Академический Документы

Профессиональный Документы

Культура Документы

Rotary Valve Fast Cycle Pressure Swing Adsorption Paper

Загружено:

abhi_mohit2005Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Rotary Valve Fast Cycle Pressure Swing Adsorption Paper

Загружено:

abhi_mohit2005Авторское право:

Доступные форматы

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

ROTARY-VALVE, FAST-CYCLE PRESSURE-SWING ADSORPTION

TECHNOLOGY ALLOWS WEST COAST PLATFORM TO MEET TIGHT

CALIFORNIA SPECIFICATIONS AND RECOVER STRANDED GAS

Joel Toreja

Venoco, Inc.

6267 Carpinteria Ave., Suite 200

Carpinteria, CA 93013

jtoreja@venocoinc.com

(805) 745-2100

Bob VanNostrand

Venoco, Inc.

7979 Hollister Avenue

Goleta, CA 93117

bvannostrand@venocoinc.com

(805) 961-2309

Nelson Chan

Xebec, Inc.

6961 Russell Ave., Burnaby

British Columbia, Canada

V5J 4R8

nchan@xebecinc.com

(604) 454-1134

John Perry Dickinson

Processes Unlimited International, Inc.

5500 Ming Avenue - Suite 400

Bakersfield, CA 93309

jpdickinson@prou.com

(805) 722-2953

ABSTRACT

Off-shore production/processing platforms often strand valuable associated and/or natural

gas reserves due to severe space and weight/or limitations on the platform prohibiting the

installation of gas processing and/or treatment facilities.

This paper will describe how one such oil producer, located in the Santa Barbara Channel,

met the aforementioned challenges by first demonstrating the effectiveness of Fast-Cycle

Pressure-Swing Adsorption through on-board, pilot plant studies, then in a full-scale

production unit capable of processing up to 5.0 MMscfd. The Rotary-Valve, Fast-Cycle

PSA, which encompasses a space on the platform no larger than 18 ft(L) X 8 ft(W) X 9 ft(H),

takes the place of three traditional gas processing plants; an amine unit (to remove CO2) a

chiller (to remove C3 + compounds) and a glycol dehydration unit, resulting in a dramatic

reduction in size and weight, thereby saving the platform millions of dollars in capital costs

as well as eliminating any need to structurally change the platform.

In addition, the Rotary-Valve, Fast-Cycle PSA has successfully proven to be able to handle

high levels of ethane, allowing the platform to meet and/or exceed stringent California Air

Resource Board standards; ethane removal has previously been proven very difficult for

other, older technologies, such as refrigeration.

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

ROTARY-VALVE, FAST-CYCLE PRESSURE-SWING ADSORPTION

TECHNOLOGY ALLOWS WEST COAST PLATFORM TO MEET TIGHT

CALIFORNIA SPECIFICATIONS AND RECOVER STRANDED GAS

Joel Toreja, Venoco, Inc., Carpinteria, CA

Bob VanNostrand,, Inc., Carpinteria, CA

Nelson Chan, Xebec, Inc., Burnaby, British Columbia, Canada

John Perry Dickinson, Processes Unlimited International, Inc., Santa Barbara, CA

Introduction

Santa Barbara Channel Oil Production

The Santa Barbara Channel, located off the Central California coast (approximately 100

miles northwest of downtown Los Angeles), has had perhaps one of the longest histories of

mans involvement with petroleum-based products and industries.

Historically, local Indians tribes produced cakes made of asphaltum - or tar from naturallyoccurring oil seeps as torches, and other trade goods. Many itemsincluding bowls,

jewelry, knives, and canoeswere decorated with asphaltum inlaid with chips of abalone

and other shells. Baskets and water bottles were waterproofed inside and out with asphaltum.

Chumash Indians used refined asphaltum to build their plank canoes, a crowning

achievement of Chumash technology.

These natural oil seeps were first recorded by Spanish explorer Juan Rodrguez Cabrillo on

Oct. 16, 1542; and then by English explorer George Vancouver two-and-a-half centuries

later.

Later, immigrants traveling across California in 1849 used oil from these natural seeps to

grease their wagon wheels. By the 1850's and 60's some of the early settlers were mining oil

from natural seeps to crudely refine in order to pave roads, burn in oil lamps, and as a

lubricant for machinery. The oil was mined by digging pits and tunnels at seep sites, and,

eventually, by drilling under natural seeps in search of underground oil reservoirs; most early

discoveries of oil in California were found in this way. In 1896, the channel was home to the

first offshore oil well, located off the cost of Summerland, California.

Platform Gail

Today, the oil from the channel is removed via twenty offshore platforms; one of the largest

of these was constructed by Chevron Corporation in 1987 and is located in 739 feet of water.

Called Platform Gail, the platform is now owned and operated by Venoco, Incorporated, (of

Carpinteria, CA) and has produced over 40 MMbbls since production began in 1988.

