Академический Документы

Профессиональный Документы

Культура Документы

H-FALR-23-1230-001-A, Black Start Up Scenario and Procedures Rev 3

Загружено:

_Anggyaa_Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

H-FALR-23-1230-001-A, Black Start Up Scenario and Procedures Rev 3

Загружено:

_Anggyaa_Авторское право:

Доступные форматы

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

CLIENT

02021 A

PT PERTAMINA (PERSERO)

PROJECT TITLE :

ARUN LNG RECEIVING HUB & REGASIFICATION

TERMINAL

LOCATIONS

BLANG LANCANG, LHOKSEUMAWE, ACEH UTARA

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

31-May-11

Issued for Bidding

FE

IRA

ADN/AB

27-May-11

Issued for Approval

FE

IRA

ADN

20-May-11

Issued for Review

FE

IRA

ADN

09-May-11

Issued for Internal Review

FE

IRA

ADN

REV

DATE

DESCRIPTION

PREPARED

CHECKED

APPROVED

TABLE OF CONTENT

SEC. TITLE

PAGE

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

1.

2.

3.

4.

02021 A

INTRODUCTION.........................................................................................................................3

PROCESS DESCRIPTION...........................................................................................................3

REFERENCE DOCUMENT.........................................................................................................4

OVERALL DESCRIPTION..........................................................................................................4

4.1 SHIP BERTHING/ARM CONNECTION............................................................................4

4.2 SHIP UNLOADING.............................................................................................................4

4.3 LNG STORAGE TANK.......................................................................................................6

4.4 BOIL-OFF HANDLING......................................................................................................9

4.5 VAPORIZER AND SEND OUT SYSTEM........................................................................11

4.6 HOLDING MODE (NO LOADING/UNLOADING)........................................................12

5. BLACK START-UP PROCEDURE............................................................................................13

5.1 PURPOSE...........................................................................................................................13

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

5.2 INITIAL START UP OVERVIEW.....................................................................................14

5.3 STEP BY STEP START-UP ARUN LNG RECEIVING - HUB REGASIFICATION

TERMINAL FACILITY.............................................................................................................15

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

1. INTRODUCTION

This document presents the black Start UP Scenario for the ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL. This philosophy base on availability of existing Arun facilities

especially power management which one will be used for Arun LNG Receiving Hub and

Regasification Terminal .

2. PROCESS DESCRIPTION

The Arun LNG Receiving -Hub & Regasification Terminal is designed to receive LNG

from Tangguh & Badak. The normal production rate is 280 MMSCFD of Send out gas

and expandable to 400 MMSCFD.

LNG from LNG ship is transferred to LNG Storage Tank (F-6001/F-6002/ F-6003/F-

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

6005) by Cargo Pump. The unloading flow rate is 10,000 m 3/hr and 5,000 m3/hr

with discharge pressure cargo pump is 10 barg.

BOG produces increase

significantly when unloading due to heat in leak a long pipe, heat loss in motor

Cargo Pump, and LNG Tank. BOG will be out from top of LNG Tank (F-6001/F-6002/

F-6003/F-6005), BOG will be split become two stream, one stream as BOG Return to

ship and another stream flow to BOG Compressor (K-6801A/BC/D). Discharge BOG

Compressor flows to BOG Cooler (E-7501A) to get outlet temperature 33 0C. It is

used as HP Fuel Gas for Power Generator and PDPA (Local Company of Aceh

Province) and PT. PLN. If there is excess HP Fuel Gas, it is will be recompressed by

BOG Booster Compressor (K-2501A) to 52 kg/cm 2g. Discharge BOG Booster

Compressor will be combined with the outlet LNG Vaporizer to reduce load of LNG

Vaporizer and will be sent to customer.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

LNG is pumped by Primary LNG Transfer Pumps (G-2306 A/B) or LNG Transfer Pump

(G-2304A/B/C) to LNG Vaporizer (E-2302A/B/C) with discharge pressure 52 kg/cm 2g.

LNG will be vaporized until 50C by Sea Water Supply from Sea Water Pumps. Then

vapor LNG will be sent to customer and for fuel gas make up if consumption of HP

Fuel Gas is increasing. It is heated by electric heater to get the temperature of fuel

gas is appropriate with specification of HP fuel gas.

The existing equipment will be reused are including:

1 LNG Loading Dock (Berth-2)

LNG Storage Tank (F-6001/6002/6003/6005)

LNG Circulation Pump (G-6802A/B/C/D/E)

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

BOG Compressor (K-6801 A/B/C/D)

BOG After Cooler (E-7501A)

BOG Booster Compressor (K-2501A)

LNG loading pump (G-6801A/B/C/D/L/M, for HUB Terminal)

As operating experience is acquired, and if conditions warrant, it may be possible to modify

certain procedures to meet a given situation as long as these modifications are in keeping with

safe operating practices and the design limitations of the equipment/system involved.

3. REFERENCE DOCUMENT

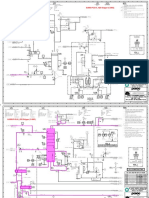

Overall Process Flow Diagram (PFD)

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

Process Flow diagram

Utility Flow diagram

4. OVERALL DESCRIPTION

4.1

SHIP BERTHING/ARM CONNECTION

LNG will be delivered by LNG carriers in the range of 75,000m 3 to 135,000m3 (maximum

size). It is assumed that at ship arrival, the berthing and mooring maneuvers will be

managed by the Port Authorities with the assistance of pilots, tug boats and ship berthing

monitoring system.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

Once the ship has been securely moored to the mooring hooks and communications have

been established, the liquid unloading and vapor return arms can be connected. The ship's

transfer piping and the liquid arms will then be cooled down.

