Академический Документы

Профессиональный Документы

Культура Документы

Preparation and UV-light Absorption Property of Oleic Acid Surface Modified ZnO Nanoparticles

Загружено:

YeeXuan TenАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Preparation and UV-light Absorption Property of Oleic Acid Surface Modified ZnO Nanoparticles

Загружено:

YeeXuan TenАвторское право:

Доступные форматы

CHEM. RES.

CHINESE UNIVERSITIES 2011, 27(3), 500502

Preparation and UV-light Absorption Property of Oleic

Acid Surface Modified ZnO Nanoparticles

KANG Jong-hun1,2, GUO Yu-peng2, CHEN Yue2 and WANG Zi-chen2*

1. Pyongyang Printing Industry University, Pyongyang, DPRK;

2. College of Chemistry, Jilin University, Changchun 130021, P. R. China

Abstract Syntheses of zince oxide(ZnO) nanoparticles by direct precipitation and surface modification with oleic

acid were reported. ZnO nanoparticles were characterized via X-ray diffractometry(XRD), transmission electron

microscopy(TEM), infrared spectroscopy(IR) and UV-Vis spectroscopy. The prepared ZnO nanoparticles were nearly

spherical and highly crystalline with an average size of 29 nm. In addition, high UV-light absorption properties of

oleic acid surface modified ZnO nanoparticles were successfully obtained for a dispersion of ZnO nanoparticles in

ethanol.

Keywords ZnO nanoparticle; Oleic acid; Modification; UV-light absorption; Dispersion

Article ID 1005-9040(2011)-03-500-03

Introduction

Zinc oxide(ZnO) nanoparticles have attracted much interest because they possess various remarkable physical and

chemical properties that are distinct from those of conventional

bulk materials. ZnO is widely used for cosmetic application

because it is a chemically stable and environmentally friendly

material that has good transparency and UV-blocking properties[13]. Different synthesis methods have been devised,

including sol-gel technique[4], microemulsion synthesis[5], mechanochemical processing[6], spray pyrolysis and drying[7,8],

thermal decomposition of organic precursor[9], RF plasma synthesis[10], supercritical-water processing[11], selfassembling[12],

hydrothermal processing[13], vapor transport process[14], sonochemical or microwave-assisted synthesis[15,16], direct precipitation[17] and homogeneous precipitation[18]. However, ZnO in

nanoparticles due to the existence of water molecules results in

hard agglomerates, which impede the application of ZnO

nanoparticles. Therefore, the removal of water moiety in the

nanoparticles is a key process for reducing hard agglomerates.

The modification of nanoparticles to enhance the surface

chemical and physical properties is the key for the successful

application of nanomaterials. Oleic acid is commonly used to

modify SiO2[19], TiO2[20], CaCO3[21], CuS[22], ZnO[23]. In particular, surface-modified ZnO particles received much attention

because of enhanced dispersability in fluids. In the present investigation, the precursor of ZnO nanoparticles was prepared

by precipitation from the solutions of zinc chloride and sodium

carbonate in the presence of surfactant and ZnO nanoparticles

were obtained after calcination. On one hand, the surface of

ZnO nanoparticles was modified with oleic acid to improve the

compatibility between inorganic nanoparticles and organic

matrix. Furthermore, the UV-light absorption property of a ZnO

nanoparticle-ethanol dispersion was also evaluated. The nanoparticles were characterized with infrared spectroscopy(IR),

transmission electron microscopy(TEM), X-ray photoelectron

spectrometry(XPS) and UV-Vis spectroscopy.

2

2.1

Experimental

Materials

Zinc chloride(ZnCl2), sodium carbonate(Na2CO3), sodium

dodecylbenzenesulfonate(SDBS), toluene, cyclohexane, dioctyl

phthalate(DOP), n-hexane and deionized-water were used in

the experiments. All the reagents used were analytical grade.

2.2

Synthesis of Nanosized ZnO

ZnO nanoparticles were synthesized by the reaction of

ZnCl2 with Na2CO3 aqueous solution. ZnCl2 and Na2CO3 were

dissolved in deionized-water to form solutions with certain

concentrations, the surfactant SDBS added into Na2CO3

aqueous solution, its concentration was 3 mmol/L. First of all,

100 mL of 0.8 mol/L ZnCl2 aqueous solution was added into a

three-neck flask, and then the temperature was raised to 80 C

in a water bath. Next, 100 mL of 0.67 mol/L Na2CO3 aqueous

solution including SDBS was added dropwise slowly to it

under continuous stirring. Last, the temperature was held at

80 C for 40 min. The precipitate was collected by filtration

and washed with distilled water and absolute ethanol for several times. Then the precipitate was dried at 80 C under vacuum

for 12 h to have the precursor ready. Afterwards the precursor

calcinated at 400 C for 2 h to obtain the ZnO nanoparticles.