Platform Gail is located approximately ten miles off the California coast, is 160 by 250 feet,

and consists of three main decks above the well bay. Generally speaking, the platform

houses between thirty and fifty operating personnel and contains 36 well slots, 26 which are

currently being used, producing 3,500 bpd of 18 API crude oil and approximately 2.0

MMscfd of associated gas from the Sockeye Field.

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

Platform Gail Operations

Original Design Operations

As shown in Figure 1, crude oil and associated gas are produced on the platform via gas lift,

where high-pressure (2,000 psig) associated gas is injected through the well tubing-casing

annulus, thereby aerating the fluid to reduce its density. The oil reservoir formation pressure

is then able to lift the oil column and force the fluid out of the wellbore and up to the

platform. There, a portion of the gas is then separated from the fluid and then re-compressed

through the gas lift compressors, completing the gas lift cycle.

Glycol Unit

Associated Gas

from Oil-Gas

Separators

Gas Sweetening

st

1 Stage

Compression

Vapor Recovery

2nd Stage

Compression

Gas Turbines

3rd Stage

Compression

Gas Lift

Production Wells

Injection Well

Figure 1. Original Platform Gail Gas Block Flow Diagram

The gas produced on Platform Gail is quite sour (containing approximately 4,000 ppm of

H2S), and is therefore sweetened through a liquid iron redox process (SulFerox ) before

being compressed to levels where stress corrosion cracking would be a concern. Following

compression to approximately 4,000 psig, a slip stream of the gas was separated from the gas

lift stream, dehydrated using triethylene glycol, and used as fuel in three 3.1MW (each) Rolls

Royce electrical-generating turbines. Approximately 1 MMcsfd of excess gas is disposed of

through an injection well (as shown in the diagram), due to insufficient on-board processing

equipment and the extreme on-shore permitting difficulties faced in California.

Stranded Gas

The associated gas produced on-board Platform Gail is quite sour, containing approximately

4,000 ppm of H2 S. The gas also contains levels of inert (primarily carbon dioxide) and heavy

light hydrocarbon compounds that are significantly higher than allowed by State of

California.

Specifications for natural gas are proposed in the state by the California Air Resource Board

(CARB) and then established by the California Public Utility Commission; these

specifications are shown in Table 1.

The stranded gas shown in Figure 1 could be sold if it met the tight California specifications.

However, due to the relatively low volume of the gas, it was always thought that treatment

would not be justified, regardless of how much Venoco desired to capture the value of the

stranded gas and also reduce compressor load

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

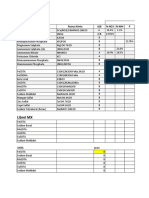

Table 1. Platform Gail Produced Gas/CA Sales Gas Specification

Component

Total Inerts (N2, CO2 and O2)

Carbon Dioxide (CO2)

Methane (CH4 )

Ethane (C2H6 )

Propanes Plus (C3H8+)

Butanes Plus (C4H10 +)

Water (H2O)

Platform Gail

Produced Associated Gas

(mol%)

15

13

64

8

13

7

Saturated

California

Sales Gas Specification

(mol%)

4.0

3.0

88.0

6.0

3.0

1.5

< 7 #/MMcf

As can be seen Table 1, not only was the associated gas produced by the platform high in

CO2, it also contained excessive levels of ethane, propane, butanes and water, all of which

resulted in a low methane content. Since this gas did not meet California sales and/or

pipeline standards, the gas was injected in a gas disposal well at an approximate 2.0 MMscfd

rate, thereby stranding the gas which resulted in a loss of revenue of approximately

$3.25MM/year (at $4/MMbtu).

Sales Gas Options

Potential Solutions

Several engineering and/or feasibility studies were undertaken in order to best determine the

optimum method for treating the stranded gas; methods researched included:

CO2 removal via processes that use aqueous solutions of various alkanolamines

Refrigeration to remove propane and heavier light hydrocarbons

Lean oil absorption in order to remove ethane (using existing on-board equipment)

Turbo expansion and molecular sieve

Dehydration by triethlyene glycol and/or adsorption

Due to the many challenges of operating offshore various combinations of the above four

listed technologies were investigated, both onshore and offshore - on Platform Gail as well as

on neighboring, sister platforms. All of these methods were eventually discarded, as it was

soon realized that while the optimum location for treating the stranded gas was aboard

Platform Gail, there was insufficient room to do so; any projects that involved the creation of

more space aboard the platform (that involved deck expansion) were prohibitively expensive.

After fruitlessly researching and investigating gas treating/processing methods for several

years, gas treating technology caught up with Venocos unique needs for multiple technology

capabilities, in a small, reliable, easy-to-operate package the Rotary-Valve, Fast-Cycle

Pressure-Swing Adsorption unit. This technology has been primarily used for gas separation

downstream of methane reformation unit or in landfill gas/biogas upgrading; although the

technology appeared to address all of Venoco needs, for CO 2 , C2H6 +, and H2O removal, it

was still very uncertain as to whether it could be applied offshore to associated gas.