4.2

SHIP LOADING/UNLOADING

The Arun LNG Receiving -Hub & Regasification Terminal is designed to loading /

unloading operation.

SHIP UNLOADING

LNG from the LNG Cargo is pumped into the LNG storage tanks F-6001/6002/

6003/6005 using the Cargo Pumps. In support of the target pilot to pilot port turn-

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

around of 24 hours, discharge times are limited to maximum 18 hours. The

unloading system is therefore based on ship pump discharge pressure 10 barg at

ship rail flange to allow unloading rates of up to 10,000 m/h into four storage

tanks. With higher pumping capacities, the unloading rates can be increased. With

smaller carriers, lower discharge rates are acceptable as the reduced parcel sizes

will still allow discharge times of 18 hours.

Due to the capacities of LNG tankers and storage tanks, four storage tanks are

normally filled in parallel from one ship, with a simultaneous unloading into and

sending-out from both tanks. Since LNG is unloaded into a single LNG storage

tank unloading rates may be limited. The LNG discharged from the tanker is

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

directed to the storage tanks via 24 two parallel lines, then through 30 headers

serving the LNG storage tanks.

The actual unloading rates are established on level indications in the onshore

storage tanks. 20 storage tanks valves allow balancing the flow into each tank. The

quality of LNG being unloaded is monitored on-line via an analyzer located on the

jetty, whilst additional manual sampling always remains open to further spot-check

the LNG qualities in the plant laboratory. The analysis of incoming LNG is done to

supplement the cargo certificates provided with the incoming CIF (Carriage,

Insurance & Freight) LNG to ensure LNG is placed appropriately into the LNG

storage tanks via top or bottom fill nozzles to avoid roll-over risks.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

Fiscal metering of the quantity of LNG unloaded per LNGC will be done based on

tank-dip surveys of the LNGC.

SHIP LOADING

As Hub Terminal, loading operation is required. Loading operation is

performed by LNG Loading Pumps (Pumps G-6801 A~D/L/M) located in

pump station of each tank group. LNG is pumped from LNG Storage Tanks F6001/2 to Berths 2 by LNG Loading Pumps G-6801 A~D/L/M. Each Loading

Pump has a capacity 2,724 m3/hr and the design loading rate of 10,900

m3/hr is achieved by four loading pumps. The LNG flows to the pumps

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

through a 48" header that splits into a 30" branch to each pump. The

discharge from each pump flows through a 20" branch into a 36" header.

Two 30" loading lines connect the Loading Berths to the header.

Three 16" identical arms, each with an Emergency Release Coupling (ERC), are provided

for ship loading/unloading, for LNG transfer from/to the storage tanks. A loading arm V6801C, identical 16" arm, is provided to route displaced gas back from/to the ship. The

maximum loading/unloading rates will be limited to 5,000 m3/h per arm.

Due to the length of the loading/unloading lines and the difference in elevation between the

ship deck and the top of the tank, hydraulic pressure drops through piping systems

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

(inclusive of its auxiliaries such as valves, elbows, and strainers) have been reduced as

much as feasible.

At the end of the ship loading/unloading, the LNG will be purged out of the unloading

arms with nitrogen connected at the top of the arm. The LNG is thus driven back into the

ship and into the 24" unloading header from the arm apex and the arm flanges are

disconnected.

Between LNG tanker arrivals, the heat ingress into the loading/unloading lines is removed

continuously by circulating a part of the send-out LNG through the unloading system. The

circulated LNG is preferably sent to the send-out system to avoid extra BOG generation in

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

the LNG storage tanks, which would trigger extra duty cycles on the BOG compressors and

thus increase the terminal electricity consumption. The line-up allows also the return of

circulated LNG to the storage tanks. Between two ships unloading, the 16" vapor return line

is also connected to the tank vapor space via the boil-off gas header line.

4.3

LNG STORAGE TANK

Four LNG tanks, existing F-6001/6002/6003/6005, each having maximum capacity of

127,000m are provided. The double wall, single containment tank was selected due to

lowest cost and proven record of operation. The working volume is set between a

minimum level at which LNG pumps can run at full capacity up to the net positive suction

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

head limit (NPSH limit), and first high level alarm. There is sufficient land area available

to meet the sitting requirements of NFPA 59A.

The storage tanks are of the single containment type. The tanks have a maximum heat

leakage rate of 0.05 % wt per day of the tank contents based on a full tank of LNG.

All fill and withdrawal connections, and all other instrumentation nozzles are top entry

through the tank roof (and suspended deck where relevant). LNG tanks will be equipped

with a top splash plate for distributing the liquid during top-filling operations and an

internally vented standpipe to accomplish bottom filling.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

The tanks F-6001/6002 are connected to 24 boil-off header. This boil-off header is

connected to the boil-off gas compressors K-6801A/B. The tank F-6003/6005 are

connected to 24 boil-off header ant the through the boil-off gas compressor K-6801C/D.

Two boil-off header connected with 30 common header, but normally connection of them

isolation by manual valve. When unloading partly of boil-off gas from F-6003/6005 split to

the vapor return line to the ship via the vapor return blower K-2302A/B, and to the flare

system if overpressure in BOG line.

