Академический Документы

Профессиональный Документы

Культура Документы

Inspection Test Plan (Itp)

Загружено:

widhisaputrawijayaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Inspection Test Plan (Itp)

Загружено:

widhisaputrawijayaАвторское право:

Доступные форматы

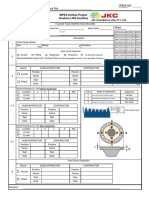

INSPECTION AND TEST PLAN

Customer

: PT. INDO SUKSES SENTRA USAHA

Material

: Vinyl Ester

Plan No

: 03/10/13

Project

: Merak

Pro.Description

: FRP STORAGE TANK

Revision

:0

PO.No.

: PI 1309005

Qty

: 9 Units

Date

: October 03th, 2013

Sample Plan

Acceptance norm.

Report

Report

to Client

TDI

~ Visual

Once per batch

No Pollution

Raw Mat'l Insp

~ Viscosity

Once per batch

Manufact. Spec.

Mat'l Certificate

Color

Once per batch

* Visual Inspection

Once per batch

Characteristic

* Mass per unit area

H-W-M-R

INDOKEMIKA

No defect

Raw Mat'l Insp

No break

Mat'l Certificate

Refer to process control data

Defects

Twice per week

No Visual Defect

Par.Control Process Prod

Build - up

Twice per week

No Visual Defect

Par.Control Process Prod

Surface Hardness

Random

90% of resin Manufacturer

Dimension and Visual Report

Surface flat

Random

appropriate SPK

Dimension and Visual Report

1 x 24 hours

No Leak

Hydrotest Report

Thick. Dim and Configuration

100%

Tolerance Specth

Dimension and Visual Report

Surface Defect

100%

ASME.RTP.1

Leak Test

onitoring

H : Hold point

R : Review

X: Document for customer

RTP Visual Accept.Criteria

Dimension and Visual Report

Complete and Accurate

Manufacturing Data Record

I : Random Witness

W / R : When Required

ection , samples may be taken from any product , any series and any order

* 1. H,W,M,R,W/R,I state in "TDI" coloum means inspection activities to be carried out by TDI , QC department without involving customer

* 2. Please review and comment,the above inspection & Test Plan ( ITP ) is considered acceptable if there is no response from client

within 2 weeks from the ITP date.

Вам также может понравиться

- Section 2 QAP, Cable TrayДокумент3 страницыSection 2 QAP, Cable TrayveerendraОценок пока нет

- Steel TankДокумент4 страницыSteel TankRanu JanuarОценок пока нет

- Itp For Installation of Pressurization UnitДокумент1 страницаItp For Installation of Pressurization UnitvictorОценок пока нет

- Chemical Resistance (LLDPE) PDFДокумент24 страницыChemical Resistance (LLDPE) PDFrubyshreeОценок пока нет

- Sample - Template - Itp For Piping Fabrication and InstallationДокумент2 страницыSample - Template - Itp For Piping Fabrication and Installationmohd as shahiddin jafriОценок пока нет

- M - AC Pipework INSPECTION CHECKLISTДокумент1 страницаM - AC Pipework INSPECTION CHECKLISTmandelaria01Оценок пока нет

- FM-16 Material Verification RecordДокумент1 страницаFM-16 Material Verification RecordBleep NewsОценок пока нет

- ITP For Hydraulic BarrierДокумент4 страницыITP For Hydraulic Barriermoytabura96Оценок пока нет

- Quality Assurance Protocol: Raw MaterialДокумент2 страницыQuality Assurance Protocol: Raw MaterialShah Newaz KabirОценок пока нет

- Bolt Tightening ReportДокумент1 страницаBolt Tightening ReportMahfudRido'iRonggomaniaОценок пока нет

- AYC IC & ITP - GRP Shade InstallationДокумент7 страницAYC IC & ITP - GRP Shade Installationmoytabura96Оценок пока нет

- Itp For Storage TanksДокумент7 страницItp For Storage TanksHamid MansouriОценок пока нет

- QAQC Form - ArchitechtureДокумент42 страницыQAQC Form - ArchitechtureMohammad Hadoumi SaldanОценок пока нет

