Академический Документы

Профессиональный Документы

Культура Документы

Operational and Maintenance Manual PDF

Загружено:

Nano VillanuevaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Operational and Maintenance Manual PDF

Загружено:

Nano VillanuevaАвторское право:

Доступные форматы

Page 1

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Operational and Maintenance Manual

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Gate Connection

Page 2

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

All the information contained in this manual is the exclusive property of Cameron International

Corporation ("Cameron"). Any reproduction or use of the calculations, drawings, photographs,

procedures or instructions, either expressed or implied, is forbidden without the written

permission of Cameron or its authorized agent.

Initial Release 01

July 2012

Copyright 2012 all rights reserved

by

Cameron International Corporation ("Cameron")

Page 3

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Cameron

P.O. Box 1212

Houston, Texas 77251-1212

713-939-2211

http://www.c-a-m.com

PREFACE

The procedures included in this book are to be performed in conjunction with the requirements

and recommendations outlined in API Specifications. Any repairs to the equipment covered by

this book should be done by an authorized Cameron service representative. Cameron will not be

responsible for loss or expense resulting from any failure of equipment or any damage to any

property or death or injury to any person resulting in whole or in part from repairs performed

by other than authorized Cameron personnel. Such unauthorized repairs shall also serve to

terminate any contractual or other warranty, if any, on the equipment and may also result in

equipment no longer meeting applicable requirements.

File copies of this manual are maintained. Revisions and/or additions will be made as deemed

necessary by Cameron. The drawings in this book are not drawn to scale, but the dimensions

shown are accurate.

This book covers Cameron products, which are products of

Cameron International Corporation ("Cameron").

Page 4

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

STOP

GATE VALVE GENERAL WARNING

READ AND UNDERSTAND ALL INSTRUCTIONS. Failure to follow may result in serious personal injury

and damage not only to the equipment but also the environment.

1. Safety is a combination of staying alert, common sense, and experience with the oil field equip ment and

environment. Read this manual prior to operating and servicing the valve. Be familiar with the operation

terminologies of gate valves and oil field equipment.

2. This document includes basic valve repair guidance. The field service personnel shall be fully

trained in all aspects of handling pressure control equipment, as well as the job that they are going

to perform. If any of the procedures and policies listed in this document cannot be followed, contact

a Cameron Representative for the best course of action.

3. Proper Personal Protective Equipment (PPE) shall be utilized according to Company policies. Al ways use

proper tools when servicing the equipment.

4. A job hazard analysis (JHA) must be performed prior to beginning any service on a well location. A

JHA review meeting will be held with all affected rig personnel PRIOR to the commencement of work

to review the results of the JHA, evacuation routes, emergency contacts, etc. All meeting at tendees and

a Company Representative will sign-off on the JHA to acknowledge this meeting has taken place.

5. Be aware of unexpected circumstances that may arise when operating or servicing the valve. Uti lize

the Step Back 5X5 process in order to assess the hazards posed before, during, and after the servicing of

equipment under pressure or with the potential of hazardous chemicals present. Be familiar with the

companys and facilitys Lockout/Tagout program in order to ensure all sources of energy (i.e. electrical,

pneumatic, pressure) are isolated and/or de-energized prior to beginning work.

6. All governmental or Company safety requirements shall be met before working on the valve. Re-

quirements of fully tested pressure barriers prior to servicing the valve shall be observed. Cameron

recommends that two mechanical pressure barriers is the preferred practice. The Lower Master Valve

(LMV) is a critical valve and additional precautions should be taken to ensure that the mechanical

pressure barriers are functioning correctly prior to any work being carried out on this particular valve.

7. Always check for any trapped pressure before servicing the valve. All valves downstream of the pressure

barriers must be cycled several times to release any trapped pressure.

8. Ensure the chemical and physical properties of the fluid flow product inside the valve are known. Obtain

applicable Material Safety Data Sheets (MSDS) for commonly encountered chemicals such as hydrogen

sulfide, cements, etc. in order to identify appropriate PPE to use, emergencies, proce dures, and methods

or exposure control.

9. Always use correct lifting devices and follow safety rules for handling heavy products. The actual valve

weight can vary for different valve configurations. Valve should be lifted from the valve body, flange

or studded end connection. Never lift valve from the hand wheel, hand wheel connection, actuator

or lower stem protector.

10. Cameron manufactures a variety of valve models with different features and operating require ments.

Be certain of the valve model and refer to the appropriate manual, before attempting any operation or

service on the valve.

SD-045055-02 Rev 01

Page 5

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Table of Contents

1.0 SCOPE ........................................................................................................ 6

2.0 GENERAL INFORMATION ......................................................................... 7

2.1 Description and Features ......................................................................................... 7

2.2 Parts List .................................................................................................................... 8

2.3 Dimensional Data ..................................................................................................... 9

2.4 Surface Safety Valve Requirements ....................................................................... 10

3.0 VALVE OPERATION ................................................................................ 11

3.1 Open Valve ............................................................................................................. 11

3.2 Close Valve .............................................................................................................. 11

3.3 Actuator Operation ................................................................................................ 11

4.0 PERIODIC MAINTENANCE ...................................................................... 12

4.1 Lubrication ............................................................................................................. 12

4.2 Lubricant Charts ..................................................................................................... 14

5.0 TROUBLESHOOTING .............................................................................. 16

5.1 Valve ........................................................................................................................ 16

5.2 Actuator .................................................................................................................. 16

6.0 BOLT TORQUE ........................................................................................ 17

Recommended Makeup Torque Ft-Lb .......................................................................... 17

Recommended Makeup Torque Nm .......................................................................... 18

7.0 ORDERING REPLACEMENT PARTS ......................................................... 19

Page 6

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

1.0 SCOPE

The standard Model FL and FLS Bi-Directional actuated gate valve is available for bore sizes and pressures

shown in the table below.