The boil-off compressors are two-stage, labyrinth piston type electrically driven

compressors. The maximum duty expected from them is for 2 machines running.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

The boil-off gas blowers are single stage dry centrifugal machines driven by electrical

motors. This blower operates during LNG unloading to keep pressure of ship LNG storage.

The tanks have a design pressure of 0.14 kg/cm 2g. The normal vapor space operating

pressures of the LNG storage tanks will range between 0.04 and 0.1 kg/cm 2g, and this

pressure will generally be controlled by selective operations of the BOG compressors.

During LNGC unloading, the tank pressures are assumed steady at a relatively high level

of 0.12 kg/cm2g, whilst the LNG transfer pumps are designed for a steady low vapor

pressure of 40 mbarg. The boil-off gas compressors are designed for the LNGC unloading

operating mode at highest unloading rate of 10,000m3/h with four storage tanks available in

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

the Terminal at a relatively high constant pressure, without taking any credit for added

vapor suppression by gradual increase in vapor pressure.

LNG storage tanks are provided with protection systems in order to prevent:

Tank over-filling by extensive level gauging with multiple instruments and a

voting regime, acting on different items (e.g. valves & pumps) and coupled to the ESD

1 (shutdown of unloading system)

Over-pressure, primarily via selective operation of BOG compressors, followed

by a pressure control valve releasing excess gas to vent at 1.16 kg/cm 2A kg/cm2g,

installed on top of the tank and ultimately as last line of defence a set of 2 pressure

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

safety valves (PSVs) at set point 1.173 kg/cm 2A on each tank roof. The overpressure

protection covers a combination of atmospheric pressure drop tank rollover (events

such as which is the design case of the PSV's), etc.

LNG stratification in the tanks. Several precaution have been taken in the design

in order to reduce the possibility of rollover considerably, such as the choice to top and

bottom-fill mode together with an extensive temperature / density measuring, a regular

renewal of tank contents, and the option to circulate LNG within the storage tanks (via

local circulation).

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

Vacuum conditions in the storage tanks are prevented initially by tripping the

on-line boil-off gas blowers and BOG compressors, followed by a small injection of

high pressure gas in the common boil-off gas header. The ultimate protection of the

tanks against vacuum is effected by recycling the LNG pumps on their kickback and

finally by a minimum of (4) air vacuum breakers at - 50 mmH2O.

Pump and piping configurations allow for individual tank mixing. Nitrogen injections

arrangements in the tank as well as vent lines are provided for tank drying, purging and

inerting. A cool-down spray ring is provided to initially cool-down the tank to put in

service or to precondition the tank prior to tanker unloading.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

4.4

02021 A

BOIL-OFF HANDLING

SHIP UNLOADING

Filling of LNG into tank, each tank has a capacity of 127,000m 3 (800,000 bbl) is to be top

filling to cool down boil off gas regardless of tank liquid level, loading or no-loading

operation. During filling operation necessary to control the filling rates to each tank by

adjusting valves on laterals to each tank, observing increase rate of tank level.

During ship unloading, the level in the on-shore storage tanks increases causing a vapor

displacement. Simultaneously, the level in the ship cargo tanks decreases at the same rate,

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

causing a negative displacement effect and therefore a pressure drop into the ship's cargo

tank.

To prevent vacuum in the ship's cargo tank, a part of the vapor displaced in the storage tanks

is sent back to the ship by means of vapor return blowers K-2302A/B through the boil-off

header and MBOG Quenching Vessel D-6804, the 16 vapor return line and the vapor return

arm V-6801C.

A LNG atomizer is incorporated in the vapor return line. This facilitates is used to cooldown of temperature vapors at start of return gas flow. When the main steady state return

flows are established, this atomizer ensures that gas returned to the ship can be maintained

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

at a temperature not warmer than -130C. Excess injected liquid is trapped in the jetty

Blowdown drum D-6802, which can also be used for quick draining of one transfer arm in

case of leakage problems.

BOG production increase significantly when unloading due to heat in leak a long pipe, heat

loss in motor Cargo Pump, pressure drop of control valve and from LNG Tank. BOG will be

generated and released to top of LNG Tank. The maximum BOG produced is 65 MMSCFD

(54.3 ton/hr), it will be split in two streams, one stream as BOG return to ship (25

MMSCFD) and another stream sent to BOG Compressor (K-6801 A/B/C/D) which is

condition 2 (two) BOG Compressor running parallel to handle BOG. Discharge BOG

Compressor flows to BOG Cooler (E-7501 A) to get outlet temperature of 33 0C. it is used

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

as HP Fuel Gas for Power Generator (PG) and PDPA (Local Company of Aceh Province)

and PT. PLN. If there is excess HP Fuel Gas, it will be recompressed by BBOG Compressor

will be combined with the outlet of LNG Vaporizer to reduce load of LNG Vaporizer Excess

boil-off gas in the LNG tanks is handled by the boil-off compressors K-6801A/B/C/D and

will be sent to fuel gas system.

NORMAL OPERATION

During normal operation (no ship unloading), boil-off from the storage tank (F6001/6002/6004/6003/6005) is compressed by one of boil-off gas compressor K6801A/B/C/D because total production BOG maximum 12 MMSCFD (9.8 ton/hr). Then

compressed gas is sent to the high pressure fuel gas system. This gives the terminal operator

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

the freedom to run a single compressor continuous in part-load condition, or to lower vapor

pressures at times of cheaper electricity and minimize running the compressors at day time.

