .or/er co!letin0 each

!roduction tas/, as is the case in 8/eKs !lan, eans that i* one .or/er is slo.ed

do.n *or an" reason or needs to ta/e a 4rea/, then there is no one to !ic/ u! the

slac/. #s a result, the .hole !rocess is ne0ativel" a1ected. #n ideal asse4l" line

should allo. .or/ers to trade eleents o* .or/ and it should 4e un!ro4leatic to

add .or/ers to the line to increase eHcienc", ho.ever the strai0ht-line la"out o*

8/eKs !lan does not satis*" these reJuireents.

Based u!on our anal"sis, althou0h 4oth !rocesses do essentiall" satis*" >.i0ht

CollierKs !roduction lead ana0eent tie conditions, .e .ould recoend that

he should trial Mi/eKs !lan. 8* there does indeed !rove to 4e a ar/et *or id !rice

ran0e custo shirts, then i!leentin0 Mi/eKs !ro!osal is the co!an"Ks 4est shot

at a/in0 a lucrative !roDt *ro this

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Drafting Basic Sleeping Garment Block Pattern LessonДокумент44 страницыDrafting Basic Sleeping Garment Block Pattern Lessonadelfa100% (6)

- A4 GBSB - Unisex KimonoДокумент73 страницыA4 GBSB - Unisex KimonoCarolina LОценок пока нет

- MDF137 - The Setaria DressДокумент46 страницMDF137 - The Setaria DressMonika SalОценок пока нет

- Behno Ki Gand Marne Ki KahaniДокумент42 страницыBehno Ki Gand Marne Ki Kahanishumail ahmad65% (17)

- 7 Garment Retailer Database SampleДокумент325 страниц7 Garment Retailer Database Samplesrinivasan100% (1)

- Find the Best Saree, Ethnic and Western Wear Retailers DatabaseДокумент146 страницFind the Best Saree, Ethnic and Western Wear Retailers Databasepihoo a100% (1)

- Clothes Vocabulary Word ListДокумент4 страницыClothes Vocabulary Word ListNatalia FurtaОценок пока нет

- FORT FrameworkДокумент7 страницFORT FrameworkAbhishek KumarОценок пока нет

- Invoice OD109172599294660000Документ2 страницыInvoice OD109172599294660000Abhishek KumarОценок пока нет

- Chapter12 SlidesДокумент15 страницChapter12 SlidesParth Rajesh ShethОценок пока нет

- Antecedent Verification ProcessДокумент4 страницыAntecedent Verification ProcessAbhishek KumarОценок пока нет

- Anova and The Design of Experiments: Welcome To Powerpoint Slides ForДокумент22 страницыAnova and The Design of Experiments: Welcome To Powerpoint Slides ForAbhishek KumarОценок пока нет

- Chapter 10 Regression SlidesДокумент46 страницChapter 10 Regression SlidesAbhishek KumarОценок пока нет

- An Example of Attribute Based MDS Using Discriminant AnalysisДокумент17 страницAn Example of Attribute Based MDS Using Discriminant AnalysisAbhishek KumarОценок пока нет

- An Example of Attribute Based MDS Using Discriminant AnalysisДокумент17 страницAn Example of Attribute Based MDS Using Discriminant AnalysisAbhishek KumarОценок пока нет

- Agency 1 IndiaHike Detailed ScheduleДокумент9 страницAgency 1 IndiaHike Detailed ScheduleAbhishek KumarОценок пока нет

- Nifty: Trading StrategiesДокумент2 страницыNifty: Trading StrategiesAbhishek KumarОценок пока нет

- Financial Modeling Case StudyДокумент7 страницFinancial Modeling Case StudyAbhishek KumarОценок пока нет

- Active Portfolio ManagementДокумент7 страницActive Portfolio ManagementAbhishek KumarОценок пока нет

- Nifty: Trading StrategiesДокумент2 страницыNifty: Trading StrategiesAbhishek KumarОценок пока нет

- Candidates Interning BFSI DomainДокумент2 страницыCandidates Interning BFSI DomainAbhishek KumarОценок пока нет

- XOLO-Snapdeal - Marketer of The YearДокумент3 страницыXOLO-Snapdeal - Marketer of The YearAbhishek KumarОценок пока нет

- Marketing of ServicesДокумент6 страницMarketing of ServicesAbhishek KumarОценок пока нет

- Absence Record PGP-1 Term IIIДокумент87 страницAbsence Record PGP-1 Term IIIAbhishek KumarОценок пока нет

- Q3fy15 Result ConcallДокумент1 страницаQ3fy15 Result ConcallAbhishek KumarОценок пока нет

- ISM-I Sec CДокумент2 страницыISM-I Sec CAbhishek KumarОценок пока нет

- Absence Record PGP-1 Term IIIДокумент123 страницыAbsence Record PGP-1 Term IIIAbhishek KumarОценок пока нет

