Академический Документы

Профессиональный Документы

Культура Документы

Job Hazard Analysis Welding & Cutting Operations: Reference: OSHA Standard 29 CFR 1926.350, Subpart J, Welding & Cutting

Загружено:

Rio de MarioОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Job Hazard Analysis Welding & Cutting Operations: Reference: OSHA Standard 29 CFR 1926.350, Subpart J, Welding & Cutting

Загружено:

Rio de MarioАвторское право:

Доступные форматы

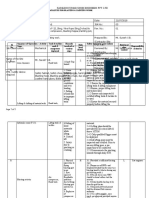

JOB HAZARD ANALYSIS

Welding & Cutting Operations

Reference: OSHA Standard 29 CFR 1926.350, Subpart J, Welding & Cutting

Job Description

PREPARATORY

OPERATIONS

WELDING OR

CUTTING

Hazard Identification

Fire

Burns

Eye Damage

Electric Shock

Cuts & Burns

Hazard Controls

1. When practical, the object to be welded, cut, or heated should

be moved to a designated safe location away from flammable

liquids and other combustibles.

2. If the object cannot be moved, positive means must be taken to

confine the heat, sparks, and slag.

3. A 20 lb, ABC dry chemical extinguisher (or equivalent) must be

immediately available in the work area and must be maintained

in a state of readiness for instant use.

4. Garbage and trash shall not be allowed to accumulate on the

premises, as it may be ignited by the sparks or slag.

5. When welding is being performed on a higher level where there

is an exposure to workers below, the area directly below the

welding shall be cleared and marked as a "Do Not Enter

Zone", to protect any workers passing underneath from being

hit by sparks or slag.

6. A fire watch must be maintained at least 30 minutes after the

hot work is completed.

7. Welding/cutting operations shall be performed by trained,

certified workers.

1. During welding/cutting operations, proper welding gloves and a

full-face, UV-ray protective shield shall be worn to prevent

injuries to the operator.

2. All electrical cords shall be inspected and in good working

condition prior to use (no missing ground pins, no damaged

cords, or frayed wires evident).

3. All small tools shall be inspected prior to use and found to be in

good working order prior to use.

Employee Instructions:

1. Hard hats, safety glasses, work clothes, and work boots shall be worn at all times.

2. Welding and Fire Watch certification must be verified prior to the start of the operation.

3. This JHA must be reviewed with all personnel involved in welding or cutting, prior to starting work.

All crew members must print/sign their name below to acknowledge their understanding of the JHA.

JHA conducted by:

Date conducted:

Manager / Supervisor Signature:

Date:

NOTE TO MANAGER, SUPERVISOR OR FOREMAN: WORK MUST NOT START UNTIL ALL HAZARDS ARE

DISCUSSED; CONTROLS ARE IN PLACE; AND ALL SIGNATURES ARE OBTAINED.

This ASCC publication should not be regarded as legal advice or a substitute for independent research, investigation, or consultation with qualified

professionals such as OSHA representatives. ASCC makes no warranty or representation as to this publications completeness, accuracy, or in the

correctness of its contents, and assumes no liability in connection therewith or any obligation to review or update this publication, or warn users in the

event errors are discovered. It is suggested that reference be made to your specific state and/or federal safety regulations.

Вам также может понравиться

- ARC130 170 ManualДокумент28 страницARC130 170 ManualPhilip Rosser100% (2)

- Working at Heights: Dr.P.MuralidharДокумент48 страницWorking at Heights: Dr.P.MuralidharRituraj SinghОценок пока нет

- Genie E Series Slab Scissor Lift Operation PDFДокумент11 страницGenie E Series Slab Scissor Lift Operation PDFRajesh gpОценок пока нет

- Updated JSA For SAPMTofficeДокумент30 страницUpdated JSA For SAPMTofficeShaikh Abu bakarОценок пока нет

- RadiographyДокумент1 страницаRadiographyNature BeautiesОценок пока нет

- AEG - JSA - 107 - Oxygen Acetylene Torch PDFДокумент2 страницыAEG - JSA - 107 - Oxygen Acetylene Torch PDFanon_421433640Оценок пока нет

- OSHA 10 Fact Sheet - Fall ProtectionДокумент1 страницаOSHA 10 Fact Sheet - Fall ProtectionJuan Carlos PlasenciaОценок пока нет

- RiggingДокумент2 страницыRiggingpruncu.alianmОценок пока нет

- JSA For KAHSДокумент6 страницJSA For KAHSFrancis Enriquez TanОценок пока нет

- TieДокумент5 страницTieshinto LawrenceОценок пока нет

- DCL (Logo) : Hand BookДокумент16 страницDCL (Logo) : Hand BookJahangir ShaОценок пока нет