The pressure in the storage tank is controlled by operations of the boil-off compressors.

Compressed excess vapors are sent to fuel gas system.

MINIMUM SEND-OUT OPERATION

The minimum send-out will be 70 MMSCFD. This rate allows for boil-off recompression

and for running one of Primary LNG Transfer Pump (G-2306A/B).

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

BOIL-OFF COMPRESSOR

Four boil-off compressors K-6801A/B/C/D are provided for the boil-off handling. During

LNG unloading two BOG compressors are to be operated to cope with the maximum boiloff gas amount 33.5 ton/hr and other for standby. If one of the compressors is trip, then the

standby compressor will be operates manually.

Each compressor with a rated flow rate of 20,820 kg/h is provide to compress LNG boil-off to 16.5

kg/cm2, to be necessary for delivered to the high fuel gas system. Actual amount of boil-off will be

depended on the operating mode.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

The compressor is provided with an anti surge control system which protects the machine

from surging by recycling vapor to the vapor space of the LNG storage tanks. This vapor is

quenched with LNG to be sprayed into the vapor recycle line upstream of the storage tanks

using a series of five LNG atomizing nozzles. Excess gas from the compressor is sent to the

high pressure fuel gas system through FV-6826C. Marine Flare pilot and purge gas is

supplied via 2" line from compressor discharge or from reverse flow from the high pressure

fuel gas system. Quenching LNG is supplied from discharge header of the loading pump or

the circulating pump which is on duty depending on the operation mode.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

4.5 SEND OUT SYSTEM

Normally LNG send-out is pumped from the storage tanks F-6003 or F-6005 by LNG

transfer pump G-2304B (installed in tank F-6003) or G-2304C or Primary LNG Transfer

Pump G-2306B (installed in tank F-6005) and sent to LNG vaporizer E-2302A/B/C. The

pumps of vertical canned types are provided. They are provided with venting and minimum

flow lines returning to the respective LNG tank. Both motor and pump are submerged in the

LNG which provides cooling and lubrication for the bearings and motor windings.

Transport LNG from storage tank to LNG vaporizer using existing header with size 48 in

suction and 12 for discharge. LNG transfer pump G-2304A, are installed in the first tank

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

group which is will be using for HUB terminal. G-2304A will be used if LNG stock from F6003/6005 was limited. A minimum flow bypass line is provided for each pump, the

discharges of which are tied into one common 16" intertank transfer line.

The small foot plinth also assists in minimizing the size of the noise shelter & crane

structure over the booster pump station. The suction header in the LNG transfer pump

station is prepared for a parallel operation of 2 LNG transfer pumps and 2 Primary LNG

Transfer Pump to achieve the maximum daily send-out rate of 400 MMSCFD.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

These pump sets are provided with individual vent pots to release the vapor from pump and

the vapor from the pots is sent back to the individual tank on level control. This line ties into

the boil-off gas recycle line, discharging into the top of the tank above the liquid level.

The gas produced by the vaporizers will split partly to fuel gas system/new costumer

(PDPA) and the fertilizer plants. The gas produced by vaporizers before sent to fuel gas

system and PDPA, it pass through a fuel gas heater E-2303 to maintain temperature as per

fuel gas specification. Then to the fertilizer plants pass through inlet facilities line and gas

metering system before being conveyed to the gas pipeline. There will be a back pressure

controller before the gas metering system to maintain a constant pressure to customer. The

gas metering system consists of three parallel metering lines (one in stand-by). An on-line

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

gas chromatograph for analyzing the gas composition is included within the gas metering

system.

Send out gas that is used within for the terminal, will be taken downstream of the LNG

vaporizer. The gas pressure is reduced before supplying it to the LNG storage tanks for

intermittent make-up as required.

The Terminal is able to adjust its high pressure LNG send-out rate between minimum sendout and maximum send-out by increasing or decreasing as required the number of parallel

operational pumps and vaporizers, and use minimum flow re-circulation loops as required

to trim actual flows. All these send-out capacity changes will be controlled through the PCS

system.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

At times of zero send-out (except when suffering from a prolonged black-out) most

cryogenic line-work in the Terminal will be kept cold via circulation loops from the LNG

tanks to LNG jetty and process area with LNG circulation pumps.

4.6

HOLDING MODE (NO LOADING/UNLOADING)

The LNG loading lines are kept cold during the no loading or unloading mode by

circulating 454 m3/h of LNG from storage tank using one circulation pump in each a

group tank.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

Normally, for the existing berth 2 loading line, cold circulation is performed by one

circulation pump out of two in the first tank group pump station, G-6802A or B. For the

loading line from F-6005 pump station, cold circulation is performed by one circulation

pump out of two in F-6005 pump station, G-6802C or D, and for the loading line from F6003 pump station to the loading lines from F-6005 pumps, one circulation pump will be

used installed in F-6003 pump station, G-6802E.

At zero send-out, no liquid is available for regasification of boil-off in the LNG vaporizers

and the compression system will not be able to accommodate the boil-off gas produced in

the terminal. This implies that vapor pressures within the Terminal will gradually rise, and if

this situation prevails for a longer period (of a few hours) the boil-off is then let-off to the

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

vent system under pressure control. As this situation conflicts with the adopted no venting

philosophies zero send-out should normally be avoided, and only be accepted for

exceptional circumstances, such as a persistent pipeline problem, or a longer black-out.

