Академический Документы

Профессиональный Документы

Культура Документы

Procedure APQP

Загружено:

Azmul FadhliАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Procedure APQP

Загружено:

Azmul FadhliАвторское право:

Доступные форматы

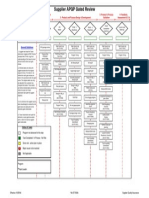

ASIAN AUTOMOTIVE STEELS

12.08.10

Customer request

Development

CONTRACT

REVIEW

Marketing

Development

Customer RFQ

product documents

delivery requirements (customer statement)

Customer

Credit Check

Credit Critera failed

Marketing

Credit / Audit Report

Project risk assessment

Vendor information

RFQ vendor

SGM / GM authorization

outsource

Vendor RFQ

Vendor feedback

No go

Request Customer

Specific Requiremen

Preliminary RFQ

analysis

Quotation

reject,

Counter

proposal

Development

Manufacturing

Purchasing

Engineering

CSR

Statement of Deliverables (internal RFQ form)

Preliminary process flow

APQP checklist

Draft APQP organization chart

Vendor

preliminary

proposals

Technical

feasibility

Reject

APQP team counter

proposal

Accept:

Team Feasibility Commitment

m/c cycle time

Costing assumption

Preliminary planning

Development

Project Development Costing

Manufacturing costing

Preliminary project schedule

Project FS

Accounts

FS documents

Document compilation

Quotation analysis, Proposal

Quotation letter

Marketing

Change

request

Management

support

Marketing

GM, SGM Endorsement

Inform customer

Close project order

MD/COO

approval

Change

request

Marketing

Signed quotation

Project Authorization

RFQ rejection

memo

Document submission

Marketing

Customer quotation forms, packaging

Delivery/Acceptance document

Project close

No

reject letter

from customer

Customer

accept?

Record in quotation file

LOI / LOA

Quotation file

Product Design &

Development

File: Procedure APQP.vsd

Page 1

Marketing

Prepared: AG

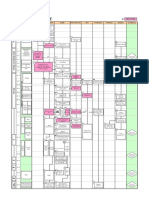

ASIAN AUTOMOTIVE STEELS

12.08.10

CONTRACT AMMENDMENT

& VA/VE

Engineering change

proposal

Customer ECN/ change

product documents

delivery requirements

Technical concept

study

Technical feasibility evidence

Preliminary

Go/No Go

Counter

Proposal

GM endorsement, customer endorsement

Commercial Feasibility not OK

Team feasibility commitment not OK

Commercial feasibility

study

Commercial Feasibility study OK

Team Feasibility commitment OK

Start decision

proceed

outsource

Not feasible

RFQ approved vendor

Vendor RFQ

Vendor feedback

Vendor proposals

Preliminary planning

Preliminary process analysis

Project Development Costing

Manufacturing costing

Preliminary project schedule

Project feasibility study

Change

request

Document compilation

Analysis documents

Preliminary quotation

Quotation Letter

Counter proposal

Change

request

GM

endorsement

Counter propose

Forward to MD

MD/SGM

endorsement

Counter proposal

Signed quotation

Project Authorization

Trasmit to customer

Confirmation of receipt

Customer

accept?

LOI / LOA/ PPA ammendment

product

development

File: Procedure APQP.vsd

Page 2

Prepared: AG

ASIAN AUTOMOTIVE STEELS

12.08.10

PRODUCT DESIGN & VALIDATION

LOI /

Customer authorization

Yes, resourcing /

localization

Design

document

avail?

No, new design

product validation req

Sample

available?

no

Customer liaison

Correspondents, minutes

Customer product

specs, stds avail?

Customer needs

analysis

yes

No / incomplete

Customer

requirements

Reverse engineering

Yes; drawing, spec, testing std

revise

Quality Requirement

analysis

Product specification

proposal

Bill of materials

incoming material requrement

process requirements

Specification list

Product design /

verification

manual calculations

FEA output

product design drawing

proto pfmea, control plan

testing list

approval

Customer-approved

PIS, testing list

Product validation

Test planning/design

Testing

Test eqpt, method

documentation

requirement

requirement

Test document

preparation

product

std

Prototype part,

interfaces

purchase / mfg

Sample

purchase

documents

Testing arrangement

equipment prep

Product analysis

QFD / DFMEA

QFD, DFMEA

form

(Specifications

not compatible,

emerging

Requirements)