- Itp Pipe SupportsДокумент4 страницыItp Pipe SupportskamlОценок пока нет

- 1.13 Inspection & Test PlansДокумент1 страница1.13 Inspection & Test Plansabimanyubawono100% (2)

- 2018-01-15 Kasuari WTP Erection & Installation ProcedureДокумент6 страниц2018-01-15 Kasuari WTP Erection & Installation ProcedureavriamandaОценок пока нет

- Flange Face Inspection Record CCPP R5Документ1 страницаFlange Face Inspection Record CCPP R5asfaruk2556100% (1)

- Burckhardt Compression (India) PVT - LTD.: 1.0 MaterialsДокумент2 страницыBurckhardt Compression (India) PVT - LTD.: 1.0 MaterialsYOGESHОценок пока нет

- Inspection Test Plan For Pipeline JobsДокумент6 страницInspection Test Plan For Pipeline Jobsمحمد أزها نو الدينОценок пока нет

- 5 - Tank Itp - Inspection & Test Plan For TanksДокумент9 страниц5 - Tank Itp - Inspection & Test Plan For Tanksmandi100% (1)

- Vishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124Документ2 страницыVishwabalaa Engineering Private Limited, Thirumazhisai, Chennai - 600124sanil50% (2)

- Inspection Checklist For: Control ValvesДокумент2 страницыInspection Checklist For: Control Valvesabdelkader benabdallahОценок пока нет

- Piping Fabrication Installation QCP On SiteДокумент1 страницаPiping Fabrication Installation QCP On SiteTarun PatelОценок пока нет

- Inspection and Test Plan Rev.0Документ3 страницыInspection and Test Plan Rev.0คุณพ่อน้อง บิ๊กบอสОценок пока нет

- RT ReportДокумент4 страницыRT ReportWeldcast Ndt100% (1)

- Hydrotest ProcedureДокумент6 страницHydrotest Procedurebagusu_6Оценок пока нет

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Документ4 страницыTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuОценок пока нет

- Hydrotest Form 1Документ2 страницыHydrotest Form 1jrod915Оценок пока нет

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauДокумент10 страницInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priОценок пока нет

- Mechanical Equipment TestingДокумент12 страницMechanical Equipment TestingChemi YeОценок пока нет

- Check List For Installation of Local Instruments.Документ1 страницаCheck List For Installation of Local Instruments.Jaya SeelanОценок пока нет

- Itp - Tanks - 01Документ10 страницItp - Tanks - 01ravigurajapuОценок пока нет

- FAT (Factory Acceptance Test)Документ4 страницыFAT (Factory Acceptance Test)MohamedОценок пока нет

- Construction Leak Test ProcedureДокумент9 страницConstruction Leak Test Procedurezack zeeartОценок пока нет

- ITP For Steel Structure1Документ3 страницыITP For Steel Structure1吴兴泊Оценок пока нет

- 201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0Документ1 страница201485-25000-QP-01-B Inspection Test Plan (ITP) For FRP Tank R0muchamad yasin100% (1)

- Material Receiving Inspection ReportДокумент2 страницыMaterial Receiving Inspection Reporttuan mai vanОценок пока нет

- ITP For Duct WorkДокумент1 страницаITP For Duct WorktreyОценок пока нет

- Ug PipingДокумент1 страницаUg PipingVinoth KumarОценок пока нет

- Storage Tank Shell Banding Quality Control and Inspection Report FormДокумент1 страницаStorage Tank Shell Banding Quality Control and Inspection Report FormAlif Rahmat FebriantoОценок пока нет

- LOG-563-03 Receiving Inspection Checklist Rev.1Документ1 страницаLOG-563-03 Receiving Inspection Checklist Rev.1Emy SumartiniОценок пока нет

- ONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCДокумент34 страницыONS-09-0-PR-5254 - R3 ITP For Atmospheric Tank Work - AFCshankarmech04@gmail.comОценок пока нет

- ITP Format For New PVДокумент8 страницITP Format For New PVDavid LambertОценок пока нет

- Check List For DI Pipe InstallationДокумент1 страницаCheck List For DI Pipe InstallationSaifur Rahman0% (1)