5.

BLACK START-UP PROCEDURE

5.1

PURPOSE

The purpose of this document is to describe a general philosophy for the initial start-up

of the Arun LNG Receiving Hub Regasification terminal facilities. Detailed

commissioning and start up packages will be developed with the project team during

detailed design and upgraded during construction. It also describes the start up of

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

the facilities following a total plant shutdown and blowdown with the facility

only on emergency power generation, which is referred to as "black start". The

black start procedure is usually completed just before start up. Training and

verification on the procedure takes place during final commissioning of the systems.

The sequence of activities and details of commissioning will be determined during

detailed design. The anticipated duration of each activity will also be defined during

this phase in conjunction with equipment vendors, operations and commissioning

personnel.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

5.2

02021 A

INITIAL START UP OVERVIEW

5.2.1 Purging

Air removal will be required for all systems in hydrocarbon services, including the

flare. Water and nitrogen are the preferred inerting materials and will require

sufficient gas supplies and the use of temporary connections. Nitrogen supply

logistics will be a subject for resolution during detailed design.

5.2.2 Services and Utilities

Start-up requires the following services and utilities to be commissioned and operational:

Emergency systems, DCS, Public address system and fire protection system;

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

Diesel fuel system and distribution

Auxiliary power on diesel fuel and Main Power generation;

Main Instrument air system and portable instrument air package;

Fresh water system and pumps

Fire water system and pumps

Flares, vents.

The flare systems will require that propane or LPG backup to the pilot fuel and

ignition system is commissioned and sufficient supplies of propane are available

until the fuel gas system to the flare pilots is available.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

As a design consideration, the emergency diesel generator shall be sized to

include all the emergency electrical generation loads detailed in the power system

philosophy.

5.2.3 Fuel Gas System

Priority should be given to starting up the fuel gas system to provide fuel to the

Power Generators. Black start power can be initially generated with the essential

LNG small pump and Ambient vaporizer. Since no gas will be available prior to

the start of production flow to the send out system . Fuel gas will be taken from

LNG storage tank. The gas from LNG Storage Tank still in liquid form and need

to be vaporizing using 2 Vaporizer using ambient air temperature, two Air

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

Ambient Vaporizer will operate alternately to ensure reliability of supply fuel

gas.

Vaporize gas will flow from Air Ambient Vaporizer to the Power

Generation PG-9001A through the fuel gas header line.

5.3

STEP BY STEP START-UP ARUN LNG RECEIVING -HUB REGASIFICATION

TERMINAL FACILITY

Initial Start-up Arun LNG receiving terminal Facility or after total shut down using Transfer

pump from storage tanks. The main step during initial Start up or after total shut down can

be done with following execution:

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

There is two option base on LNG availability in LNG Storage Tank :

A. if LNG Storage tank level in Low low condition, cooling down of LNG line and Tank

should be start from LNG Ship at Berth 2. Start Unloading LNG to LNG Storage Tank

until certain Level of LNG at Tank appropriate to starting LNG small Pump.

B. If LNG Storage tank in adequate level to start LNG small pump and Air Ambient

Vaporizer, Start LNG small pump using portable Generator and send out LNG to Air

Ambient Vaporizer to get Fuel gas for running Power Generator A/C

Step By Step for Black Start up

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

1.

02021 A

Conform diesel fuel available for Emergency Power Generator, Diesel Engine at

PG-9001A and Diesel fire Water Pump.

2.

Conform that Power always available for small LNG pump in order to run the

pump and Ambient vaporizer ready for operation.

3.

Confirm fire water pond filled by Well Water Pump with raw water

4.

Conform all safety equipment include PSV, emergency relieve valve, etc at

condition ready for operation if overpressure condition happen.

5.

Conform all ESD system at stand by condition and ready for operation, PSD will

action if deviation un control process happen caused and reach limit high-high or limit

low-low signal activated the process shut down. ESD will activated if un control

process happen and to avoid hazard condition caused of overpressure, badly leakage,

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

02021 A

environmental problem, etc by isolate inlet and outlet hydrocarbon, isolate heat

sources (Electric heater, evaporizer , etc), stop critical equipment by activated ESD

from push button in the control room. Detail explanation about ESD refers to ESD

Philosophy.

6.

Conform that Marine flare stack ready for operation with fuel gas from LNG

Back-up pump G-2305 and LNG Back-up Vaporizer E-2304A/B

7.

Commissioning gas purge to flare header and make sure flare header in positive

pressure and ready for receive gas.

8.

START to Operate Emergency Power Generator for supply power requirement to

Cooling water pump and Fin fan Cooler

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

9.

02021 A

START to Operate Diesel Power Generator for supply power requirement to

LNG Back-up pump.

Note: Diesel Power Generator Designed for 8 hours continuous operation.

10.

Ensure that power available for supply power for LNG Back-up pump and get

fuel gas system from Ambient vaporizer.

11.

Line up the system ,and start to run LNG Back-up pump G-2305

12.

Start 1 Power Generator (PG-9001A) for supplying electrical power to LNG

Circulation pump and BOG Compressor including cooling water system.

13.

Start LNG Circulation pump and BOG compressor for continuous fuel gas

supply to Power Generation A, then stop Emergency Power Generator.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

14.