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption

The Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption gas separation system, developed,

designed and manufactured by Xebec, Incorporated (of Blainville, Quebec), is designed to

separate gas mixtures by means of the Pressure Swing Adsorption (PSA) process. This

process selectively adsorbs different gases by adsorbents when subjected to varying

pressures. The gas mixture (Feed Gas) is made to flow vertically upwards through a tall

column of adsorbent material at relatively high pressure. The adsorbed components of the

mixture (heavy components) are retained by the adsorbent while the less easily adsorbed

gases (light components such as methane) are released from the top of the column as

purified (product) gas. Before the adsorbent material becomes saturated by the heavy gas

components, pressure is released from the bottom of the adsorbent column/bed. The lower

pressure releases the heavy gases from the adsorbent as exhaust gases; the adsorbent bed is

then re-pressurized and is ready to repeat the cycle.

To ensure a continuous supply of product gas, the PSA is equipped with six adsorbent beds

which are cycled in a sequential manner through identical operating cycles. The system

contains four slowly rotating, multi-port, selector valves, which are central to the operation of

the unit. These four valves help to create a very efficient, rapid PSA cycle, and replace over

two dozen high-maintenance, solenoid-type valves found in conventional systems; thereby

allowing Xebec to utilize a more efficient, faster PSA cycle that translates into smaller

equipment packages with reduced capital and installation costs.

Figure 2. Detailed Photographs of Heavies/Lights Xebec Rotary Valves

Two valves control the gas flows into the bottom end of the adsorbent beds and are called the

Heavies Valve, while the other two valves control the flow at the top end of the beds and

are conversely called the Lights Valve. These valves are driven by a gear motor and a

variable frequency drive, in order to adjust valve speed, and therefore, bed cycle time.

Unit performance (i.e. product purity and flow) are controlled by bed cycle time, and

therefore rotary-valve speed. For example, an increase in the valve speed will decrease the

bed cycle time resulting in a more pure (less contaminant-laden) product stream. Although

the product stream will increase in purity with increasing valve speed, the product volume

will decrease, resulting in an increase in exhaust flow. Therefore, final gas product purity

can be controlled by simply adjusting the rotary-valve speed and controlling contaminant

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

removal and methane recovery, thereby making the unit very operator-friendly, and

therefore, well suited for offshore operations.

Figure 3. Detailed Drawing of Xebec Model M-3100 Used on Platform Gail

The use of the rotary valves, therefore, made the operation of the PSA more operator friendly, by following the two basic rules outlined found on the following page.

1. If a higher methane purity is required, then the rotary valve speed is increased, which

will result in a decreased volume of a more pure product stream, thereby increasing

the exhaust gas stream flow rate

2. If a lower methane purity is required, then the rotary valve speed is decreased, which

will result in an increased volume of a dilute product stream, resulting in a decrease in

the exhaust gas stream volume

In addition, to being easy-to-operate, having much fewer moving parts than conventional

Pressure-Swing Adsorption Units, the Rotary-Valve, Fast-Cycle PSA would cover a much

smaller footprint (18 ft(L) X 8 ft(W) X 9 ft(H)) than conventional PSA (which probably

would be several times larger than the Rotary-Valve, Fast-Cycle Unit) and/or the other

technology applications that Venoco was investigating (which would have encompassed

several decks).

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

Adsorbent Selection

The adsorbents used in the Xebec Rotary-Valve, Fast-Cycle M-3100 units are selected based

on several criteria.

Adsorption capacity for the target components

o Affinity for CO2 , ethane, water, but not methane

Selectivity between components competing for the same adsorption sites

o For example, the preferential adsorption of H2O over CO2 has to be accounted

for

Regenerability

o The adsorbent must release the adsorbed target components at a reasonable

pressure rate of gas diffusion into the adsorbent bead

o This affects the size of bead that is chosen and consequently the pressure drop

across the bed

An insufficient diffusion rate requires smaller diameter beads that

result in higher pressure drop and increased operating costs

Chemical compatibility

o Ensure that no chemical attack that would poison or destroy the adsorbent

(such as liquid hydrocarbons causing physical breakdown of the adsorbent,

resulting in loss of efficiency and backpressure)

After Xebecs laboratory/modeling of available adsorbents, non-silica, metal-based, solid

adsorbents were selected in order to provide Venoco with the proper contaminant removal to

meet the tight California sales gas specifications.

Testing

Demonstration Plant Study

Still remaining however, were questions about extended-term performance using associated

gas in an offshore platform environment especially considering the variability of feedstock

quality; Venoco and Xebec therefore agreed to an on-site, pilot/demonstration test in order to

resolve these unanswered questions.

