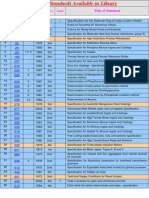

Академический Документы

Профессиональный Документы

Культура Документы

MSU Copper Casting Alloys 2011

Загружено:

Daniel CringusАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

MSU Copper Casting Alloys 2011

Загружено:

Daniel CringusАвторское право:

Доступные форматы

Published by the Copper Casting Alloy Department

(Gesamtverband der Deutschen Buntmetallindustrie) in the

WirtschaftsVereinigung Metalle e.V., Berlin, Germany

G

r

a

p

h

ic

-

D

e

s

ig

n

:

K

o

m

m

u

n

ik

a

t

io

n

u

n

d

D

e

s

ig

n

B

e

r

n

a

r

d

L

a

n

g

e

r

o

c

k

,

D

s

s

e

ld

o

r

f,

w

w

w

.la

n

g

e

r

o

c

k

d

e

s

ig

n

.d

e

Copper casting alloys

European Standard EN 1982:2008

MSU Metallschmelzwerk Ulm

Metallschmelzwerk Ulm GmbH

Daimlerstrae 20, 89079 Ulm-Donautal, Germany

P.O. Box 2310, 89013 Ulm-Donautal, Germany

Phone +49 (0) 731 946 23-0

Fax +49 (0) 731 48 17 22

E-Mail msupost@msu-ulm.com

Website www.msu-ulm.com

MSU Metallschmelzwerk Ulm

Organisation of European

Copper Alloy Ingot

Makers

Since 1998, MSU has been the

leading German manufacturer of

highly polishable, fine-grain brass

alloys as well as other copper

casting alloys in continuous casting

quality. The pouring out into two

four-strand systems guarantees

the customer an absolutely homo-

genous product both analytically

as well as with regards to the

microstructure. This is further

evidence of how the wishes of

the customer are implemented

through tailor-made solutions at

Metallschmelzwerk Ulm GmbH.

C O N T I N U O U S

CASTING QUALITY

In the EN 1982:2008 Standard, each copper casting alloy is assigned with a

number and a symbol. The following conventions apply:

Representation in number form:

Ingot: CB

Casting material: CC

Representation in symbol form:

Ingot: -B

Casting material: -C

The following conventions apply for the old abbreviated designations also listed:

Ingot: GB-

General casting material: G-

Casting materials for particular casting processes (partially listed):

Sand casting: GS-

Permanent mould casting: GM-

Centrifugal casting: GZ-

Continuous casting: GC-

Pressure die casting: GP-

Details of the numbering system

The material number must be made up of alphabetic (Latin capital letters) and

numeric (Arabic numerals) characters.

The numbering system may only issue one number for each material.

A number that has been assigned to a particular material may not be assigned to

any other material, even in the event that the first material has been withdrawn.

Structure of the material numbers

The material number must be made up of 6 characters. The characters have the

following positions:

Position 1:

In accordance with ISO/TR 7003, the character in the first position must be the

letter C in order to describe the copper material.

Position 2:

The character in the second position must be one of the following letters:

B Materials in block form (e.g. ingots) for re-melting during the manufacture

of castings

C Materials in casting form

F Welding fillers and hard solders

M Master alloys

R Refined unwrought copper

S Materials in scrap form

W Wrought materials

X Non-standardised materials

Positions 3 - 5:

The characters in the third, fourth and fifth positions must form a figure

between 000 and 799 with standardised copper materials and must form a

figure between 800 and 999 with non-standardised copper materials.

These characters have no further particular meaning.

Position 6:

The character in the sixth position must be a letter, with which one of the

following material groups is described:

A, B Copper

C, D Low alloy copper alloys (alloying elements amount to less than 5 %)

E, F Special copper alloys (alloying elements amount to a minimum of 5 %)

G Copper-aluminium alloys

H Copper-nickel alloys

J Copper-nickel-zinc alloys

K Copper-tin alloys

L, M Copper-zinc alloys, dual-material alloy

N, P Copper-zinc-lead alloys

R, S Copper-zinc alloys, multi-material alloys

Note:

The bold, non-italic values illustrated in the alloy composition in percent

(mass fractions) tables describe the alloy constituents; the non-bold, italic values

illustrated describe the permitted additions or impurities.

Explanatory comments on the alloy tables

1 2 3 4 5 6

Introduction

The European EN 1982:2008 Standard has been prepared by

Technical Committee CEN/TC 133 'Copper and Copper Alloys',

the Secretariat of which is held by DIN and was accepted by

the CEN (Comit de Normalisation) on the 21st of March 2008.

It exists in three official versions (English, French, German).

With respect to the old version from 1998, various modifications

and amendments have been made, in particular incorporation

of a new alloy in section 4 (CB499K + CC499K).

This new European Standard for copper alloy ingots and

copper and copper alloy castings is based upon previous

national standards and harmonises the chemical compositions

and mechanical properties required. Furthermore, it provides

information with regard to the individual areas of application.

For reasons of simplification, the old abbreviated designations

as well as the old standard designations have been placed

opposite the individual alloys.

This standard does not include copper refinery shapes which

are intended for working into wrought products. These are the

subject of EN 1976. Master alloys are also not included in this

standard. They are the subject of EN 1981.

The European EN 1982:2008 Standard specifies the composition,

mechanical properties and other relevant characteristics of the

materials. The sampling procedures and test methods for the

verification of conformity to the requirements of this standard

are also specified.

The standard is applicable for:

a) copper alloy ingots intended to be remelted for the

production of castings; and

b) copper and copper alloy castings which are intended for use

without subsequent working other than machining. The

castings may be manufactured by the sand, permanent

mould, centrifugal, continuous or pressure die casting process.

Please consult the complete version for further details with

regard to this standard, published by Beuth Verlag GmbH,

D-10722 Berlin, Germany.

The details in this list are provided to the best of our knowledge.

However, the application of these details in practice is subject to

many influencing factors beyond our control, meaning that we

cannot assume any liability for this.

Reproduction from this list is only permitted with

acknowledgement of the publisher:

Gesamtverband der Deutschen Buntmetallindustrie e.V.,

Berlin, Copper Casting Alloy Department

Copper and copper-chromium alloy 1

Copper-zinc alloys 2

Copper-tin alloys 3

Copper-tin-lead alloys 4

Copper-aluminium alloys 5

Copper-manganese-aluminium alloy 6

Copper-nickel alloys 7

CC040A Cu-C G-Cu L 35

Copper and

copper-chromium alloy

CC140C CuCr1-C

Cu

no

composition

specified

Remainder

a)

0.4 - 1.2

a)

Designation accord. to EN 1982:2008

Number Symbol

Former abbreviated

designation

Former standard

designation

1 Casting material: DIN 17655 (1981)

Ingot: DIN 17656 (1973)

Casting material: DIN 1709 (1981)

Chemical composition in percent (mass fraction)

Cr

Cu Al As B Fe Mn Ni

CB750S CuZn33Pb2-B

CC750S CuZn33Pb2-C

Copper-zinc alloys

CB751S CuZn33Pb2Si-B

CC751S

a)

CuZn33Pb2Si-C

63.0- 66.0

a)

63.0- 67.0

a)

< 0.1

b)

< 0.1

< 0.7

< 0.8

< 0.2

< 0.2

< 0.1

< 0.15

< 1.0

< 1.0

63.5- 65.5

b)

63.5- 66.0

b)

< 0.10

< 0.10

0.25- 0.50

0.25- 0.5

< 0.80

< 0.8

< 0.1

< 0.1

61.5 - 65.0

61.5 - 64.5

0.3 - 0.7

0.3 - 0.70

0.04- 0.12

0.04- 0.14

b)

< 0.3

< 0.3

< 0.2

< 0.2

< 0.20

< 0.20

58.0- 60.0

b)

58.0- 61.0

b)

0.4 - 0.8

0.4 - 0.8

0.5 - 0.8

0.5 - 0.8

a)

a)

0.5 - 1.2

0.5 - 1.2

< 0.5

< 0.5

58.0- 62.0

a)

58.0- 63.0

a)

0.10 - 0.8

b)

< 0.8

b)

< 0.7

< 0.7

< 1.0

< 1.0

< 0.05

< 0.05

59.0- 60.5

59.5- 61.0

0.4 - 0.65

0.4 - 0.7

0.06- 0.15

0.05- 0.15

0.05- 0.2

0.05- 0.2

< 0.2

< 0.2

< 0.1

< 0.1

83.0- 87.5

83.0- 88.0

< 0.01

< 0.01

< 0.15

< 0.15

< 0.1

< 0.1

< 0.2

< 0.2

78.5 - 82.0

78.0 - 83.0

< 0.10

< 0.1

< 0.5

< 0.6

< 1.0

< 1.0

2

G-CuCr F 35

GB-CuZn33Pb

G-CuZn33Pb

GB-Ms 65 A

Dezincification-

resistant brass

(pressure die casting)

Dezincification-

resistant brass

(permanent mould

casting)

Ms 60 Fine grain

Si-Tombak

GB-CuZn37Pb

GK-CuZn37Pb

GD-CuZn37Pb

G-CuZn15

GB-CuZn15Si4

G-CuZn15Si4

GK-CuZn15Si4

GD-CuZn15Si4

CB752S CuZn35Pb2Al-B

CC752S

a)