If the bore size and pressure of a particular valve is not listed in this manual, contact Cameron for the ap-

propriate maintenance manual for the valve.

This Manual is for

Bore Pressure Rating

1-13/16" 2000-20,000 psig

2-1/16" 2000-20,000 psig

2-9/16" 2000-20,000 psig

3-1/8" 2000-5000 psig

3-1/16" 10,000-15,000 psig

4-1/8" 2000-5000 psig

4-1/16" 10,000-15,000 psig

5-1/8" 2000-10,000 psig

6-1/8" 2000-5000 psig

6-3/8" 2000-5000 psig

This Manual is NOT for

Bore Pressure Rating

1-13/16" 30,000 psig

2-9/16" 30,000 psig

3-1/16" 20,000 psig

4-1/16" 20,000-30,000 psig

5-1/8" 15,000 psig

6-3/8" 10,000-15,000 psig

7-1/16" 2000-20,000 psig

9" 2000-5000 psig

Page 7

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

2.0 GENERAL INFORMATION

2.1 Description and Features

2.1.1. The Model FL and FLS actuated gate valve has a slab gate design. A tight mechanical seal is

obtained by the floating of the gate against the downstream seat.

2.1.2. Model FL and FLS bi-directional gate valve seals in either direction.

2.1.3. Please read the name plate to identify the valve model and other valve information.

2.1.4. The following are standard features of the FL and FLS bi-directional actuated gate valve:

Full bore, through-conduit API gate valve

Slab gate design

Bi-directional

Metal-to-metal sealing (gate-to-seat and seat-to-body)

Cavity parts are field replaceable

Page 8

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

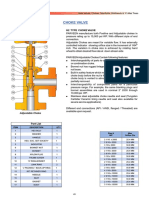

1

6 4 3

10 3

2

7

8

9

5

11

( 2,000-5,000 PSI ONLY )

(FLS ONLY)

SD 042574

2.2 Parts List

Model FL and FLS Bi-Directional Gate Valve

1-13/16" through 6-3/8"

Item Description

1 Stud

2 Nut

3 Gasket

4 Pin (Gate to Stem)

5 Seat

6 Gate

7 Body

8 Seal Ring OD

9 Seal Ring ID

10 Dowel Pin (2000-5000 only)

11 Nameplate

Page 9

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Size

Working

Pressure

A

Inch (mm)

B

Inch (mm)

C

Inch (mm)

D

Inch (mm)

Weight

Lb. (kg)

1-13/16

10,000 18.25 (463.6) 9.00 (228.6) 3.88 (98.6) 5.75 (146.1) 180 (82)

15,000 18.00 (457.2) 9.50 (241.3) 3.88 (98.6) 5.88 (149.4) 230 (104)

20,000 21.00 (533.4) 11.38 (289.1) 3.88 (98.6) 7.88 (200.2) 450 (204)

2-1/16

2000 11.62 (295.1) 6.09 (154.7) 3.85 (97.8) 5.28 (134.1) 74 (34)

3000 14.50 (368.3) 7.00 (177.8) 3.85 (97.8) 5.50 (139.7) 127 (58)

5000 14.50 (368.3) 7.00 (177.8) 3.85 (97.8) 5.50 (139.7) 127 (58)

10,000 20.50 (520.7) 9.00 (228.6) 3.88 (98.6) 5.62 (142.7) 197 (89)

15,000 19.00 (482.6) 9.62 (244.3) 3.88 (98.6) 5.88 (149.4) 244 (111)

20,000 23.00 (584.2) 11.75 (298.5) 4.55 (115.6) 7.50 (190.5) 661 (300)

2-9/16

2000 13.12 (333.2) 7.00 (177.8) 4.66 (118.5) 6.00 (152.4) 109 (50)

3000 16.62 (422.1) 7.88 (200.2) 4.66 (118.5) 6.00 (152.4) 184 (84)

5000 16.62 (422.1) 7.88 (200.2) 4.66 (118.5) 6.00 (152.4) 184 (84)

10,000 22.25 (565.2) 9.38 (238.3) 4.70 (119.3) 6.75 (171.5) 301 (136)

15,000 21.00 (533.4) 11.25 (285.8) 4.88 (124.0) 7.75 (196.9) 449 (204)

20,000 26.50 (673.1) 14.62 (371.3) 6.50 (165.1) 10.00 (254.0) 988 (448)

3-1/8

2000 14.12 (358.6) 7.88 (200.2) 5.57 (141.5) 7.12 (180.8) 173 (79)

3000 17.12 (434.8) 8.38 (212.9) 5.57 (141.5) 7.25 (184.2) 213 (96)

