Академический Документы

Профессиональный Документы

Культура Документы

Concrete Roads

Загружено:

gimanuАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Concrete Roads

Загружено:

gimanuАвторское право:

Доступные форматы

Concrete Roads

Concrete roads have a large number of advantages over bituminious ones. These advantages include:

Fuel Saving:Concrete roads are rigid pavements, which do not deflect under loaded trucks, unlike bitumen

pavements. Hence load carriers require less energy when travelling on concrete roads (since no effort is

expended in getting out of deflection 'ruts'). Trials carried out have shown that laden goods carriers

consume 15-20% less fuel on concrete roads as compared to bituminious ones. Considering the fact that

about 60% of our country's goods traffic moves by road, construction of a nation-wide network of concrete

roads could thus save us lot of foreign exchange now being spent on importing petroleum products.

Long Maintenance-Free Life:Concrete roads have a life of 40 years or more, compared to 10 years for

bituminious ones. In addition, concrete roads require almost no maintenance, whereas bituminious ones

need frequent repairs due to damage by traffic, weather, etc.

Gain in Traffic Speed:Concretising of existing roads has shown that this leads to significant gains in

traffic speeds, making in turn for a notable reduction in congestion and jams on high traffic density roads.

This increase in speed of vehicular movement , is due to the smooth concrete road surface which neither

needs repairs, nor allows digging can be dug up for laying utilities (for which ducts provided in advance

below the road surface). Increased traffic flow means saving of both time and fuel, as well as reduction of

pollution caused by idling engines.

Resistance to Weather, Oil Spils, etc.: Concrete roads are neither damaged by rain (being waterproof),

nor softened and distorted by heat. They also do not lose their binder due to leakage of oil from vehicles.

Hence they remain damagefree under most adverse conditions.

Economy in use of materials:For the same traffic load conditions, concrete pavements are thinner than

bituminious ones. Where the load bearing capacity of the soil is poor, a bituminious pavements may have

to be made more than one-and-a-half times thicker than a concrete one. Concrete roads thus use less

aggregates, which are in short supply or difficult to procure in many places.

Enviormental Friendliness:Concrete roads score over bitumen ones, as far as enviornmental friendliness

is concerned, in several ways. Firstly, production of concrete does not foul the atmosphere like the hot-mix

bitumen-based plants (the latter have been banned from operating in some cities, due to their polluting

nature). Secondly, concrete pavements can utilise fly ash, a polluting byproduct of thermal power plants.

Addition of fly ash to concrete increases its density as well as its resistance to chemical attack. Finally, as

already mentioned, faster movement of vehicles on concrete roads leads to lower pollution from vehicular

emissions.

Use of Indigenous Materials:Concrete roads use cement, which is manufactured from indegenously

available materials like limestone, of which a plentiful supply is available. Bituminious roads need

bitumen, which is obtained from imported crude oil (since Indian crude contains almost no bitumen).

Besides which, availability of crude oil both in India and abroad is likely to reduce in the near future , thus

jeopardising bitumen supplies required to repair existing bituminious roads.

Other Advantages:These include better reflectivity due to lighter colour(hence greater safety and lower

lighting requirements), greater skid resistance and so on.

Concrete roads, however, have one disadvantage vis-a-vas bituminious ones, in that they are initially costlier to

construct. However, with the price of bitumen going up steadily, and the use of fly ash (available free from power

plants) in making concrete mixes for pavements now being accepted, the relative cost of these two types of

pavements could become quite comparable.

When life-cycle costs are considered, concrete pavements with their long life and negligible maintenance, come

out invariably superior to bituminious ones.

As regards the economic costs to the country, fuel saving and enviornmental friendliness make concrete roads a far

superior choice over bituminous ones.

.

Traffic and life

Heavy traffic, particularly heavy truck traffic, can affect pavement life.

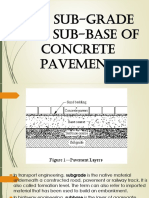

The study started by comparing the structural characteristics of rigid (concrete) and flexible pavements.

Flexible pavements rely on the asphalt, base, and subbase layers to transfer the applied load.

Typical Flexible and Rigid Pavement Layers

Typical Load Distribution for Flexible and Rigid Pavement

Layers

What makes a good installation:

1. Test borings will establish whether soil will support the subbase and pervious soils that contain significant levels

of silt or clay that are either highly compressible, lack cohesion, or expand or contract with moisture absorption.

These may not be suitable for concrete pavement unless remediation steps are taken to stabilize the soil.

2. Base preparation. Before concrete is placed, the subbase must be compacted using a vibratory or other suitable

piece of equipment to achieve a minimum density of 90 to 95%. The compacted base must be done prior to the

placement of paving material, but no puddles of free-standing water can be tolerated.

3. The amount and timing of the addition of water to the mix is critical. Too much water will carry the cement

slurry to the base of the pavement, creating a barrier that prevents water from passing into the subbase and

substrate. Too little water prevents bonding of the aggregate to the cementitious mixtures.