- Hydrotest QI304-sampleДокумент3 страницыHydrotest QI304-sampleHanuman Rao100% (1)

- FGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDДокумент10 страницFGD Project at 2X 525 MW MPL: Document Title: FQP For General Structural Works of FGDBhanu Pratap Choudhury100% (1)

- MS For Fabrication of Above-Ground Storage TankДокумент8 страницMS For Fabrication of Above-Ground Storage Tankdadz mingiОценок пока нет

- Field Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectДокумент12 страницField Mechanical Work Inspection & Test Plan: Job No.: Owner: Client: ProjectbasukiОценок пока нет

- Inspection and Test Plan (Itp) For Fabrication Pressure VesselДокумент1 страницаInspection and Test Plan (Itp) For Fabrication Pressure VesselNikki RobertsОценок пока нет

- Diaphragm Pumps SOWДокумент30 страницDiaphragm Pumps SOWalliancemarine2011Оценок пока нет

- LAser Alignment ChecklistДокумент1 страницаLAser Alignment ChecklistAnand Narayanan100% (1)

- 5 - Tank Itp - Inspection & Test Plan For TanksДокумент10 страниц5 - Tank Itp - Inspection & Test Plan For TanksAhmed Hassan100% (2)

- Itp PipingДокумент40 страницItp PipingBUDAPESОценок пока нет

- IRN For QC 64210-1 Ansao Venturi Pin (1-800)Документ1 страницаIRN For QC 64210-1 Ansao Venturi Pin (1-800)Senthil KumarОценок пока нет

- QAP Format - QA 01 F 01Документ1 страницаQAP Format - QA 01 F 01Murukan PadmanabhanОценок пока нет

- Itp Piping PDFДокумент4 страницыItp Piping PDFdashОценок пока нет

- ITP - OF - Structural Work FOR PARADEEPДокумент4 страницыITP - OF - Structural Work FOR PARADEEPRajeev KumarОценок пока нет

- (A) Dimensions: (D) Cupping TestДокумент5 страниц(A) Dimensions: (D) Cupping Testanon_115606397100% (7)

- SWCДокумент56 страницSWCNageswar RaoОценок пока нет

- Physical Inspection Report On Hardware - Fittings Components.Документ20 страницPhysical Inspection Report On Hardware - Fittings Components.რაქსშ საჰაОценок пока нет

- Australian Standard: Steel Tanks For Flammable and Combustible LiquidsДокумент7 страницAustralian Standard: Steel Tanks For Flammable and Combustible Liquidswidhisaputrawijaya0% (2)

- ANSI Standard Pipe ChartДокумент4 страницыANSI Standard Pipe ChartwidhisaputrawijayaОценок пока нет

- Amberlite™ Xad7Hp: Industrial Grade Polymeric AdsorbentДокумент5 страницAmberlite™ Xad7Hp: Industrial Grade Polymeric AdsorbentwidhisaputrawijayaОценок пока нет

- 0EEA06 Calculation of Flow Rate For Orifice Venturi or Flow Nozzle Meter Si UnitsДокумент18 страниц0EEA06 Calculation of Flow Rate For Orifice Venturi or Flow Nozzle Meter Si UnitswidhisaputrawijayaОценок пока нет

- PE-D-ln10-422.002-PS-DAS-002-D0-E WTIS - DATA SHEET FOR CLOSED DRAIN ...Документ6 страницPE-D-ln10-422.002-PS-DAS-002-D0-E WTIS - DATA SHEET FOR CLOSED DRAIN ...widhisaputrawijayaОценок пока нет

- ANSI Standard Pipe ChartДокумент4 страницыANSI Standard Pipe ChartwidhisaputrawijayaОценок пока нет

- Cost Calculations: Conditions For The Pipe System Piping SystemДокумент3 страницыCost Calculations: Conditions For The Pipe System Piping SystemwidhisaputrawijayaОценок пока нет

- Water Content Hydrocarbon GasДокумент1 страницаWater Content Hydrocarbon GaswidhisaputrawijayaОценок пока нет

- Process/Plant EngineerДокумент1 страницаProcess/Plant EngineerwidhisaputrawijayaОценок пока нет