CuZn35Pb2Al-C

CB754S CuZn39Pb1Al-B

CC754S CuZn39Pb1Al-C

CB760S CuZn15As-B

CC760S CuZn15As-C

CB761S CuZn16Si4-B

CC761S CuZn16Si4-C

CB753S

a)

CuZn37Pb2Ni1AlFe-B

CC753S CuZn37Pb2Ni1AlFe-C

CB755S CuZn39Pb1AlB-B

CC755S CuZn39Pb1AlB-C

P Pb Sb Si Sn Zn

1.0 - 2.8

1.0 - 3.0

0.8 - 2.0

0.8 - 2.2

< 0.02

< 0.05

< 0.05

< 0.05

0.70 - 1.0

0.65- 1.1

< 0.04

< 0.05

< 1.5

< 1.5

< 0.80

< 0.8

Remainder

Remainder

Remainder

Remainder

1.5 - 2.1

1.5 - 2.2

0.04- 0.12

b)

< 0.14

b) c)

< 0.02

< 0.02

< 0.3

< 0.3

Remainder

Remainder

1.8 - 2.50

1.8 - 2.50

< 0.02

< 0.02

< 0.05

< 0.05

< 0.05

< 0.05

< 0.8

< 0.8

Remainder

Remainder

0.5 - 2.4

0.5 - 2.5

< 0.02

< 0.02

< 0.05

< 0.05

c)

< 1.0

< 1.0

Remainder

Remainder

1.2 - 1.7

1.2 - 1.7

< 0.03

< 0.05

< 0.3

< 0.3

Remainder

Remainder

< 0.5

< 0.5

< 0.02

< 0.02

< 0.3

< 0.3

Remainder

Remainder

< 0.6

< 0.8

< 0.02

< 0.03

< 0.05

< 0.05

3.0 - 5.0

3.0 - 5.0

< 0.25

< 0.3

Remainder

Remainder

CC040A Cu-C G-Cu L 35

Copper and

copper-chromium alloy

CC140C CuCr1-C

Designation accord. to EN 1982:2008

Number Symbol

Former abbreviated

designation

Former standard

designation

1 Casting material: DIN 17655 (1981)

Ingot: DIN 17656 (1973)

Casting material: DIN 1709 (1981)

CB750S CuZn33Pb2-B

CC750S CuZn33Pb2-C

Copper-zinc alloys

CB751S CuZn33Pb2Si-B

CC751S

a)

CuZn33Pb2Si-C

2

G-CuCr F 35

GB-CuZn33Pb

G-CuZn33Pb

GB-Ms 65 A

Dezincification-

resistant brass

(pressure die casting)

Dezincification-

resistant brass

(permanent mould

casting)

Ms 60 Fine grain

Si-Tombak

GB-CuZn37Pb

GK-CuZn37Pb

GD-CuZn37Pb

G-CuZn15

GB-CuZn15Si4

G-CuZn15Si4

GK-CuZn15Si4

GD-CuZn15Si4

CB752S CuZn35Pb2Al-B

CC752S

a)

CuZn35Pb2Al-C

CB754S CuZn39Pb1Al-B

CC754S CuZn39Pb1Al-C

CB760S CuZn15As-B

CC760S CuZn15As-C

CB761S CuZn16Si4-B

CC761S CuZn16Si4-C

CB753S

a)

CuZn37Pb2Ni1AlFe-B

CC753S CuZn37Pb2Ni1AlFe-C

CB755S CuZn39Pb1AlB-B

CC755S CuZn39Pb1AlB-C

Casting process

and designation

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

Sand GS

Centrifugal GZ

180

180

70

70

12

12

45

50

Tensile strength

R

m

N/mm

2

min.

0.2 %proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

150

150

150

150

300

300

40

40

40

40

25

25

25

25

40

40

40

40

(400 ) (280 ) (5 ) (110 )

280

(340 )

120

(215 )

10

(5 )

70

(110 )

350

(350 )

180

(250 )

13

(4 )

90

(110 )

300 150 15 90

160 70 20 45

220

280

(350 )

280

80

120

(250 )

120

15

10

(4 )

10

65

70

(110 )

70

Pressure die cast GP

Perm. mould GM

Pressure die cast GP

Perm. mould GM

Sand GS

Perm. mould GM

Pressure die cast GP

Centrifugal GZ

Perm. mould GM

Pressure die cast GP

Sand GS

Mechanical properties

Elect. conductivity

MS/m min.

55

50

45

32

Perm. mould GM

Sand GS

Grade A

Grade B

Grade C

a)

Perm. mould GM

Sand GS

200

200

10

10

95

95

45

b)

45

b)

400

500

(530 )

500

230

300

(370)

300

10

8

(5 )

8

100

130

(150 )

130

Sand GS

Perm. mould GM

Pressure die cast GP

Centrifugal GZ

a) Including nickel

b) For ingots intended for the manufacture of pressure-tight sand

castings and centrifugal castings, aluminium shall be restricted

to 0.02 % max.

a) Castings in this alloy shall conform to the dezincification

resistance requirements, i.e. Grade A: max. 200 m;

Grade B: average dezincification depth not above 200 m,

max. dezincification depth of 400 m.

b) Including nickel

Note: The mechanical properties for pressure die castings (shown

bracketed) are not mandatory requirements, but are given for

information only, as they depend on the casting parameters.

a) Castings in this alloy shall conform to the dezincification

resistance requirements, i.e. Grade A: max. 200 m;

Grade B: average dezincification depth not above 200 m,

max. dezincification depth of 400 m.

b) In castings for non drinking water applications, Sb can be

used as alternative inhibitor of dezincification. If Sb is added as

the inhibitor, then the As content shall be 0.04 % maximum.

(Sb + As) shall be 0.14 % maximum.

c) For drinking water applications, Sb shall be )0.02 %.

Note 1: The mechanical properties for pressure die castings

(shown bracketed) are not mandatory requirements, but are

given for information only, as they depend on the casting

parameters.

Note 2: For special applications requiring fine-grained castings,

the ingots may be ordered and supplied grain refined to a

maximum average grain diameter of 0.150 mm.

Note 3: For drinking water applications no other single element

should be more than 0.02 %. The sum of these single

elements should not exceed 0.25 %.

a) Unless it is agreed between the purchaser and the supplier

that other grain refining agents may be used, ingots in this

alloy shall be grain refined using zirconium, to have a

maximum average grain diameter of 0.300 mm.

b) Including nickel

a) Including nickel

b) For ingots for the manufacture of sand castings or centrifugal

castings, the aluminium content shall be restricted to 0.02 %

max.

c) For pressure die castings the silicon shall be increased to

0.30 % max.

Note 1: For special applications requiring fine-grained castings,

the ingots may be ordered and supplied grain refined to a

maximum average grain diameter of 0.150 mm.

Note 2: The mechanical properties for pressure die castings

(shown bracketed) are not mandatory requirements, but are

given for information only, as they depend on the casting

parameters.

a) Unless it is agreed between the purchaser and the supplier

that other grain refining agents may be used, ingots in this

alloy shall be grain refined using boron, to have a maximum

average grain diameter of 0.100 mm.

Note 1: The mechanical properties for pressure die castings

(shown bracketed) are not mandatory requirements, but are

given for information only, as they depend on the casting

parameters.

Note 2: For drinking water applications no other single element

should be more than 0.02 %. The sum of these single

elements should not exceed 0.25 %.

a) Grade C is intended for certain heat transfer applications,

such as water-cooled hot blast equipment.

Note: Ingots in this material are not specified.

Grate and shaft cooling boxes,

cooling rings, slag moulds, blow

moulds for blast furnaces

Switching components, contact jaws,

electrode arms and holders, current-

carrying parts for the electrical

engineering in the event of increased

requirements concerning strength,

hardness and wear properties

Heat treatment is required in order

to achieve the ideal electrical and

thermal conductivity.

a) The sum of Cu + Cr shall be 99.5 %.

b) In fully heat treated condition

Note: Ingots in this material are not specified.

Housing for gas and water fittings,

construction parts and fittings for

machine construction, electrical

engineering, precision engineering,

optics, etc.

Construction material corrosion

resistant against domestic water up

to approximately 90 C, electrical

conductivity between approximately

10 and 14 m/(+ mm

2

)

General fittings and construction

parts, thin-walled pressure die cast

components for indoor and outdoor

decorations

Construction material corrosion

resistant

Special alloy for premium brass cast-

ing parts, fittings and construction

parts, sanitary appliances with

varying wall strengths and high

demands on the surface processing,

low-pressure casting parts for

machine construction and electrical

engineering

Construction material corrosion

and dezincification resistant, good

resistance against sea-water

For all types of mounting housings

with varying wall strengths, water

meter housing, stacking fittings,

sanitary appliances with high

demands on the surface processing.

Construction material good

machining properties, high mould

filling capability, good fluidity

General fittings and construction

parts, sanitary and stacking fittings;

Pressure die cast components for

machine construction, electrical

engineering, precision engineering,

optics, etc.