2.3

Surface Modification with Oleic Acid

For the surface modification with oleic acid, the amount of

*Corresponding author. E-mail: wangzc@jlu.edu.cn

Received May 17, 2010; accepted June 13, 2010.

Supported by the Key Project of the National Eleventh Five-Year Research Programe of China(No.2008BAE66B00).

No.3

KANG Jong-hun et al.

oleic acid was varied in the experiments. Typically, oleic acid

of 0.05 g was dissolved in 100 mL of absolute ethanol in a

flask to form the solution, and the mass ratio of oleic acid to

ZnO is 5%. The above ZnO nanoparticles of 1 g were then

added to the solution to react for 2 h at 60 C under stirring.

The particles were collected by filtration and washed with distilled water and absolute ethanol for several times, then dried at

50 C for 24 h.

2.4

LD =

V

100%

V + 50

Particle Characterization

Fourier transform infrared(FTIR) analysis was performed

on FTIR-8400S(Shimadzu, Japan) with KBr method. X-ray

diffraction(XRD) analysis for powders was performed on

XRD-6000(Shimadzu, Japan). The size and shape of nanoparticles were determined under a transmission electron microscope JEM-1200EX(JEOL, Japan). UV-Vis absorption of ZnO

nanoparticles was measured on a UV-2550 spectrophotometer

(Shimadzu, Japan) by dispersing nanoparticles in ethanol.

3

3.1

half-maximum, and is the Bragg diffraction angle. The XRD

peak (101) gives an average diameter of about 29 nm for ZnO

nanoparticles.

Fig.2 illustrates the TEM images of ZnO nanoparticles

without surface modification. ZnO nanoparticles consist mainly

of nearly spherical particles of a size of about 29 nm.

Measurement of Lipophilic Degree

The lipophilic degree(LD) of ZnO nanoparticles was characterized by dispersing the nanoparticles of 0.5 g in water of

50 mL with the addition of methanol[16]. When ZnO nanoparticles were put into distilled water, the unmodified ZnO nanoparticles precipitated in water, while the modified ZnO nanoparticles which grafted with oleic acid, floated on the water

surface. When methanol was dropped into the water slowly

with continually stirring, the modified ZnO nanoparticles were

wetted and hence precipitated gradually. The volume of the

methanol(V) used was recorded and the LD was calculated

according to the following equation:

2.5

501

Results and Discussion

Fig.2

3.2

TEM image of ZnO nanoparticles

Surface Modification with Oleic Acid

The surface groups of ZnO nanoparticles before and after

modification were characterized by IR.

Fig.3 curves ac show the FTIR spectra of non-modified

ZnO nanoparticles, oleic acid modified ZnO nanoparticles

(OA-ZnO) and modification agent OA, respectively.

In Fig.3 curve a, the peak at 3438 cm1 shows that the

stretching vibration of the OH group is present in the

non-modified ZnO nanoparticles. In Fig.3 curve c, the peak at

1729 cm1 corresponds to COOH in OA. In Fig.3 curve b,

OA-ZnO corresponding to carboxylate appears, the strong

symmetric carboxylate stretching bands of oleate at 1402 and

1461 cm1, the asymmetric carboxylate stretching band of

oleate at 1551 cm1, and the peaks at 2926 and 2855 cm1 corresponding to long alkyl chain of OA were all found in the

FTIR spectrum of OA-ZnO. Thus, it can be concluded that the

OA-COOH has reacted with OH on the surface of ZnO, and

the product is carboxylate.

Characterization of ZnO Nanoparticles

The XRD pattern of ZnO nanoparticles is illustrated in

Fig.1. All the peaks can be well indexed to the zincite phase of

ZnO(International Center for Diffraction Data, JCPDS No. 361451). No peaks from other phase of ZnO and impurities were

observed, suggesting that high-purity ZnO was obtained.

