Академический Документы

Профессиональный Документы

Культура Документы

Cs-P06-Ca & Pa

Загружено:

Idrus IsmailИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cs-P06-Ca & Pa

Загружено:

Idrus IsmailАвторское право:

Доступные форматы

CSL TECHNOLOGIES (M) SDN BHD

LRC TECH (M) SDN BHD

CORRECTIVE & PREVENTIVE ACTIONS

PROCEDURE

Ref. No.

Revision No.

Effective Date

Page

CS-P06

00

01/11/2010

1 of 3

REVISION HISTORY

Rev

No.

00

Effective Date

01/11/2010

Affected

Page

All

Change Descriptions

Reviewed

By

Approved

By

New Issue

Document Distribution Acknowledgement:

Dept. /

Position

Business

Development

Director

Admin

Sales &

Marketing

Design

Production

R&D

Acknowledge

ment

Date

Note: The details and the reason of change are documented in the Revision History state above and file at DCC.

This procedure is a controlled document and authorized for use. When printed from this share drive, this

document is uncontrolled. Before using a printed copy of this document, ensure that it is the same as the latest

version on share drive.

CSL TECHNOLOGIES (M) SDN BHD

LRC TECH (M) SDN BHD

CORRECTIVE & PREVENTIVE ACTIONS

PROCEDURE

1.0

Ref. No.

Revision No.

Effective Date

Page

CS-P06

00

01/11/2010

2 of 3

PURPOSE

The purpose of this procedure is to define a system to ensure that:

(i)

Root cause of non-conformity is promptly analyzed and effective Corrective Action is

taken to prevent its recurrence.

(ii)

Root cause of potential non-conformity is promptly analyzed and effective

Preventive Action is taken to prevent its occurrence and also for continual

improvement activities.

2.0

SCOPE

This procedure applies to internal audit, customers complaint (related to product / service

quality management system), and any activities that could identify existing or potential NC.

3.0

DEFINITION

MR = Management Representative

NC = Non-Conformity

CA = Corrective Action: Actions taken to prevent recurrence of existing NC

PA = Preventive Action: Actions taken to prevent occurrence of potential NC

CAR = Corrective Action Request

PAR = Preventive Action Request

THIS IS AN UNCONTROLLED COPY OF A CONTROLLED DOCUMENT PRINTED

CSL TECHNOLOGIES (M) SDN BHD

LRC TECH (M) SDN BHD

CORRECTIVE & PREVENTIVE ACTIONS

PROCEDURE

4.0

Ref. No.

Revision No.

Effective Date

Page

CS-P06

00

01/11/2010

3 of 3

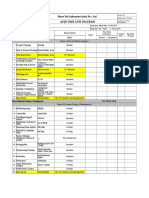

PROCEDURE DETAILS

Process Flow

Description

CAR / PAR issued for

Identified NC / Potential NC

Investigation

Determine Action

Plan

Verification

Solved /

Improvement?

YES

Keep Records

NO

Documents /

Ref.

Personnel

- NC or Potential NC as identified

in Internal Audit or Customers

Complaint, or any other activities.

- Potential NC could be identified

through analysis of factual data,

trend or process monitoring.

- NCR (CS-F11)

- MR

- Any other

personnel that

bring identified

NC

- MR assign appropriate personnel

to investigate for the root cause of

NC or Potential NC by:

Interviewing relevant personnel

Assess relevant records

Review the cause(s)

Other cause analysis tools

- NCR (CS-F11)

- MR &

appropriate

personnel

- Based on result, personnel incharge shall evaluate the need for

CA / PA / both, and propose

appropriate action plan to address

the NC or potential NC.

- MR shall review & approve, as

well as assign proper personnel

and time frame for implementing

the plan.

- NCR (CS-F11)

- Appointed

Personnel

- After the stated time frame, the

CAR / PAR shall be returned for

verification by Director / MR.

- Effective CA / PA will be

approved by Director / MR for

closing the CAR / PAR.

- Otherwise, action plan may be

extended or investigation will be reconducted & a new CAR / PAR will

be issued.