Construction material can be

machined well

Special alloy for premium brass

casting parts, e.g.: Fittings and

construction parts, sanitary

appliances with varying wall

strengths and high demands on the

surface processing, stacking fittings

and special housings. This alloy is

preferably used in low-pressure

casting.

Known under the name of: Fine-

grained brass construction material

good machining properties, high

mould filling capability, excellent

fluidity and polishability.

For parts that are to be soldered,

e.g. flanges and other components

for ship construction, machine

construction, electrical engineering,

precision engineering, optics, etc.

Construction material good resistance

against sea-water, excellent soft and

hard soldering properties, electrical

conductivity approx. 15 m/( 1 mm

2

)

Highly-stressed, thin-walled,

sophisticated construction parts for

machine and ship construction,

electrical industry, precision

engineering, etc.

Construction material good

corrosion and sea-water resistance,

can be very easily cast

Notes Comments Information for use

Note: The mechanical properties for pressure die castings (shown

bracketed) are not mandatory requirements, but are given for

information only, as they depend on the casting parameters.

Designation accord. to EN 1982:2008

Number Symbol

Ingot: DIN 17656 (1973)

Casting material: DIN 1709 (1981) Cu Al As B Fe Mn Ni Copper-zinc alloys 2

3.0 - 5.0

2.5 - 5.0

60.0- 66.0

a)

60.0- 67.0

a)

4.0 - 7.0

3.0 - 7.0

1.5 - 3.5

1.5 - 4.0

< 2.7

< 3.0

1.0 - 3.5

1.0 - 3.5

59.0- 67.0

a)

59.0- 67.0

a)

1.0 - 2.5

1.0 - 2.5

0.5 - 2.0

0.5 - 2.0

< 2.5

< 2.5

1.0 - 3.5

b)

1.0 - 4.0

b)

55.0- 65.0

a)

55.0- 66.0

a)

1.5 - 3.0

1.0 - 3.0

0.8 - 2.0

0.5 - 2.5

< 2.7

< 3.0

0.5 - 2.5

b)

0.5 - 3.0

b)

56.0- 64.0

a)

57.0 - 65.0

a)

0.7 - 2.2

0.5 - 2.5

0.5 - 1.8

0.5 - 2.0

< 6.0

< 6.0

< 0.4

< 0.5

60.0- 63.0

a)

60.0- 64.0

a)

0.6 - 1.8

0.3 - 1.8

< 0.4

< 0.5

< 1.8

< 2.0

< 0.4

< 0.5

59.0- 64.0

a)

59.0- 64.0

a)

0.1 - 0.8

0.1 - 0.8

< 0.4

< 0.5

< 0.8

< 1.0

So-Ms F75

So-Ms F60

So-Ms F45

GB-CuZn25Al5

G-CuZn25Al5

GK-CuZn25Al5

GZ-CuZn25Al5

GB-CuZn34Al2

G-CuZn34Al2

GK-CuZn34Al2

GZ-CuZn34Al2

GB-CuZn35Al1

G-CuZn35Al1

GK-CuZn35Al1

GZ-CuZn35Al1

GB-CuZn37Al1

GK-CuZn37Al1

GB-CuZn38Al

GK-CuZn38Al

CB762S CuZn25Al5Mn4Fe3-B

CC762S CuZn25Al5Mn4Fe3-C

CB763S CuZn32Al2Mn2Fe1-B

CC763S CuZn32Al2Mn2Fe1-C

CB764S CuZn34Mn3Al2Fe1-B

CC764S CuZn34Mn3Al2Fe1-C

CB765S CuZn35Mn2Al1Fe1-B

CC765S CuZn35Mn2Al1Fe1-C

CB766S CuZn37Al1-B

CC766S CuZn37Al1-C

CB767S CuZn38Al-B

CC767S CuZn38Al-C

CB480K CuSn10-B

CC480K CuSn10-C

GB-CuSn10

G-CuSn10

GB-CuSn12Pb

G-CuSn12Pb

GZ-CuSn12Pb

GC-CuSn12Pb

GB-CuSn12

G-CuSn12

GZ-CuSn12

GC-CuSn12

GB-CuSn12Ni

G-CuSn12Ni

GZ-CuSn12Ni

GC-CuSn12Ni

Gbz 10

P-Bz

Gbz 12 Pb

Gbz 12 Ni

Gbz 12

Copper-tin alloys

CB481K CuSn11P-B

CC481K CuSn11P-C

CB482K CuSn11Pb2-B

CC482K CuSn11Pb2-C

Cu

88.5- 90.5

a)

88.0- 90.0

a)

< 0.01

< 0.01

< 0.15

< 0.2

< 0.10

< 0.10

< 1.8

< 2.0

< 0.05

< 0.2

< 0.8

< 1.0

87.0 - 89.3

87.0 - 89.5

< 0.01

< 0.01

< 0.10

< 0.10

< 0.05

< 0.05

< 0.10

< 0.10

0.6 - 1.0

a)

0.5 - 1.0

a)

< 0.25

< 0.25

83.5- 86.5

83.5- 87.0

< 0.01

< 0.01

< 0.15

< 0.20

< 0.2

< 0.2

< 2.0

< 2.0

< 0.05

< 0.40

0.7 - 2.5

0.7 - 2.5

85.5- 88.5

a)

85.0- 88.5

a)

< 0.01

< 0.01

< 0.15

< 0.2

< 0.2

< 0.2

< 2.0

< 2.0

< 0.20

< 0.60

< 0.6

< 0.7

84.0- 87.0

84.5- 87.5

< 0.01

< 0.01

< 0.15

< 0.20

< 0.10

< 0.2

1.5 - 2.4

1.5 - 2.5

< 0.05

0.05- 0.40

< 0.2

< 0.3

3

Ingot: DIN 17656 (1973)

Casting material: DIN 1705 (1981) Al

CB483K CuSn12-B

CC483K CuSn12-C

CB484K CuSn12Ni2-B

CC484K CuSn12Ni2-C

Fe Mn Ni P Pb

Former abbreviated

designation

Former standard

designation Chemical composition in percent (mass fraction)

P Pb Sb Si Sn Zn

< 0.20

< 0.2

< 0.02

< 0.03

< 0.03

< 0.03

< 0.08

< 0.1

< 0.20

< 0.2

Remainder

Remainder

< 1.5

< 1.5

< 0.08

< 0.08

< 1.0

< 1.0

< 1.0

< 1.0

Remainder

Remainder

< 0.2

< 0.3

< 0.02

< 0.03

< 0.05

< 0.05

< 0.08

< 0.1

< 0.3

< 0.3

Remainder

Remainder

< 0.5

< 0.5

< 0.02

< 0.03

< 0.08

< 0.08

< 0.10

< 0.1

< 0.8

< 1.0

Remainder

Remainder

< 0.4

< 0.50

< 0.02

< 0.05

< 0.1

< 0.5

< 0.6

< 0.4

< 0.50

Remainder

Remainder

< 0.1

< 0.1

< 0.05

< 0.05

< 0.2

< 0.1

< 0.1

Remainder

Remainder

< 0.04

< 0.05

< 0.15

< 0.2

< 0.01

< 0.02

9.3 -11.0

9.0 -11.0

< 0.5

< 0.5

< 0.05

< 0.05

< 0.05

< 0.05

< 0.01

< 0.01

10.2 - 11.5

10.0 - 11.5

< 0.05

< 0.05

< 0.08

< 0.08

< 0.20

< 0.2

< 0.01

< 0.01

10.7 - 12.5

10.5 - 12.5

< 2.0

< 2.0

< 0.05

< 0.05

< 0.15

< 0.15

< 0.01

< 0.01

11.2 - 13.0

11.0 - 13.0

< 0.4

< 0.5

< 0.04

< 0.05

< 0.05

< 0.1

< 0.01

< 0.01

11.3 - 13.0

11.0 - 13.0

< 0.3

< 0.4

S Sb Si Sn Zn

Designation accord. to EN 1982:2008

Number Symbol

Ingot: DIN 17656 (1973)

Casting material: DIN 1709 (1981) Copper-zinc alloys 2

So-Ms F75

So-Ms F60

So-Ms F45

GB-CuZn25Al5

G-CuZn25Al5

GK-CuZn25Al5

GZ-CuZn25Al5

GB-CuZn34Al2

G-CuZn34Al2

GK-CuZn34Al2

GZ-CuZn34Al2

GB-CuZn35Al1

G-CuZn35Al1

GK-CuZn35Al1

GZ-CuZn35Al1

GB-CuZn37Al1

GK-CuZn37Al1

GB-CuZn38Al

GK-CuZn38Al

CB762S CuZn25Al5Mn4Fe3-B

CC762S CuZn25Al5Mn4Fe3-C

CB763S CuZn32Al2Mn2Fe1-B

CC763S CuZn32Al2Mn2Fe1-C

CB764S CuZn34Mn3Al2Fe1-B

CC764S CuZn34Mn3Al2Fe1-C

CB765S CuZn35Mn2Al1Fe1-B

CC765S CuZn35Mn2Al1Fe1-C

CB766S CuZn37Al1-B

CC766S CuZn37Al1-C

CB767S CuZn38Al-B

CC767S CuZn38Al-C

CB480K CuSn10-B

CC480K CuSn10-C

GB-CuSn10

G-CuSn10

GB-CuSn12Pb

G-CuSn12Pb

GZ-CuSn12Pb

GC-CuSn12Pb

GB-CuSn12

G-CuSn12

GZ-CuSn12

GC-CuSn12

GB-CuSn12Ni

G-CuSn12Ni

GZ-CuSn12Ni

GC-CuSn12Ni

Gbz 10

P-Bz

Gbz 12 Pb

Gbz 12 Ni

Gbz 12

Copper-tin alloys

CB481K CuSn11P-B

CC481K CuSn11P-C

CB482K CuSn11Pb2-B

CC482K CuSn11Pb2-C

3

Ingot: DIN 17656 (1973)

Casting material: DIN 1705 (1981)

CB483K CuSn12-B

CC483K CuSn12-C

CB484K CuSn12Ni2-B

CC484K CuSn12Ni2-C

Former abbreviated

designation

Former standard

designation Mechanical properties Notes Comments Information for use

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

a) Including nickel Construction material with very

high static load capacity

Statically very highly strained construction parts e.g.

bearings with high loads and low speed, highly-

stressed, slow-running worm gear sets, inner parts

from high-pressure fittings

Construction material with

moderate sliding properties

Suitable for compression cap nuts for rolling mills

and spindle presses, base and stuffing bushes,

ship propellers, thin-walled parts that can be

manufactured via the pressure die casting process.