Fig.3

Fig.1 XRD pattern for ZnO nanoparticles

The ZnO particle diameter D was calculated via the

Debye-Sherrer formula D=K/(cos), where K is Sherrer constant, is the X-ray wavelength, is the peak width of

IR spectra of non-coated ZnO nanoparticles(a),

oleic acid modified ZnO nanoparticles(b) and

modification agent OA(c)

The influence of the mass ratio of oleic acid to ZnO(%) on

lipophilic degree(LD) is illustrated in Fig.4.

As shown in Fig.4, the LD increases with increasing the

amount of OA when the amount of oleic acid is less than 4%;

when the amount increases above 4%, the LD decreases. This

indicates that OA reached the saturation of single-molecularlayer adsorption when the amount of OA was 4%, and higher

amount of OA have no effect on improving the LD. When the

amount of OA increases further, the long chain of OA entangles

502

CHEM. RES. CHINESE UNIVERSITIES

Fig.4 Influence of the amount of oleic acid on

modification effect

with each other, hindering the carboxyl group(COOH) of OA

to react with the hydroxide group on the surface of ZnO nanoparticles. The characteristics of oleic acid modified ZnO nanoparticles are shown in Table 1. The dispersabilities of T1 in

organic solvents were significantly improved compared with

that of non-modified ZnO nanoparticles.

Table 1

Run

Vol.27

Conclusions

Syntheses of zinc oxide nanomaterials by direct precipitation and surface modification with oleic acid have been reported. Furthermore, the UV absorption property of a ZnO

nanoparticle-ethanol dispersion was also evaluated. The following conclusions can be drawn from our experiments and

analyses: The ZnO nanoparticles obtained here were nearly

spherical particles with a size about 29 nm. The oleic acidmodified ZnO nanoparticles were obtained by the reaction between OH group on the nanoparticles and COOH of the

oleic acid. FTIR results confirm that an organic layer exists and

the linkage between inorganic nuclei and organic layer is

chemical bond. In addition, the LD of ZnO nanoparticles was

measured. A low-concentration dispersion of ZnO nanoparticles

in ethanol exhibited excellent UV shielding and transparency

properties.

Dispersibility of T0 and T1 in organic solvents*

Solvent

1

2

Toluene

Cyclohexane

Hexane

DOP

Sedimentation time/min

T0

<1

13

T1

40

125

150

52

380

5

Ethanol

5

890

* The amount of oleic acid is T0: 0%, T1: 5%; sedimentation time was

determined via a dispersed solution(10%, mass fraction) at room temperature.

The UV absorption property of the ZnO-ethanol dispersions was highly dependent on the ZnO nanoparticle concentration. The correlation between UV absorption property and

concentration in dispersion systems is well known. The

as-prepared ZnO nanoparticles exhibit high UV-blocking capacity, which makes the nanoparticles potentially useful in

cosmetic application.

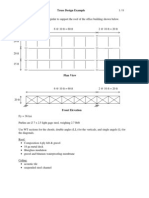

For evaluation of UV absorption property, different concentrations of ZnO nanoparticles dispersions in ethanol were

prepared. The UV absorption spectra of the ZnO nanoparticleethanol dispersions with various mass fractions(0.005%

0.075%) are shown in Fig.5.

References

[1]

Nasu A., Otsubo Y., J. Colloid Interface Sci., 2007, 310, 617

[2]

Zhou Z., Zhao Y., Cai Z., Applied Surface Science, 2010, 256, 4724

[3]

Sosa I. O., Noguez C., Barrera R. G., J. Phys. Chem., 2003, B107,

6269

[4]

Tokumoto M. S., Pulcinelli S. H., Santilli C. V., J. Phys. Chem.,

2003, B107, 568

[5]

Feldmann C., Adv. Fundam. Mater., 2003, 13, 101

[6]

Damonte L. C., Mendoza Zlis L. A., Mar Soucase B., Fenollosa M.

A. H., Powder Technol., 2004, 148, 15

[7]

Korotcenkov G., Cho B. K., Nazarov M., Noh D. Y., Kolesnikova E.