5000 18.62 (472.9) 9.12 (231.6) 5.57 (141.5) 7.25 (184.2) 260 (118)

3-1/16

10,000 24.38 (619.3) 10.12 (257.0) 5.60 (142.3) 8.12 (206.2) 408 (185)

15,000 23.50 (596.9) 13.75 (349.3) 6.13 (155.8) 9.75 (247.7) 726 (329)

4-1/8

2000 17.12 (434.8) 9.62 (244.3) 7.20 (182.8) 9.00 (228.6) 292 (132)

3000 20.12 (511.0) 10.38 (263.7) 7.20 (182.8) 8.75 (222.3) 351 (159)

5000 21.62 (549.1) 10.75 (273.1) 7.20 (182.8) 9.88 (251.0) 468 (212)

4-1/16

10,000 26.12 (663.4) 12.75 (323.9) 7.23 (183.6) 10.25 (260.4) 713 (324)

15,000 29.00 (736.6) 14.50 (368.3) 7.70 (195.5) 11.62 (295.1) 1136 (515)

5-1/8

2000 22.12 (561.8) 11.00 (279.4) 8.85 (224.8) 12.62 (320.5) 831 (377)

3000 24.00 (609.6) 13.00 (330.2) 8.85 (224.8) 12.75 (323.9) 852 (387)

5000 28.62 (726.9) 11.50 (292.1) 8.85 (224.8) 12.62 (320.5) 984 (446)

10,000 29.00 (736.6) 14.50 (368.3) 9.44 (239.7) 13.25 (336.6) 1013 (459)

6-1/8 5000 29.00 (736.6) 14.12 (358.6) 10.32 (262.1) 12.88 (327.2) 1021 (463)

6-3/8

2000 22.12 (561.8) 12.38 (314.5) 10.32 (262.1) 12.88 (327.2) 785 (356)

3000 24.12 (612.6) 12.62 (320.5) 10.32 (262.1) 12.88 (327.2) 864 (392)

5000 29.00 (736.6) 14.12 (358.6) 10.32 (262.1) 12.88 (327.2) 997 (452)

2.3. Dimensional Data

Page 10

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

2.4 Surface Safety Valve Requirements (SSV)

2.4.1 SSV Inspection

The following procedure is to be performed in conjunction with applicable API

specification recommendations.

2.4.1.1 Valve Inspection Procedure Prior to Hook-Up

Visually inspect and contact Cameron for any repair work.

1. Valves Prepped for Actuator

a. End connection ring grooves and bonnet face for any damage.

b. Insure that the body thru bore and cavity are free of all foreign material,

such as solid particles, grit, trash, etc.

2. Valve with Actuator Installed

a. End connection ring grooves for any damage.

b. Insure that the body thru bore is free of all foreign material, such as

solid particles, grit, trash, etc.

2.4.2 SSV Installation and Testing

1.) The Cameron SSV operates properly when installed in any orientation.

2.) Refer to the actuator manufacturer's instructions for information on

installing the actuator onto the valve.

3.) Install the valve and actuator assembly (SSV) onto the Christmas Tree using

the correct end connection gaskets. Apply lubrication to the stud threads

and nut bearing faces and tighten in criss-cross pattern. See BOLT TORQUE

section of this manual for bolt torque requirements.

Page 11

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

3.0 VALVE OPERATION

STOP

VALVE OPERATION

1. Be aware of the surrounding environment and the valve condition when operating the

valve. Be certain of the gate position (open/close) before operating the valve. Be aware

that unexpected circumstances may arise when operating or servicing the valve. Review

the completed JHA and perform a Step Back 5X5 to prepare for unplanned situations.

2. Always use the correct operating media for the actuator cylinder.

3. Do not exceed the operating pressure rating of the actuator cylinder. Exceeding the

maximum cylinder pressure rating can damage the actuator or the valve.

4. If the valve does not operate to the full open or full close position refer to the Trouble-

shooting Section of this manual.

5. When pressure is bled from the valve bore, there may be trapped pressure in the cavity

when the valve is in either the open or close position. The valve should be cycled to relieve

this pressure.

SD-045055-10 Rev 01

3.1. Open Valve

3.1.1. The valve is opened by applying control pressure to the actuator cylinder.

3.2. Close Valve

3.2.1. The valve is closed by releasing control pressure from the actuator cylinder. This

allows pressure in the valve cavity acting across the stem and the springs in the

actuator to close the valve.

The gate must be positioned either "fully-open" or "fully-closed". Leaving the valve in the

partially open position can cause throttling and damage the valve components.

3.3. Actuator Operation

3.3.1. Refer to the actuator manufacture procedures for the actuator operating instruc-

tions.

Page 12

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

4.0 PERIODIC MAINTENANCE

STOP

VALVE CAVITY LUBRICATION

1. Danger: Lubricating the valve involves injection into the valve body. This can present a hazard while the

well is fowing or under pressure. Be aware of unexpected circumstances during or after lubricating the

valve. Review the completed JHA and perform a 'Step Back 5x5" to prepare for unplanned situations.