4. The subbase must be compacted to specification. Ruts created by equipment or vehicles prior to placement must

be eliminated and recompaction used. Forms must be built to specified grades. Rail-mounted leveling equipment

should be aligned and placed prior to beginning placement. The material should be discharged from the trucks as

rapidly as possible and feasible. In leveling, the paved area must be rolled immediately, using a full-length roller

and supplemental compaction if needed.

5. Following placement, the pervious concrete should be covered with polyethylene film, which should be held

down securely. Curing time without traffic is seven days.

6.Air-entrained concrete, where thousands of microscopic air bubbles are introduced, lets the pavement material

withstand the effects of freeze/thaw cycles.

Вам также может понравиться

- Modern Soil Stabilization TechniquesДокумент25 страницModern Soil Stabilization TechniquesSagar Jha100% (3)

- Concrete in Highway Engineering: International Series of Monographs in Civil EngineeringОт EverandConcrete in Highway Engineering: International Series of Monographs in Civil EngineeringРейтинг: 4 из 5 звезд4/5 (5)

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsОт EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsОценок пока нет

- Concrete Vs AsphaltДокумент2 страницыConcrete Vs AsphaltGregor GrbecОценок пока нет

- Final Report BTДокумент12 страницFinal Report BTSANSKAR AGRAWALОценок пока нет

- Benefits of Concrete Roads Over Bituminous RoadsДокумент12 страницBenefits of Concrete Roads Over Bituminous RoadsVirendra RaiОценок пока нет

- Comparison Concrete and Asphalt PavementДокумент6 страницComparison Concrete and Asphalt PavementJulius OgowewoОценок пока нет

- Bitumen UsesДокумент4 страницыBitumen UsesMasood MxОценок пока нет

- Site Visit Full ReportДокумент34 страницыSite Visit Full ReportNinie Azrin100% (2)

- Bituminous MaterialsДокумент4 страницыBituminous Materialshi im number oneОценок пока нет

- Civil Highway Network System Report - AAAAAДокумент28 страницCivil Highway Network System Report - AAAAAThirupathi YadavОценок пока нет

- Comparison of Concrete Road Vs Asphalt RoadДокумент6 страницComparison of Concrete Road Vs Asphalt RoadAhmadОценок пока нет

- Ready Mix ConcreteДокумент15 страницReady Mix ConcreteSharukh KhanОценок пока нет

- Ready Mix ConcreteДокумент5 страницReady Mix ConcreteSanu GhoshОценок пока нет

- Claycrete English v3Документ22 страницыClaycrete English v3supernaenergy100% (1)

- Why Is BitumenДокумент23 страницыWhy Is BitumenShita AlemieОценок пока нет

- Green Highway - Concrete PavementДокумент12 страницGreen Highway - Concrete PavementKhabilongtshup KhumujamОценок пока нет

- Construction of Bituminous RoadДокумент21 страницаConstruction of Bituminous RoadShafiullah PopalzaiОценок пока нет

- Transportation of ConcreteДокумент12 страницTransportation of Concretesagar devidas khot100% (3)

- Bitumen Used in Road ConstructionДокумент5 страницBitumen Used in Road ConstructionNino Celso AstilleroОценок пока нет

- Chapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Документ30 страницChapter 5 - Flexible and Composite Pavements Final (Individual Narrative Reports)Frederick AgliamОценок пока нет

- Road Construction With AsphaltДокумент6 страницRoad Construction With AsphaltbabeОценок пока нет

- Pavement and Materials Design Manual 1999 - CHAPTER 8Документ12 страницPavement and Materials Design Manual 1999 - CHAPTER 8Kisali Sarakikya100% (2)

- BT RoadsДокумент24 страницыBT RoadsSri HarshaОценок пока нет

- Analysis and Design of Rigid Pavement: A Review: Ravpreet Singh Ahsan RabbaniДокумент5 страницAnalysis and Design of Rigid Pavement: A Review: Ravpreet Singh Ahsan RabbaniveereshОценок пока нет

- Water Abserbation Concrete RoadДокумент11 страницWater Abserbation Concrete RoadsethyankitaraniОценок пока нет

- CE2102: Construction Materials & Introduction To Design: Rgu Iiit NuzvidДокумент22 страницыCE2102: Construction Materials & Introduction To Design: Rgu Iiit NuzvidPeraka Naga Siva Pavani ce18e013Оценок пока нет

- VidyaДокумент30 страницVidyaManoj RockyОценок пока нет

- Important Points From IRC Roads and Bridge Codes PDFДокумент23 страницыImportant Points From IRC Roads and Bridge Codes PDFrajasekaran123Оценок пока нет

- 1.1 Brief Introduction To Concrete Construction IndustryДокумент12 страниц1.1 Brief Introduction To Concrete Construction IndustryGauresh GawasОценок пока нет

- Iii) Why Is Bitumen Used in Road Construction? Properties and Advantage of Bitumen For PavementsДокумент6 страницIii) Why Is Bitumen Used in Road Construction? Properties and Advantage of Bitumen For PavementsraniОценок пока нет