Construction material with high

static strength and hardness

Statically strained construction parts, valve and

control parts, seatings, discs

Construction material with

moderate sliding properties

Compression cap nuts for rolling mills and spindle

presses, base and stuffing boxes, ship propellers

Construction material Construction parts for machine construction,

electrical engineering, precision engineering, etc.

Construction material can be

easily cast, low-temperature resist-

ant, corrosion-resistant against the

atmosphere, electrical conductivity

approximately 12 m/( 1 mm

2

)

For all types of sophisticated construction parts,

primarily in the electrical industry and in the field

of machine construction

a) Including nickel

Note: The mechanical properties for pressure die

castings (shown bracketed) are not mandatory

requirements, but are given for information only,

as they depend on the casting parameters.

a) Including nickel

b) For permanent mould castings, the minimum

manganese content shall be 0.3 % for ingots

and castings.

a) Including nickel

b) For permanent mould castings, the minimum

manganese content shall be 0.3 % for ingots

and castings.

Note: For certain applications a minimum

proportion of alpha-phase in the microstructure

of castings is required.

a) Including nickel

a) Including nickel

430

(440 )

150

(330 )

10

(3 )

100

(130 )

450 170 25 105

380 130 30 75

750

750

750

750

450

480

480

480

8

8

5

5

180

180

190

190

450

475

500

500

170

200

200

200

20

18

18

18

110

110

120

120

600

600

620

250

260

260

15

10

14

140

140

150

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

Sand GS

Perm. mould GM

Centrifugal GZ

Sand GS

Pressure die cast GP

Perm. mould GM

Perm. mould GM

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

250

270

280

280

250

310

350

330

130

160

170

160

18

10

10

10

70

80

80

80

a) Including nickel

a) For sand castings for non-bearing applications

the phosphorus may be restricted to 0.15 max.

(Note: See ordering information of

EN 1982:2008 for different compositions for

special applications).

a) For continuous castings and centrifugal castings,

the minimum tin content for ingots shall be

10.7 % and for castings 10.5 % and the

maximum copper content for ingots and castings

shall be 89.0 %.

Mounting and pump housings, guide / running /

paddle wheels for pumps and water turbines

Construction material with high

elongation, corrosion and sea-

water resistant

Same fields of application as CC482K and CC483K. Alloy from Great Britain. Has a

tendency to react to the moulding

material due to the high phos-

phorus content. Phosphorus in-

creases the hardness and strength

at the expense of the elongation.

Slide bearings with high peak loads (impact loads

of up to 6000 N/mm

2

) highly-stressed slide plates

and slide rails

Slide bearings with high peak loads for p of up to

12000 N/cm

2

, e.g. crank and toggle lever bearings,

small end bushes, bushes for crane running wheels,

spindle nuts under load and moving at high-speed;

very highly-stressed slide rails

G-CuSn12Pb: Bearing material

with good emergency running

properties and wear resistance;

corrosion and sea-water resistant

GZ-CuSn12Pb / GC-CuSn12Pb:

See G-CuSn12Pb properties, is

more uniform however, 0.2 limit,

higher tensile strength and

hardness

Coupling blocks and units, spindle nuts under load

and moving, worm and helical gears

Ring and tube shaped construction parts as well as

longitudinal profiles, e.g. worm gear sets, cylinder

inserts, highly strained adjustment and slide rails

G-CuSn12: Material with good

wear resistance; corrosion and

sea-water resistant. The materials

G-CuSn12Ni and G-CuSn12Pb

were developed from this alloy

and are characterised by increa-

sed strength and wear resistance /

improved emergency running

properties.

GZ-CuSn12 / GC-CuSn12:

See G-CuSn12 properties, is more

uniform however, 0.2 limit, higher

tensile strength and hardness

Highly-strained coupling blocks and units, spindle

nuts under load and moving, quick-moving worm

gear and helical gear sets under a higher level of

strain. Highly-stressed fittings and pump housings,

guide / running / paddle wheels for pumps and

water turbines

Strain parameters:

For worm gears on endurance run depending upon

slide speed c = 150 - 800 N/cm

2

, in the event of

brief strain: c = 2000 - 2500 N/cm

2

Ring and tube shaped construction parts, nuts

under load and moving, quick-moving worm gear

and helical gear sets under highest level of strain

Strain parameters:

For worm gears on endurance run depending upon

slide speed c = 200 - 1250 N/cm

2

, in the event of

brief strain: c = 4000 - 4500 N/cm

2

G-CuSn12Ni: Construction

material with excellent wear

resistance; corrosion and sea-

water resistant, durable against

cavitation strains

GZ-CuSn12Ni / GC-CuSn12Ni:

See G-CuSn12Ni properties, is

more uniform however, 0.2 limit,

higher tensile strength and

hardness

Sand GS

Perm. mould GM

Continuous GC

Centrifugal GZ

Sand GS

Perm. mould GM

Continuous GC

Centrifugal GZ

130

170

170

170

5

2

5

4

60

85

85

85

240

280

280

Sand GS

Centrifugal GZ

Continuous GC

130

150

150

5

5

5

80

90

90

260

270

300

280

Sand GS

Perm. mould GM

Continuous GC

Centrifugal GZ

140

150

150

150

7

5

6

5

80

80

90

90

280

300

300

Sand GS

Centrifugal GZ

Continuous GC

160

180

180

12

8

10

85

95

95

< 0.50

< 0.5

Ingot: DIN 17656 (1973)

Casting material: DIN 1705 (1981)

Ingot: DIN 17656 (1973)

Casting material: DIN 1716 (1981)

Cu Al As Bi Cd Cr Fe

CB490K CuSn3Zn8Pb5-B

CC490K CuSn3Zn8Pb5-C

Copper-tin-lead alloys

81.0 - 85.5

a)

81.0 - 86.0

a)

< 0.01

< 0.01

< 0.25

< 0.3

83.0- 86.5

a)

83.0- 87.0

a)

< 0.01

< 0.01

< 0.20

< 0.2

85.0- 88.5

a)

85.0- 89.0

a)

< 0.01

< 0.01

< 0.20

< 0.2

81.0 - 84.5

a) b)

81.0 - 85.0

a) b)

< 0.01

< 0.01

< 0.25

< 0.25

86.0- 89.5

a)

86.0- 90.0

a)

< 0.01

< 0.01

< 0.20

< 0.25

< 0.2

< 0.2

80.0- 86.5

a)

80.0- 87.0

a)

< 0.01

< 0.01

< 0.20

< 0.25

< 0.2

< 0.2

78.0 - 81.5

a)

78.0 - 82.0

a)

< 0.01

< 0.01

< 0.20

< 0.25

< 0.20

< 0.20

74.0 - 79.5

a)

74.0 - 80.0

a)

< 0.01

< 0.01

< 0.20

< 0.25

< 0.20

< 0.20

70.0 - 77.5

a)

70.0 - 78.0

a)

< 0.01

< 0.01

4

GB-CuSn2ZnPb

G-CuSn2ZnPb

CB494K CuSn5Pb9-B

CC494K CuSn5Pb9-C

CB495K CuSn10Pb10-B

CC495K CuSn10Pb10-C

GB-CuPb10Sn

G-CuPb10Sn

GZ-CuPb10Sn

GC-CuPb10Sn

Pb-Bz 10

Pb-Bz 15

Pb-Bz 20

CB496K CuSn7Pb15-B

CC496K CuSn7Pb15-C

GB-CuPb15Sn

G-CuPb15Sn

GZ-CuPb15Sn

GC-CuPb15Sn

CB497K CuSn5Pb20-B

CC497K CuSn5Pb20-C

GB-CuPb20Sn

G-CuPb20Sn

CB491K CuSn5Zn5Pb5-B

CC491K CuSn5Zn5Pb5-C

GB-CuSn5ZnPb

G-CuSn5ZnPb

Rg 5

Rg 2

CB492K CuSn7Zn2Pb3-B

CC492K CuSn7Zn2Pb3-C

GB-CuSn6ZnNi

G-CuSn6ZnNi

CB493K CuSn7Zn4Pb7-B

CC493K CuSn7Zn4Pb7-C

GB-CuSn7ZnPb

G-CuSn7ZnPb

GZ-CuSn7ZnPb

GC-CuSn7ZnPb

Rg 7

CB498K CuSn6Zn4Pb2-B

CC498K CuSn6Zn4Pb2-C

Designation accord. to EN 1982:2008

Number Symbol

CB330G CuAl9-B

CC330G CuAl9-C

Copper-aluminium alloys Cu

88.0- 91.5

a)