02021 A

Conform Plant Fire Protection include Fire Water system and F&G detector are

in operation.

15.

Conform Power Generation C at standby position and ready for operation if

needed.

16.

Utility Units include Air system, Fire Protection systems, Fuel gas conditioning

include fuel gas electric heater, Power generator, Diesel system, Sea Water Cooling

system and Flare system are in operation.

17.

Conform Sea Water line and pump available and ready for operation

18.

Start Sea Water Pump and circulating line to LNG Vaporizer until operating

condition

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

19.

02021 A

Start LNG Circulating Pump to cooling down all LNG line gradually to

operating condition.

20.

Starts pressurize BOG Compressor System until reach suction operation pressure of

BOG compressor used manual by pass valve slowly (keep pressure stable by venting

to flare by pressure control if pressure increased suddenly)

21.

Start sealing gas for BOG compressor, lube oil pump, then make sure seal gas and

lube oil system on stable condition

22.

Start BOG Compressor with follow the step chart of BOG compressor start up and

make sure anti surging valve working well.

23.

Conform fuel gas supply to Main Power Generator A and to flare are in normal

condition and under control.

ARUN LNG RECEIVING HUB &

REGASIFICATION TERMINAL

Doc. No. : H-FALR-23-1230-001-A

BLACK START-UP SCENARIO AND PROCEDURES

KLIENT:

KONTRAKTOR:

NAMA PROYEK :

LOKASI PROYEK :

Rev. No.

: 3

Page

: of 15

PT. PERTAMINA (PERSERO)

PT. INTI KARYA PERSADA TEHNIK

PROYEK PEMBANGUNAN FASILITAS PENGUMPUL GAS MERBAU

DAN

FASILITAS

PENYERAHAN

GAS

PAGARDEWA

DOH

SUMBAGSEL (PAKET-III)

LAPANGAN MERBAU PAGARDEWA,

DAERAH OPERASI HULU (DOH) SUMBAGSEL,

INDONESIA

NOMOR

PROYEK :

24.

02021 A

Conform LNG Transfer pump and line ready to operation after cooling down to

normal operating condition.

25.

Start LNG Transfer Pump to LNG vaporizer to produce Gas for Client and ensure

continuous flow fuel gas to Power Generation.

Вам также может понравиться

- PP Aaa PP1 112Документ22 страницыPP Aaa PP1 112Rabah AmidiОценок пока нет

- PP Aaa PP1 109Документ18 страницPP Aaa PP1 109Rabah AmidiОценок пока нет

- PP Aaa PP1 110Документ16 страницPP Aaa PP1 110Rabah AmidiОценок пока нет

- PP Aaa PP1 150Документ17 страницPP Aaa PP1 150Rabah AmidiОценок пока нет

- PP Aaa PP1 117Документ15 страницPP Aaa PP1 117Rabah AmidiОценок пока нет

- PP Aaa PP1 132Документ20 страницPP Aaa PP1 132Rabah Amidi100% (1)

- PP Aaa PP1 121Документ20 страницPP Aaa PP1 121Rabah AmidiОценок пока нет

- PP Aaa PP1 115Документ40 страницPP Aaa PP1 115Rabah AmidiОценок пока нет

- PP Aaa PP1 147Документ9 страницPP Aaa PP1 147Rabah AmidiОценок пока нет

- PP Aaa PP1 106Документ36 страницPP Aaa PP1 106Rabah AmidiОценок пока нет

- Sag15010 P 02F 0023 PDFДокумент142 страницыSag15010 P 02F 0023 PDFrizwan khanОценок пока нет

- RDMP Ru V Balikpapan: Piping & Instrument Diagram Refinery Fuel Oil & Fuel Gas System Distribution System To Plant 2Документ1 страницаRDMP Ru V Balikpapan: Piping & Instrument Diagram Refinery Fuel Oil & Fuel Gas System Distribution System To Plant 2dian yuristiaОценок пока нет

- PP Aaa PP1 145Документ13 страницPP Aaa PP1 145Rabah AmidiОценок пока нет

- PCRP Rev 1 g1-Nt-plnx0000303.PDF - SFLBДокумент63 страницыPCRP Rev 1 g1-Nt-plnx0000303.PDF - SFLBal bauerОценок пока нет

- Lesson 2 Rev Introduction To Power PlantДокумент53 страницыLesson 2 Rev Introduction To Power Plantfelix asadeОценок пока нет

- Worley Parsons - Balikpapan Project Overview - 2020Документ4 страницыWorley Parsons - Balikpapan Project Overview - 2020Vraja DasiОценок пока нет

- Haryana Power 800mwДокумент61 страницаHaryana Power 800mwprakashkumarsinghgkp01Оценок пока нет

- PP Aaa PP1 105Документ21 страницаPP Aaa PP1 105Rabah AmidiОценок пока нет

- PP Aaa PP1 111Документ18 страницPP Aaa PP1 111Rabah AmidiОценок пока нет

- Shut Down LP Compressor C-2650Документ12 страницShut Down LP Compressor C-2650adi SaputraОценок пока нет

- Catalysis in A RefineryДокумент54 страницыCatalysis in A RefineryJacqueline WoodsОценок пока нет