- JSA-03 Shed DismantlingДокумент3 страницыJSA-03 Shed DismantlingSwaroop Cherry0% (1)

- Construction Job Safety/Hazard Analysis Job #: Location/Description: OwnerДокумент33 страницыConstruction Job Safety/Hazard Analysis Job #: Location/Description: OwnerHortencio SamuelОценок пока нет

- Safety in Metallizing: Presentation By, A.Mohan RajДокумент10 страницSafety in Metallizing: Presentation By, A.Mohan RajMohan RajОценок пока нет

- JSA - Bolt TensioningДокумент5 страницJSA - Bolt TensioningRaju KhalifaОценок пока нет

- PDF Gi 0002721 2016 Arc Flash CompressДокумент23 страницыPDF Gi 0002721 2016 Arc Flash CompressMark DingalОценок пока нет

- Mechanical Job Hazard Analysis Name of The Job: WELDING JOBДокумент1 страницаMechanical Job Hazard Analysis Name of The Job: WELDING JOBbrandybuckОценок пока нет

- JSA Welding and Cutting Metals Using Oxy AcetyleneДокумент5 страницJSA Welding and Cutting Metals Using Oxy AcetyleneVictor John PingkianОценок пока нет

- JHA Welding Arc and Cutting (Hotwork)Документ2 страницыJHA Welding Arc and Cutting (Hotwork)Popo EaldamaОценок пока нет

- JHA - (Power Brush & Touch-Up Painting Activities 1)Документ1 страницаJHA - (Power Brush & Touch-Up Painting Activities 1)shaiful annuarОценок пока нет

- Rigging JSA RiggerДокумент12 страницRigging JSA RiggeraQiLGunawanОценок пока нет

- Fire Prevention PlanДокумент25 страницFire Prevention PlanEMILYN DEPOLLOОценок пока нет

- Appendix A-Job Safety Analysis FormДокумент3 страницыAppendix A-Job Safety Analysis Formjiks_i4uОценок пока нет

- JHA Arc WeldingДокумент2 страницыJHA Arc WeldingechaОценок пока нет

- Topic For TBMДокумент19 страницTopic For TBMdauxomОценок пока нет

- Covering Holes Tailgate Safety TalkДокумент1 страницаCovering Holes Tailgate Safety TalkBalaji RajasekaranОценок пока нет

- Standard Operating Procedures of Hand and Power Tool SafetyДокумент3 страницыStandard Operating Procedures of Hand and Power Tool Safetysingenaadam100% (1)

- JSA Mechanical Plant and Machinery SafetyДокумент8 страницJSA Mechanical Plant and Machinery SafetyMazlan Ashaari100% (1)

- CatalogoДокумент153 страницыCatalogomilecsaОценок пока нет

- Safety Management: Scaffolds and BarricadesДокумент25 страницSafety Management: Scaffolds and BarricadesIrene Pudiquet SilvaniaОценок пока нет

- Caretaker Risk Assessment - Working at HeightДокумент8 страницCaretaker Risk Assessment - Working at HeightLina MarcelaОценок пока нет

- 16.18 TBT - Gas Welding and CuttingДокумент2 страницы16.18 TBT - Gas Welding and Cuttinggrant100% (1)

- 1 Fall Hazards Trainer GuideДокумент39 страниц1 Fall Hazards Trainer Guidedroffilcz27100% (1)

- JSA Pipe Installation 2012Документ2 страницыJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Welding Oxy A4Документ2 страницыWelding Oxy A4LoveОценок пока нет

- Confined Space - IntroductionДокумент23 страницыConfined Space - Introductionyogeshwaran NОценок пока нет

- TBT ExcavationsДокумент2 страницыTBT ExcavationsJohn Vem BansagОценок пока нет

- Jha WTPДокумент3 страницыJha WTPYer SonmoОценок пока нет

- Self-Retracting Devices: Labels & MarkingsДокумент1 страницаSelf-Retracting Devices: Labels & Markingsghifariaghnia0% (1)

- Plastering & RenderingДокумент7 страницPlastering & Renderingmohd firdausОценок пока нет

- 42 Rigging 1. Procedure 1. Rigging SafetyДокумент15 страниц42 Rigging 1. Procedure 1. Rigging SafetyGopal ChoudharyОценок пока нет

- JSA For Manual Excavation Inside The Operation Area (Access Road)Документ6 страницJSA For Manual Excavation Inside The Operation Area (Access Road)Mohammed MinhajОценок пока нет

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedДокумент2 страницыJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiОценок пока нет

- Job Safety Analysis WorksheetДокумент4 страницыJob Safety Analysis WorksheetSAHIL SHARMAОценок пока нет

- Job Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Документ5 страницJob Safety Analysis:: RTR DRAIN LINE REPLACEMENT (Excavation and Backfilling)Madhan KannanОценок пока нет