88.0- 92.0

a)

8.2 - 10.5

8.0 - 10.5

< 1.0

< 1.2

< 0.50

< 0.50

5

Ingot: DIN 17656 (1973)

Casting material: DIN 1714 (1981) Al

83.0- 89.0

83.0- 89.5

8.7 - 10.5

8.5 - 10.5

1.5 - 3.3

1.5 - 3.5

< 1.0

< 1.0

< 0.05

< 0.05

CB331G CuAl10Fe2-B

CC331G CuAl10Fe2-C

GB-CuAl10Fe

G-CuAl10Fe

GK-CuAl10Fe

GZ-CuAl10Fe

Fe-Al Bz

Bi Cr Fe Mg Mn

Mn

< 0.30

< 0.30

84.0- 87.5

84.0- 88.0

< 0.01

< 0.01

< 0.03

< 0.03

< 0.02

< 0.02

< 0.02

< 0.02

< 0.02

< 0.02

CB499K CuSn5Zn5Pb2-B

CC499K CuSn5Zn5Pb2-C

Former abbreviated

designation

Former standard

designation Chemical composition in percent (mass fraction)

< 0.01

< 0.01

S Sb Si Sn Zn

< 0.25

< 0.30

< 0.08

< 0.10

2.2 - 3.5

2.0 - 3.5

7.5 - 10.0

7.0 - 9.5

< 0.01

< 0.01

< 0.25

< 0.25

< 0.08

< 0.10

4.2 - 6.0

4.0 - 6.0

4.5 - 6.5

4.0 - 6.0

< 0.01

< 0.01

< 0.25

< 0.25

< 0.08

< 0.10

6.2 - 8.0

b)

6.0 - 8.0

b)

1.7 - 3.2

1.5 - 3.0

< 0.01

< 0.01

< 0.30

< 0.3

< 0.08

< 0.10

6.2 - 8.0

b)

6.0 - 8.0

b)

2.3 - 5.0

2.0 - 5.0

< 0.01

< 0.01

< 0.25

< 0.25

< 0.08

< 0.10

5.7 - 6.5

5.5 - 6.5

3.2 - 5.0

3.0 - 5.0

< 0.01

< 0.01

< 0.5

< 0.5

< 0.08

< 0.10

4.2 - 6.0

4.0 - 6.0

< 2.0

< 2.0

< 0.01

< 0.01

< 0.5

< 0.5

< 0.08

< 0.10

9.2 - 11.0

9.0 - 11.0

< 2.0

< 2.0

< 0.01

< 0.01

< 0.5

< 0.5

< 0.08

< 0.10

6.2 - 8.0

6.0 - 8.0

< 2.0

< 2.0

< 0.01

< 0.01

< 0.75

< 0.75

< 0.08

< 0.10

4.2 - 6.0

4.0 - 6.0

< 2.0

< 2.0

< 1.0

< 1.0

< 0.25

< 0.30

< 0.15

< 0.20

< 0.25

< 0.30

< 0.40

< 0.50

< 1.5

< 1.5

< 0.03

< 0.10

a)

< 0.15

< 0.2

< 0.20

< 0.20

< 0.50

< 0.50

Ni Pb Si Sn Zn

Ni P Pb

< 2.0

< 2.0

< 0.03

< 0.05

3.5 - 5.8

3.0 - 6.0

< 2.0

< 2.0

< 0.03

< 0.10

4.2 - 5.8

4.0 - 6.0

< 2.0

b)

< 2.0

b)

< 0.03

< 0.10

2.7 - 3.5

2.5 - 3.5

< 2.0

< 2.0

< 0.03

< 0.10

5.2 - 8.0

5.0 - 8.0

< 1.0

< 1.0

< 0.03

< 0.05

1.2 - 2.0

1.0 - 2.0

< 2.0

< 2.0

< 0.10

< 0.10

8.2 - 10.0

8.0 - 10.0

< 2.0

< 2.0

< 0.10

< 0.10

8.2 - 10.5

8.0 - 11.0

0.5 - 2.0

0.5 - 2.0

< 0.10

< 0.10

13.2 - 17.0

13.0 - 17.0

0.5 - 2.5

0.5 - 2.5

< 0.10

< 0.10

19.0 - 23.0

18.0 - 23.0

< 0.01

< 0.01

< 0.10

< 0.10

< 0.04

< 0.04

4.2 - 6.0

4.0 - 6.0

4.5 - 6.5

4.0 - 6.0

< 0.60

< 0.60

< 0.03

< 0.04

< 3.0

< 3.0

Ingot: DIN 17656 (1973)

Casting material: DIN 1705 (1981)

Ingot: DIN 17656 (1973)

Casting material: DIN 1716 (1981)

CB490K CuSn3Zn8Pb5-B

CC490K CuSn3Zn8Pb5-C

Copper-tin-lead alloys 4

GB-CuSn2ZnPb

G-CuSn2ZnPb

CB494K CuSn5Pb9-B

CC494K CuSn5Pb9-C

CB495K CuSn10Pb10-B

CC495K CuSn10Pb10-C

GB-CuPb10Sn

G-CuPb10Sn

GZ-CuPb10Sn

GC-CuPb10Sn

Pb-Bz 10

Pb-Bz 15

Pb-Bz 20

CB496K CuSn7Pb15-B

CC496K CuSn7Pb15-C

GB-CuPb15Sn

G-CuPb15Sn

GZ-CuPb15Sn

GC-CuPb15Sn

CB497K CuSn5Pb20-B

CC497K CuSn5Pb20-C

GB-CuPb20Sn

G-CuPb20Sn

CB491K CuSn5Zn5Pb5-B

CC491K CuSn5Zn5Pb5-C

GB-CuSn5ZnPb

G-CuSn5ZnPb

Rg 5

Rg 2

CB492K CuSn7Zn2Pb3-B

CC492K CuSn7Zn2Pb3-C

GB-CuSn6ZnNi

G-CuSn6ZnNi

CB493K CuSn7Zn4Pb7-B

CC493K CuSn7Zn4Pb7-C

GB-CuSn7ZnPb

G-CuSn7ZnPb

GZ-CuSn7ZnPb

GC-CuSn7ZnPb

Rg 7

CB498K CuSn6Zn4Pb2-B

CC498K CuSn6Zn4Pb2-C

Designation accord. to EN 1982:2008

Number Symbol

CB330G CuAl9-B

CC330G CuAl9-C

Copper-aluminium alloys 5

Ingot: DIN 17656 (1973)

Casting material: DIN 1714 (1981)

CB331G CuAl10Fe2-B

CC331G CuAl10Fe2-C

GB-CuAl10Fe

G-CuAl10Fe

GK-CuAl10Fe

GZ-CuAl10Fe

Fe-Al Bz

CB499K CuSn5Zn5Pb2-B

CC499K CuSn5Zn5Pb2-C

Former abbreviated

designation

Former standard

designation

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

Sand GS

Centrifugal GZ

Continuous GC

180

220

220

85

100

100

15

12

12

60

70

70

200

220

250

250

90

110

110

110

13

6

13

13

60

65

65

65

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

200

220

250

250

90

110

110

110

13

6

13

13

60

65

65

65

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

230

230

260

270

130

130

130

130

14

12

12

12

65

70

70

70

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

230

230

260

260

120

120

120

120

15

12

12

12

60

60

70

70

Sand GS

Perm. mould GM

Continuous GC

Centrifugal GZ

220

220

240

240

110

110

110

110

15

12

12

12

65

70

70

70

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

160

200

200

200

60

80

90

100

7

5

6

9

55

60

60

60

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

180

220

220

220

80

110

110

110

8

3

6

8

60

65

70

70

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

170

200

200

80

90

90

8

8

7

60

65

65

Sand GS

Continuous GC

Centrifugal GZ

150

180

170

70

90

80

5

7

6

45

50

50

Sand GS

Continuous GC

Centrifugal GZ

Mechanical properties

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

500

450

180

160

20

15

100

100

Perm. mould GM

Centrifugal GZ

500

600

550

550

180

250

200

200

18

20

18

15

100

130

130

130

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

a) Including nickel The alloy is especially used for thin-walled fittings

(wall thickness of up to 12 mm); suitable for use up

to 225 C

Medium hard construction material, can be easily

cast, corrosion-resistant against domestic water

even in the event of increased temperatures

Water and steam mounting housings up to 226 C,

normal-strained pump housings and thin-walled

sophisticated castings

Construction material can be easily cast, good

soft soldering and, to a limited extent, good hard

soldering properties, sea-water resistant

Fittings and pump housings as well as casting parts,

where pressure tightness is required above all.