V., Current Applied Phys., 2010, 10, 1123

[8]

[9]

Okuyama K., Lenggoro I. W., Chem. Eng. Sci., 2003, 58, 537

Rataboul F., Nayral C., Casanove M. J., J. Organomet. Chem., 2002,

643/644, 307

[10]

Sato T., Tanigaki T., Suzuki H., Saito Y., Kido O., Kimura Y., Kaito

C., Takeda A., Kaneko S., J. Cryst. Growth, 2003, 255, 313

[11]

Viswanathan R., Lilly G. D., Gale W. F., Ind. Eng. Chem. Res., 2003,

42, 5535

[12]

Koh Y. W., Lin M., Tan C. K., J. Phys. Chem., 2004, B108, 11419

[13]

Liu B., Zeng H. C., J. Am. Chem. Soc., 2003, 125, 4430

[14]

Yu W. D., Li X. M., Gao X. D., Cryst. Growth Des., 2005, 5, 151

[15]

Hu X. L., Zhu Y. J., Wang S. W., Mater. Chem. Phys., 2004, 88, 421

[16]

Hong R. Y., Shen Z. H., Li H. Z., Chin. J. Process Eng., 2005, 5,

693

[17]

Wang J. M., Gao L., Inorg. Chem. Commun., 2003, 6, 877

[18]

Kim J. H., Choi W. C., Kim H. Y., Powder Technol., 2005, 153, 16

[19]

Li Z. W., Zhu Y. F., Applied Surface Science, 2003, 211, 315

[20]

Gao Y. J., Zhang G. C., Zhang Z. J., Zhang Z., Xue Q., Wear, 2002,

252, 454

[21]

Fig.5

UV absorption property of different mass fractions

of ZnO nanoparticles with an average size of 29 nm

dispersed in ethanol

Mass fraction of ZnO nanoparticles: a. 0.005%; b. 0.01%;

c. 0.05%; d. 0.075%.

Wang C. Y., Sheng Y., Wang Z. C., Materials Science and Engineering, 2007, C27, 42

[22]

Kang X. H., Wang B., Zhu L., Zhu H., Wear, 2008, 265, 150

[23]

Veriansyaha B., Kima J. D., Mina B. K., J. Supercritical Fluids,

2010, 52, 76

Вам также может понравиться

- Supercritical PlantДокумент71 страницаSupercritical PlantNitish KumarОценок пока нет

- Truss Design Example: CE 331, Fall 2000Документ8 страницTruss Design Example: CE 331, Fall 2000anbugobi80% (5)

- 5 Lesson Plan On HeatДокумент4 страницы5 Lesson Plan On HeatJustine Collamar GanabОценок пока нет

- Excel FormulasДокумент2 страницыExcel FormulasJK100% (2)

- Excel FormulasДокумент2 страницыExcel FormulasJK100% (2)

- Excel FormulasДокумент2 страницыExcel FormulasJK100% (2)

- Quantum Espresso TutorialДокумент23 страницыQuantum Espresso TutorialCarla Vieira SoaresОценок пока нет

- Aspen Plus Simulation Biomass GasificationДокумент39 страницAspen Plus Simulation Biomass Gasificationprash_1367% (3)

- 2021 Equipment Thermal Guidelines For Data Processing EnvironmentsДокумент8 страниц2021 Equipment Thermal Guidelines For Data Processing EnvironmentsTrần Độ100% (1)

- Synthesis and Characterization of Zno Nanopowder by Non-Basic RouteДокумент9 страницSynthesis and Characterization of Zno Nanopowder by Non-Basic RouteOvidiu CristiОценок пока нет

- Photocatalytic Degradation of Organic Contaminants in Water by Zno Nanoparticles: RevisitedДокумент7 страницPhotocatalytic Degradation of Organic Contaminants in Water by Zno Nanoparticles: Revisitedjacobo bustamanteОценок пока нет

- Synthesis of Zinc Oxide Nanoparticles VIДокумент10 страницSynthesis of Zinc Oxide Nanoparticles VIHarden PatilОценок пока нет

- Gold Si Zinc 2Документ6 страницGold Si Zinc 2Claudia UngureanuОценок пока нет

- Research Article Synthesis and Characterization of Zno-Zro Nanocomposites For Photocatalytic Degradation and Mineralization of PhenolДокумент13 страницResearch Article Synthesis and Characterization of Zno-Zro Nanocomposites For Photocatalytic Degradation and Mineralization of PhenolBagya RajОценок пока нет

- Synthesis of ZnO Nanospheres With Uniform Nanopores by A Hydrothermal ProcessДокумент6 страницSynthesis of ZnO Nanospheres With Uniform Nanopores by A Hydrothermal ProcessSekhar BabuОценок пока нет

- Kimia AnorganikДокумент21 страницаKimia AnorganikSeptiaОценок пока нет

- A Simple Preparation Technique For Shape-Controlled Zinc OxideДокумент6 страницA Simple Preparation Technique For Shape-Controlled Zinc OxideDrMarouf SaraОценок пока нет