The test was designed using a single, conventional, full-scale Model M-3100 Unit and was

conducted in late April 2006. This test processed 1 st Stage Outlet Gas at 145 psig as shown

in Figure 4 on the following page; exhaust gas was vented back to the vacuum system at 5

psig.

The results of the demonstration plant were quite dramatic, as the PSA decreased the total

inert levels in the produced gas from fifteen to less than four percent, reduced the ethane

level eight to slightly more than two percent, and increased the methane concentration in the

gas from sixty-seven to more than ninety-three percent. In addition, to the successful

performance of the unit, off-shore operations personal were greatly impressed by the

operability, the compactness, the very few moving parts, as well as the potential for

additional revenue offered by the Xebec unit.

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

Glycol Unit

Associated Gas

from Oil-Gas

Separators

Gas Sweetening

3rd Stage

Compression

Gas Lift

2nd Stage

Compression

st

1 Stage

Compression

Vapor Recovery

Gas Turbines

Demonstration

Test PSA

Xebec M-3100

Production Wells

Injection Well

Figure 4. PSA Demonstration Test Block Flow Diagram

Due to the results listed in the above paragraph, which are detailed in Table 2 (below), and

due to trouble-free way the PSA operated during the demonstration test, the evaluation of the

Xebec Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption Unit was deemed a success.

Table 2. Demonstration Test Results

Component

Total Inerts (N2, CO2 and O2)

Carbon Dioxide (CO2)

Methane (CH4 )

Ethane (C2H6 )

Propanes Plus (C3H8+)

Butanes Plus (C4H10 +)

Water (H2O)

Platform Gail

Produced

Associated Gas

(mol%)

15

13

64

8

13

7

Saturated

Demonstration Test

Product Gas

(mol%)

3.70

2.03

93.64

2.35

0.32

0.03

3 #/MMcf

California

Sales Gas

Specification

(mol%)

4.0

3.0

88.0

6.0

3.0

1.5

< 7 #/MMcf

Based upon the success of the demonstration test results, it was decided to install a full-scale,

M-3100 Xebec Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption Unit in order to

process excess production/lift gas to meet the sales gas specifications. The unit was sized to

handle up to 5.0 MMscfd at approximately 300 psig.

Commercial Application

Re-Designed Platform Gas Treatment Operations

The new unit was placed downstream of the fuel gas dehydration unit, in order that the PSA

exhaust stream would not contain any appreciable amounts of water, and therefore, affect

turbine operation and/or performance. An existing rotary-screw compressor was used as a

tail gas compressor for the new unit. Total weight added to the platform was 42 tons (after

32 tons of abandoned equipment was removed).

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

Figure 5 provides a basic sketch of how gas is currently processed aboard Platform Gail.

Sales Gas

To Shore

Rotary-Valve, FastCycle PSA

Xebec M-3100

Glycol Unit

Associated Gas

from Oil-Gas

Separators

Gas Sweetening

1st Stage

Compression

Vapor Recovery

2nd Stage

Compression

Tail Gas

Compresor

Gas Turbines

3rd Stage

Compression

Gas Lift

Production Wells

Injection Well

Figure 5. Current Platform Gail Gas Block Flow Diagram

As can be seen from the above sketch, excess production gas at 400 psig is dehydrated using

triethylene glycol; it is then sent to the M-3100 Xebec Rotary-Valve, Fast-Cycle PressureSwing Adsorption Unit in order to produce sales quality gas prior to shipping the gas to

shore. This design was selected because it offers Venoco several attractive features:

Excess gas is no longer pressurized to 2,000 psig, thereby saving energy as well as

compressor capacity

Sales quality gas is now injected into the approximately 10-mile long pipeline to

shore, negating the need for line pigging and subsequent need for line shutdown

Dehydration of the gas prior to the PSA results in no water vapor being handled by

the electrical-generating turbines, resulting in higher turbine efficiencies

Processing the PSA Vent Gas through the turbine allows Venoco to benefit from:

o Capture of the higher, light hydrocarbons in the feed gas (mostly C2 through C5)

o Processing the high amounts of CO2 (approximate 15 mol%) from the PSA helps to

lower the flame temperature in the turbine, thereby negating any potential negative

effects from ignition of the heavier hydrocarbons described above

The system as outlined in the drawing on the preceding page has been on-line since May;

start-up was remarkably trouble-free, prompting one executive from Venoco to term it as

the easiest start-up in the history of the company.

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

In addition, due the small size of the unit (and the companion Tail Gas Compressor skid),

transportation of the PSA from land to the platform was accomplished by the standard

workboat. A larger skid and/or unit would have required a bigger boat to be used, thereby

creating potential logistical issues and adding to installation costs (a breakdown of project

costs are provided later in this paper).

Operation of the M-3100 Xebec Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption Unit

continues to be unproblematic; thus far slightly more than 2.5 MMscfd (average flow) of

previously stranded gas has been recovered by Platform Gail since start-up on 05/10/10.