Is already frequently used as a construction material

Construction material with good strength and

elongation, can be easily cast, sea-water resistant

Axle bearing shells and coupling rod bearings, slide

bearing shells for general machine construction

(peak loads of p up to 4000 N/cm

2

permitted);

moderately-stressed slide plates and rails, normal

and highly-stressed slide bearing bushes and shells

when using shafts manufactured from non-

hardened construction steels and surface-hardened

steels, also in the event of slight edge compression.

Small end bushes for p of up to 4000 N/cm

2

;

crank and toggle lever bearings with peak loads of

p up to 3000 N/cm

2

; marine shaft coverings and

cylinder insert bushes, base and stuffing bush

linings, moderate to highly-stressed slide and steel

rails for machine tools, moderately-stressed coupling

units, friction rings and discs

G-CuSn7Zn4Pb7: Moderately hard slide bearing

material with good emergency running properties;

sea-water resistant

GZ-CuSn7Zn4Pb7 / GC-CuSn7Zn4Pb7: See

G-CuSn7Pb properties, is more uniform however

and has improved wear resistance

Pump housings, thin-walled sophisticated castings Construction material with viable strength proper-

ties and elongation, can be easily cast, similar to

CC491K, with lower Pb and Zn contents however,

sea-water resistant

a) Including nickel

Potable water transporting components,

components that must comply with the European

Waste Electrical and Electronic Equipment

Regulation or the End of Life Vehicle Regulation.

Construction material can be easily cast, good

soft soldering and limited hard soldering properties,

sea-water resistant.

Note: For drinking water

applications no other single

element should be more than

0.02 %. The sum of these

single elements should not

exceed 0.25 %.

a) Including nickel

b) (Tin + nickel) content shall

be in the range 7.0 % to 8.0 %.

a) Including nickel

b) For continuous castings and

centrifugal castings, the

minimum tin content for ingots

shall be 5.4 % and for castings

5.2 % and the maximum

copper content for ingots shall

be 85.0 % and for castings

86.0 %.

a) Including nickel

a) Including nickel Sliding material soft material Bearing bushes, slide bearings

Bearing material with good sliding properties and

good wear resistance.

Suitable for use as a compound casting material.

Good corrosion resistance

Slide bearings with high surface pressures where edge

compressions may occur, e.g. calender rolls, vehicle

bearings, bearings for hot rolling mills, peak stresses

with good lubrication of up to p = 6000 N/cm

2

.

Stress of up to 10,000 N/cm

2

when dealing with

composite bearings in combustion engines, e.g.

small end and transmission bushes, starting discs

Bearing material with good sliding and emergency

running properties in the event of a temporary lack

of lubricant and in the event of water lubrication;

suitable for use as a compound casting material,

good resistance against sulphuric acid

Press bearings with high surfaces where edge

compressions may occur. Bearings without babbitt

lining, also with embedded copper cooling pipes for

cold rolling mills. Peak stress with good lubrication

of up to p = 5000 N/cm

2

.

Composite bearings for combustion engines,

preferably small end bushes with a maximum stress

of up to 7000 N/cm

2

, acid resistant fittings and

castings.

Bearing material with the best sliding properties,

particularly good emergency running properties in

the event of a temporary lack of lubricant and in

the event of water lubrication. Suitable for use as a

compound casting material. Good resistance against

sulphuric acid. Inferior casting properties when

compared to G-CuPb15Sn, which is to be preferred

for this reason.

Bearings also with high sliding speeds; Bearings for

milling machines, water pumps, cold and foil rolling

mills. Peak stress with good lubrication of up to

p = 4000 N/cm

2

Corrosion-resistant fittings and castings.

Highly-stressed composite bearings in combustion

engines, e.g. small end bushes with stresses of up to

p = 7000 N/cm

2

.

Construction material with high strength properties.

Resistance properties against corrosion are

unfavourable compared to CC311G and CC333G

as a result of the missing Ni content.

Similar to CC331G CC333G. Suitable for the

chemical industry, resistant against sulphuric and

acetic acid, suitable for heat exchangers.

Construction material only low temperature

dependency between -200 C and +200 C

Mechanically-stressed parts; levers, housings, bushes,

carbon holders in the electrical industry, fittings in the

furniture industry, bevel and mitre wheels, synchroni-

sing discs, selector segments and selector forks, in the

textile machine and automobile construction fields

a) Including nickel

a) Including nickel

a) Including nickel

Notes Comments Information for use

a) Including nickel

a) For castings intended to be

welded, the maximum lead

content shall be 0.03 %.

Copper-aluminium alloys Cu 5

Ingot: DIN 17656 (1973)

Casting material: DIN 1714 (1981) Al

80.0- 85.5

a)

80.0- 86.0

a)

8.7 - 10.5

b)

8.5 - 10.5

b)

1.0 - 2.8

1.0 - 3.0

< 0.05

< 0.05

< 2.0

< 2.0

76.0 - 82.5

76.0 - 83.0

8.8 - 10.0

8.5 - 10.5

< 0.01

< 0.01

< 0.05

< 0.05

4.0 - 5.3

a)

4.0 - 5.5

a)

< 0.05

< 0.05

< 2.5

< 3.0

72.0- 81.5

a)

72.0- 82.5

a)

10.3 - 12.0

a)

10.0 - 12.0

a)

4.2 - 7.0

a)

4.0 - 7.0

a)

< 0.05

< 0.05

< 2.5

< 2.5

Ni-Al Bz

G-CuNi 10 CuNi 90/10

CuNi 70/30

CB332G CuAl10Ni3Fe2-B

CC332G CuAl10Ni3Fe2-C

GB-CuAl9Ni

G-CuAl9Ni

GK-CuAl9Ni

GZ-CuAl9Ni

CB333G CuAl10Fe5Ni5-B

CC333G CuAl10Fe5Ni5-C

GB-CuAl10Ni

G-CuAl10Ni

GK-CuAl10Ni

GZ-CuAl10Ni

GC-CuAl10Ni

CB334G CuAl11Fe6Ni6-B

CC334G CuAl11Fe6Ni6-C

GB-CuAl11Ni

G-CuAl11Ni

GK-CuAl11Ni

GZ-CuAl11Ni

Bi Cr Fe Mg Mn

CC212E CuMn11Al8Fe3Ni3-C

Copper-manganese-

aluminium alloy Cu

68.0- 77.0 7.0 - 9.0 2.0 - 4.0 < 0.05 8.0 - 15.0 1.5 - 4.5 < 0.05

6 Casting material: DIN 1714 (1981) Al Fe Mg Mn Ni Pb

CB380H CuNi10Fe1Mn1-B

CC380H CuNi10Fe1Mn1-C

Copper-nickel alloys Cu

> 84.5

> 84.5

7

Ingot: DIN 17656 (1973)

Casting material: DIN 17658 (1973) Al B Bi C Cr Fe Mg Mn Nb

> 64.5

> 64.5

Remainder

Remainder

< 0.01

< 0.01

< 0.01

< 0.01

< 0.01

< 0.01

< 0.01

< 0.01

< 0.002

< 0.01

< 0.10

< 0.10

< 0.02

< 0.03

< 0.03

< 0.03

1.5 - 2.0

1.2 - 1.8

1.0 - 1.8

0.5 - 1.5

0.5 - 1.5

0.5 - 1.0

0.5 - 1.5

< 0.01

< 0.01

1.2 - 1.5

1.0 - 1.5

0.7 - 1.2

0.6 - 1.2

0.5 - 1.0

0.6 - 1.2

< 1.0

< 1.0

0.5 - 1.0

Cd

< 0.02

CB381H CuNi30Fe1Mn1-B

CC381H CuNi30Fe1Mn1-C

CC382H CuNi30Cr2FeMnSi-C

G-CuNi30 CC383H CuNi30Fe1Mn1NbSi-C

Designation accord. to EN 1982:2008

Number Symbol

Ingots refer to notes

Ingots refer to notes

Ingots refer to notes

Former abbreviated

designation

Former standard

designation Chemical composition in percent (mass fraction)

1.5 - 4.0

b)

1.5 - 4.0

b)

< 0.03

< 0.10

c)

< 0.15

< 0.2

< 0.20

< 0.20

< 0.50

< 0.50

4.0 - 5.5

a)

4.0 - 6.0

a)

< 0.03

< 0.03

< 0.10

< 0.1

< 0.1

< 0.1

< 0.40

< 0.50

4.3 - 7.5

4.0 - 7.5

< 0.04

< 0.05

< 0.10

< 0.1

< 0.20

< 0.2

< 0.40

< 0.50

Ni Pb Si Sn Zn

< 0.1 < 0.5 < 1.0

Si Sn Zn

Ni P Pb S Se Si Te Ti Zn Zr

9.2 - 11.0

9.0 - 11.0

29.2- 31.0

29.0- 31.0

29.0-32.0

29.0- 31.0

< 0.01

< 0.01

< 0.01

< 0.01

< 0.03

< 0.03

< 0.03

< 0.03

< 0.005

< 0.01

< 0.01

< 0.01

< 0.01

< 0.01

< 0.005

< 0.01

< 0.10

< 0.10

< 0.10

< 0.1

0.15-0.50

0.3 - 0.7

< 0.005

< 0.01

< 0.25

< 0.50

< 0.5

< 0.50

< 0.5

< 0.2

< 0.50

< 0.15

Copper-aluminium alloys 5

Ingot: DIN 17656 (1973)