- Verified NCR

- Director / MR

- Closed CAR / PAR should be

kept, which will be presented &

discussed in Management Review

for Continual Improvement

Program.

- Closed NCR

to be filed

- Refer to

Management

Review

- MR

THIS IS AN UNCONTROLLED COPY OF A CONTROLLED DOCUMENT PRINTED

- MR

Вам также может понравиться

- Organizational Structures Compendium - MelcrumДокумент15 страницOrganizational Structures Compendium - MelcrumDiogo Pimenta BarreirosОценок пока нет

- CS-P03-HR Recruitment TrainingДокумент5 страницCS-P03-HR Recruitment TrainingIdrus IsmailОценок пока нет

- CS P11 PurchasingДокумент4 страницыCS P11 PurchasingIdrus IsmailОценок пока нет

- CS P09 Project ManagementДокумент4 страницыCS P09 Project ManagementIdrus IsmailОценок пока нет

- CS-P14-Control of NC Product (KIV)Документ4 страницыCS-P14-Control of NC Product (KIV)Idrus IsmailОценок пока нет

- Safety: A) Machine Safety SystemДокумент5 страницSafety: A) Machine Safety SystemSagar DaundОценок пока нет

- Estimating Process Section 11: Quality Assurance ManualДокумент4 страницыEstimating Process Section 11: Quality Assurance ManualNgonidzashe ZvarevasheОценок пока нет

- Process Flow ChartДокумент2 страницыProcess Flow ChartBASAVA ENGINEERINGОценок пока нет

- CSL P5-007229 AuditReportДокумент5 страницCSL P5-007229 AuditReportIdrus IsmailОценок пока нет

- QM 01 ANNEX II Key Busines ProcessДокумент4 страницыQM 01 ANNEX II Key Busines ProcessVinod SaleОценок пока нет

- SQMP ManualДокумент81 страницаSQMP ManualAnkita DwivediОценок пока нет

- RP SP F 01 System Review MeetingДокумент3 страницыRP SP F 01 System Review MeetingAnonymous SAWWr9Y3lyОценок пока нет

- QSPIFCДокумент3 страницыQSPIFCsathyabalaraman100% (1)

- Procedure For Material Requirement Planning & PurchasingДокумент1 страницаProcedure For Material Requirement Planning & PurchasingHarkesh KumarОценок пока нет

- QUAMA000Документ41 страницаQUAMA000Abd ZouhierОценок пока нет

- Training Plan For Year 2010: CSL Technologies (M) SDN BHD LRC Tech (M) SDN BHDДокумент1 страницаTraining Plan For Year 2010: CSL Technologies (M) SDN BHD LRC Tech (M) SDN BHDIdrus IsmailОценок пока нет

- JAI Revision Record Sheet: TitleДокумент2 страницыJAI Revision Record Sheet: TitleSanjay MalhotraОценок пока нет

- MSP ProceduresДокумент18 страницMSP ProcedurestarunОценок пока нет

- 0701 Sales Management & Contract ReviewДокумент4 страницы0701 Sales Management & Contract ReviewSundara Rajan RamakrishnanОценок пока нет

- DCC F04 NCRДокумент2 страницыDCC F04 NCRSyahir AhmadОценок пока нет

- Internal Audit Checklist - Plant ServicesДокумент4 страницыInternal Audit Checklist - Plant ServiceskumarОценок пока нет

- QAD Procedure - Corrective Action P2Документ1 страницаQAD Procedure - Corrective Action P2sumanОценок пока нет

- PUR-PM-06 Initial Flow Control For PCS SupplierДокумент4 страницыPUR-PM-06 Initial Flow Control For PCS SupplierIsmail BiradarОценок пока нет

- HRD Procedure - Employee Motivation & Empowerment P2Документ1 страницаHRD Procedure - Employee Motivation & Empowerment P2sumanОценок пока нет

- QAD Procedure - Lab Management P2Документ1 страницаQAD Procedure - Lab Management P2sumanОценок пока нет

- ASP-NPD-04 (Process of Product Safety)Документ5 страницASP-NPD-04 (Process of Product Safety)akash.vd.1603Оценок пока нет

- ISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical SpecificationДокумент52 страницыISO 9001:2008 ISO/TS 16949:2009 Added Requirement: 0.5 Goal of This Technical Specificationsupady5751Оценок пока нет

- HR-2-001, Issue 01, Procedure For Training & DevelopmentДокумент2 страницыHR-2-001, Issue 01, Procedure For Training & Developmentsajid waqasОценок пока нет

- Form - Scar LogДокумент18 страницForm - Scar LogHarie BongkyОценок пока нет

- Stanzen Links: Procedure For Control of DocumentsДокумент5 страницStanzen Links: Procedure For Control of DocumentsasderbvaОценок пока нет

- Software Development and Delivery Process (SDDP)Документ4 страницыSoftware Development and Delivery Process (SDDP)api-138317568Оценок пока нет

- Quality ControlДокумент51 страницаQuality ControlOprisor CostinОценок пока нет

- 1 Internal & Product AuditДокумент3 страницы1 Internal & Product AuditPrafull BhamareОценок пока нет

- (QSP-MR-02) Control RecordsДокумент2 страницы(QSP-MR-02) Control RecordsBASAVA ENGINEERING100% (1)

- Management Review Agenda and Minutes: M: Name Title Here Name Title HereДокумент5 страницManagement Review Agenda and Minutes: M: Name Title Here Name Title HereTrivesh SharmaОценок пока нет

- Personal Annual Plan For The Year: 2019: BAM International BV Projects Ade Tedi Subcon ManagerДокумент3 страницыPersonal Annual Plan For The Year: 2019: BAM International BV Projects Ade Tedi Subcon ManagerMark RamirezОценок пока нет

- QS-2-010, Issue 01, Procedure For Control & Handling of Non Confirming Products, Corrections, Corrective & Preventive ActionsДокумент2 страницыQS-2-010, Issue 01, Procedure For Control & Handling of Non Confirming Products, Corrections, Corrective & Preventive Actionssajid waqasОценок пока нет

- 08.03.04-Quality Assurance of Materials - Approval of Source-R2Документ4 страницы08.03.04-Quality Assurance of Materials - Approval of Source-R2tanmayascribdОценок пока нет

- Shree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramДокумент2 страницыShree Ved Industries India Pvt. Ltd. Apqp Time Line DiagramS. R. OvhalОценок пока нет

- Product Development ProcedureДокумент2 страницыProduct Development ProcedureLuke BilisОценок пока нет

- 4-04-1 Contract ReviewДокумент4 страницы4-04-1 Contract Reviewjeric bañaderaОценок пока нет

- SYS Procedure - Internal Quality Audit P1Документ1 страницаSYS Procedure - Internal Quality Audit P1sumanОценок пока нет

- Minutes of Management Review MeetingДокумент5 страницMinutes of Management Review Meetingwinston11Оценок пока нет

- 2016 Functional ObjectivesДокумент8 страниц2016 Functional ObjectivesHILLARY YOLANDAОценок пока нет

- RC 2022 Summary CAFDДокумент4 страницыRC 2022 Summary CAFDEjazОценок пока нет

- D Control of Records Section 4Документ3 страницыD Control of Records Section 4Ngonidzashe ZvarevasheОценок пока нет

- Check List - Product Realisation ProcessДокумент4 страницыCheck List - Product Realisation ProcessDisha ShahОценок пока нет

- MRM PlanДокумент2 страницыMRM Plang.kannan100% (1)

- SOP - CTR - 01 Contract ReviewДокумент3 страницыSOP - CTR - 01 Contract ReviewShahfri ShafОценок пока нет

- (QSP-HR-01) Education & Training Procedure NewДокумент7 страниц(QSP-HR-01) Education & Training Procedure NewGourav SainiОценок пока нет

- Draft Document Control ProcedureДокумент3 страницыDraft Document Control ProcedureThee BouyyОценок пока нет

- DWM FormatДокумент4 страницыDWM Formatdharmendra ChaurasiaОценок пока нет

- Standard Operating Process Company Logo: Approved by Verified by Prepared byДокумент2 страницыStandard Operating Process Company Logo: Approved by Verified by Prepared byMau TauОценок пока нет