Operations and maintenance personal continue to be extremely happy with the operability of

the unit that was demonstrated during on-board testing.

Figure 6. Photograph of Entire Xebec Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption

Unit On-Board Platform Gail (note above rotary valves)

PSA Performance

Performance of the M-3100 Xebec Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption

Unit closely resembles those results obtained during the on-board demonstration test, as

shown in the table in Table 3.

Once again, the unit has proven successful at absorption and reduction of ethane, by

adsorbing slightly more than sixty-three percent of this compound from the associated gas,

and exceeding the sales gas specification on this and all other components.

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

Table 3. Rotary-Valve, Fast-Cycle PSA Performance

Component

Total Inerts (N2/CO2/O2)

Carbon Dioxide (CO2)

Methane (CH4 )

Ethane (C2H6 )

Propanes Plus (C3H8+)

Butanes Plus (C4H10 +)

Water (H2O)

Specific Gravity

GHV, dry (btu/scf)

GHV, wet (btu/scf)

Platform Gail

Produced

Associated Gas

(mol%)

15

13

64

8

13

7

Saturated

0.8735

1,153

1,134

Exhaust Gas

from M-3100

PSA

(mol%)

18

17

40

10

32

22

1.248

1,709

1,679

Sales Gas from

M-3100 PSA

(mol%)

2.61

1.42

93.08

2.95

1.36

0.57

< 7 #/MMcf

0.6043

1,033

1,015

California

Sales Gas

Specification

(mol%)

4.0

3.0

88.0

6.0

3.0

1.5

< 7 #/MMcf

-

PSA Inlet/Outlet Flow Rate

Using Venocos data archive system, which records data every nine minutes, PSA

flow rate data was tabulated and then plotted on the following page in Graph 1. As

can be seen from the plotted data, the sales gas flow is slightly less than two-thirds of

Graph 1. PSA Inlet (upper) and Sales (lower) Flow Rates

the inlet flow; while this may seem like a low recovery for this type of a system, one

must keep in mind that in this particular design, every molecule passed through the

M-3100 Xebec Rotary-Valve, Fast-Cycle Pressure-Swing Adsorption Unit is

recovered either as sales gas (approximately 62 % recovery), or as turbine fuel.

As also shown by the data, there were several (if not many) interruptions in the

operation of the PSA. This was due to periods when one of the turbines was off-line

and the platform needed to terminate operation of the Tail Gas Compressor in order to

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

shed load to meet the electrical output of the two, remaining, on-line turbines.

During these periods when one of the turbines is down, Venoco is currently

investigating allowing the PSA exhaust gas to be temporarily vented to the Vapor

Recovery System, thereby eliminating the need for PSA shutdown and improving

program economics.

CO2 Removal

Using the data archive system along with on-line gas chromatograph data, the CO2

level in the sales gas was graphed and is provided on the following page. As can be

seen by the data provided, the CO2 level of the sales gas was consistently below the

specification limit of 3.0 mole percent.

As stated earlier in this report, CO2 removal and sales gas flow rate are both functions

of rotary valve speed; as the speed of the rotary valve is increased the quality of the

sales gas improves (i.e. the CO 2 level in the sales gas decreases), but the rate of the

sales gas decreases. As shown by the two graphs, Venoco could slow down the

rotary valve speed, allowing the CO 2 content of the gas to slightly increase, and also

increase the flow rate of the sales gas, improving program economics.

These and other optimization steps are currently being planned for this project, and

will be undertaken in the near future.

Graph 2. Sales Gas (PSA Outlet) CO2 Level

Ethane Removal

Table 4 provides an overview of ethane removal results through the M-3100 unit; as

can be seen, removal results vary between fifty and seventy percent. When CO2

removal is considered, ethane removal is actually between 57 and 79 percent. On the

full-scale unit C2H6 removal is actually higher than in Xebec laboratory

screening/modeling and in the demonstration tests.

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

Table 4. Ethane Removal through Rotary-Valve, Fast-Cycle PSA

C2 Inlet (mol%)

C2 Outlet (mol%)

Laboratory Tests

7.5

3.25

Demonstration Test

8.0

2.35

Actual Unit

8.0

2.95

Turbine Emissions

Table 5. Turbine Exhaust NO x Level

Turbine Exhaust NOx Level (ppm)

Turbine

Five months prior to PSA Start-up

Five months after PSA Start-up

G-01

0.61

0.50

G-02

1.85

0.57

G-03

1.12

0.94

A potential concern of this project was the effect of the heavy light hydrocarbons

upon turbine emissions; a meeting with Rolls-Royce was conducted, and subsequent

modeling data indicated that the effect of the heavier gas stream would be negligible,

more than likely, due to the increased CO 2 in this gas stream.