Casting material: DIN 1714 (1981)

Ni-Al Bz

G-CuNi 10 CuNi 90/10

CuNi 70/30

CB332G CuAl10Ni3Fe2-B

CC332G CuAl10Ni3Fe2-C

GB-CuAl9Ni

G-CuAl9Ni

GK-CuAl9Ni

GZ-CuAl9Ni

CB333G CuAl10Fe5Ni5-B

CC333G CuAl10Fe5Ni5-C

GB-CuAl10Ni

G-CuAl10Ni

GK-CuAl10Ni

GZ-CuAl10Ni

GC-CuAl10Ni

CB334G CuAl11Fe6Ni6-B

CC334G CuAl11Fe6Ni6-C

GB-CuAl11Ni

G-CuAl11Ni

GK-CuAl11Ni

GZ-CuAl11Ni

CC212E CuMn11Al8Fe3Ni3-C

Copper-manganese-

aluminium alloy 6 Casting material: DIN 1714 (1981)

CB380H CuNi10Fe1Mn1-B

CC380H CuNi10Fe1Mn1-C

Copper-nickel alloys 7

Ingot: DIN 17656 (1973)

Casting material: DIN 17658 (1973)

CB381H CuNi30Fe1Mn1-B

CC381H CuNi30Fe1Mn1-C

CC382H CuNi30Cr2FeMnSi-C

G-CuNi30 CC383H CuNi30Fe1Mn1NbSi-C

Designation accord. to EN 1982:2008

Number Symbol

Former abbreviated

designation

Former standard

designation

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

Mechanical properties

500

600

550

550

180

250

220

220

18

20

20

20

100

130

120

120

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

600

650

650

650

250

280

280

280

13

7

13

13

140

150

150

150

Sand GS

Perm. mould GM

Centrifugal GZ

Continuous GC

680

750

750

320

380

380

5

5

5

170

185

185

Sand GS

Perm. mould

a)

GM

Centrifugal GZ

630 275 18 150 Sand GS

Casting process

and designation

Tensile strength

R

m

N/mm

2

min.

0.2 % proof strength

R

p0.2

N/mm

2

min.

Elongation

A % min.

Brinell hardness

HBW min.

280

280

280

120

100

100

20

25

25

70

70

70

Sand GS

Centrifugal GZ

Continuous GC

340

340

120

120

18

18

80

80

Sand GS

Centrifugal GZ

440 250 18 115 Sand GS

440 230 18 115 Sand GS

a) For permanent mould castings,

the maximum copper content

for ingots and castings shall be

88.5 %.

b) For castings for sea-water

applications, the aluminium

content shall be such that

Al % < (8.2 + 0.5 Ni %).

c) For castings intended to be

welded, the maximum lead

content shall be 0.03 %.

Construction material good strength properties,

resistant in cold and hot sea-water as well as in

non-oxidising acids, salt solutions and particular lyes.

Very easy to weld and therefore particularly suitable

for mixtures consisting of casting and wrought

material

Corrosion-stressed parts; Fittings for aggressive

waters, variable pitch propellers, stem parts, flanges

for ship construction, construction parts for food

processing machines, pickling drums and contacting

containers for the chemical industry

Construction material with further improved

strength properties, resistant in cold and hot sea-

water, good fatigue strength

For parts that are highly-stressed with regard to

strength and corrosion resistance; superheated

steam fittings, distribution heads and reversing

bottoms in apparatus construction as well as petro-

chemistry, ship propellers, stem pipes, running

wheels, pump housings.

As centrifugal and continuous casting see comments

and notes with regard to G-CuAl11Ni

Construction material, high strength properties,

resistant in cold and hot sea-water: Excellent fatigue

strength in air and sea-water: Very cavitation-

resistant, highly durable with good wear resistance

(good lubrication required)

As with G-CuAl10Ni however, increased require-

ments concerning the cavitation and / or wear

resistance; internal parts for extreme pressure fit-

tings in the hydraulics, slide bearings with very high

impact loads; crank and toggle lever bearings with

high peak loads (p up to 2500 N/cm

2

), worm and

helical gears, flexible jaws and compression cap

nuts, Francis wheels and Kaplan blades, pump

running wheels

Construction material. Primarily used in Great

Britain, with low permeability.

Construction parts for the shipping industry, also

suitable for use as propeller material.

a) For permanent mould castings,

the minimum iron content

of ingots and castings shall be

3.0 % and the minimum

nickel content shall be 3.7 %.

a) For permanent mould castings,

the minimum iron content

of ingots and castings shall be

3.0 % and the minimum

aluminium content shall be

9.0 %. In this case, the

maximum copper content

shall be 84.5 %.

Note: Ingot properties for

producing castings conforming

to CuMn11Al8Fe3Ni3-C

(CC212E) are not specified in

this standard. The composition

limits for ingots are at the

discretion of the purchaser and

shall be stated on the enquiry

and order (see ordering

information of EN 1982:2008).

Note: Ingot properties for

producing castings conforming

to CuNi30Cr2FeMnSi-C

(CC382H) are not specified in

this standard. The composition

limits for ingots are at the

discretion of the purchaser and

shall be stated on the enquiry

and order (see ordering

information of EN 1982:2008).

Note: Ingot properties for

producing castings conforming

to CuNi30Fe1Mn1NbSi-C

(CC383H) are not specified in

this standard. The composition

limits for ingots are at the

discretion of the purchaser and

shall be stated on the enquiry

and order (see ordering

information of EN 1982:2008).

Notes Comments Information for use

Excellent corrosion resistance against all types of

water such as drinking water, river water, brackish

water, mine water, sea-water as well as acidic and

ammoniacal condensates.

No sensitivity against stress corrosion cracking.

Good erosion and cavitation resistance.

Can be welded easily when the Si and Nb

contents are matched correctly can also be

welded with c-steels.

Both alloys can be soft and hard soldered

however, welding is preferable.

Can be machined well.

Used in ship construction, paper machine

construction, in the foodstuff and drinks industry,

in power plants and in the chemical industry for

fittings, mountings, pumps, measurement devices,

agitators, filling units, etc.

Excellent corrosion resistance against all types of

water such as drinking water, river water, brackish

water, mine water, sea-water as well as acidic and

ammoniacal condensates.

No sensitivity against stress corrosion cracking.

Good erosion and cavitation resistance.

Can be welded easily when the Si and Nb

contents are matched correctly can also be

welded with c-steels.

Both alloys can be soft and hard soldered

however, welding is preferable.

Can be machined well.

Used in ship construction, paper machine

construction, in the foodstuff and drinks industry,

in power plants and in the chemical industry for

fittings, mountings, pumps, measurement devices,

agitators, filling units, etc.

Master alloy for the alloying of Ni into Cu alloys. Use as with CC380H and CC383H. Can be welded

easily, excellent corrosion resistance.

This product contains 1.5 - 2.0 % Cr. Excellent

corrosion resistance against all types of water such

as drinking water, river water, brackish water, mine

water, sea-water as well as acidic and ammoniacal

condensates.

Use as with CC380H and CC383H.

Вам также может понравиться

- Astm B187Документ9 страницAstm B187Plata Elpidio100% (3)

- GB3077-1999 English VersionДокумент20 страницGB3077-1999 English VersionHermanto SupuОценок пока нет

- ARI 700 StandardДокумент19 страницARI 700 StandardMarcos Antonio MoraesОценок пока нет

- Stainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedДокумент28 страницStainless Steel Flat Products For Building - The Grades in EN 10088-4 ExplainedLeo TuckerОценок пока нет

- GB 2585 - 2007 Hot-Rolled Steel Rails For RailwayДокумент58 страницGB 2585 - 2007 Hot-Rolled Steel Rails For Railwaytran_lam100% (1)

- Asna 2050Документ9 страницAsna 2050Carlos Arévalo100% (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39От EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Рейтинг: 5 из 5 звезд5/5 (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceОт EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceРейтинг: 5 из 5 звезд5/5 (1)

- Masonry Concrete Masonry HandbookДокумент31 страницаMasonry Concrete Masonry HandbookNguyễn Hoàng Bảo100% (2)

- Flat Oval Tube (Oval - Hotchkiss)Документ9 страницFlat Oval Tube (Oval - Hotchkiss)Blanca LopezОценок пока нет

- MSU Copper Casting Alloys 2011 PDFДокумент10 страницMSU Copper Casting Alloys 2011 PDFVahid SarfarazОценок пока нет

- EN10083 Part 2Документ39 страницEN10083 Part 2Chandran Santhanam100% (1)

- DIN en 10250-2 1999 Open Die Steel Forgings For General Engineering Purposes-Part 2 Non-Alloy Quality and Special SteelsДокумент10 страницDIN en 10250-2 1999 Open Die Steel Forgings For General Engineering Purposes-Part 2 Non-Alloy Quality and Special SteelsBui Chi TamОценок пока нет

