Академический Документы

Профессиональный Документы

Культура Документы

904 L

Загружено:

komailОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

904 L

Загружено:

komailАвторское право:

Доступные форматы

High performance austenitic stainless steels differ substantially from more conventional grades with regard to resistance to corrosion

and, in some cases, also mechanical and physical properties. This is mainly due to the high contents of chromium, nickel, molybdenum

and nitrogen. High performance austentic stainless steels have good weldability and excellent formability. Outokumpu manufactures a

number of steels of this type: 904L, 254 SMO

,4565 and 654 SMO

. Grade 4529 can also be delivered if specified.

Typi c al appl i c at i ons

Process equipment in chemical industry

Bleaching equipment in the pulp and paper industry

Flue gas cleaning

Desalination

Seawater handling

Hydrometallurgy

Food and beverage

Pharmaceuticals

Heat exchangers

St andar ds & appr oval s

Outokumpu produce and certify materials to most international and national standards. Work is continuously on-going to get the

different grades approved for relevant standards. The most commonly used international product standards are given in the table below.

Standard Designation

ASME SA-240M Code Sect. II. Part A UNS N08904

ASTM A240/A240M UNS N08904

EN 10028-7, PED 97/23/EC 1.4539

EN 10088-2 1.4539

EN 10088-4 1.4539

WUHAN Doc. No. 050MPS-MA-12P UNS N08904

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page1of 11

Pr oduc t s & di mensi ons

Cold rolled products available dimensions in mm

Continous Hot rolled products available dimensions in mm

Coil / Strip Plate / Sheet

Finish Thickness Width Thickness Width

2B Cold rolled, heat treated, pickled, skin passed 1,50-6,00 800-2032 1,50-6,00 300-2032

2E Cold rolled, heat treated, mech. desc. pickled 0,40-6,00 36-2032 0,40-6,00 300-2032