Project Economics

Cost break-down of the project was as follows:

Engineering

PSA Skid

Compressor Skid

Demolition

Structural Modification

Installation

Materials (pipes, electrical, etc)

Total

$180,000

$770,000

$600,000

$130,000

$300,000

$750,000

$100,000

$2,830,000

At current projections, project payback is approximately one and one-half years (at sales gas

value of $4.00/MMbtu). Some of the optimization steps discussed in this report should

shorten that time considerably Venoco is very pleased with the success of this project and

is currently investigating the feasibility of installing another unit on another platform (also

located in the Santa Barbara Channel).

Optimization

Future Plans Best Practices Learned from PXP-Adams Street (Downtown Los Angeles)

At an on-shore site, located in downtown Los Angeles, an M-3100 Xebec Rotary-Valve,

Fast-Cycle Pressure-Swing Adsorption Unit has been successfully operating for

File: Rotary-Valve Fast-Cycle Pressure-Swing Adsorption Paper (FINAL)

approximately two years. This particular application is primarily concerned with ethane

removal as well as heavy light hydrocarbons, as carbon dioxide reduction is not a concern at

this location.

At this location the speed of the rotary-valve is control by a gas chromatograph in order to

control methane number, a requirement mandated by the purchaser of the gas; the sales

specification is greater than 80 MN. The gas is currently controlled at 80.5 MN via the gas

chromatograph, and the system is working well at this mostly unmanned site.

With the success of the above application, especially the automatic control of the rotary valve

speed, effort should be made to implement the same type of control onboard Platform Gail.

Вам также может понравиться

- Process Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationОт EverandProcess Systems and Materials for CO2 Capture: Modelling, Design, Control and IntegrationAthanasios I. PapadopoulosОценок пока нет

- Handbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7От EverandHandbook of Thermal Conductivity, Volume 2: Organic Compounds C5 to C7Оценок пока нет

- Successful Design of Catalysts: Future Requirements and DevelopmentОт EverandSuccessful Design of Catalysts: Future Requirements and DevelopmentОценок пока нет

- Insights into Chemical Engineering: Selected Papers of P.V. DanckwertsОт EverandInsights into Chemical Engineering: Selected Papers of P.V. DanckwertsОценок пока нет

- 3 - Li2016 Article PressureSwingAdsorptionMembranДокумент10 страниц3 - Li2016 Article PressureSwingAdsorptionMembranMohammadAsifОценок пока нет

- Micro Fuel Cells: Principles and ApplicationsОт EverandMicro Fuel Cells: Principles and ApplicationsTim ZhaoОценок пока нет

- Heat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferОт EverandHeat and Fluid Flow in Power System Components: Hmt The Science & Applications of Heat and Mass TransferA. M. A. RezkОценок пока нет

- Metal-Hydrogen Systems: Proceedings of the Miami International Symposium on Metal-Hydrogen Systems, 13-15 April 1981, Miami Beach, Florida, U.S.A.От EverandMetal-Hydrogen Systems: Proceedings of the Miami International Symposium on Metal-Hydrogen Systems, 13-15 April 1981, Miami Beach, Florida, U.S.A.Оценок пока нет

- Oxy-fuel Combustion: Fundamentals, Theory and PracticeОт EverandOxy-fuel Combustion: Fundamentals, Theory and PracticeChuguang ZhengОценок пока нет

- Water and Thermal Management of Proton Exchange Membrane Fuel CellsОт EverandWater and Thermal Management of Proton Exchange Membrane Fuel CellsОценок пока нет

- Incineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987От EverandIncineration of Municipal Waste: Specialized Seminars on Incinerator Emissions of Heavy Metals and Particulates, Copenhagen, 18–19 September 1985 and Emission of Trace Organics from Municipal Solid Waste Incinerators, Copenhagen, 20–22 January 1987Robert B. DeanОценок пока нет

- Biorefineries and Chemical Processes: Design, Integration and Sustainability AnalysisОт EverandBiorefineries and Chemical Processes: Design, Integration and Sustainability AnalysisОценок пока нет

- International Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectОт EverandInternational Thermodynamic Tables of the Fluid State, Argon, 1971: Division of Physical Chemistry, Commission on Thermodynamics and Thermochemistry, Thermodynamic Tables ProjectОценок пока нет

- Waste Biorefineries: Advanced Design Concepts for Integrated Waste to Energy ProcessesОт EverandWaste Biorefineries: Advanced Design Concepts for Integrated Waste to Energy ProcessesОценок пока нет

- Handbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28От EverandHandbook of Thermal Conductivity, Volume 3: Organic Compounds C8 to C28Оценок пока нет

- Handbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4От EverandHandbook of Thermal Conductivity, Volume 1: Organic Compounds C1 to C4Рейтинг: 5 из 5 звезд5/5 (1)

- Separation and Purification Technologies in BiorefineriesОт EverandSeparation and Purification Technologies in BiorefineriesShri RamaswamyОценок пока нет

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsОт EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengОценок пока нет

- Preparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsОт EverandPreparation of Catalysts II: Scientific Bases for the Preparation of Heterogeneous CatalystsОценок пока нет

- Design and Operation of Solid Oxide Fuel Cells: The Systems Engineering Vision for Industrial ApplicationОт EverandDesign and Operation of Solid Oxide Fuel Cells: The Systems Engineering Vision for Industrial ApplicationОценок пока нет

- Pukrushpan2003a (Modeling and Control of Fuel Cell Systems and Fuel Processors) PDFДокумент147 страницPukrushpan2003a (Modeling and Control of Fuel Cell Systems and Fuel Processors) PDFBill MooreОценок пока нет

- (Marko Zlokarnik) Scale-Up in Chemical EngineeringДокумент9 страниц(Marko Zlokarnik) Scale-Up in Chemical EngineeringakilaprabuОценок пока нет

- Introduction of Pressure Swing AdsorptionДокумент1 страницаIntroduction of Pressure Swing AdsorptionjokishОценок пока нет

- Python Intro ChE CompДокумент55 страницPython Intro ChE CompTayná GonsalvesОценок пока нет

- (Martin, John H.) Natural Gas ConversionДокумент577 страниц(Martin, John H.) Natural Gas Conversionfjguevara2Оценок пока нет

- Shell and Tube Heat ExchangersДокумент4 страницыShell and Tube Heat ExchangersMohamed Ashraf0% (1)

- Vacuum Swing AdsorptionДокумент3 страницыVacuum Swing AdsorptionnagsraviОценок пока нет

- Heuristic Design of Pressure Swing AdsorptionДокумент19 страницHeuristic Design of Pressure Swing AdsorptionGenoa SweatersОценок пока нет

- Catalyst in Refining PetrochemicalsДокумент5 страницCatalyst in Refining PetrochemicalsgshdavidОценок пока нет

- Pipephase 9.1: User's GuideДокумент104 страницыPipephase 9.1: User's GuideGabi AraujoОценок пока нет

- PsaДокумент5 страницPsaSamanta De Jesus Ferreira100% (1)

- Legend Sheet P&ID For As-Built - Drafting On 20210722-5Документ1 страницаLegend Sheet P&ID For As-Built - Drafting On 20210722-5Ludi D. LunarОценок пока нет

- IAR Systems AB: Information For End UsersДокумент20 страницIAR Systems AB: Information For End UsersJohnnybacsiОценок пока нет

- Batch Processing Systems Engineering - Fundamentals and Applications For Chemical EngineeringДокумент885 страницBatch Processing Systems Engineering - Fundamentals and Applications For Chemical EngineeringitzelselОценок пока нет

- 1998-Plasma Reforming of MethaneДокумент8 страниц1998-Plasma Reforming of MethaneakkusawОценок пока нет

- Kinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasДокумент8 страницKinetics of The Synthesis of Higher Aliphatic Alcohols From SyngasLina ArevaloОценок пока нет

- FYDP Slide PresentationДокумент51 страницаFYDP Slide PresentationNor Asyiqin Zainal AbidinОценок пока нет

- AdsorptionДокумент17 страницAdsorptionAbi Nash100% (2)

- Abts Uqair-B.2Документ1 страницаAbts Uqair-B.2Anonymous BZQOJwWIh6Оценок пока нет

- Jet Venturi Fume ScrubbersДокумент7 страницJet Venturi Fume ScrubbersihllhmОценок пока нет

- Cat 6Документ4 страницыCat 6stamatsОценок пока нет

- Process Plant Piping OverviewДокумент133 страницыProcess Plant Piping Overviewskdalalsin100% (8)

- Flow Considerations in Industrial Silencer DesignДокумент8 страницFlow Considerations in Industrial Silencer DesignktsnlОценок пока нет

- Air SystemДокумент22 страницыAir Systemabhi_mohit2005100% (1)

- IP2007 Vol 1Документ383 страницыIP2007 Vol 1Nitisha80% (5)

- E 2 o Future of Mobility BrochureДокумент9 страницE 2 o Future of Mobility Brochureabhi_mohit2005Оценок пока нет

- Sample Question & AnswersДокумент9 страницSample Question & Answersabhi_mohit2005Оценок пока нет

- Pressure Vessel Fabrication ManualДокумент67 страницPressure Vessel Fabrication Manualabhi_mohit2005100% (2)

- PVElite ManualДокумент691 страницаPVElite Manuals.mladin75% (4)

- Drive Works X PressДокумент21 страницаDrive Works X Pressabhi_mohit2005Оценок пока нет

- Pressure Vessel, Asme CodeДокумент10 страницPressure Vessel, Asme Codeabhi_mohit2005100% (1)

- Fundamentals of Drafting SampleДокумент21 страницаFundamentals of Drafting Sampleabhi_mohit2005Оценок пока нет

- Solid Works Flow Simulations 2012Документ266 страницSolid Works Flow Simulations 2012Milasinovic Marko100% (1)