- Indian Institute of Management Indore: MT ET CP AssignmentДокумент2 страницыIndian Institute of Management Indore: MT ET CP AssignmentAbhishek KumarОценок пока нет

- Indian Institute of Management Indore: MT ET CP AssignmentДокумент2 страницыIndian Institute of Management Indore: MT ET CP AssignmentAbhishek KumarОценок пока нет

- Support Service PDF PackДокумент15 страницSupport Service PDF PackAnderson CostaОценок пока нет

- Absence Record PGP-1 Term IIIДокумент87 страницAbsence Record PGP-1 Term IIIAbhishek KumarОценок пока нет

- INOX Leisure Ltd. Location Listing with Over 40 LocationsДокумент2 страницыINOX Leisure Ltd. Location Listing with Over 40 LocationsAbhishek KumarОценок пока нет

- BC Sec CДокумент2 страницыBC Sec CAbhishek KumarОценок пока нет

- Overview of HR FunctionsДокумент24 страницыOverview of HR FunctionsAbhishek KumarОценок пока нет

- Pharmacy Service Improvement atДокумент5 страницPharmacy Service Improvement atAbhishek KumarОценок пока нет

- SHRMДокумент13 страницSHRMRachit Pradhan100% (1)

- Qt-Iii - 2012-14Документ71 страницаQt-Iii - 2012-14Abhishek KumarОценок пока нет

- Cynthia Tan Price ListДокумент13 страницCynthia Tan Price ListCindy BriaОценок пока нет

- Uniform PolicyДокумент3 страницыUniform PolicybkwsubantingОценок пока нет

- SHEIN ICON Bikercore Letter Embroidery Contrast Binding Halter Top SHEIN USAДокумент1 страницаSHEIN ICON Bikercore Letter Embroidery Contrast Binding Halter Top SHEIN USAesmeraldakara2Оценок пока нет

- Draft A Kimono Sleeve From Block PatternДокумент34 страницыDraft A Kimono Sleeve From Block PatternDamaris GОценок пока нет

- Behariji EnterprisesДокумент16 страницBehariji EnterprisesTinaОценок пока нет

- Student checklist for international tripДокумент3 страницыStudent checklist for international tripNik Muhammad FadleyОценок пока нет

- Ricky & Angel - Prewedding RundownДокумент9 страницRicky & Angel - Prewedding RundownVynica SeptarianiОценок пока нет

- Sale PDFДокумент10 страницSale PDFMoudud HossainОценок пока нет

- Fabric Consumption of A Basic ShirtДокумент7 страницFabric Consumption of A Basic ShirtEmdad ApmОценок пока нет

- BasicInstincT Pattern CopyShopДокумент1 страницаBasicInstincT Pattern CopyShopRocío PaucarОценок пока нет

- T-Shirt Fom BasicДокумент3 страницыT-Shirt Fom BasicmxpxaxoОценок пока нет

- TTT TTTTT TTTTTДокумент2 страницыTTT TTTTT TTTTTMustafijur RahmanОценок пока нет

- PothysДокумент2 страницыPothyspothyschennai123Оценок пока нет

- Evolution of Indian Blouse Over CenturiesДокумент1 страницаEvolution of Indian Blouse Over CenturiesSimran MehtaОценок пока нет

- Clothes Vocabulary Esl Unscramble The Words Worksheets For KidsДокумент4 страницыClothes Vocabulary Esl Unscramble The Words Worksheets For KidsMonica IonОценок пока нет

- 40 Types of Dresses For Every Women Should Know: RelatedДокумент43 страницы40 Types of Dresses For Every Women Should Know: Relatedjazzy mallariОценок пока нет

- HKFW July - 2010 2 PDFДокумент12 страницHKFW July - 2010 2 PDFCafuné DenimОценок пока нет

- UnPivot Columns - Basics Pivot ColumnДокумент7 страницUnPivot Columns - Basics Pivot ColumnLeonardo GeovanniОценок пока нет

- Price List Harga Paket Pengadaan Seragam Nite & Day Hotel Berdasarkan Klasifikasi Dan Kelas ProdukДокумент19 страницPrice List Harga Paket Pengadaan Seragam Nite & Day Hotel Berdasarkan Klasifikasi Dan Kelas ProdukKontraОценок пока нет

- Designation Wise Approved Dress Code RevisedДокумент9 страницDesignation Wise Approved Dress Code RevisedRahul JalauniaОценок пока нет

- Scania Truck GearДокумент15 страницScania Truck GearSandor PetrusОценок пока нет

- Infinity Analysis YtdДокумент747 страницInfinity Analysis YtdTanu DhankarОценок пока нет

- Body &collar Cuff Consumption Formula For PoloДокумент2 страницыBody &collar Cuff Consumption Formula For Polosazia nituОценок пока нет