Product

Change

Request

sample parts

Fitting, performance

analysis

Fitting trial checksheet

Testing checksheets

Status reports

inspection

checksheet

template

Prototype testing,

analysis

Sample

testing

results

Spec

review /

DQCM

PRODUCT SPECIFICATIONS

Product drawing (comp & assy)

Testing specification,

Part Inspection Standard

Packaging specification

Product

document

release

File: Procedure APQP.vsd

Page 3

Prepared: AG

ASIAN AUTOMOTIVE STEELS

12.08.10

PRODUCT DOCUMENT RELEASE

Product specification

product document

draft / update/ correction

draft drawing

document log update

update drawing log

change request

customer

EC approval

req?

yes

EC Request

no

(customer

preliminary document

review)

approve for final submission

final document preparation

final document

document

check - approve

signed document

document submission

proof of delivery

contract

ammendment

req?

customer

endorsement

yes

customer-approved document

Document Control

Contract Ammendment

no

Process development

planning

File: Procedure APQP.vsd

Page 4

Prepared: AG

ASIAN AUTOMOTIVE STEELS

12.08.10

PROCESS DEVELOPMENT PLANNING

LOI / LOA +

Product Specifications

Process requirement

analysis

Process flow diagram

PFMEA

Special Process characteristics

Sourcing plan

Production

Process, inspection

planning

Production Control Plan

Pre-launch Control Plan

Factory layout,

manpower plan

Material, component

sourcing

Engineering

Development Analysis

DevelopmentInspection

/ test eqpt spec MSA plan

Development process flow

Process validation plan

Prelaunch control plan

Equipment Specifications

Development project

planning

Testing inst

development/acq

analysis

Test eqpt requirement /

devp plan

Production m/c requistion /eng development plan

Development Project schedule,

resource requirement, cost estimate

Final proposal

preparation / revision

Change

request

Project Proposal

Management

review

change

request

Authorization to proceed

Confirmed project plan

Transmit final proposal

to customer

management approved proposal

Customer

review

Process

Development &

Validation

File: Procedure APQP.vsd

Page 5

Prepared: AG

ASIAN AUTOMOTIVE STEELS

12.08.10

PROCESS DEVELOPMENT & VALIDATION

Authorization to proceed

PROCESS VALIDATION

ENGINEERING DEVELOPMENT

Inst purchase/ devp /

mod / training

Eqpt purchase/devp/

mod

Vendor selection

A9 checking aids

inspection jig

Purchasing records

Vendor LOI

checksheet

confirmation

Equipment testing /

checksheets

product

characteristic

ng

test

equipment

fail

VENDOR DEVELOPMENT

mc

ng Agreement

not possible

Equip testing checksheet

Part inspection

standard devp

Vendor drawing

Draft PIS

Eqpt

testing

Approved checksheets

Hard tooling

Product

samples

arbitration

Equip / test reports

Change

terms

Vendor

Devp

failed

Vendor inspection agreement

development contract / LOA

approved quality checksheets

Line trials

line operation status OK

improvement areas

Vendor development

line improvement

Vendor progress reports

Product testing

Dimensional inspection

report, AAR, testing report

Product evaluation

improvement

needed

Vendor monitoring

Line trials

Child

part

ng

sample submission

Sample approval

Vendor evaluation sample

Child part testing

preliminary

PFMEA update

Module testing results

Child part

evaluation

Child part approval

pp appointment

satisfactory

RPN

Vendor PP

Vendor pp summary

Approval Record

master parts

MASS

PRODUCTION

PREPARATION

Subsupplier

PQCM

sign-off

Vendor PQCM

signed vendor PSW

minutes PQCM

Vendor LOA,

draft PPA

draft LOA, PPA

contract nego

term agreement

Vendor PPA

File: Procedure APQP.vsd

Page 6

Prepared: AG

ASIAN AUTOMOTIVE STEELS

12.08.10

MASS PRODUCTION PREPARATION

process development

review prelaunch

control plan

updated prelaunch, production control plan

list equipment, instrument, work instruction, QC checksheets, manpower

list material & child part ordering

prelaunch preparation

meeting

prelaunch checksheet updata