2. Isolate valve pressure source and release valve pressure before lubricating the valve whenever possible.

If a valve is lubricated under pressure, a second check valve or needle valve should be manifolded onto

the grease ftting as a second barrier. This can isolate pressure if the grease ftting check fails. Reference

the facility's work instruction on grease gun safety in order to verify condition of grease equipment before

performing the work.

3. Besides wearing appropriate PPE, be sure to read and understand the Material Safety Data Sheet (MSDS)

of the grease or any other chemicals being used on the job to ensure adequate control measures are in

place.

4. Be aware of trapped pressure and the physical and chemical properties of well fuids. Stroke the valve

to verify the release of any trapped pressure. Use proper unseating tool to check any residual trapped

pressure through grease ftting.

5. When removing the ftting cap be certain the ftting does not rotate with the cap. If a constant pressure

release is heard when loosening the cap, re-tighten the cap and plan to replace the ftting.

6. During lubrication or other maintenance operations, do not place any part of one's body in front of the

ftting, especially when removing the ftting or ftting cap.

7. The standard gate valves do not have a buried check valve. However, some special customer designs

may have a buried check valve with the word "CHECK" stamped next to the grease ftting.

8. During lubrication do not exceed the rated working pressure of the valve. A slowdown in the pumping

speed shows resistance and can be an indication that the valve cavity is full.

SD-045055-05 Rev 01

4.1.1. Valve Body Cavity Lubrication

Proper lubrication will improve the performance and the life of the valve. It is recommended

to lubricate the valve cavity after ten operating cycles. One cycle equals opening and clos-

ing the valve one time. The service interval can vary according to application, fluids used,

and well conditions. If pressure is equalized across the valve before it is opened, the service

interval can be extended. If the valve is removed from service, the body cavity should be

lubricated before it is returned to service or put in storage.

4.1. Lubrication

NOTICE

Page 13

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

If it becomes necessary to cement, acidize, frac through, or subject the valve to any other

unusual service, it is recommended to lubricate the valve body cavity before the operation.

After the operation, flush the valve with an appropriate cleaning/neutralizing fluid. Then

operate the valve with fresh water or appropriate neutralizing fluid in the line. Finally,

lubricate the valve body cavity again. Cycling the valve during flushing and the lubrication

will greatly improve the effectiveness of the maintenance.

The lubricant selection chart, Table V, recommends the proper grease for different valve

service conditions. Table IV shows the amount of grease required for different Model FL and

FLS valves. Lubrication of the valve cavity is performed through the grease fitting located

on the actuator bonnet as follows:

4.1.1.1. Isolate the valve from flowline pressure.

4.1.1.2. Operate the valve to the fully-open position.

4.1.1.3. Remove the safety cap from the grease fitting located on the actuator bonnet.

When removing the grease fitting cap be certain the fitting does not rotate with

the cap. Do not place any part of one's body in from of the fitting vent.

4.1.1.4. Attach the high-pressure grease gun to the bonnet grease fitting. Pump the required

amount of grease into the valve body. Refer to Tables IV and V.

The lubricating pressure must not exceed the rated working pressure of the valve.

4.1.1.5. When the valve cavity has been filled, remove the grease gun and re-install the

grease fitting cap. For Cameron actuators, torque to 50-60 ft-lb (70-85 Nm). Refer

to the actuator manufature procedures for non-Cameron actuators.

4.1.1.6. Operate the valve several times, and then return it to its normal operating position.

Page 14

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

4.2 Lubricant Charts

Bore Size

(Inch)

Pressure Rating

Volume of Grease Required Weight of Grease Required

cu in cc lb kg

1-13/16 10,000 - 20,000 45 745 1.50 0.7

2-1/16 2000 - 20,000 45 745 1.50 0.7

2-9/16

2000 - 10,000 91 1,490 3.00 1.4

15,000 106 1,738 3.50 1.6

20,000 121 1,986 4.00 1.8

3-1/8 2000 - 5000 136 2,235 4.50 2.0

3-1/16

10,000 133 2,185 4.40 2.0

15,000 182 2,979 6.00 2.7

4-1/8 2000 - 5000 303 4,966 10.00 4.5

4-1/16

10,000 303 4,966 10.00 4.5

15,000 333 5,462 11.00 5.0

5-1/8

2000 - 5000 379 6,207 12.50 5.7

10,000 561 9,187 18.50 8.4

6-1/8 2000 - 5000 697 11,421 23.00 10.4

6-3/8 2000 - 5000 697 11,421 23.00 10.4

Table IV Grease Volume Requirements

Page 15

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Table V Lubricant Selection

Service

Service

Temperature

Operational

Properties

Quantities (By Part Number)

Available on a Standard Order Basis

S

t

a

n

d

a

r

d

C

r

u

d

e

D

i

e

s

e

l

W

i

t

h

H

2

S

W

i

t

h

H

i

g

h

C

O

2

(

P

e

r

P

o

u

n

d

)

5

l

b

C

a

n

2

5

l

b

P

a

i

l

1

2

0

l

b

D

r

u

m

4

0

0

l

b

D

r

u

m

Standard

-20 to 250 F

(-29 to 121 C)

E P F P 700149 700667 700668* 700669 700670

Low

Temp

-50 to 250 F

(-46 t0 121 C)

