Академический Документы

Профессиональный Документы

Культура Документы

Valve II Valve II Valve II: Dome Dome Dome

Загружено:

Shukla SuyashОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Valve II Valve II Valve II: Dome Dome Dome

Загружено:

Shukla SuyashАвторское право:

Доступные форматы

Dome Valve II

Dome Valve II

inflatable seat valve

A pioneering and innovative departure

from the traditional valve seat approach

to achieving sealing efficiency and acceptable valve seat life.

Dome Valve II

advanced features

principle of operation

The dome component closes beneath the seat (seal) when the seal

is relaxed (not inflated), allowing a controlled gap between the seat

(seal) and the closing member (dome). Material is allowed to pass

through or enter the controlled gap if, due to its characteristics, it is

pulled into the gap by the action of the dome component moving

to its closed position. In the closed position, high pressure air or

other gas enters the space between the back of the seal face and

the insert ring to cause the seal face to expand onto and around

the periphery of the dome component. Material particles are entrapped by the seal against the dome surface, irrespective of particle size or shape. Before opening the valve, the seat is relaxed, and

the controlled gap is reestablished before the dome component

moves to its open position. The seal is a loose component clamped

into place by a spigot piece and external fasteners holding the top

plate assembly to the body. The seal is easily removed for inspection.

simplicity

high torque, double

acting actuator

the problem solver

special performance advantages

zero-contact proximity

switch for inflatable

seal operation

one piece precision

molded inflatable seat

abrasive materials

single gasket assembly

air supply

Pressure differential also causes accelerated seat wear in conventional seat valves. The inflatable seal provides continuous

wear compensation.

high temperature

Inflatable flexible seats entrap particles that are normally the cause

of seat erosion. Particles are induced to move across valve seats

under the influence of pressure differentials on either side of the

closing member. Entrapping particles within a flexible face during

the period of valve closure prevents particle movement and considerably reduces valve seat wear. Inflatable seats allow automatic

wear compensation.

Particle entrapment prevents seal/seat

erosion, solving the cause of valve wear.

durability

flexible seats

Flexible seats that do not inflate require the force of engagement

on closing to entrap particles. However the flexible valve seat has

limited life because the worn surface of the flexible seat cannot

continue to reengage the closing member and entrap particles.

Inflatable seats compensate for wear to the seat and provide

longer sealing life.

inflated seat

dome component

U.S. Patent No. 4,137,935

Thermal expansion prevents consistent valve seat action. The

inflatable seal provides compensation throughout the temperature range of 0 to 350C. Temperatures above this range

may be accepted using special valve configurations.

close and seal

The action of the rotating dome within the valve housing allows displacement of material so that a choke-filled Dome

Valve will close and seal through most packed materials.

hard seats

The conventional hard material approach to valve seat life relies on

crushing particles between the faces. This approach does not attempt to entrap particles, but causes the particles remaining to

become very small to reduce their erosion effect on the valve seat.

However small the particles are, each particle contributes to continuing erosion. Particle movement and initial erosion allows accelerated subsequent erosion since the hard seats cannot compensate

for wear.

Slurries, bulk powders, granules, lumps or dust-laden gases

cause seat erosion and ineffective closure. The inflatable seal

provides continuous wear compensation.

pressure differential

inflatable seats

relaxed seat

dome component

The Dome Valve is used in a wide variety of applications in

almost every process. The unique closing and sealing action of

the Dome Valve enables continuous reliable operation where

conventional valves fail to perform. Here is why:

1

2

3

4

5

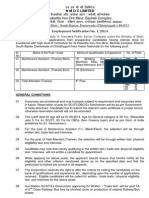

TOP PLATE BOLTS

TOP PLATE

INSERT RING

INFLATABLE SEAL

SPIGOT PIECE

6

7

8

9

10

11

12

13

14

15

16

17

18

19

GASKET

VALVE BODY

DOME

V-RING

PIVOT SHAFT

DRIVE SHAFT

SHAFT SEAL

SEAL RETAINER

BEARING

ACTUATOR DRIVE ASSEMBLY

ACTUATOR MOUNT

ACTUATOR

PROXIMITY SWITCH

DOME-TO-SHAFT BOLT

seal and protection

simple fastener assembly

In M & F connection

Seal protection and dome scraper ring remove particles adhering to the dome surface that affect seal performance.