- Self Evaluation Form - FY19 - FinalДокумент3 страницыSelf Evaluation Form - FY19 - FinalVijay TamboliОценок пока нет

- Audit Check List WP 16 WI 01Документ11 страницAudit Check List WP 16 WI 01milind bedarkarОценок пока нет

- RMR-HSMS-P-014 OHS Management System Internal AuditДокумент5 страницRMR-HSMS-P-014 OHS Management System Internal AuditkamranОценок пока нет

- List of Records - Formats & RegistersДокумент1 страницаList of Records - Formats & RegistersSuraj KadamОценок пока нет

- Sr. No. Metric Goal Data Source Base Line: TallbrosДокумент3 страницыSr. No. Metric Goal Data Source Base Line: TallbrosVikas KashyapОценок пока нет

- Centurion Power Cables (P) LTD.: Control of DocumentДокумент4 страницыCenturion Power Cables (P) LTD.: Control of DocumenttriveshОценок пока нет

- CS P12 Drawing Control ProcedureДокумент4 страницыCS P12 Drawing Control Procedurerichard nagilusОценок пока нет

- CS-P07 - Sales & Marketing Proceduce BackupДокумент6 страницCS-P07 - Sales & Marketing Proceduce BackupIdrus Ismail100% (1)

- Words by Qaisara Binti IdrusДокумент3 страницыWords by Qaisara Binti IdrusIdrus IsmailОценок пока нет

- Start: Check Items in DO Against POДокумент8 страницStart: Check Items in DO Against POIdrus IsmailОценок пока нет

- CS F24 Purchase OrderДокумент1 страницаCS F24 Purchase OrderIdrus IsmailОценок пока нет

- Cityscape MotherboardДокумент1 страницаCityscape MotherboardIdrus IsmailОценок пока нет

- Variable Speed DriveДокумент12 страницVariable Speed DriveIdrus IsmailОценок пока нет

- CS-F21-Daily Site Inspection ReportДокумент1 страницаCS-F21-Daily Site Inspection ReportIdrus IsmailОценок пока нет

- CS F18 Production Advise (CSL)Документ1 страницаCS F18 Production Advise (CSL)Idrus IsmailОценок пока нет

- Cs f11 Non Conformity ReportДокумент1 страницаCs f11 Non Conformity ReportIdrus IsmailОценок пока нет

- CS F15 Project Payment CertДокумент1 страницаCS F15 Project Payment CertIdrus IsmailОценок пока нет

- CS-F17 Drawing JobsheetДокумент1 страницаCS-F17 Drawing JobsheetIdrus IsmailОценок пока нет

- CS-P12 - Drawing Control ProcedureДокумент4 страницыCS-P12 - Drawing Control ProcedureIdrus IsmailОценок пока нет

- CS F19 Comfirmation Order FormДокумент3 страницыCS F19 Comfirmation Order FormIdrus IsmailОценок пока нет

- Cs f10 NCR Status LogДокумент1 страницаCs f10 NCR Status LogIdrus IsmailОценок пока нет

- Cs-f02 - Training Attendance RecordДокумент1 страницаCs-f02 - Training Attendance RecordIdrus IsmailОценок пока нет

- CSL Technologies (M) SDN BHD LRC Tech (M) SDN BHD Audit ChecklistДокумент1 страницаCSL Technologies (M) SDN BHD LRC Tech (M) SDN BHD Audit ChecklistIdrus IsmailОценок пока нет

- Training Plan For Year 2010: CSL Technologies (M) SDN BHD LRC Tech (M) SDN BHDДокумент1 страницаTraining Plan For Year 2010: CSL Technologies (M) SDN BHD LRC Tech (M) SDN BHDIdrus IsmailОценок пока нет

- CS-F03 - Employment Application FormДокумент6 страницCS-F03 - Employment Application FormIdrus IsmailОценок пока нет

- CS-F01-Quality Record Disposal LogДокумент1 страницаCS-F01-Quality Record Disposal LogIdrus IsmailОценок пока нет

- CS-P10 - Research Development ProcedureДокумент4 страницыCS-P10 - Research Development ProcedureIdrus IsmailОценок пока нет