E P F P 700123 700671 700672 700673 700674

-75 to 350 F

(-59 to 177 C)

E P F P 711027 711027-01 711027-02 711027-03 711027-04

Diesel

Resistant

-20 to 350 F

(-29 to 177 C)

E E G G 713837-10 713837-01 713837-02 713837-03 713837-04

High

Temp

0 to 450 F

(-18 to 232 C)

G P F P 700217 700679 700680 700681 700682

-20 to 500 F

(-29 to 260 C)

G P F P 710194 710194-01 710194-02 710194-03 710194-04

E = Excellent (Recommended) F = Fair (Not Recommended)

G = Good (Recommended) P = Poor (Not Recommended)

*Available in 20 lb pail only

SD-045055-07 Rev 01

Page 16

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Symptom Cause Action

Fluid leaks past the

gate and seat assembly

1. Gate is not closed

2. Gate or seats are worn

1. Stroke valve open and close (A,B)

2. Replace the gate or seats (A,B)

Fluid leaks at the

bonnet flange

1. Bonnet seal ring is worn

2. Bonnet or body ring

groove is damaged

1. Replace the bonnet gasket (A,B)

2. Return the valve to Cameron for

repair

Fluid leaks from the

bonnet grease fitting

1. Check valve inside the

grease fitting is worn

2. Leaking by thread

Refer to actuator manufacture

operating instructions

Valve does not close

1. Pressure remains in

actuator cylinder

2. Excessive friction on gate

1. Bleed off actuator pressure (A,B)

2. Lubricate the valve (A,B)

5.0 TROUBLESHOOTING

5.1. Valve

5.2. Actuator

5.2.1. Refer to the Actuator manufacture procedures for the actuator operating instructions.

A - These actions are recommended for Cameron personnel or facilities only.

B - Refer to Repair Manual.

Page 17

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Recommended Makeup Torque Ft-Lb

6.0 BOLT TORQUE

Per API 6A: preload = .50Sy

Bolt Size

Nom OD - TPI

B7M, L7M (80 ksi Sy) B7, L7, 660 (105 ksi)

cf=0.07 cf=0.13 cf=0.07 cf=0.13

.500-13 27 45 35 59

.625-11 52 88 68 115

.750-10 90 153 118 200

.875-9 143 243 188 319

1.000-8 213 361 279 474

1.125-8 305 523 401 686

1.250-8 421 726 553 953

1.375-8 563 976 739 1280

1.500-8 733 1280 962 1680

1.625-8 934 1640 1230 2150

1.750-8 1170 2050 1530 2700

1.875-8 1440 2540 1890 3330

2.000-8 1750 3090 2300 4060

2.250-8 2500 4440 3280 5820

2.500-8 3430 6120 4500 8030

2.625-8 3970 7100 4720 8430

2.750-8 4570 8180 5420 9700

3.000-8 5930 10,700 7050 12,700

3.250-8 7550 13,600 8970 16,100

3.500-8 9430 17,000 11,200 20,200

3.750-8 11,600 21,000 13,800 24,900

3.875-8 12,800 23,200 15,200 27,500

4.000-8 14,100 25,500 16,700 30,300

The information in this table is based on API-6As recommended torques for a given bolt size. The information is

presented for the convenience of the user and is based on assumptions of certain coefficients of friction (cf). The

coefficients of friction are based on approximations of the friction between the studs and nuts, as well as the nuts and

flange face. A coefficient friction of 0.13 assumes the threads and nut bearing surfaces are bare metal and are well

lubricated with thread compound. A coefficient of friction of 0.07 assumes the thread and nuts are coated with a

fluoropolymer material.

It is essential that threads and nut faces are well lubricated with an appropriate lubricant prior to assembly. Accept-

able lubricants include thread compounds that meet API RP 5A3/ISO 13678. (Ref. Cameron PN: 2737980-02 for 1 Lb

can).

Studs and nuts coated with a fluorapolymer material in accordance with a Cameron procedure do not require lubrica-

tion. However, a light coat of API RP 5A3/ISO 13678 thread compound is recommended as aid to assembly.

SD-045055-06 Rev 02

NOTICE

Page 18

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

Recommended Makeup Torque Nm

Per API 6A: preload = .50Sy

Bolt Size

Nom OD - TPI

B7M, L7M (80 ksi Sy) B7, L7, 660 (105 ksi)

cf=0.07 cf=0.13 cf=0.07 cf=0.13

.500-13 36 61 48 80

.625-11 70 118 92 155

.750-10 122 206 160 270

.875-9 193 328 253 429

1.000-8 288 488 376 639

1.125-8 413 706 540 925

1.250-8 569 981 745 1290

1.375-8 761 1320 996 1730

1.500-8 991 1730 1300 2270

1.625-8 1260 2210 1660 2910

1.750-8 1580 2780 2080 3650

1.875-8 1950 3440 2560 4500

2.000-8 2370 4190 3100 5500

2.250-8 3380 6000 4440 7880

2.500-8 4640 8290 6100 10,900

2.625-8 5380 9620 6390 11,500

2.750-8 6190 11,100 7350 13,200

3.000-8 8050 14,400 9560 17,200

3.250-8 10,200 18,400 12,200 21,900

3.500-8 12,800 23,000 15,200 27,400

3.750-8 15,700 28,400 18,700 33,800

3.875-8 17,400 31,400 20,600 37,300

4.000-8 19,100 34,600 22,700 41,000

The information in this table is based on API-6As recommended torques for a given bolt size. The information is

presented for the convenience of the user and is based on assumptions of certain coefficients of friction (cf). The

coefficients of friction are based on approximations of the friction between the studs and nuts, as well as the nuts and

flange face. A coefficient friction of 0.13 assumes the threads and nut bearing surfaces are bare metal and are well

lubricated with thread compound. A coefficient of friction of 0.07 assumes the thread and nuts are coated with a

fluoropolymer material.