- IACS Req Pipes Pressure VesselДокумент69 страницIACS Req Pipes Pressure VesselFrancesco CauzОценок пока нет

- Proposed Design Criterion For Vessel Lifting Lugs in Lieu of ASME B30.20Документ8 страницProposed Design Criterion For Vessel Lifting Lugs in Lieu of ASME B30.20cpchonburi0% (1)

- Homework Chapter 22 Solutions PDFДокумент16 страницHomework Chapter 22 Solutions PDFbidinОценок пока нет

- Hardness Temperature in MetalsДокумент6 страницHardness Temperature in MetalsStevenJacomeОценок пока нет

- Laboratory Worksheet: Pre-Lab QuestionsДокумент2 страницыLaboratory Worksheet: Pre-Lab QuestionsKelee DeWittОценок пока нет

- Drug and Alcohol AbuseДокумент24 страницыDrug and Alcohol AbuseParitosh Kumar100% (3)

- Catalogo Alu MarketДокумент40 страницCatalogo Alu MarketMiguel Angel Diaz Escobar100% (2)

- MS 628-2 2014 - Prepdf PDFДокумент9 страницMS 628-2 2014 - Prepdf PDFzulkainiОценок пока нет

- Done By: Neha Jain Priya Upadhyay Saanchi AroraДокумент13 страницDone By: Neha Jain Priya Upadhyay Saanchi AroraPriya UpadhyayОценок пока нет

- Excel Meracik Nutrisi Bandung 11 Feb 2018Документ30 страницExcel Meracik Nutrisi Bandung 11 Feb 2018Ariev WahyuОценок пока нет

- PNSC0021Документ12 страницPNSC0021romerobernaОценок пока нет

- Forensic Assignment Muhammad Asghar Roll No. 2357Документ5 страницForensic Assignment Muhammad Asghar Roll No. 2357Faisal AwanОценок пока нет

- A192577 Report CaffeineДокумент6 страницA192577 Report CaffeineNOR AFIFAH BINTI MOHD AKHIARОценок пока нет

- Water VapourДокумент11 страницWater VapourivanmjwОценок пока нет

- Api 510 Q&aДокумент13 страницApi 510 Q&aShaikh Aftab100% (2)

- Rectifier Design For Fuel Ethanol PlantsДокумент7 страницRectifier Design For Fuel Ethanol PlantsenjoygurujiОценок пока нет

- Deck CrainДокумент540 страницDeck Crainpraveen67% (3)

- 2 Manuale D Uso GB 03 12 CE C-0104Документ33 страницы2 Manuale D Uso GB 03 12 CE C-0104vtechelectricОценок пока нет

- Aquaponics Common Sense Guide PDFДокумент28 страницAquaponics Common Sense Guide PDFTrey BarnesОценок пока нет

- Chem Lab 1 Itlog AssignmentДокумент2 страницыChem Lab 1 Itlog Assignmentfamigo451Оценок пока нет

- Electrical Design and Aspects of Hvac: Unit - 4: Heating Control DevicesДокумент49 страницElectrical Design and Aspects of Hvac: Unit - 4: Heating Control DevicesRakesh MoparthiОценок пока нет

- Cake ResistanceДокумент2 страницыCake ResistanceHossein NajafiОценок пока нет

- Have You Ever Imagined An Environment That Is Not GreenДокумент2 страницыHave You Ever Imagined An Environment That Is Not GreenGeorge Anderson Loza FloresОценок пока нет

- Enzymes Lab ReportДокумент11 страницEnzymes Lab ReportAra Alibasa75% (4)

- STRUCTURE OF ATOMS - DoneДокумент16 страницSTRUCTURE OF ATOMS - DoneRaghvendra ShrivastavaОценок пока нет

- WPS (Gtaw)Документ2 страницыWPS (Gtaw)Ramadhan AdityaОценок пока нет

- Steel Bars: For Automotive ApplicationsДокумент4 страницыSteel Bars: For Automotive ApplicationsSunil AundhekarОценок пока нет

- Swing Arm Calculation and Analysis JournalДокумент5 страницSwing Arm Calculation and Analysis JournalBálají SèlvakümárОценок пока нет

- Ardrox 8901w Aerosol Msds v1 5Документ6 страницArdrox 8901w Aerosol Msds v1 5arunkumarОценок пока нет

- K02 Mechanical Seal Leak - RCA DocumentДокумент8 страницK02 Mechanical Seal Leak - RCA DocumentMidha NeerОценок пока нет

- (Autex Research Journal) Analysis of Moisture Evaporation From Underwear Designed For Fire-FightersДокумент13 страниц(Autex Research Journal) Analysis of Moisture Evaporation From Underwear Designed For Fire-FightersHafez HawasОценок пока нет

- VSEPR ShortcutДокумент3 страницыVSEPR ShortcutSubhojyotiDasОценок пока нет