- Working at Height On 25.03.2021Документ80 страницWorking at Height On 25.03.2021AMAN GUPTAОценок пока нет

- JSA Formet New Blasting & PaintingДокумент5 страницJSA Formet New Blasting & Paintingsakthi venkatОценок пока нет

- Welding ArcДокумент1 страницаWelding ArcLove100% (1)

- Rock Breaker Self ChecklistДокумент1 страницаRock Breaker Self ChecklistNair R RakeshОценок пока нет

- Iosh Osha Interveiw Session11Документ45 страницIosh Osha Interveiw Session11Sameer RajuОценок пока нет

- Glenbrook Rd. Demolition and Disposal PlanДокумент56 страницGlenbrook Rd. Demolition and Disposal PlanBruno CarvalheiroОценок пока нет

- Eye WashДокумент21 страницаEye Washapi-273019508100% (1)

- Z - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Документ3 страницыZ - MP-EHS-01 IRA - 03 Install HDPE Pipe Sleeve (1aug2023)Din JalilОценок пока нет

- Jsa Insulation WorkДокумент20 страницJsa Insulation WorkazerОценок пока нет

- Scaffolding Hazard PreventionДокумент2 страницыScaffolding Hazard PreventionRavikant PandeyОценок пока нет

- Permit To Work Shafts and Elevators: Compliance ChecklistДокумент1 страницаPermit To Work Shafts and Elevators: Compliance ChecklistNeil Buyco VillamorОценок пока нет

- Confined Spaces CardsДокумент1 страницаConfined Spaces CardsJafar KhanОценок пока нет

- A Complete Guide To Working at Height Regulations by At-HeightДокумент6 страницA Complete Guide To Working at Height Regulations by At-Heightat-height0% (1)

- Studyguide PDFДокумент52 страницыStudyguide PDFMarcelo VeronezОценок пока нет

- Pto Doc Pc6-InglДокумент2 страницыPto Doc Pc6-InglRio de MarioОценок пока нет

- Form Travelling ExpansesДокумент1 страницаForm Travelling ExpansesRio de MarioОценок пока нет

- Open Hole Logging Services: Logging Tool Mnemonic Logging Tool Name Log Type Formation Property Measured CommentДокумент5 страницOpen Hole Logging Services: Logging Tool Mnemonic Logging Tool Name Log Type Formation Property Measured CommentRio de MarioОценок пока нет

- Product Data Sheet: C120 - Circuit Breaker - C120N - 1P - 63A - C CurveДокумент2 страницыProduct Data Sheet: C120 - Circuit Breaker - C120N - 1P - 63A - C CurveRio de MarioОценок пока нет

- Vickers General Hydraulic BookДокумент29 страницVickers General Hydraulic BookKarthik Sarang100% (15)

- XZU Chap02Документ7 страницXZU Chap02Rio de MarioОценок пока нет

- Resistivity LoggingДокумент26 страницResistivity LoggingRio de Mario100% (1)

- 550FC With AC61 Data PageДокумент3 страницы550FC With AC61 Data PageRio de MarioОценок пока нет

- T2B2 Spec Sheet June2013Документ2 страницыT2B2 Spec Sheet June2013Rio de MarioОценок пока нет

- Inspection Certificate Type 3.1 Per EN 10204:2004: Zapp Precision Wire IncДокумент2 страницыInspection Certificate Type 3.1 Per EN 10204:2004: Zapp Precision Wire IncRio de MarioОценок пока нет

- Soft Skills Interview QuestionsДокумент3 страницыSoft Skills Interview QuestionsRio de MarioОценок пока нет

- Slickline Basics.51 60Документ10 страницSlickline Basics.51 60Rio de MarioОценок пока нет

- Wireline Works Tech-BulletinsДокумент25 страницWireline Works Tech-BulletinsRio de Mario100% (1)

- Sonic Logging TestДокумент3 страницыSonic Logging TestRio de MarioОценок пока нет

- A1 001 Wireline Unit PTO SwapBody 24ftДокумент2 страницыA1 001 Wireline Unit PTO SwapBody 24ftRio de MarioОценок пока нет

- Dhesives Ealants: RubberbondДокумент2 страницыDhesives Ealants: RubberbondRio de MarioОценок пока нет

- Logging Masts - Lightweight AluminumДокумент2 страницыLogging Masts - Lightweight AluminumRio de MarioОценок пока нет

- ZP Mast SteelДокумент2 страницыZP Mast SteelRio de MarioОценок пока нет

- Wireline Equipment Standard-Norsok PDFДокумент14 страницWireline Equipment Standard-Norsok PDFRio de Mario100% (2)

- Wireline DrumsДокумент1 страницаWireline DrumsRio de MarioОценок пока нет

- Slickline Basics.61 70Документ10 страницSlickline Basics.61 70Rio de MarioОценок пока нет