It is essential that threads and nut faces are well lubricated with an appropriate lubricant prior to assembly. Accept-

able lubricants include thread compounds that meet API RP 5A3/ISO 13678. (Ref. Cameron PN: 2737980-02 for 1 Lb

can).

Studs and nuts coated with a fluorapolymer material in accordance with a Cameron procedure do not require lubrica-

tion. However, a light coat of API RP 5A3/ISO 13678 thread compound is recommended as aid to assembly.

SD-045055-06 Rev 02

NOTICE

Page 19

TC-010091-02

Model FL and FLS Bi-Directional Gate Valve

Prepared for Actuator

Normally Closed/Threaded Connection

7.0 ORDERING REPLACEMENT PARTS

The only information needed for ordering replacement parts for a Cameron gate valve is the

original valve assembly part number and the description of the part. The valve assembly part

number is stamped on the valve body nameplate. It is recommended that a description of

the valve assembly (size, pressure, trim) is included as a check on the assembly number, but

this is not necessary if the assembly number is clearly readable.

It is not recommended to order replacement parts by using the part number off the old

part or by referring to a file copy of the valve assembly bill of material. If an engineering

change has been implemented to the valve assembly to replace one component part num-

ber with another, the only way to ensure getting the updated component is to reference

the valve assembly number and to reference the part by description (gate, seat, stem, etc.)

Part descriptions are shown in the Parts List section of the manual. Cameron personnel can

then check the latest revision of the assembly bill-of-material to obtain the appropriate and

current replacement part number.

Contact your Cameron representative for replacement part inquiries.

Вам также может понравиться

- Cortec Choke CatalogДокумент8 страницCortec Choke Catalogamjath584100% (1)

- API Flange Slide RuleДокумент3 страницыAPI Flange Slide Rulehai minhОценок пока нет

- Valves HCR CameronДокумент5 страницValves HCR CameronmanuelperdomotОценок пока нет

- Model FC PDFДокумент22 страницыModel FC PDFAbde Esselam100% (1)

- SPM Hammer Union ChartДокумент6 страницSPM Hammer Union ChartmattfridgeОценок пока нет

- 2P36784, Plug ValveДокумент34 страницы2P36784, Plug ValveEdwin HernandezОценок пока нет

- Valvula Chek Cameron PDFДокумент4 страницыValvula Chek Cameron PDFelisanaОценок пока нет

- Check Valve MS PDFДокумент4 страницыCheck Valve MS PDFazeazeazeОценок пока нет

- Cameron MBO Multi-Bowl Wellhead SystemДокумент6 страницCameron MBO Multi-Bowl Wellhead SystemiswantmachooОценок пока нет

- Cameron ChokeДокумент20 страницCameron ChokeMichael Haise0% (1)

- Operacion y Manual de HCR 5000 Psi (Actuador Hidraulico)Документ22 страницыOperacion y Manual de HCR 5000 Psi (Actuador Hidraulico)Juan Miguel Robledo100% (2)

- Anson Gate Valves, Manifolds, and TreesДокумент9 страницAnson Gate Valves, Manifolds, and TreesBala KrishnanОценок пока нет

- FMC Flowline Products and Services 002Документ74 страницыFMC Flowline Products and Services 002Agustin ParadisoОценок пока нет

- COS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronДокумент5 страницCOS Gate Valve API 6A - FLS S Gate Valve - Brochure - CameronYudaОценок пока нет

- Gate Valve CameronДокумент13 страницGate Valve CameronJohn Jairo Simanca100% (1)

- REPEDE Cataloque (Wellhead)Документ80 страницREPEDE Cataloque (Wellhead)didikhartadi50% (2)

- Swivel Joints, Interchangeable FMC and SPMДокумент3 страницыSwivel Joints, Interchangeable FMC and SPMAlice MiОценок пока нет

- Westrom Cameron PartsДокумент22 страницыWestrom Cameron PartsEd CalheОценок пока нет

- Installation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Документ8 страницInstallation & Routine Maintenance Manual: FOR Type: 3" Mud Gate Valve (Model I)Sergio Fabian VasicekОценок пока нет

- Wellhead Brochure - DP PDFДокумент12 страницWellhead Brochure - DP PDFmaso0140100% (1)

- FMC Flowline Product CatalogДокумент80 страницFMC Flowline Product CatalogRodrigo França100% (2)

- Cameron Diverter OverviewДокумент8 страницCameron Diverter OverviewSener GocogluОценок пока нет

- Maintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesДокумент32 страницыMaintenance and Operation Manual: Ultra Flow Type 'E-Fc' Gate ValvesNeilton Junior100% (2)