2H Work hardened 1,90-2,10 400-1300

2R Cold rolled, bright annealed 0,05-1,50 3-1050 0,10-1,20 5-1050

Coil / Strip Plate / Sheet

Finish Thickness Width Thickness Width

1C 1C 2,00-65,00 400-3000

1D Hot rolled, heat treated, pickled 6,00-10,00 96-2032 2,00-65,00 300-3000

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page2of 11

Quarto plate products available dimensions in mm

Coil / Strip Plate / Sheet

Finish Thickness Width Thickness Width

1C 1C 2,00-65,00 400-3000

1D Hot rolled, heat treated, pickled 2,00-65,00 400-3000

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page3of 11

Process pipes ASME B36.19M available dimensions

Sc hedul e

DN mm NPS OD mm 5S/5 10S 40S/STD 80S/XS

10,00 3/8 17,10 1,65

15,00 1/2 21,30 1,65 2,11 2,77

20,00 3/4 26,70 1,65 2,11 2,87 3,91

25,00 1 33,40 1,65 2,77 3,38 4,55

32,00 1 1/4 42,20 1,65 2,77 3,56 4,85

40,00 1 1/2 48,30 1,65 2,77 3,68 5,08

50,00 2 60,30 1,65 2,77 3,91 5,54

65,00 2 1/2 73,00 2,11 3,05 5,16 7,01

80,00 3 88,90 2,11 3,05 5,49 7,62

100,00 3 1/2 101,60 2,11 3,05 5,74 8,08

4 114,30 2,11 3,05 6,02 8,56

125,00 5 141,30 2,77 3,40 6,55

150,00 6 168,30 2,77 3,40 7,11 10,97

200,00 8 219,10 2,77 3,76 8,18 12,70

250,00 10 273,00 3,40 4,19 9,27 12,70

300,00 12 323,90 3,96 4,57 9,53 12,70

350,00 14 355,60 3,96 4,78 9,53 12,70

400,00 16 406,40 4,19 4,78 9,53 12,70

450,00 18 457,00 4,19 4,78 9,53 12,70

500,00 20 508,00 4,78 5,54 9,53 12,70

550,00 22 559,00 4,78 5,54 9,53 12,70

600,00 24 610,00 5,54 6,35 9,53 12,70

26 660,00 9,53 12,70

700,00 28 711,00 9,53 12,70

30 762,00 6,35 7,92 9,53 12,70

800,00 32 813,00 9,53 12,70

34 864,00 9,53 12,70

900,00 36 914,00 9,53 12,70

38 965,00 9,53 12,70

1000,00 40 1016,00 9,53 12,70

42 1067,00 9,53 12,70

1100,00 44 1118,00 9,53 12,70

46 1168,00 9,53 12,70

1200,00 48 1219,00 9,53 12,70

52 1321,00 9,53 12,70

54 1372,00 9,53 12,70

56 1422,00 9,53 12,70

60 1524,00 9,53 12,70

64 1626,00 9,53 12,70

68 1727,00 9,53 12,70

72 1829,00 9,53 12,70

76 1930,00 9,53 12,70

80 2032,00 9,53 12,70

Represent standard dimension, normally keept in stock

Dimension available on request

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page4of 11

Process pipes ASME B36.10M available dimensions

Sc hedul e

DN mm NPS OD mm 10 20 30 40 60 80 100 120 140 160 XXS

10,00 3/8 17,10 1,65

15,00 1/2 21,30 2,11 2,77

20,00 3/4 26,70 2,11 2,87 3,91

25,00 1 33,40 2,77 3,38 4,55

32,00 1 1/4 42,20 2,77 3,56 4,85

40,00 1 1/2 48,30 2,77 3,68 5,08

50,00 2 60,30 2,77 3,91 5,54

65,00 2 1/2 73,00 3,05 5,16 7,01

80,00 3 88,90 3,05 5,49

100,00 3 1/2 101,60 3,05 5,74 8,08

100,00 4 114,30 3,05 6,02 8,56

125,00 5 141,30 3,40 6,55

150,00 6 168,30 3,40 7,11 10,97

200,00 8 219,10 3,76 6,35 8,18 10,31 12,70 15,09

250,00 10 273,00 4,19 6,35 9,27 12,70 15,09 21,44 25,40 28,58 25,40

300,00 12 323,90 4,57 6,35 10,31 14,27 17,48 21,44 25,40 28,58 33,32 25,40

350,00 14 355,60 6,35 7,92 9,53 11,13 15,09 19,05 23,83 27,79 31,75 35,71 25,40

400,00 16 406,40 6,35 7,92 9,53 12,70 16,66 21,44 26,19 30,96 36,53 40,49 25,40

450,00 18 457,00 6,35 7,92 11,13 14,27 19,05 23,83 29,36 34,93 39,68 45,24 25,40

500,00 20 508,00 6,35 9,53 12,70 15,09 20,62 26,19 32,54 38,10 44,45 50,01 25,40

550,00 22 559,00 6,35 9,53 12,70 22,23 28,58 34,93 41,28 47,63 25,40

600,00 24 610,00 6,35 9,53 14,27 17,48 30,96 38,89 46,02 25,40

26 660,00 7,92 12,70 30,96 38,10 41,28 44,45 25,40

700,00 28 711,00 7,92 12,70 15,88 30,96 38,10 41,28 44,45 25,40

30 762,00 7,92 12,70 15,88 30,96 38,10 41,28 44,45 25,40

800,00 32 813,00 7,92 12,70 15,88 17,48 30,96 38,10 41,28 44,45 25,40

34 864,00 7,92 12,70 15,88 17,48 30,96 38,10 41,28 44,45 25,40

900,00 36 914,00 7,92 12,70 15,88 19,05

1000,00 40 1016,00 14,27 15,88 17,48 19,05

42 1067,00 11,13 14,27 15,88 17,48 19,05

1100,00 44 1118,00 11,13 14,27 15,88 17,48 19,05

46 1168,00 11,13 14,27 15,88 17,48 19,05

1200,00 48 1219,00 11,13 14,27 15,88 17,48 19,05

52 1321,00 11,13 14,27 15,88 17,48 19,05

54 1372,00 11,13 14,27 15,88 17,48 19,05

56 1422,00 11,13 14,27 15,88 17,48 19,05

60 1524,00 11,13 14,27 15,88 17,48 19,05

64 1626,00 11,13 14,27 15,88 17,48 19,05

68 1727,00 11,13 14,27 15,88 17,48 19,05

72 1829,00 11,13 14,27 15,88 17,48 19,05

76 1930,00 11,13 14,27 15,88 17,48 19,05

80 2032,00 11,13 14,27 15,88 17,48 19,05

Represent standard dimension, normally

keept in stock

Dimension available on request

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page5 of 11

Chemi c al c omposi t i on

The typical chemical composition for this grade is given in the table below, together with composition limits given for this grade according

to different standards. The required standard will be fully met as specified on the order.