- Steps in Bituminous Road ConstructionДокумент3 страницыSteps in Bituminous Road Constructionlance lancelottiОценок пока нет

- Conc - Tech Lec-3 (Copy)Документ35 страницConc - Tech Lec-3 (Copy)kassawОценок пока нет

- Construction of Road ConcreteДокумент58 страницConstruction of Road Concretevickram jainОценок пока нет

- Di Mascio Et Al. (2021)Документ11 страницDi Mascio Et Al. (2021)محمد يمان فارسОценок пока нет

- RMC Batching PlantДокумент20 страницRMC Batching Plantaditishah20392Оценок пока нет

- Roads and PavementsДокумент3 страницыRoads and PavementspreethamОценок пока нет

- Use of Fly Ash in Highway Embankment: Final Year Project PresentationДокумент25 страницUse of Fly Ash in Highway Embankment: Final Year Project Presentationjg100% (1)

- Mini Project Advance PavementsДокумент39 страницMini Project Advance PavementsSD TECHОценок пока нет

- 131 PavingДокумент28 страниц131 PavingHan MirzОценок пока нет

- 23.4roadway Pavement DesignДокумент13 страниц23.4roadway Pavement DesignAnonymous MklNL77Оценок пока нет

- Ready Mix Plant Ak Gupta Ee (Training) DATE 14/02/2017Документ36 страницReady Mix Plant Ak Gupta Ee (Training) DATE 14/02/2017Prafull AgrawalОценок пока нет

- Mechanical Properties of Cement-Bitumen Composites For Semi-Flexible Pavement SurfacingДокумент9 страницMechanical Properties of Cement-Bitumen Composites For Semi-Flexible Pavement SurfacingMuslim AFHОценок пока нет

- Investigation of The Properties of Cast Asphalt CoДокумент22 страницыInvestigation of The Properties of Cast Asphalt ConvmhumgОценок пока нет

- RHPC & RMCДокумент2 страницыRHPC & RMC3deepОценок пока нет

- Guidelines For The Design - Irc-37 (Shahbaz Alam)Документ57 страницGuidelines For The Design - Irc-37 (Shahbaz Alam)engrarzooОценок пока нет

- Road Construction SpecificationДокумент49 страницRoad Construction SpecificationFiona steel100% (1)

- Seminar Report On Highway Management SystemДокумент22 страницыSeminar Report On Highway Management SystemAditya ansuman RoutОценок пока нет

- Ready Mix Plant Rajan Pandey (Training) DATE 22/06/2017Документ36 страницReady Mix Plant Rajan Pandey (Training) DATE 22/06/2017rajan pandeyОценок пока нет

- Civil Highway Network System ReportДокумент30 страницCivil Highway Network System Reportsayali patilОценок пока нет

- Ankit Internship ReportДокумент19 страницAnkit Internship Reportaugust18adarshОценок пока нет

- Concrete Roads - PQC, Methods of Construction and How It Is MadeДокумент19 страницConcrete Roads - PQC, Methods of Construction and How It Is Madesravan shettyОценок пока нет

- Concrete Technology - Reading Material - Units 4Документ21 страницаConcrete Technology - Reading Material - Units 4s200708 KAMATHAM KEERTHIОценок пока нет

- Unit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Документ29 страницUnit 7 (CONSTRUCTION OF RIGID/CONCRETE PAVEMENT)Zara Nabilah76% (33)

- Scope of Rigid PavementДокумент1 страницаScope of Rigid PavementMudduKrishna shettyОценок пока нет

- The Sub-Grade and Sub-Base of Concrete PavementДокумент16 страницThe Sub-Grade and Sub-Base of Concrete PavementPatrick TaylorОценок пока нет

- ReportДокумент17 страницReportCaleb KhisaОценок пока нет

- Field Trip QuestionsДокумент4 страницыField Trip QuestionsYRA sachachОценок пока нет

- California Bearing Ratio (CBR) TestДокумент6 страницCalifornia Bearing Ratio (CBR) TestgimanuОценок пока нет

- Semi Structural SurfacingsДокумент2 страницыSemi Structural Surfacingsgimanu100% (1)

- Distress Identification: Distresses For Pavements With Asphalt Concrete SurfacesДокумент2 страницыDistress Identification: Distresses For Pavements With Asphalt Concrete SurfacesgimanuОценок пока нет

- Pavement Overlay or New DesignДокумент20 страницPavement Overlay or New Designgimanu100% (1)

- Equivalent Single Axle Load Calculations: Traffic AnalysisДокумент8 страницEquivalent Single Axle Load Calculations: Traffic AnalysisgimanuОценок пока нет

- Uncertain Activity Duration: Consider The IS Development Project Network Given Below: 3 A C E GДокумент18 страницUncertain Activity Duration: Consider The IS Development Project Network Given Below: 3 A C E GgimanuОценок пока нет

- TerminologyДокумент2 страницыTerminologygimanuОценок пока нет

- ContractsДокумент3 страницыContractsgimanuОценок пока нет