- CS-P07 - Sales & Marketing Proceduce BackupДокумент6 страницCS-P07 - Sales & Marketing Proceduce BackupIdrus Ismail100% (1)

- Introduction To Strategic Supply Chain ManagementДокумент31 страницаIntroduction To Strategic Supply Chain Managementshamimahmed313100% (3)

- Hoshin Planning Process: Workshop Month XX, 20xxДокумент45 страницHoshin Planning Process: Workshop Month XX, 20xxAngarEnkhzaya100% (1)

- Certified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsДокумент2 страницыCertified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsSunStar Philippine NewsОценок пока нет

- Information BulletinДокумент63 страницыInformation BulletinPrincess ContemplacionОценок пока нет

- Business ResponsibilityДокумент12 страницBusiness ResponsibilityJayaram ParlikadОценок пока нет

- Certified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsДокумент2 страницыCertified List of Candidates For Congressional and Local Positions For The May 13, 2013 2013 National, Local and Armm ElectionsSunStar Philippine NewsОценок пока нет

- Mckinsey 7S Model: A Strategic Assessment and Alignment ModelДокумент4 страницыMckinsey 7S Model: A Strategic Assessment and Alignment ModelVishu SinhaОценок пока нет

- Human Resource PlanningДокумент4 страницыHuman Resource PlanningPeterGomesОценок пока нет

- Glossary of Terms Macedonain - EnglishДокумент10 страницGlossary of Terms Macedonain - EnglishМарија РашковскаОценок пока нет

- Supreme Student Government ElectionДокумент2 страницыSupreme Student Government ElectionjasminevanessacОценок пока нет

- Salary Structure of Indian IT CompaniesДокумент12 страницSalary Structure of Indian IT CompaniesSankar OracleappsОценок пока нет

- Democratic InterventionsДокумент80 страницDemocratic InterventionsRichmond Jake Almazan100% (1)

- 5s in IciciДокумент12 страниц5s in IciciKabin Bora50% (2)

- Global RPO DirectoryДокумент70 страницGlobal RPO DirectoryajlpodeОценок пока нет

- Budget AccountabilityДокумент2 страницыBudget AccountabilityAi Ai Serna LawangonОценок пока нет

- Chap 011Документ24 страницыChap 011Muhammad Ikhlaq Ahmed KalrooОценок пока нет

- Atkinson CH 1 LectureДокумент42 страницыAtkinson CH 1 LectureAsad Zaman0% (1)

- Red State StrategiesДокумент2 страницыRed State StrategieslakecountyohОценок пока нет

- Accounting For Ourselves - Print PDFДокумент26 страницAccounting For Ourselves - Print PDFDafni KatsaraОценок пока нет

- Doctrine of Role of Public Accountbillity in Governance in IndiaДокумент6 страницDoctrine of Role of Public Accountbillity in Governance in IndiaPintu Kumar King PatelОценок пока нет

- IEBC Gazettes Names of Returning Officers Ahead of August ElectionsДокумент9 страницIEBC Gazettes Names of Returning Officers Ahead of August ElectionsThe Star Kenya50% (2)

- Room&Board AДокумент10 страницRoom&Board AClyde TorresОценок пока нет

- Strategic Planning ProcessДокумент4 страницыStrategic Planning ProcessRobbi WanОценок пока нет

- Chap 02 - Company and Marketing Strategy - Partnering To Build Customer RelationshipsДокумент32 страницыChap 02 - Company and Marketing Strategy - Partnering To Build Customer RelationshipsRoma VadolaОценок пока нет

- Angat, Bulacan 1Документ9 страницAngat, Bulacan 1BL ARОценок пока нет

- Birch - 2007 - Electoral Systems and Electoral MisconductДокумент25 страницBirch - 2007 - Electoral Systems and Electoral MisconductBayu Airlangga100% (1)

- 4PLДокумент4 страницы4PLswapnil08100% (1)

- Jitli:) Bepartmmt of EbucationДокумент2 страницыJitli:) Bepartmmt of EbucationTanglaw Laya May PagasaОценок пока нет

- Production Planning and ControlДокумент80 страницProduction Planning and ControlRazi Haziq100% (1)