- PP Aaa PP1 127Документ36 страницPP Aaa PP1 127Rabah AmidiОценок пока нет

- PP Aaa PP1 131Документ33 страницыPP Aaa PP1 131Rabah AmidiОценок пока нет

- 12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksДокумент12 страниц12.PDE-CMG-G000-EC-00003 - 000 - 02 - ES Welding of Storage TanksIonut FloricaОценок пока нет

- Ethanol Plant Commissioning Startup and ShutdownДокумент5 страницEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083Оценок пока нет

- Energy World - Sengkang LNGДокумент267 страницEnergy World - Sengkang LNGtcandelario100% (1)

- PP Aaa PP1 107Документ18 страницPP Aaa PP1 107Rabah AmidiОценок пока нет

- PP Aaa PP1 102Документ29 страницPP Aaa PP1 102Rabah AmidiОценок пока нет

- VA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Документ1 страницаVA1-LLM18-00100-GE-M8-PRO-00005 Rev.A (Cover)Anonymous JtYvKt5XEОценок пока нет

- Vv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationДокумент30 страницVv31g0-002-A-105 - 1 - 001 Method Statement For Piping and Equipments InstallationPhong ĐỗОценок пока нет

- Mechanical Data Sheet For 73-T105C/D Light Naphtha Storage TankДокумент9 страницMechanical Data Sheet For 73-T105C/D Light Naphtha Storage TankGorkem DoraОценок пока нет

- DSISPP TS - MS - 004 Tendon Stressing Without JSEA& RD 20.04.21Документ56 страницDSISPP TS - MS - 004 Tendon Stressing Without JSEA& RD 20.04.21Panha PorОценок пока нет

- PP Aaa PP1 149Документ14 страницPP Aaa PP1 149Rabah AmidiОценок пока нет

- Specification For Control System (DCS) : Final IssueДокумент38 страницSpecification For Control System (DCS) : Final Issueanon_951110102Оценок пока нет

- PreComm-Comm & RR Execution Plan Rev 0 PDFДокумент22 страницыPreComm-Comm & RR Execution Plan Rev 0 PDFMaulana HaniefОценок пока нет

- Sonatrach: JOB NO.: J6404Документ56 страницSonatrach: JOB NO.: J6404Rabah AmidiОценок пока нет

- PP Aaa PP1 162Документ40 страницPP Aaa PP1 162Rabah AmidiОценок пока нет

- 15no03 Ds 020 010 Emergency Diesel GeneratorДокумент11 страниц15no03 Ds 020 010 Emergency Diesel Generatorbagus handokoОценок пока нет

- PP Aaa PP1 108Документ18 страницPP Aaa PP1 108Rabah AmidiОценок пока нет

- VS2158-260-A-800 1 Compressor Installation ManualДокумент114 страницVS2158-260-A-800 1 Compressor Installation ManualLongTuanОценок пока нет

- Australia Pacific LNG ProjectДокумент78 страницAustralia Pacific LNG ProjectkrishnaОценок пока нет

- Laporan Hyrant and Springkle System R3Документ44 страницыLaporan Hyrant and Springkle System R3Wacoman RazanОценок пока нет

- Cause and Effect Diagram: Doc No.: IONE-VP-02-K-001-005Документ9 страницCause and Effect Diagram: Doc No.: IONE-VP-02-K-001-005ضياء محمدОценок пока нет

- Technical Bid No 1Документ235 страницTechnical Bid No 1kaushalОценок пока нет

- Witness Joint & Sampling MatrixДокумент13 страницWitness Joint & Sampling MatrixPazhamalai RajanОценок пока нет

- Att#20 - 7077T-000-PP-0000-108 - 00 List of Codes and StandardsДокумент62 страницыAtt#20 - 7077T-000-PP-0000-108 - 00 List of Codes and Standardsabdelmalek boudjemaaОценок пока нет

- White Paper Repurposing Pipelines HydrogenДокумент21 страницаWhite Paper Repurposing Pipelines Hydrogentopspeed1100% (1)

- B-XX - XXX - O - Technical Specification For Pipeline ValvesДокумент20 страницB-XX - XXX - O - Technical Specification For Pipeline ValvesEmmanuel Lawrence100% (1)

- 12 00 Pi SPC 00022Документ12 страниц12 00 Pi SPC 00022Erdal CanОценок пока нет

- NGL Extraction TechnologiesДокумент10 страницNGL Extraction Technologieswylie010% (1)

- 05 FS GduДокумент18 страниц05 FS GduAnonymous O0lyGOShYGОценок пока нет

- SNBP2-00-MEC-RFQ-009 - Reva RFQ For Instrument Air Receiver Rev - PatraДокумент13 страницSNBP2-00-MEC-RFQ-009 - Reva RFQ For Instrument Air Receiver Rev - PatraRisyda PutriОценок пока нет

- Val RepДокумент175 страницVal RepRdy SimangunsongОценок пока нет

- 2302036-Gl-In-001 Feasibility Report For Water and Power Supply - Rev0Документ46 страниц2302036-Gl-In-001 Feasibility Report For Water and Power Supply - Rev0benjamin britoОценок пока нет

- LPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1Документ8 страницLPBFP - Sizing Calculation LP HRSG Feed Pump - Doc PG DC 292 100 d603 - R 1anbesivam87_49857255Оценок пока нет

- N-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Документ9 страницN-0900-P-03-01 - H2S Stripper (C-0903) : Z-0901 D-0915X E-0913 D-0909Darrel Espino AranasОценок пока нет