- User Manual of S-Type Ram BOPДокумент26 страницUser Manual of S-Type Ram BOPhebert perez100% (1)

- WPCE Wellhead Adapter FlangeДокумент1 страницаWPCE Wellhead Adapter Flangeashad100% (3)

- API 6a Flanges CatalogueДокумент37 страницAPI 6a Flanges CatalogueSend MailОценок пока нет

- Best Swivel Joints CatalogДокумент8 страницBest Swivel Joints CatalogWalter PierОценок пока нет

- 5c928989ac4f9 TSICanadaManualS PDFДокумент144 страницы5c928989ac4f9 TSICanadaManualS PDFAnggi SujiwoОценок пока нет

- Axon-Type50u Ram BopДокумент4 страницыAxon-Type50u Ram BopMohie Khosravani0% (1)

- Stripper TOT 2.50 10M DS34 TechMan1146Документ13 страницStripper TOT 2.50 10M DS34 TechMan1146Diego OspinaОценок пока нет

- Bop TestДокумент1 страницаBop TestAbdul Hameed OmarОценок пока нет

- Side Pocket Mandrel CatalogДокумент32 страницыSide Pocket Mandrel CatalogMehdi NorouziОценок пока нет

- Choke ParveenДокумент3 страницыChoke ParveenYM Edwin Gil BeltranОценок пока нет

- Shaffer ShpericalДокумент11 страницShaffer Shpericaljeinerdt100% (1)

- Gate Valves Wellhead API 6AДокумент20 страницGate Valves Wellhead API 6ARicardo Paz Soldan100% (1)

- Nexus 4in 10k 2-Door WBA Stripper Manual - REV 13Документ26 страницNexus 4in 10k 2-Door WBA Stripper Manual - REV 13Pastor Velasquez100% (1)

- 120 Ton Power Swivels PISДокумент17 страниц120 Ton Power Swivels PISgheorgheОценок пока нет

- GE HY Kellyguard FS 080709-2Документ2 страницыGE HY Kellyguard FS 080709-2caballero_tigreОценок пока нет

- SC-90 Conventional Surface Wellhead System PDFДокумент12 страницSC-90 Conventional Surface Wellhead System PDFErcan YilmazОценок пока нет

- RP Insp Rep 01Документ8 страницRP Insp Rep 01advantage025Оценок пока нет

- M60eh44 Man 001Документ40 страницM60eh44 Man 001Riski KurniawanОценок пока нет

- Pressure Control EquipmentДокумент62 страницыPressure Control EquipmentCARLOSELSOARESОценок пока нет

- Catalog 2Документ44 страницыCatalog 2Enrique HortaОценок пока нет

- Heshka Oil Catalog 2019Документ16 страницHeshka Oil Catalog 2019Michael PerschkeОценок пока нет

- API Slide Rule (Flange & Hub)Документ3 страницыAPI Slide Rule (Flange & Hub)didikhartadiОценок пока нет

- Rotary Cutters PDFДокумент3 страницыRotary Cutters PDFAlleyson AkinОценок пока нет

- Wellhead and Valves DataДокумент14 страницWellhead and Valves Datajairaso2950Оценок пока нет

- Snubbing PDFДокумент134 страницыSnubbing PDFNavin SinghОценок пока нет

- Ingram Cactus - Exact 15 Universal Slim-Hole Wellhead SystemДокумент5 страницIngram Cactus - Exact 15 Universal Slim-Hole Wellhead SystemYougchu LuanОценок пока нет

- WellheadДокумент2 страницыWellheadRicardo Paz SoldanОценок пока нет

- DL Annular Blowout Preventer 21-1/4" 3000 Psi WPДокумент27 страницDL Annular Blowout Preventer 21-1/4" 3000 Psi WPJeneesh Shanmughan100% (1)

- Subsurface Flow Control Systems 8-1Документ68 страницSubsurface Flow Control Systems 8-1gonzalito777Оценок пока нет

- Anson E Typs Gate Valve With Fail Safe Closed ActuatorДокумент12 страницAnson E Typs Gate Valve With Fail Safe Closed ActuatorWeniton Oliveira0% (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОт EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryОценок пока нет

- Operational and Maintenance Manual PDFДокумент19 страницOperational and Maintenance Manual PDFYuda100% (1)

- TC148-1 Manual GV Repair ManualДокумент24 страницыTC148-1 Manual GV Repair ManualFam Escalante OnofreОценок пока нет

- Tc148-2 Manual GV O&mДокумент20 страницTc148-2 Manual GV O&mFam Escalante OnofreОценок пока нет

- Man Valve OM FLS-TC148-2 O&M Rev08 Dec 2009Документ20 страницMan Valve OM FLS-TC148-2 O&M Rev08 Dec 2009Adrian Cantaragiu100% (3)

- BP - Deep Water Horizon - Gulf Mexico - Oil-Cause-0507101Документ1 страницаBP - Deep Water Horizon - Gulf Mexico - Oil-Cause-0507101Nano VillanuevaОценок пока нет

- P9 Guidelines For The Flushing of Hydraulic Systems I2Документ18 страницP9 Guidelines For The Flushing of Hydraulic Systems I2Nano VillanuevaОценок пока нет