- Journal of Alloys and CompoundsДокумент5 страницJournal of Alloys and CompoundsCarlos LopezОценок пока нет

- Review On The Photocatalytic Degradation of Dyes and Antibacterial Activities of Pure and Doped-ZnoДокумент13 страницReview On The Photocatalytic Degradation of Dyes and Antibacterial Activities of Pure and Doped-ZnoDaniel SusantoОценок пока нет

- Degradation of Metronidazole From Aqueous Environment Using Hydrothermally Synthesized ZN o N Doped ZN o and ZN o Ac NanoparticlesДокумент13 страницDegradation of Metronidazole From Aqueous Environment Using Hydrothermally Synthesized ZN o N Doped ZN o and ZN o Ac NanoparticlesHadi jameel hadiОценок пока нет

- Hong 2009Документ7 страницHong 2009Saniaputri WulandariОценок пока нет

- Journal of Alloys and Compounds: Mahsa Pirhashemi, Aziz Habibi-YangjehДокумент8 страницJournal of Alloys and Compounds: Mahsa Pirhashemi, Aziz Habibi-YangjehbismuthsunilОценок пока нет

- 10 1134/S0036024415130154Документ6 страниц10 1134/S0036024415130154AnaGomezОценок пока нет

- Zhu 2014 Fabrication of ZnO and TiO2 Combined Activated Carbon NanocompositeДокумент4 страницыZhu 2014 Fabrication of ZnO and TiO2 Combined Activated Carbon Nanocompositeluke nguОценок пока нет

- Ultraviolet-Visible Spectral Properties of Nanometer Zinc Oxide Colloidal SolutionДокумент4 страницыUltraviolet-Visible Spectral Properties of Nanometer Zinc Oxide Colloidal SolutionAnonymous cYpEVvoОценок пока нет

- 1.obsevrve The Optical Properties of Zno After Modification Through Laser AbliationДокумент14 страниц1.obsevrve The Optical Properties of Zno After Modification Through Laser Abliationsidra khalidОценок пока нет

- ZnO SynthesisДокумент4 страницыZnO Synthesissoumendra ghoraiОценок пока нет

- م.م حيدر محمودДокумент5 страницم.م حيدر محمودم.م حيدر محمودОценок пока нет

- OJC Vol 31 (2) p1219-1221Документ3 страницыOJC Vol 31 (2) p1219-1221chuyiОценок пока нет

- Photocatalytic Degradation of Diclofenac Sodium in Aqueous Solution Using N, S, and C-Doped ZnoДокумент6 страницPhotocatalytic Degradation of Diclofenac Sodium in Aqueous Solution Using N, S, and C-Doped ZnoAnaGomezОценок пока нет

- 25 255 PDFДокумент5 страниц25 255 PDFVu Duc TuОценок пока нет

- JCTM 48 2013 259 ZnOpowdKatjaДокумент6 страницJCTM 48 2013 259 ZnOpowdKatjaPavithra selvamОценок пока нет

- Surface-Modification of Sio Nanoparticles With Oleic Acid: Zongwei Li, Yongfa ZhuДокумент6 страницSurface-Modification of Sio Nanoparticles With Oleic Acid: Zongwei Li, Yongfa ZhuSebastianDiazОценок пока нет

- Sol Gel Method Zinc OxideДокумент10 страницSol Gel Method Zinc OxideAdzan RamadhanОценок пока нет

- SYNTHESIS OF ZnO NANOPARTICLES FOR ORGANIC POLLUTANT DEGRADATION PDFДокумент9 страницSYNTHESIS OF ZnO NANOPARTICLES FOR ORGANIC POLLUTANT DEGRADATION PDFumar raza khanОценок пока нет

- Highly Oriented 1-D Zno Nanorod Arrays On Zinc Foil: Direct Growth From Substrate, Optical Properties and Photocatalytic ActivitiesДокумент5 страницHighly Oriented 1-D Zno Nanorod Arrays On Zinc Foil: Direct Growth From Substrate, Optical Properties and Photocatalytic ActivitiesAleandra Rasyid AzuraОценок пока нет

- Gold Nanoparticles Prepared by Sonochemical Method in Thiol-Functionalized Ionic LiquidДокумент5 страницGold Nanoparticles Prepared by Sonochemical Method in Thiol-Functionalized Ionic LiquidZaheerAhmedAhmedОценок пока нет