C Mn Cr Ni Mo N Other

Typical 904L 0.010 20.0 25.0 4.3 Cu:1.5

050MPS-MA-12P UNS N08904 0.020 2.00 19.0-23.0 23.0-28.0 4.0-5.0 Cu:1.0-2.0

ASME II A SA-240 UNS N08904 0.020 2.00 19.00-23.00 23.0-28.0 4.00-5.00 0.10 Cu:1.0-2.0

ASTM A240 UNS N08904 0.020 2.00 19.0-23.0 23.0-28.0 4.0-5.0 0.10 Cu:1.0-2.0

EN 10028-7 1.4539 0.020 2.00 19.0-21.0 24.0-26.0 4.0-5.0 0.15 Cu:1.20-2.00

EN 10088-2 1.4539 0.020 2.0 19.0-21.0 24.0-26.0 4.0-5.0 0.15 Cu:1.2-2.0

EN 10088-4 1.4539 0.020 2.0 19.0-21.0 24.0-26.0 4.0-5.0 0.15 Cu:1.2-2.0

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page6 of 11

Mec hani c al pr oper t i es

The mechanical properties of the available products are given in the table below.

R

p0.2

R

p1.0

R

m

A

5

Impact strength Rockwell HB HV

MPa MPa MPa % J

Product type: Cold rolled coil and sheet

Typical (Thickness 1mm) 904L 340 375 655 55

050MPS-MA-12P UNS N08904

ASME II A SA-240 UNS N08904 220 490 90HRB

ASTM A240 UNS N08904 220 490

EN 10028-7 1.4539 240 270 530 - 730 35

EN 10088-2 1.4539 240 270 530 - 730 35

EN 10088-4 1.4539 240 270 530 - 730 35

Product type: Hot rolled coil and sheet

Typical (Thickness 4mm) 904L

ASME II A SA-240 UNS N08904 220 490 90HRB

ASTM A240 UNS N08904 220 490

EN 10028-7 1.4539 240 270 530 - 730 35

EN 10088-2 1.4539 240 270 530 - 730 35

EN 10088-4 1.4539 240 270 530 - 730 35

Product type: Hot rolled quarto plate

Typical (Thickness 15mm) 904L 260 285 600 50 155

050MPS-MA-12P UNS N08904 220 490 70 - 90HRB

ASME II A SA-240 UNS N08904 220 490 90HRB

ASTM A240 UNS N08904 220 490 90HRB

EN 10028-7 1.4539 220 260 520 - 720 35

EN 10088-2 1.4539 220 260 520 - 720 35

EN 10088-4 1.4539 220 260 520 - 720 35

Product type: Wire rod

Typical 904L 260 300 600 50

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page7of 11

Typical values for Standard steels for comparsion

Physi c al pr oper t i es

The physical properties at room temperature are shown in the table below. Data according to EN10088 or EN10095.

Cor r osi on r esi st anc e

Uniform corrosion

Uniform corrosion occurs when all, or at least a large section, of the passive layer is destroyed. This typically occurs in acids or in hot

alkaline solutions. The influence of the alloy composition on the resistance to uniform corrosion may vary significantly between

different environments; chromium is essential for ensuring the passivity of stainless steels, nickel helps reduce the corrosion rate of

depassivated steel, molybdenum enhances passivity (except for strongly oxidising environments, such as warm concentrated nitric acid)

and copper has a positive effect in the presence of reducing acids such as dilute sulphuric acid. In an environment with constant

temperature and chemical composition, uniform corrosion occurs at a steady rate. This rate is often expressed as a loss of thickness per

unit time, e.g. mm/y. Stainless steels are normally considered to be resistant to uniform corrosion in environments in which the

corrosion rate does not exceed 0.1 mm/y. Impurities may drastically affect the corrosivity of acid solutions. For guidance on materials

selection in a large number of environments capable of causing uniform corrosion, the tables and iso-corrosion diagrams in Outokumpu

Corrosion Handbook may be consulted.

Pitting and Crevice corrosion

Chloride ions in a neutral or acidic environment facilitate local breakdown of the passive layer. As a result, pitting and crevice corrosion

can propagate at a high rate, causing corrosion failure in a short time. Since the attack is small and may be covered by corrosion

products or hidden in a crevice, it often remains undiscovered until perforation or leakage occurs.