U.S. Patent No. 5642751

abrasion / temperature / pressure

double shaft seals

quality

stainless steel

shafts

Dome Valve can achieve operating reliability in severe applications combining abrasive materials, high temperature and

high pressure differential.

reliability

A heavy-duty valve designed to perform where other valves

cannot. Rated for hundreds of thousands of cycles between

inspections in approved applications.

applications in every process worldwide

More than 100,000 Dome Valves are in operation in

almost every country of the world, providing long life and

operating reliability where conventional valves have failed.

reliability

Dome Valve II

standard configurations

bulkhead

Macawber China Ltd.

Suite 901, 145 PuJian Rd.

Pudong, Shanghai, China 200127

Tel: +86 (021) 6875 1377

Fax: +86 (021) 5831 2152

macawber@macawber.com.cn

www.macawber.com.cn

Mactenn Systems Ltd.

Unit 6, Bull Lane Industrial Estate

Acton, Sudbury, Suffolk CO10 0BD, UK

Tel: +44 (0) 1787 882 422

Fax: +44 (0) 1787 882 433

sales@mactenn.com

www.mactenn.com

Macawber Engineering Systems

India Pvt. Ltd.

130-131, Hindustan Kohinoor Complex,

LBS Rd., Vikhroli, Mumbai 400083

response@macawberindia.com

www.macawberindia.com

PDL Sistemas, Brazil

Av. Pedro Lessa, 1.064/31 - Aparecida

11025-000, Santos, Sao Paulo , Brazil

Tel/Fax: +55 13 3278 3380

pdl@pdl.com.br

www.pdl.com.br

Dome Valve II

standard options

inflatable seat valves

size (in): 2, 4, 6, 8, 10, 12, 16

design temp: 230F/110C, 536F/280C, 662F/350C

design pressure: 100 psig / 7 barg

flanges: ANSI 150 / PN 10 / PN 16

construction: Cast Iron A278 C40 / Stainless 304/316

the process engineering valve solution

non-standard options

inline

size options (in): up to 30

design temp: up to 1500F/815C *

design pressure: up to 630 psig / 43 barg

ISO 9001 REGISTERED

Macawber Engineering Inc.

inflatable seat valves

advanced pneumatic conveying systems

controlled rate injection systems

1829 Clydesdale Street, Maryville, TN 37801, USA

Tel: 800.433.2213 Fax: 865.977.4131

www.macawber.com

webinquiry@macawber.com

Your Local Distributor:

*Requires high temp batching valve

Вам также может понравиться

- M1 DataДокумент306 страницM1 DataShukla SuyashОценок пока нет

- 4e1adcf3-0ec0-4c57-9d5e-0ca5c0a80121Документ117 страниц4e1adcf3-0ec0-4c57-9d5e-0ca5c0a80121Shukla SuyashОценок пока нет

- Address Research Group F 2021-07-09Документ6 страницAddress Research Group F 2021-07-09Shukla SuyashОценок пока нет

- Prasad Setty WorkbookДокумент22 страницыPrasad Setty WorkbookShukla SuyashОценок пока нет

- Major Sites of Indus Valley CivilizationДокумент1 страницаMajor Sites of Indus Valley CivilizationShukla SuyashОценок пока нет

- SC Strikes Down NJAC - Logic and ImplicationsДокумент4 страницыSC Strikes Down NJAC - Logic and ImplicationsShukla SuyashОценок пока нет

- Master File of School Emails Across USAДокумент4 126 страницMaster File of School Emails Across USAShukla Suyash75% (4)

- upGrad ed-tech startupДокумент1 страницаupGrad ed-tech startupShukla SuyashОценок пока нет