- Din 1480 2005Документ6 страницDin 1480 2005PacoОценок пока нет

- BS 970Документ5 страницBS 970aezeadОценок пока нет

- Astmb283 PDFДокумент8 страницAstmb283 PDFtulioОценок пока нет

- BS 970 SteelsДокумент8 страницBS 970 SteelsTamal Guha100% (2)

- 2872Документ24 страницы2872Kaushik SenguptaОценок пока нет

- Welded Stainless Steel Tubes: SectionДокумент6 страницWelded Stainless Steel Tubes: Sectionrudiskw456Оценок пока нет

- Metrode P92 Consumables Jul2006Документ28 страницMetrode P92 Consumables Jul2006Claudia MmsОценок пока нет

- Din en 1561Документ21 страницаDin en 1561Daniela Barbu100% (2)

- BS4190-2001 ISO Metric Black Hexagon Bolts - Screws - Nuts Specification PDFДокумент32 страницыBS4190-2001 ISO Metric Black Hexagon Bolts - Screws - Nuts Specification PDFTan100% (4)

- Utp Cast Iron GBДокумент8 страницUtp Cast Iron GBhrk100Оценок пока нет

- Welding Filler Metals For Power Plant EngineeringДокумент20 страницWelding Filler Metals For Power Plant EngineeringgogotigОценок пока нет

- Scanned Indian Standards ListДокумент30 страницScanned Indian Standards ListJignesh TrivediОценок пока нет

- ST 14Документ40 страницST 14harshОценок пока нет

- Copper MouldsДокумент6 страницCopper Mouldsherbie_astaОценок пока нет

- Armatura OkДокумент10 страницArmatura OkDragos PetrovicОценок пока нет

- SB 111-SB 111MДокумент14 страницSB 111-SB 111MRoberto Faustino FaustinoОценок пока нет

- Din en 485-2Документ46 страницDin en 485-2chris771963100% (3)

- ASTM B111 - Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule StockДокумент18 страницASTM B111 - Standard Specification For Copper and Copper-Alloy Seamless Condenser Tubes and Ferrule Stockfininho555Оценок пока нет

- #Fffi : Adwdnced Fittinas LidДокумент10 страниц#Fffi : Adwdnced Fittinas LidadfitindiaОценок пока нет

- ISO - TR - 15608 - Welding Guide Line PDFДокумент10 страницISO - TR - 15608 - Welding Guide Line PDFDacher DanielОценок пока нет

- Cold Drawn Seamless Steel Tubes For Mechanical ApplicationsДокумент8 страницCold Drawn Seamless Steel Tubes For Mechanical ApplicationsDiego TrinidadОценок пока нет

- En10028 2Документ12 страницEn10028 2Patilea Daniela100% (1)

- Durham Foundry NiResistДокумент1 страницаDurham Foundry NiResistTerminatorX75Оценок пока нет

- Copper and Copper Alloy Ingots and CastingsДокумент2 страницыCopper and Copper Alloy Ingots and CastingspoopОценок пока нет

- Web Page Blocked: Home Matter IndexДокумент5 страницWeb Page Blocked: Home Matter Index4arunpandeyОценок пока нет

- List 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & BarsДокумент75 страницList 1 Approved Steelmakers and Manufacturers of Rolled Steel Plates, Strip, Sections & Barswyvren88Оценок пока нет

- BS en 12420 (1999)Документ40 страницBS en 12420 (1999)cejotafual67% (3)

- Wi Cswip 3.1 Part 21Документ8 страницWi Cswip 3.1 Part 21Ramakrishnan AmbiSubbiahОценок пока нет

- British and ISO Standards Related ToДокумент14 страницBritish and ISO Standards Related Tocao thanh quocОценок пока нет

- DIN 2093 2006-03 eДокумент18 страницDIN 2093 2006-03 eLuis Testa100% (1)

- Australian Standard: Compacted (Vermicular) Graphite Cast Irons-ClassificationДокумент10 страницAustralian Standard: Compacted (Vermicular) Graphite Cast Irons-ClassificationMarcos CarreroОценок пока нет

- Vol-7 (No1) 9Cr FluageДокумент10 страницVol-7 (No1) 9Cr FluageClaude BouillotОценок пока нет

- Gost 1583-93Документ53 страницыGost 1583-93KannanОценок пока нет

- BS en 758-97 PDFДокумент16 страницBS en 758-97 PDFAhmet Memiş100% (1)

- Die Casting Metallurgy: Butterworths Monographs in MaterialsОт EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsРейтинг: 3.5 из 5 звезд3.5/5 (2)

- Steel and Its Heat Treatment: Bofors HandbookОт EverandSteel and Its Heat Treatment: Bofors HandbookРейтинг: 2.5 из 5 звезд2.5/5 (3)

- Weld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingОт EverandWeld Quality: The Role of Computers: Proceedings of the International Conference on Improved Weldment Control with Special Reference to Computer Technology Held in Vienna, Austria, 4–5 July 1988 under the Auspices of the International Institute of WeldingОценок пока нет

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20От EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20Оценок пока нет

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesОт EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesОценок пока нет

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОт EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonОценок пока нет

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesОт EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesОценок пока нет

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОт EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОценок пока нет

- 2015-11-09 Press Release Lehnhoff - Komatsu EnglДокумент2 страницы2015-11-09 Press Release Lehnhoff - Komatsu EnglDaniel CringusОценок пока нет

- Ck45 Mechanical PropertiesДокумент3 страницыCk45 Mechanical PropertiesDaniel CringusОценок пока нет

- Candidates Information Booklet: WWW - Cpsa.ieДокумент12 страницCandidates Information Booklet: WWW - Cpsa.ieDaniel CringusОценок пока нет

- 5878 en-GB Loadall RB 1Документ28 страниц5878 en-GB Loadall RB 1Daniel CringusОценок пока нет

- K 3Документ1 страницаK 3ilyaskureshiОценок пока нет

- Holmbury Hose Burst Valve VPC PDFДокумент2 страницыHolmbury Hose Burst Valve VPC PDFDaniel CringusОценок пока нет

- A46JE SnorkelДокумент2 страницыA46JE SnorkelDaniel CringusОценок пока нет

- BROCHURE Xylem - Pump Selection Guide 0412Документ82 страницыBROCHURE Xylem - Pump Selection Guide 0412Christy MaxwellОценок пока нет

- Cylinder 3dДокумент2 страницыCylinder 3dDaniel CringusОценок пока нет

- SH TD enДокумент112 страницSH TD enDaniel CringusОценок пока нет

- 95 AU V 142-EnДокумент2 страницы95 AU V 142-EnDaniel CringusОценок пока нет

- Orifice Disc Installation & Sizing Guide: Housings and Accessory ProductsДокумент4 страницыOrifice Disc Installation & Sizing Guide: Housings and Accessory ProductsDaniel CringusОценок пока нет

- Ulysses: by James JoyceДокумент579 страницUlysses: by James JoyceDaniel CringusОценок пока нет

- Fisa Tehnica Weldox 700Документ2 страницыFisa Tehnica Weldox 700Daniel CringusОценок пока нет

- 94 AU 925-EnДокумент2 страницы94 AU 925-EnDaniel CringusОценок пока нет

- Surface Crack DetectionДокумент8 страницSurface Crack DetectionDaniel CringusОценок пока нет

- 107 - WELDOX - 700 - UK - Data Sheet PDFДокумент2 страницы107 - WELDOX - 700 - UK - Data Sheet PDFDaniel CringusОценок пока нет

- 0.188 375 12 RectangularKeystockДокумент2 страницы0.188 375 12 RectangularKeystockDaniel CringusОценок пока нет

- IndexДокумент50 страницIndexSonja Stojaković100% (1)

- JM Fatc GuideДокумент32 страницыJM Fatc Guidewreckedweasel100% (3)

- JISДокумент30 страницJISImam SalehОценок пока нет

- Q150 R Plus Brochure V1Документ4 страницыQ150 R Plus Brochure V1toansОценок пока нет

- Approval Ballast eДокумент7 страницApproval Ballast eAbd ZouhierОценок пока нет

- Flooring Construction CoatingsДокумент5 страницFlooring Construction CoatingsWall E NguyễnОценок пока нет

- Ecodial Advance Calculation 4.1Документ33 страницыEcodial Advance Calculation 4.1Youwan LeeОценок пока нет

- Chemical Cleaning of Stator WaterДокумент7 страницChemical Cleaning of Stator WaterprakashОценок пока нет

- Son Sob SRN SRB Sov SRV (GB) 06.02Документ21 страницаSon Sob SRN SRB Sov SRV (GB) 06.02OlegОценок пока нет

- Lenovo V370 Hardware Maintenance Manual (English)Документ84 страницыLenovo V370 Hardware Maintenance Manual (English)dantzy72Оценок пока нет

- Mechanic Machine Tool Maintenance-Nsqf PDFДокумент63 страницыMechanic Machine Tool Maintenance-Nsqf PDFUjjwal Chauhan100% (3)

- Stoody 104Документ1 страницаStoody 104JUAN DAVID ESPITIAОценок пока нет

- E9018 M Specifications PDFДокумент2 страницыE9018 M Specifications PDFMohamed MostafaОценок пока нет