Resistance to pitting corrosion is determined mainly by the content of chromium, molybdenum and nitrogen in the stainless steel. This

is often illustrated using the pitting resistance equivalent (PRE) for the material, which can be calculated using the formula: PRE = %Cr

+ 3.3 x %Mo + 16 x %N. The PRE value can be used for rough comparisons of different materials. A more reliable means, however, is

to rank the steel according to the critical pitting temperature (CPT) of the material. There are several different methods available, for

example ASTM G 150 that uses the Avesta Cell with a 1M NaCl solution (35 000 ppm or mg/l chloride ions). The CPT-values are

shown in the table below. Higher contents of chromium, molybdenum and nitrogen also enhance the crevice corrosion resistance of the

stainless steel. Typical values of the critical crevice corrosion temperature (CCT) in 6% FeCl3 + 1% HCl according to ASTM G48

Method F are included in the table below. The CPT and CCT values vary with product form and surface finish, the values given are for

ground surfaces. Both ASTM G150 and G48 are methods for ranking the relative pitting or crevice corrosion resistance for the different

stainless steels but they do not give the maximum temperature for using these alloys in real service environments.

R

p0.2

R

p1.0

R

m

A

5

Impact strength Rockwell HB HV

MPa MPa MPa % J

Product type: Cold rolled coil and sheet

Typical (Thickness 1mm) 2205 690 740 880 47

Product type: Hot rolled coil and sheet

Typical (Thickness 4mm) 2205 630 725 840 30 250

Product type: Hot rolled quarto plate

Typical (Thickness 15mm) 2205 510 750 35 230

Product type: Wire rod

Typical 2205 510 750 35

OK

Grade

Density

Modulus of

elasticity

Thermal exp. at 100

C

Thermal

conductivity

Thermal

capacity

Electrical

resistance

Magnetisability

kg/dm

3

GPa 10

-6

/C W/mC J/kgC m

2205 7.8 200 13 15 500 0.8 Yes

904L 8.0 195 15,8 12 500 1.0 No

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page8of 11

Stress Corrosion Cracking

Conventional stainless steels such as 4307 and 4404 are sensitive to stress corrosion cracking (SCC) under certain onditions, i.e. a

special environment in combination with tensile stress in the material and often also an elevated temperature. Resistance to SCC

increases with the increased content of above all nickel and molybdenum. This implies that the high performance austenitic steels 904L,

254 SMO

, 654 SMO

and 4565 have very good resistance to SCC.

PRE Pitting Resistant Equivalent calculated using the formula: PRE = %Cr + 3.3 x %Mo + 16 x %N

CPT Corrosion Pitting Temperature as measured in the Avesta Cell (ASTM G 150), in a 1M NaCl solution (35,000 ppm or mg/l

chloride ions).

CCT Critical Crevice Corrosion Temperature is the critical crevice corrosion temperature which is obtained by laboratory tests

according to ASTM G 48 Method F

CPT according to ASTM G150. Wet

ground to 120 grit

CPT according to ASTM G48E. Dry

ground to 120 grit

CCT according to ASTM G48F. Dry

ground to 120 grit

Pitting corrosion resistance Crevice corrosion resistance

OK Grade PRE CPT CCT

2205 35 523 20

904L 34 623 10

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page9of 11

Fabr i c at i on

Machining

Austenitic stainless steels work harden quickly and this, together with their toughness, means that they are often perceived as

problematic from a machining perspective, e.g. n operations such as turning, milling and drilling. However, with the right choice of

tools, tool settings and cutting speeds, these materials can be sucessfully machined. For further information contact Outokumpu.

Welding

All the highly alloyed austenitic steels are well suited for welding and the methods used for welding conventional austenitic steels can

also be used on 904L. However, due to the stable austenitic structure, it is somewhat more sensitive to hot cracking in connection with

welding and generally welding should be performed using a low heat input.On delivery, sheet, plate and other processed products

have a homogeneous austenitic structure with an even distribution of alloying elements in the material. Solidification after partial

remelting, e.g. by welding, causes redistribution of certain elements such as molybdenum, chromium and nickel. These variations,

segregation, remain in the cast structure of the weld and can impair the materials corrosion resistance in certain environments.