QC checksheet

preparation

prelaunch, production

work instruction

preparation

equipment servicing,

instrument MSA

prelaunch production

planning

prelaunch material

order

preparation

monitoring

not ready

prelaunch checksheet complete

prelaunch briefing

small batch

trial production

product, process data

minor

issues

product

audit

process ok

line production

confirmation trial

product, process data

product

audit

major issues

process ok

Process

Development

line run at rate

Quality Council

Enquiry

Customer PQCM/PCPN Sign-off

PQP Summary & Sign-off

Production part

documentation

compilation

correction

request

File: Procedure APQP.vsd

APQP records

Project Exit Review

PPAP, Pqcm report

minutes

PQCM

Quality document

update

PSW Sign off

project file document update

product quality standard update

Early production

containment

Project APQP doc

QMS update

Page 7

Prepared: AG

ASIAN AUTOMOTIVE STEELS

12.08.10

KAIZEN / PROCESS IMPROVEMENT

SCHEDULED

PRODUCTION

Improvement

needed?

Operational problem

Production

QC report

no

Quality

problems?

Quality problem

Improvement possible

Problem analysis

Kaizen request for

proposals

Improvement

ideas

Kaizen submission

Additional Testing /

data gathering

Kaizen

Evaluation

Proposal accepted

Test reports,

data analysis

Project planning

Kaizen proposal

Minutes

project schedule

Modification

Tooling / mc redesign,

fabrication

Problem

description

Temp rigging,

work inst

Temporary production

rigging, work inst

Process ref update

m/c maintenance log update

Off-line testing

m/c maintenance log update

Problem

resolved?

Target achieved

Supervised

production

Statistical data

PFMEA updates

process improvement activities update

SPC data update

Acceptable?

improvement

project close

File: Procedure APQP.vsd

Kaizen award

presentation

Page 8

Prepared: AG

ASIAN AUTOMOTIVE STEELS

12.08.10

PROJECT GO/NO-GO DECISION

Volume commitment

Material

cost quotation

Dev cost

estimate

Compute costs / pc,

capital investment

Process cost

estimate

Standard costing sheets

Marginal cost meet

customer price?

No

Yes

Management

prerogative

No

Full costing meet

customer price?

Yes

Project Authorization Memo

4TH down & 20

GO FOR IT!

Quotation issue

Inform customer NG

File: Procedure APQP.vsd

Page 9

Prepared: AG

Вам также может понравиться

- APQP DeliverablesДокумент1 страницаAPQP DeliverablesYo GoldОценок пока нет

- APQP Matrix Pedal Yl1 at IsgДокумент11 страницAPQP Matrix Pedal Yl1 at Isgkaran singh100% (2)

- Quality Assurance Vs Quality ControlДокумент1 страницаQuality Assurance Vs Quality Controlpsathishthevan100% (1)

- Advanced Product Quality Planning and Control Plan: Second EditionДокумент5 страницAdvanced Product Quality Planning and Control Plan: Second EditionDavid Sigalingging36% (11)

- APQP WorkbookДокумент20 страницAPQP WorkbookMahmoud Ben Nahia100% (6)

- Advance Product Quality Planning - MatrixДокумент6 страницAdvance Product Quality Planning - Matrixomm100% (1)

- Apqp PpapДокумент50 страницApqp PpapEvandro Ribeiro50% (2)

- CD6 Prototype Control PlanДокумент3 страницыCD6 Prototype Control Planmpedraza-1Оценок пока нет

- KSS Global Standard Supplier Advanced Product Quality Planning (APQP) ProcedureДокумент12 страницKSS Global Standard Supplier Advanced Product Quality Planning (APQP) ProcedureNabeel Arya ZahranОценок пока нет

- Responsibility Matrix 1of ApqpДокумент4 страницыResponsibility Matrix 1of ApqpanuailddОценок пока нет

- APQP Phases ActivitiesДокумент1 страницаAPQP Phases Activitiesaorto3919Оценок пока нет

- Ford Full ApqpДокумент169 страницFord Full ApqpCésar Meza83% (6)

- PPAP ManualДокумент102 страницыPPAP Manualsuresh196950% (2)

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionОт EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Advantages of A Tree Structure FMEA Agility Scalability and Accelerated Quality FeedbackДокумент6 страницAdvantages of A Tree Structure FMEA Agility Scalability and Accelerated Quality Feedbackchemikas8389Оценок пока нет