- PZ Service ManualДокумент40 страницPZ Service Manualjulioramca100% (5)

- Ir 2100Документ148 страницIr 2100Nano VillanuevaОценок пока нет

- D811000252 Man 001Документ557 страницD811000252 Man 001Nano VillanuevaОценок пока нет

- SM00053 DДокумент347 страницSM00053 DNano Villanueva100% (1)

- SM 00292Документ28 страницSM 00292Nano VillanuevaОценок пока нет

- New Deepwater RegsДокумент44 страницыNew Deepwater RegsNano VillanuevaОценок пока нет

- Parenting Styles and Social Interaction of Senior Secondary School Students in Imo State, NigeriaДокумент10 страницParenting Styles and Social Interaction of Senior Secondary School Students in Imo State, NigeriaInternational Educational Applied Scientific Research Journal (IEASRJ)Оценок пока нет

- Single Conductor 15KV, Shielded, MV-105Документ2 страницыSingle Conductor 15KV, Shielded, MV-105henry hernandezОценок пока нет

- Dingenen 2017Документ14 страницDingenen 2017pedro.coleffОценок пока нет

- AlaTOP Allergy Screen OUS - IMMULITE 2000 Systems - Rev 21 DXDCM 09017fe98067cfcb-1645658153157Документ28 страницAlaTOP Allergy Screen OUS - IMMULITE 2000 Systems - Rev 21 DXDCM 09017fe98067cfcb-1645658153157Pierre LavoisierОценок пока нет

- Pay Slip SampleДокумент3 страницыPay Slip SampleJoseph ClaveriaОценок пока нет

- Fitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsДокумент24 страницыFitting in and Fighting Back: Stigma Management Strategies Among Homeless KidsIrisha AnandОценок пока нет

- Static Fluid: It Is Mass Per Unit Volume at Certain TemperatureДокумент11 страницStatic Fluid: It Is Mass Per Unit Volume at Certain TemperatureMohamed El-GoharyОценок пока нет

- How To Self-Decontaminate After A Radiation Emergency - CDCДокумент2 страницыHow To Self-Decontaminate After A Radiation Emergency - CDCZankanotachiОценок пока нет

- Blotter EntryДокумент2 страницыBlotter EntryCharline Khie Silvestra PortemCamposanoОценок пока нет

- Midas Tutorial Fea 7Документ3 страницыMidas Tutorial Fea 7sasiОценок пока нет

- Yuasa NPL Range: VRLA BatteriesДокумент2 страницыYuasa NPL Range: VRLA BatteriesVuro BegaОценок пока нет

- Vocabulary June v22Документ2 страницыVocabulary June v22Wiston TonwisОценок пока нет

- Supplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11Документ81 страницаSupplementary Spec To API Specification 17D Subsea Wellhead and Tree Equipment With Justifications S 561Jv2022 11maximusala83Оценок пока нет

- Connection Manual: BNP-B2203D (ENG)Документ122 страницыConnection Manual: BNP-B2203D (ENG)Allison CarvalhoОценок пока нет

- Vertical Mills V2 0Документ56 страницVertical Mills V2 0recai100% (1)

- Fulltext PDFДокумент55 страницFulltext PDFManikandan VpОценок пока нет

- Ashin Tejaniya: Questions & Answers WithДокумент241 страницаAshin Tejaniya: Questions & Answers WithharioОценок пока нет

- PASSMEDICINE MCQs-PHARMACOLOGYДокумент107 страницPASSMEDICINE MCQs-PHARMACOLOGYMohammad Saleh100% (1)

- Comparative Study of DEA and MDEAДокумент4 страницыComparative Study of DEA and MDEAsaleh4060Оценок пока нет

- Punjab National BankДокумент4 страницыPunjab National BankShubham RajОценок пока нет

- Megapower: Electrosurgical GeneratorДокумент45 страницMegapower: Electrosurgical GeneratorAnibal Alfaro VillatoroОценок пока нет

- Sebuguero V NLRC Case Digest PDFДокумент2 страницыSebuguero V NLRC Case Digest PDFYodh Jamin Ong0% (1)

- Child Abuse Lesson PlanДокумент7 страницChild Abuse Lesson PlanIrvie manalacОценок пока нет

- CPHQ Text BookДокумент20 страницCPHQ Text BookCphq Cphq Ali100% (2)

- Exam G-9 CookeryДокумент5 страницExam G-9 Cookeryaileenarcabal01Оценок пока нет

- MAUS Catalogue PDFДокумент10 страницMAUS Catalogue PDFCarolina Garcés MoralesОценок пока нет

- Big BazaarДокумент6 страницBig BazaaraniketsangodcarОценок пока нет

- Mental Health Activity ProposalДокумент2 страницыMental Health Activity ProposalJustin Tagumasi Agustin100% (1)

- Equipment Available From SJ Turbine Inc.: LM Package Parts LM Package Parts High VoltageДокумент59 страницEquipment Available From SJ Turbine Inc.: LM Package Parts LM Package Parts High VoltageAnibal QuezadaОценок пока нет

- 2nd Comprehensive ExamДокумент15 страниц2nd Comprehensive ExamLoala SMDОценок пока нет