- CCPL Strategy Deputy Manager JobДокумент3 страницыCCPL Strategy Deputy Manager JobShukla SuyashОценок пока нет

- Public-Administration Previous Paper 1998Документ2 страницыPublic-Administration Previous Paper 1998pratyoОценок пока нет

- Survey Primary Teachers Attitudes Towards STEM EducationДокумент27 страницSurvey Primary Teachers Attitudes Towards STEM EducationShukla SuyashОценок пока нет

- PUB AD (9 A) - Chapter - 9 - Importance of HRD, Recruitment, Training PDFДокумент8 страницPUB AD (9 A) - Chapter - 9 - Importance of HRD, Recruitment, Training PDFShukla SuyashОценок пока нет

- Rebel WBBL match scheduleДокумент201 страницаRebel WBBL match scheduleShukla SuyashОценок пока нет

- Address Research Group F 2021-07-09Документ6 страницAddress Research Group F 2021-07-09Shukla SuyashОценок пока нет

- 8 Sapru PDFДокумент19 страниц8 Sapru PDFShukla SuyashОценок пока нет

- What Is PolicyДокумент24 страницыWhat Is Policydedon1234Оценок пока нет

- References and Further Reading on Governance and Public-Private PartnershipsДокумент2 страницыReferences and Further Reading on Governance and Public-Private PartnershipsShukla SuyashОценок пока нет

- OptPubAdm7 - Personnel AdministrationДокумент28 страницOptPubAdm7 - Personnel AdministrationShukla SuyashОценок пока нет

- 5837 LM PAD P01 M20 Behavioural Approach LMДокумент2 страницы5837 LM PAD P01 M20 Behavioural Approach LMShukla SuyashОценок пока нет

- 09 Administrative Law PDFДокумент21 страница09 Administrative Law PDFShukla SuyashОценок пока нет

- GeomorphologyДокумент207 страницGeomorphologymkprabhu100% (1)

- Jindal Steel & Power Limited: P.B.No.86.Barbil-Joda Highway, Barbil-758035 (Orissa)Документ1 страницаJindal Steel & Power Limited: P.B.No.86.Barbil-Joda Highway, Barbil-758035 (Orissa)Shukla SuyashОценок пока нет

- What Is Vibration ?: Imperfections in The Machine: Design Assembly Manufacture Operation Installation MaintenanceДокумент2 страницыWhat Is Vibration ?: Imperfections in The Machine: Design Assembly Manufacture Operation Installation MaintenanceShukla SuyashОценок пока нет

- Low Heat Input SMAW Welding ElectrodesДокумент62 страницыLow Heat Input SMAW Welding ElectrodesShukla SuyashОценок пока нет

- Result of Postman and MTS Examination Held On 3rd Aug 2014 in Keonjhar DivisionДокумент1 страницаResult of Postman and MTS Examination Held On 3rd Aug 2014 in Keonjhar DivisionShukla SuyashОценок пока нет

- Postman Mail Guard and MTS Examination PUBLIC NOTICEДокумент1 страницаPostman Mail Guard and MTS Examination PUBLIC NOTICEShukla SuyashОценок пока нет

- OTE Outotec Pallet Cars For Sintering and PelletizДокумент4 страницыOTE Outotec Pallet Cars For Sintering and PelletizShukla SuyashОценок пока нет

- Service Manual: Parts ListДокумент6 страницService Manual: Parts ListShukla SuyashОценок пока нет

- FA-MA (Trainee) English Adv FinalДокумент6 страницFA-MA (Trainee) English Adv FinalUmesh PatelОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Quiz6 AnswerДокумент8 страницQuiz6 AnswerTrí Tạ MinhОценок пока нет

- Technical manual for Felt Compulsion mountain bike suspension systemДокумент15 страницTechnical manual for Felt Compulsion mountain bike suspension systemDiogo SilvaОценок пока нет

- LP Galvo Scanner LaserphotoДокумент16 страницLP Galvo Scanner LaserphotoCostin DinamaxОценок пока нет