- Adani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaДокумент34 страницыAdani House, NR Mithakhali Circle, Navrangpura, Ahmedabad 380 009, Gujarat, IndiaphanikrishnabОценок пока нет

- PP Aaa PP1 123Документ20 страницPP Aaa PP1 123Rabah AmidiОценок пока нет

- Mac LS 0 002 0Документ4 страницыMac LS 0 002 0arifayee-1Оценок пока нет

- 01 - Doc and Drawing Register - MOGS-Botling Plant Dtd. 04.1.12Документ6 страниц01 - Doc and Drawing Register - MOGS-Botling Plant Dtd. 04.1.12SaraswatapalitОценок пока нет

- Nace Mr0175Документ37 страницNace Mr0175_Anggyaa_Оценок пока нет

- Fire Assesment AnalysisДокумент53 страницыFire Assesment Analysis_Anggyaa_Оценок пока нет

- 1492Документ15 страниц1492_Anggyaa_Оценок пока нет

- Seabed Model Data SheetДокумент2 страницыSeabed Model Data Sheet_Anggyaa_Оценок пока нет

- FINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Документ45 страницFINAL VERSION On Assessment Tool For CDCs LCs Sept. 23 2015Edmar Cielo SarmientoОценок пока нет

- Clinical Skills TrainingДокумент12 страницClinical Skills TrainingSri Wahyuni SahirОценок пока нет

- Diagnosis ListДокумент1 страницаDiagnosis ListSenyorita KHayeОценок пока нет

- Communication Skill - Time ManagementДокумент18 страницCommunication Skill - Time ManagementChấn NguyễnОценок пока нет

- Solutions DPP 2Документ3 страницыSolutions DPP 2Tech. VideciousОценок пока нет

- Chapter 4: Thermal ComfortДокумент16 страницChapter 4: Thermal ComfortWengelОценок пока нет

- Module 7 NSTP 1Документ55 страницModule 7 NSTP 1PanJan BalОценок пока нет

- Revenue Memorandum Circular No. 55-2016: For ExampleДокумент2 страницыRevenue Memorandum Circular No. 55-2016: For ExampleFedsОценок пока нет

- Measuring Road Roughness by Static Level Method: Standard Test Method ForДокумент6 страницMeasuring Road Roughness by Static Level Method: Standard Test Method ForDannyChaconОценок пока нет

- Aircraft Wiring Degradation StudyДокумент275 страницAircraft Wiring Degradation Study320338Оценок пока нет

- Fuentes v. Office of The Ombudsman - MindanaoДокумент6 страницFuentes v. Office of The Ombudsman - MindanaoJ. JimenezОценок пока нет

- This Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiДокумент7 страницThis Is A Short Presentation To Explain The Character of Uncle Sam, Made by Ivo BogoevskiIvo BogoevskiОценок пока нет

- PM 50 Service ManualДокумент60 страницPM 50 Service ManualLeoni AnjosОценок пока нет

- Worked Solution Paper5 A LevelДокумент8 страницWorked Solution Paper5 A LevelBhoosan AncharazОценок пока нет

- Extraction of Mangiferin From Mangifera Indica L. LeavesДокумент7 страницExtraction of Mangiferin From Mangifera Indica L. LeavesDaniel BartoloОценок пока нет

- Role of Communication at Mahabharatha WarДокумент19 страницRole of Communication at Mahabharatha WarAmit Kalita50% (2)

- Oil List: Audi Front Axle DriveДокумент35 страницOil List: Audi Front Axle DriveAska QianОценок пока нет

- Ppap - 2556 PDFДокумент7 страницPpap - 2556 PDFMohamed ElmakkyОценок пока нет

- Learning Competency PDFДокумент1 страницаLearning Competency PDFLEOMAR PEUGALОценок пока нет

- Partnership Digest Obillos Vs CIRДокумент2 страницыPartnership Digest Obillos Vs CIRJeff Cadiogan Obar100% (9)

- Monitor 14sepДокумент2 страницыMonitor 14sepabhaymvyas1144Оценок пока нет

- CV Ashish PDFДокумент3 страницыCV Ashish PDFRoshan KejariwalОценок пока нет

- Written Report SampleДокумент16 страницWritten Report Sampleallanposo3Оценок пока нет

- Punches and Kicks Are Tools To Kill The Ego.Документ1 страницаPunches and Kicks Are Tools To Kill The Ego.arunpandey1686Оценок пока нет

- The Phases of The Moon Station Activity Worksheet Pa2Документ3 страницыThe Phases of The Moon Station Activity Worksheet Pa2api-284353863100% (1)

- Kallatam of Kallatar (In Tamil Script Tscii Format)Документ78 страницKallatam of Kallatar (In Tamil Script Tscii Format)rprabhuОценок пока нет

- ACC030 Comprehensive Project April2018 (Q)Документ5 страницACC030 Comprehensive Project April2018 (Q)Fatin AkmalОценок пока нет

- EC 2012 With SolutionsДокумент50 страницEC 2012 With Solutionsprabhjot singh1Оценок пока нет

- Post Renaissance Architecture in EuropeДокумент10 страницPost Renaissance Architecture in Europekali_007Оценок пока нет

- Collecting, Analyzing, & Feeding Back DiagnosticДокумент12 страницCollecting, Analyzing, & Feeding Back DiagnosticCaroline Mariae TuquibОценок пока нет