- Wireline Equipment Checks: - 2. Wire HistoryДокумент10 страницWireline Equipment Checks: - 2. Wire HistoryRio de MarioОценок пока нет

- Slickline Basics.41 50Документ10 страницSlickline Basics.41 50Rio de MarioОценок пока нет

- Slickline Basics.41 50Документ10 страницSlickline Basics.41 50Rio de MarioОценок пока нет

- Slickline Basics.11 20Документ10 страницSlickline Basics.11 20Rio de MarioОценок пока нет

- Net Jets Pilot & Benefits PackageДокумент4 страницыNet Jets Pilot & Benefits PackagedtoftenОценок пока нет

- PHIL 125: Practical Logic: University of Alberta Sam Hillier, Fall 2013Документ12 страницPHIL 125: Practical Logic: University of Alberta Sam Hillier, Fall 2013Harry WeiОценок пока нет

- The Warehouse Group Annual Report 2020Документ92 страницыThe Warehouse Group Annual Report 2020Meaza Kidusan ElhamОценок пока нет

- LPV Fault Detection of Glucose-Insulin System: Cite This PaperДокумент6 страницLPV Fault Detection of Glucose-Insulin System: Cite This PaperfatihaОценок пока нет

- 16 MSDS NaHSO3Документ6 страниц16 MSDS NaHSO3Furqan SiddiquiОценок пока нет

- How To Write A Case Report PDFДокумент6 страницHow To Write A Case Report PDFironОценок пока нет

- Columbia-Presbyterian Patient Safety StudyДокумент9 страницColumbia-Presbyterian Patient Safety StudyKathleen Beatty100% (1)

- Experiment NoДокумент3 страницыExperiment NoMaxene Kaye PeñaflorОценок пока нет

- Prehension, Mastication, and DeglutitionДокумент3 страницыPrehension, Mastication, and DeglutitionAnjelica Louise MartinОценок пока нет

- 23 Medicinal Plants The Native Americans Used On A Daily Basis - MSYCДокумент15 страниц23 Medicinal Plants The Native Americans Used On A Daily Basis - MSYCLeandro RodriguesОценок пока нет

- Organ SystemsДокумент2 страницыOrgan SystemsArnel LaspinasОценок пока нет

- Pacific CrossДокумент27 страницPacific Crossanon_873405382Оценок пока нет

- 2011 Urine Therapy J of NephrolДокумент3 страницы2011 Urine Therapy J of NephrolCentaur ArcherОценок пока нет

- Pre-Emplopyment RequirementsДокумент2 страницыPre-Emplopyment RequirementsPatricia TorrianaОценок пока нет

- Intentional Replantation - An Underused Modality?Документ7 страницIntentional Replantation - An Underused Modality?Mohammad Abdulmon’emОценок пока нет

- Latin Eugenics in Comparative PerspectiveДокумент356 страницLatin Eugenics in Comparative PerspectivemafeОценок пока нет

- How To Sleep BetterДокумент9 страницHow To Sleep BetterMariaОценок пока нет

- 3f PDFДокумент4 страницы3f PDFYidne GeoОценок пока нет

- Climbing Training Log - TemplateДокумент19 страницClimbing Training Log - TemplateKam Iqar ZeОценок пока нет

- Phil Airlines v. NLRCДокумент1 страницаPhil Airlines v. NLRCAlec VenturaОценок пока нет

- Normal GFR in ChildДокумент8 страницNormal GFR in ChildbobbypambudimdОценок пока нет

- Daftar PustakaДокумент2 страницыDaftar PustakaameliaaarrОценок пока нет

- Nursing Care Plan: Phinma University of PangasinanДокумент1 страницаNursing Care Plan: Phinma University of PangasinanShaira De La CruzОценок пока нет

- Acetylsalicylic AcidДокумент6 страницAcetylsalicylic AcidAdmin DownloadОценок пока нет

- Hearing Handicap Inventory For The Elderly (HHIE)Документ5 страницHearing Handicap Inventory For The Elderly (HHIE)Is GutiérrezОценок пока нет

- Trasturel 440mg Anti CancerДокумент3 страницыTrasturel 440mg Anti CancerRadhika ChandranОценок пока нет

- Accupressure Points Chart PDFДокумент20 страницAccupressure Points Chart PDFshule1100% (2)

- Mapeh 2ND QДокумент5 страницMapeh 2ND QMaxicris SlowerОценок пока нет

- PSC Question BankДокумент9 страницPSC Question BankFaisal qblp100% (29)

- Enucleation Surgery-Orbital Implants and Surgical Techniques - 1Документ3 страницыEnucleation Surgery-Orbital Implants and Surgical Techniques - 1Satria Adi MarhendraОценок пока нет