- Bus Network Topology GuideДокумент8 страницBus Network Topology GuideMjjames Manalo100% (1)

- Introduction to Nautilus 8 Mold Qualification and Design of Experiments SoftwareДокумент66 страницIntroduction to Nautilus 8 Mold Qualification and Design of Experiments SoftwareJohn SuperdetalleОценок пока нет

- TVS Apache RTR 180 Service ManualДокумент25 страницTVS Apache RTR 180 Service ManualSandino JoseОценок пока нет

- Convert Decimal To Binary Sunday ClassДокумент14 страницConvert Decimal To Binary Sunday ClassLaila HammadОценок пока нет

- Syngas Synthesis & Its UseДокумент18 страницSyngas Synthesis & Its UseAekkasit SenaartОценок пока нет

- PDCT - Hydraulic Torque Wrench - Hangzhou Penad Machinery Co.,LtdДокумент4 страницыPDCT - Hydraulic Torque Wrench - Hangzhou Penad Machinery Co.,LtdQS BMDSОценок пока нет

- 11.rolling Disc SolutionДокумент12 страниц11.rolling Disc SolutionAlimin AnniОценок пока нет

- Installation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Документ62 страницыInstallation and Setup Guide For The Cisco Active Directory Agent, Release 1.0Madelaine Velasquez Blacutt100% (1)

- Datasheet PDFДокумент16 страницDatasheet PDFSergio Daniel BarretoОценок пока нет

- Tecquipment - Flumes - Data SheetДокумент3 страницыTecquipment - Flumes - Data SheetArthur BritoОценок пока нет

- LCD Interfacing PDFДокумент37 страницLCD Interfacing PDFPeeyush Kp100% (1)

- HistoryДокумент87 страницHistoryMatthew MathewsОценок пока нет

- CH1 The Foundations - Logic and ProofsДокумент106 страницCH1 The Foundations - Logic and ProofsMOHAMED BACHARОценок пока нет

- Flight Planning For ATTДокумент106 страницFlight Planning For ATTTienek Lee100% (1)

- (17417899 - Reproduction) Understanding The Regulation of Pituitary Progesterone Receptor Expression and PhosphorylationДокумент9 страниц(17417899 - Reproduction) Understanding The Regulation of Pituitary Progesterone Receptor Expression and Phosphorylationتقوى اللهОценок пока нет

- Mathematical Investigation of Trigonometric FunctionsДокумент12 страницMathematical Investigation of Trigonometric FunctionsFirasco100% (13)

- Lecture 5 (River As A Geological Agent)Документ20 страницLecture 5 (River As A Geological Agent)Boos yousufОценок пока нет

- Unit Vi: Classification and PredictionДокумент29 страницUnit Vi: Classification and PredictionpalaniappanОценок пока нет

- Manual LDM5 U enДокумент3 страницыManual LDM5 U enLuizAugustoMedeirosОценок пока нет

- Electronic Principles IV, 7-8. Military Curriculum Materials For Vocational and Technical Education.Документ571 страницаElectronic Principles IV, 7-8. Military Curriculum Materials For Vocational and Technical Education.SolОценок пока нет

- QST HamClockДокумент3 страницыQST HamClockCPC PHCОценок пока нет

- DMPA CombinedДокумент527 страницDMPA Combinedlolzcat3454Оценок пока нет

- COSC 2307: Sub-QueriesДокумент23 страницыCOSC 2307: Sub-QueriesBhavikDaveОценок пока нет

- Maths Comparison Summary ReportДокумент274 страницыMaths Comparison Summary ReportShahrukh MunirОценок пока нет

- Control of Multiple-Input, Multiple-Output ProcessesДокумент27 страницControl of Multiple-Input, Multiple-Output Processesmeseret sisayОценок пока нет

- DT022BTFT v10Документ12 страницDT022BTFT v10Johny JongОценок пока нет

- GU - Cabine MT BT (EN) - 1VCP000591 1511Документ88 страницGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariОценок пока нет