- APQP TrainingДокумент22 страницыAPQP TrainingSandeep Malik100% (1)

- PPAP-APQP Guide B45157 - Rev-AДокумент29 страницPPAP-APQP Guide B45157 - Rev-AMoti Ben-ZurОценок пока нет

- Apqp TrackerДокумент17 страницApqp TrackerKrunal PandyaОценок пока нет

- APQP Timing PlanДокумент2 страницыAPQP Timing Plancertifiq8213100% (3)

- Types of Production ProcessДокумент24 страницыTypes of Production ProcessPRIYANK89% (18)

- APQP Check ListДокумент17 страницAPQP Check ListmdjeckelОценок пока нет

- PFMEA ExampleДокумент14 страницPFMEA Examplekalebasveggie100% (1)

- Apqp Status LogДокумент1 страницаApqp Status Logsathyabalaraman67% (3)

- Appendix 25 VDA 6 3 Process AuditДокумент12 страницAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- APQP CourseДокумент151 страницаAPQP Courseignaunaq100% (3)

- PPAP ChecklistДокумент3 страницыPPAP Checklistmassfrompak80% (5)

- Intro To APQP On Site PPAP TrainingДокумент240 страницIntro To APQP On Site PPAP Trainingalexrferreira100% (3)

- X Ppap 4Документ75 страницX Ppap 4Komomondoor Varadhan100% (13)

- APQP ENG SiemensДокумент12 страницAPQP ENG SiemensVikash KumarОценок пока нет

- Seven Essentials of Supplier Quality Management A Concise Guide: A systematic approach in managing supplier towards delivering zero-defect material consistentlyОт EverandSeven Essentials of Supplier Quality Management A Concise Guide: A systematic approach in managing supplier towards delivering zero-defect material consistentlyРейтинг: 4 из 5 звезд4/5 (2)

- PPAP TemplatesДокумент23 страницыPPAP Templatestejesh77100% (1)

- Product Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementДокумент8 страницProduct Characteristic Matrix (PCM) & Safe Launch Plan - Alignment & AgreementDavid MorenoОценок пока нет

- TQM Multiple Choice QuestionsДокумент5 страницTQM Multiple Choice QuestionsLia OngОценок пока нет

- APQP Project Management ChecklistДокумент51 страницаAPQP Project Management Checklistrobbie86290% (10)

- Process Costing TestbankДокумент46 страницProcess Costing TestbankDaniel Ong100% (10)

- APQP Documentation ChecklistsДокумент67 страницAPQP Documentation ChecklistsNeumar NeumannОценок пока нет

- APQP Supplier ProcedureДокумент20 страницAPQP Supplier ProcedurepharmatonОценок пока нет

- Apqp FormsДокумент25 страницApqp FormsgkspОценок пока нет

- Bamboo fiberboard properties from Phyllostachys pubescensДокумент76 страницBamboo fiberboard properties from Phyllostachys pubescenskanha15102003Оценок пока нет

- Supplier Performance Management Process A Complete Guide - 2019 EditionОт EverandSupplier Performance Management Process A Complete Guide - 2019 EditionОценок пока нет

- APQP Flow Chart and ProcedureДокумент7 страницAPQP Flow Chart and Procedurearun100% (1)

- Advanced Product Quality Planning (APQP)Документ22 страницыAdvanced Product Quality Planning (APQP)mjapmgОценок пока нет

- GP-12 Activity Checklist Ensures Quality FlatpacksДокумент2 страницыGP-12 Activity Checklist Ensures Quality FlatpacksLam Nguyen100% (4)

- Ppap - Aiag ManualДокумент102 страницыPpap - Aiag Manualquintozh100% (1)

- APQP ChecklistДокумент18 страницAPQP ChecklistmichaelbarkovicОценок пока нет

- APQP FormsДокумент23 страницыAPQP FormsJOECOOL670% (1)

- Supplier Apqp Gated ReviewДокумент1 страницаSupplier Apqp Gated Reviewtanto_deep_15Оценок пока нет

- GM APQP For SuppliersДокумент73 страницыGM APQP For Supplierscalinfn100% (1)

- Apqp Workflow - EXAMPLEДокумент1 страницаApqp Workflow - EXAMPLEMiguel NetoОценок пока нет