- IOSR JournalsДокумент7 страницIOSR JournalsInternational Organization of Scientific Research (IOSR)Оценок пока нет

- Articol 2Документ6 страницArticol 2thomasОценок пока нет

- Photocatalytic Degradation of Organic Dyes With Manganese-Doped Zno NanoparticlesДокумент7 страницPhotocatalytic Degradation of Organic Dyes With Manganese-Doped Zno NanoparticlesГулинурОценок пока нет

- Optical MaterialsДокумент9 страницOptical MaterialsAmrita PalaiОценок пока нет

- Functionalization-Mediated Physicochemical Properties of inДокумент6 страницFunctionalization-Mediated Physicochemical Properties of inNguyen Cong TuОценок пока нет

- 18 - Shen2008, Photocatalytic Degradation For Methylene Blue Using Zinc Oxide PreparedДокумент4 страницы18 - Shen2008, Photocatalytic Degradation For Methylene Blue Using Zinc Oxide Preparedhellna284Оценок пока нет

- Materialsand Semiconductor Processing Paper PDFДокумент11 страницMaterialsand Semiconductor Processing Paper PDFANANDAKUMAR B.SОценок пока нет

- Synthesis of Palladium-Coated Magnetic Nanoparticle and Its Application in Heck ReactionДокумент6 страницSynthesis of Palladium-Coated Magnetic Nanoparticle and Its Application in Heck Reactionapi-3773399Оценок пока нет

- Synthesis and Optical Characterization of Aluminum Doped ZnO NanoparticlesДокумент7 страницSynthesis and Optical Characterization of Aluminum Doped ZnO NanoparticlesmegamishuraОценок пока нет

- R2 Eece 1065Документ10 страницR2 Eece 1065windyОценок пока нет

- English 6Документ9 страницEnglish 6Sitii NurjannahОценок пока нет

- ZnO Nanoparticles With High Degradation Efficiency of Organic DyesДокумент4 страницыZnO Nanoparticles With High Degradation Efficiency of Organic DyesJohnny Lorenz Galvez CubasОценок пока нет

- Eer 2022 606Документ11 страницEer 2022 606ali abdulrahman al-ezziОценок пока нет

- Samad I Pak Chin 2017Документ37 страницSamad I Pak Chin 2017banepostingОценок пока нет

- Leiming Li Et Al - Assembling A Lasing Hybrid Material With Supramolecular Polymers and NanocrystalsДокумент6 страницLeiming Li Et Al - Assembling A Lasing Hybrid Material With Supramolecular Polymers and NanocrystalsHumdsОценок пока нет

- Studies On DNA Interaction of Alanine and L-Cysteine Functionalized ZnO NanoparticlesДокумент6 страницStudies On DNA Interaction of Alanine and L-Cysteine Functionalized ZnO NanoparticlesInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Synthesis and Characterization of Nanoparticles of Iron OxideДокумент8 страницSynthesis and Characterization of Nanoparticles of Iron OxideDipteemaya BiswalОценок пока нет

- Eljamal 2016Документ32 страницыEljamal 2016Nautam ParasanaОценок пока нет

- Synthesis of Nanosized R-Nickel Hydroxide by A Sonochemical MethodДокумент4 страницыSynthesis of Nanosized R-Nickel Hydroxide by A Sonochemical MethodemediageОценок пока нет

- E Cient Zno-Based Visible-Light-Driven Photocatalyst For Antibacterial ApplicationsДокумент11 страницE Cient Zno-Based Visible-Light-Driven Photocatalyst For Antibacterial ApplicationsDhandapani PerumalОценок пока нет

- Vis-Active Photocatalytic Composite Thin Films For Advanced Wastewater TreatmentДокумент10 страницVis-Active Photocatalytic Composite Thin Films For Advanced Wastewater TreatmentAnca DutaОценок пока нет

- Aquier 2018Документ22 страницыAquier 2018William CárdenasОценок пока нет

- Fabrication of PolyacrylonitrileДокумент21 страницаFabrication of PolyacrylonitrileFadhilatul AdhaОценок пока нет

- Ravi FinalДокумент56 страницRavi Finalanand sureshОценок пока нет

- Paper 21Документ6 страницPaper 21Emon AzharОценок пока нет

- Hong Goo ChoiДокумент3 страницыHong Goo ChoiHaiОценок пока нет

- 1 s2.0 S1381116905004474 MainДокумент6 страниц1 s2.0 S1381116905004474 MainHaileyesus HatanoОценок пока нет