Mor e i nf or mat i on

A number of publications regarding this steel grade are available for downloading from our publications system. The downloads can be

found under Products/Useful Tools Online/Publications. Below are a few publications that might be of interest.

High Performance Austenitic Stainless Steel - 904L. 254 SMO

. 4529. 4565. 654 SMO

Material data sheet presenting the properties for Outokumpu Stainless most corrosion resistant alloys.

Acom 2010 Ed:4

Acom chronicle 1980-2010

J. Gunnarsson

Superaustenitic stainless steels in demanding environments

M. Liljas. C. Canderyd. R. Pettersson. M. Willfr

Lean duplex - the first decade of service experience

E. Alfonsson

80 years with duplex steels - a historic review and prospects for the future

M. Liljas

30 years with acom (index) - in order

30 years with acom (index) - by subject

Acom 2007 Ed:4

Stainless Steels for Flue Gas Cleaning - laboratory trials. field tests and service experience.

B. Beckers. A. Bergquist. C.-O. A. Olsson. M. Snis. and E. Torsner. Outokumpu Stainless AB

Acom 2003 Ed: 1

In-Plant Corrosion Testing in Ozone Bleaching Environments

Pekka Pohjanne and Marko Siltala

Acom 2003 Ed:4

Stainless steels for SWRO plants high-pressure piping. properties and experience MSF chambers of solid duplex stainless steel

Acom 2007 Ed:3

Stainless Steel for Hydrometallurgy Plants

J. Olsson

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page10of 11

Di sc l ai mer

Cont ac t s & Enqui r i es

Information given in this brochure may be subject to

alterations without notice. Care has been taken to ensure

that the contents of this publication are accurate but

Outokumpu and its affiliated companies do not accept

responsibility for errors or for information which is found

to be misleading. Suggestions for or descriptions of the

end use or application of products or methods of working

are for information only and Outokumpu and its affiliated

companies accept no liability in respect thereof. Before

using products supplied or manufactured by the company

the customer should satisfy himself of their suitability.

Outokumpu is a global leader in stainless steel. Our

vision is to be the undisputed number one in

stainless, with success based on operational

excellence. Customers in a wide range of industries

use our stainless steel and services worldwide. Being

fully recyclable, maintenance-free, as well as very

strong and durable material, stainless steel is one of

the key building blocks for sustainable future.

What makes Outokumpu special is total customer

focus all the way, from R&D to delivery. You have

the idea. We offer world-class stainless steel,

technical knowhow and support. We activate your

ideas.

Commercial enquiries

Contact nearest sales office, see

http://www.outokumpu.com

Technical enquiries

Outokumpu Stainless AB, Avesta Research Centre

Box 74, SE-774 22 Avesta, Sweden

Tel. +46 (0)226 810 00, Fax +46 (0)226 810 77

Out ok umpu 904L

Pr i nt ed:27 aug 2014Super sedes al l pr evi ous edi t i ons. Page11of 11

Вам также может понравиться

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Piping DocumentsДокумент12 страницPiping Documentskomail0% (1)

- Cold Formed SteelДокумент66 страницCold Formed Steelarkirthi1175Оценок пока нет

- V D Batteries Recycling1 PDFДокумент26 страницV D Batteries Recycling1 PDFJazmin Orbea100% (1)

- Tubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex WeldsДокумент5 страницTubular TYK Fabrication and Inspection: It Is Important To Plan Ahead For These Complex Weldsluz82Оценок пока нет

- Questions For RiggersДокумент5 страницQuestions For RiggersJitendra Kumar Anand100% (2)

- Name: ANEEZ Wri 3 Batch: PDO Interview QuestiansДокумент9 страницName: ANEEZ Wri 3 Batch: PDO Interview QuestiansMohammed Raje100% (1)

- Nioec Vendor List PDFДокумент545 страницNioec Vendor List PDFkomail0% (1)

- Materials Guideline Update: Preliminary Survey ResultsДокумент44 страницыMaterials Guideline Update: Preliminary Survey ResultsmrinalkantibhaduriОценок пока нет

- Presperse Catalog - Europe Asia 12-2011 PDFДокумент13 страницPresperse Catalog - Europe Asia 12-2011 PDFponian9338Оценок пока нет

- Flame Straightening S355Документ9 страницFlame Straightening S355Anonymous oI04sS100% (1)