- Production Part Approval Process A Complete Guide - 2019 EditionОт EverandProduction Part Approval Process A Complete Guide - 2019 EditionОценок пока нет

- Automotive Quality Systems Handbook: ISO/TS 16949:2002 EditionОт EverandAutomotive Quality Systems Handbook: ISO/TS 16949:2002 EditionРейтинг: 3 из 5 звезд3/5 (5)

- 01.IATF 16949 AwarnessДокумент48 страниц01.IATF 16949 AwarnessMahi Reddy88% (8)

- APQP Process FlowДокумент13 страницAPQP Process Flowshukumar_24Оценок пока нет

- Fsqm-080 Ppap ChecklistДокумент14 страницFsqm-080 Ppap ChecklistMohamed Khalifa100% (1)

- Apqp - DR SHFTДокумент60 страницApqp - DR SHFTrajesh5000100% (2)

- Project Management Knowledge AreasДокумент18 страницProject Management Knowledge AreasSHOAIB RAIS SIDDIQUI100% (1)

- VDA 6.3 supplier assessmentДокумент11 страницVDA 6.3 supplier assessmentSeda De Drasnia100% (4)

- Manual - APQP 20121017 PDFДокумент135 страницManual - APQP 20121017 PDFBerk NoyanОценок пока нет

- Valeo IATF Communication To SuppliersДокумент33 страницыValeo IATF Communication To SuppliersubllcОценок пока нет

- Scientific Theory of Frederick TaylorДокумент15 страницScientific Theory of Frederick TaylorCh FarrukhОценок пока нет

- VDA 6.3 Based Supplier AssessmentДокумент11 страницVDA 6.3 Based Supplier AssessmentGrecu Dragos100% (1)

- Volvo ApqpДокумент30 страницVolvo ApqpAmolPagdalОценок пока нет

- Alliance Supplier Guide 2.3Документ3 страницыAlliance Supplier Guide 2.3MОценок пока нет

- Rivas 2014Документ2 страницыRivas 2014Azmul FadhliОценок пока нет

- Intro To ML - ABCДокумент30 страницIntro To ML - ABCAzmul FadhliОценок пока нет

- Binet All HairДокумент1 страницаBinet All HairAzmul FadhliОценок пока нет

- Effect of Orientation of Bamboo Fiber in Epoxy CompositesДокумент3 страницыEffect of Orientation of Bamboo Fiber in Epoxy CompositesAzmul Fadhli100% (1)

- Describing The Creative Design Process by The Integration of Engineering Design and Cognitive Psychology LiteratureДокумент21 страницаDescribing The Creative Design Process by The Integration of Engineering Design and Cognitive Psychology LiteratureAzmul FadhliОценок пока нет

- Insect Warfare ManipulatorДокумент7 страницInsect Warfare ManipulatorAzmul FadhliОценок пока нет

- As Opposed To HelleДокумент1 страницаAs Opposed To HelleAzmul FadhliОценок пока нет

- As Opposed To HelleДокумент1 страницаAs Opposed To HelleAzmul FadhliОценок пока нет

- TPoints RedemptionДокумент24 страницыTPoints RedemptionApple KWОценок пока нет

- Wohler CurveДокумент1 страницаWohler CurveAzmul FadhliОценок пока нет

- BandMT 08Документ10 страницBandMT 08Azmul FadhliОценок пока нет

- Higher Algebra - Hall & KnightДокумент593 страницыHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Scaling Analysis of The Tensile Strength of Bamboo Fibers Using Weibull StatisticsДокумент7 страницScaling Analysis of The Tensile Strength of Bamboo Fibers Using Weibull StatisticsAzmul FadhliОценок пока нет

- Tensile Properties of Bamboo Fiber Reinforced Biodegradable PlasticsДокумент4 страницыTensile Properties of Bamboo Fiber Reinforced Biodegradable PlasticsAzmul FadhliОценок пока нет

- Coelho - Unknown - NEW FRONTIERS PDFДокумент202 страницыCoelho - Unknown - NEW FRONTIERS PDFAzmul FadhliОценок пока нет

- Carbon Nanotube Yarn Strain SensorsДокумент6 страницCarbon Nanotube Yarn Strain SensorsAzmul FadhliОценок пока нет