- Accepted ManuscriptДокумент33 страницыAccepted Manuscriptchikh MELKAOUIОценок пока нет

- Wang 2014Документ7 страницWang 2014Syafrian AzmiОценок пока нет

- Use of Advance Oxidation Process For Removal of Carcinogenic Contaminant From WaterДокумент3 страницыUse of Advance Oxidation Process For Removal of Carcinogenic Contaminant From WaterDanish IqbalОценок пока нет

- Nano and Bulk Crystals of Zno: Synthesis and CharacterizationДокумент9 страницNano and Bulk Crystals of Zno: Synthesis and CharacterizationbudhladaОценок пока нет

- Fourth International Conference on Non-Aqueous Solutions: Vienna 1974От EverandFourth International Conference on Non-Aqueous Solutions: Vienna 1974V. GutmannОценок пока нет

- CommonlyUsedExcelFunctions v1Документ17 страницCommonlyUsedExcelFunctions v1Duyen YoungОценок пока нет

- C-Zone SDN BHD: Price List Effective 03 JAN 2019Документ2 страницыC-Zone SDN BHD: Price List Effective 03 JAN 2019YeeXuan TenОценок пока нет

- Excel Functions - Full ListДокумент13 страницExcel Functions - Full ListKhan MohammadОценок пока нет

- ���װ�ڰڰ� Jb/Rn ϱ��϶�� �� �� ���Документ1 страница���װ�ڰڰ� Jb/Rn ϱ��϶�� �� �� ���YeeXuan TenОценок пока нет

- Excel Formulae and FunДокумент8 страницExcel Formulae and FunYeeXuan TenОценок пока нет

- ���װ�ڰڰ� Jb/Rn ϱ��϶�� �� �� ���Документ1 страница���װ�ڰڰ� Jb/Rn ϱ��϶�� �� �� ���YeeXuan TenОценок пока нет

- ���װ�ڰڰ� Jb/Rn 1 ϱ��϶�� �� �� ����Документ1 страница���װ�ڰڰ� Jb/Rn 1 ϱ��϶�� �� �� ����YeeXuan TenОценок пока нет

- Energies: Gasification of Biochar From Empty Fruit Bunch in A Fluidized Bed ReactorДокумент9 страницEnergies: Gasification of Biochar From Empty Fruit Bunch in A Fluidized Bed ReactoryemresimsekОценок пока нет

- Apple ThreeeДокумент1 страницаApple ThreeeYeeXuan TenОценок пока нет

- ���װ�ڰڰ� Jb/Rn ϱ��϶�� �� �� ���Документ1 страница���װ�ڰڰ� Jb/Rn ϱ��϶�� �� �� ���YeeXuan TenОценок пока нет

- Development of An ASPEN PLUS Physical Property Database For Biofuels ComponentsДокумент36 страницDevelopment of An ASPEN PLUS Physical Property Database For Biofuels ComponentsoslemmОценок пока нет

- Full TextДокумент7 страницFull TextYeeXuan TenОценок пока нет

- Thermal Power Plant Boiler Misoperation - Case Study Using CFDДокумент4 страницыThermal Power Plant Boiler Misoperation - Case Study Using CFDSumukh BharadwajОценок пока нет

- Thermo-Economic Analysis of A Novel Conceptual Process Model For Sustainable Power Plants Using Empty Fruit BunchesДокумент5 страницThermo-Economic Analysis of A Novel Conceptual Process Model For Sustainable Power Plants Using Empty Fruit BunchesYeeXuan TenОценок пока нет

- Painting A Clear Picture of Suspension RheologyДокумент2 страницыPainting A Clear Picture of Suspension RheologyDanielОценок пока нет

- Economic ReportДокумент9 страницEconomic ReportYeeXuan TenОценок пока нет

- ExamplesДокумент14 страницExamplesYeeXuan TenОценок пока нет

- H84ACM Coursework GuidelinesДокумент6 страницH84ACM Coursework GuidelinesYeeXuan TenОценок пока нет

- Acceleration of Catalytic Activity of Calcium Oxide For Biodiesel ProductionДокумент1 страницаAcceleration of Catalytic Activity of Calcium Oxide For Biodiesel ProductionYeeXuan TenОценок пока нет

- Process Simulation and Optimization of Palm Oil Waste Combustion Using Aspen PlusДокумент16 страницProcess Simulation and Optimization of Palm Oil Waste Combustion Using Aspen PlusYeeXuan TenОценок пока нет