- WES Hygienic Design Handbook - Jan 01Документ54 страницыWES Hygienic Design Handbook - Jan 01Alfonso FuentesОценок пока нет

- General Guidelines for Equipment and Piping LocationДокумент6 страницGeneral Guidelines for Equipment and Piping Locationkomail0% (1)

- Logo FSSДокумент2 страницыLogo FSSkomailОценок пока нет

- Final AppendixДокумент14 страницFinal AppendixkomailОценок пока нет

- Naming OF PDMS CATALUGEДокумент59 страницNaming OF PDMS CATALUGEkomailОценок пока нет

- Pdms ManualДокумент203 страницыPdms ManualkomailОценок пока нет

- 00 AutoLISP - AfraLISPДокумент6 страниц00 AutoLISP - AfraLISPkomailОценок пока нет

- PDMS Pipe Design Software TrainingДокумент1 страницаPDMS Pipe Design Software TrainingkomailОценок пока нет

- 02 The Basics in A Nutshell - Part 2 - AfraLISPДокумент5 страниц02 The Basics in A Nutshell - Part 2 - AfraLISPkomailОценок пока нет

- 00 AutoLISP - AfraLISPДокумент6 страниц00 AutoLISP - AfraLISPkomailОценок пока нет

- ValvesДокумент9 страницValveskomailОценок пока нет

- Sort Macro (For PDMS)Документ1 страницаSort Macro (For PDMS)komailОценок пока нет

- TMT RebarsДокумент15 страницTMT RebarsMohan Dakshina0% (1)

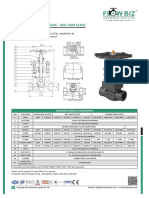

- FlowBiz Forged Steel Globe Valve 1500 ClassДокумент2 страницыFlowBiz Forged Steel Globe Valve 1500 ClassFlowBiz Exports Pvt. Ltd.Оценок пока нет

- Aluminium-Alloy-6082-T6 or T651Документ2 страницыAluminium-Alloy-6082-T6 or T651Marcelo Noé CorsiОценок пока нет

- Unit 04 - Study Guide - ANSWERSДокумент2 страницыUnit 04 - Study Guide - ANSWERSBipin GhimireОценок пока нет

- Astm f436 Type 1Документ1 страницаAstm f436 Type 1seenudesignОценок пока нет

- Easycut 46Документ2 страницыEasycut 46trumukyОценок пока нет

- Indian Boiler Regulations: (Xiii)Документ1 страницаIndian Boiler Regulations: (Xiii)Vishal SoniОценок пока нет

- p8 BB 6000Документ4 страницыp8 BB 6000Ramesh KrishnanОценок пока нет

- ME6403 Materials and MetallurgyДокумент1 страницаME6403 Materials and MetallurgyBalaji KingОценок пока нет

- MP Lab ReportДокумент4 страницыMP Lab ReportAbdul RehmanОценок пока нет

- A 270 - 02 Qti3mc0wmke - PDFДокумент5 страницA 270 - 02 Qti3mc0wmke - PDFLuis Daniel ContrerasОценок пока нет

- Crosby ShacklesДокумент1 страницаCrosby Shacklesroy sihalohoОценок пока нет

- AL - CU - Integration - Preso - v7 24 Jul 08 ZipДокумент80 страницAL - CU - Integration - Preso - v7 24 Jul 08 ZipFreddy CadenaОценок пока нет

- Avail 9 WДокумент1 страницаAvail 9 WnistianaОценок пока нет

- Surface Treatment and Painting ProcedureДокумент7 страницSurface Treatment and Painting ProcedureMohamedОценок пока нет

- Bestolife, Now in India Call +91-98851-49412Документ1 страницаBestolife, Now in India Call +91-98851-49412Project Sales CorpОценок пока нет

- ACFAA67 ASTM Specialty HandbookДокумент8 страницACFAA67 ASTM Specialty HandbookSusana PiresОценок пока нет

- Defect in Casting For Amie Manufacturing Technology and Manufacturing ScienceДокумент33 страницыDefect in Casting For Amie Manufacturing Technology and Manufacturing ScienceparameshwaranpraveenОценок пока нет

- Exploded assembly drawing caster parts listДокумент1 страницаExploded assembly drawing caster parts listlianaОценок пока нет

- Grade 9 MetalworkДокумент13 страницGrade 9 MetalworkAidan O'HaraОценок пока нет