- Design and Fabrication of Single-Walled Carbon Nanonet Flexible Strain SensorsДокумент12 страницDesign and Fabrication of Single-Walled Carbon Nanonet Flexible Strain SensorsAzmul FadhliОценок пока нет

- FigurecdscДокумент11 страницFigurecdscAzmul FadhliОценок пока нет

- FigurecdscДокумент11 страницFigurecdscAzmul FadhliОценок пока нет

- Getting Started in Electronics - 3ed - (Forrest M.Mims) PDFДокумент128 страницGetting Started in Electronics - 3ed - (Forrest M.Mims) PDFDavid Corbin100% (9)

- Workshop Schedule - 12-14 January 2016 Final (Lampiran B)Документ3 страницыWorkshop Schedule - 12-14 January 2016 Final (Lampiran B)Azmul FadhliОценок пока нет

- D3039 - 3039M (Tensile Properties of Composites)Документ12 страницD3039 - 3039M (Tensile Properties of Composites)Azmul FadhliОценок пока нет

- Smith 1977Документ7 страницSmith 1977Azmul Fadhli100% (1)

- 2008 Lancer Short Shifter Install Manual PDFДокумент16 страниц2008 Lancer Short Shifter Install Manual PDFAzmul FadhliОценок пока нет

- CH 6 Product 1011Документ51 страницаCH 6 Product 1011Amir BhattiОценок пока нет

- Lean manufacturing case study improves process cycle efficiencyДокумент13 страницLean manufacturing case study improves process cycle efficiencyசரவணகுமார் மாரியப்பன்Оценок пока нет

- Kunjaw AkbДокумент6 страницKunjaw AkbdindaОценок пока нет

- Activity-based costing provides more accurate product costsДокумент5 страницActivity-based costing provides more accurate product costsKhaliddawar100% (1)

- The Production Process: BECO201: - TUTORIAL6 - SolutionsДокумент8 страницThe Production Process: BECO201: - TUTORIAL6 - Solutionsloor chidiacОценок пока нет

- Case MRPДокумент2 страницыCase MRPRosie KahlonОценок пока нет

- Leviticus Inc. machine hours and electricity costs reportДокумент1 страницаLeviticus Inc. machine hours and electricity costs reportIrish Nicole RouraОценок пока нет

- SCM Test 2Документ4 страницыSCM Test 2hmichaelkimОценок пока нет

- Lecture 02 01 Process DevelopmentДокумент20 страницLecture 02 01 Process DevelopmentDon ReloОценок пока нет

- Taka Ni Mali - An Experience of ArushaДокумент21 страницаTaka Ni Mali - An Experience of ArushaMarcoChachaОценок пока нет

- Unit V SDMДокумент33 страницыUnit V SDMChirag JainОценок пока нет

- Engineering Management Lecture 3 Pert PresentationДокумент17 страницEngineering Management Lecture 3 Pert PresentationWasim KhawajaОценок пока нет

- TQM, Target CostingДокумент3 страницыTQM, Target CostingarroshanОценок пока нет

- Kanban Pull System ExplainedДокумент9 страницKanban Pull System ExplainedPrakritiОценок пока нет

- Machining Questions on Tool Life, Cutting Forces, Location SystemsДокумент1 страницаMachining Questions on Tool Life, Cutting Forces, Location SystemspmagrawalОценок пока нет

- Autoliv Special Characteristics Classification June 2016Документ13 страницAutoliv Special Characteristics Classification June 2016David GarafutdinovОценок пока нет

- Holistic Approach To Quality Management - TQMДокумент21 страницаHolistic Approach To Quality Management - TQMADEFIOYE AdeniyiОценок пока нет

- Otto-Leibinger Dental Instruments CatalogДокумент51 страницаOtto-Leibinger Dental Instruments CatalogpuspaОценок пока нет

- Logistics and Supply Chain Management Paper 2015Документ3 страницыLogistics and Supply Chain Management Paper 2015Sagar PatilОценок пока нет

- Sample Productivity ProblemsДокумент5 страницSample Productivity ProblemsCassia MontiОценок пока нет

- GE8077 – INTRODUCTION TO TOTAL QUALITY MANAGEMENTДокумент12 страницGE8077 – INTRODUCTION TO TOTAL QUALITY MANAGEMENTsafina rahmanОценок пока нет

- MAW KitДокумент3 страницыMAW KitdrustagiОценок пока нет