- Process Simulation and OptimizationДокумент8 страницProcess Simulation and OptimizationKai Yuan TeoОценок пока нет

- Ajme 1 4 3Документ7 страницAjme 1 4 3YeeXuan TenОценок пока нет

- Materials RequiredДокумент13 страницMaterials RequiredYeeXuan TenОценок пока нет

- Test 111Документ4 страницыTest 111YeeXuan TenОценок пока нет

- LicenseДокумент21 страницаLicenseYeeXuan TenОценок пока нет

- Chapter 2 The Chemistry of Life Section 2-1 The Nature of MatterДокумент3 страницыChapter 2 The Chemistry of Life Section 2-1 The Nature of MatterAmy GibbonsОценок пока нет

- ChE 101.01 Physical and Thermal PropertiesДокумент49 страницChE 101.01 Physical and Thermal Propertieshamz786Оценок пока нет

- Lesson 8 - SolutionsДокумент13 страницLesson 8 - SolutionsscientistgenerosoОценок пока нет

- A1-1 Otec 2Документ109 страницA1-1 Otec 2Dondee Sibulo AlejandroОценок пока нет

- Chemical Bonding Advance (Micro)Документ28 страницChemical Bonding Advance (Micro)Anant JainОценок пока нет

- BASF Alumina Catalysts Broschuere UpdateДокумент13 страницBASF Alumina Catalysts Broschuere Updatevibage2942Оценок пока нет

- Particle Observation Using A Cloud Chamber: 5. First Year Experiment SuggestionsДокумент1 страницаParticle Observation Using A Cloud Chamber: 5. First Year Experiment SuggestionsJose David MuñetónОценок пока нет

- StandardizationДокумент18 страницStandardizationCHEA MICH L. ABELLANOОценок пока нет

- DinamikaДокумент11 страницDinamikaUmi LatifahОценок пока нет

- JAE 1991 ReviewДокумент10 страницJAE 1991 ReviewCan ERTANОценок пока нет

- Bimbel 2Документ6 страницBimbel 2Wibowo Sugandi, S.T.Оценок пока нет

- Ks Permaglide CatalogueДокумент76 страницKs Permaglide CatalogueSkocko SkockicОценок пока нет

- 25008Документ13 страниц25008AdyОценок пока нет

- Anomalous Zeeman EffectДокумент2 страницыAnomalous Zeeman EffectSantiago Cifuentes AlmanzaОценок пока нет

- Metastable IonsДокумент10 страницMetastable IonsKavya EОценок пока нет

- Experiment 1: Crystallization of Impure Acetanilide ObjectiveДокумент4 страницыExperiment 1: Crystallization of Impure Acetanilide ObjectiveEZLYEN AZLINОценок пока нет

- Thermo Chemical Reaction EquilibriaДокумент41 страницаThermo Chemical Reaction EquilibriaDede SyahputraОценок пока нет

- Chapter 36 DiffractionДокумент36 страницChapter 36 DiffractionMark ReyesОценок пока нет

- Solution Manual For Fluid Mechanics 1St Edition by Hibbeler Isbn 0132777622 9780132777629 Full Chapter PDFДокумент30 страницSolution Manual For Fluid Mechanics 1St Edition by Hibbeler Isbn 0132777622 9780132777629 Full Chapter PDFscott.fischer352100% (9)

- Introduction To Multi-Component Polymer Systems: M.SC - Polymer EngineeringДокумент22 страницыIntroduction To Multi-Component Polymer Systems: M.SC - Polymer EngineeringItamar PolitzerОценок пока нет

- Atoms Molecules and IonsДокумент3 страницыAtoms Molecules and Ionsapi-304350501Оценок пока нет

- 02 StoichiometryДокумент4 страницы02 StoichiometryChrispin MachilikaОценок пока нет

- P P W V: MEEN 310-Thermodynamics II Exam 1 Equation SheetДокумент5 страницP P W V: MEEN 310-Thermodynamics II Exam 1 Equation SheetmikemcchezzОценок пока нет

- Vsepr: Predicting Molecular Geometry and HybridizationДокумент2 страницыVsepr: Predicting Molecular Geometry and HybridizationARMANDO SIERRA QUEZADAОценок пока нет

- Atomic Physics Notes QuestionsДокумент17 страницAtomic Physics Notes QuestionsvijayaraghavanОценок пока нет