Академический Документы

Профессиональный Документы

Культура Документы

Sea-Struct Groutbag PDF

Загружено:

Erica MartinИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Sea-Struct Groutbag PDF

Загружено:

Erica MartinАвторское право:

Доступные форматы

Sea-Struct Groutbags

Custom Manufacture

Through the combination of its in house design

capabilities, engineering expertise and extensive

offshore installation experience, Sea-Struct can

provide clients with custom designed and bespoke

products such as Grout Tubes, Pile Plug Bags and

Cross-over bags that can be tailored to meet their

specific project needs. Additionally, Sea-Struct can

manufacture its standard product line in larger

dimensions to client specification.

Sea-Struct Groutbags

Offshore Grouting

Diver Installed Supports

The Pipeline Support System

The process of installing supports using divers includes comprehensive

procedures for diver intervention. Features such as over-pipe straps,

corner tie down fixtures and ball valve water vents that are incorporated

into the Groutbag design assist with diver installation.

ROV Installed Supports

Sea-Struct has pioneered the installation of Pipeline Freespan Supports

in deep water using remotely operated vehicles (ROV). The combination

of unique installation equipment and the implementation of procedures

that have been successfully utilised to install more than 3000 bags has

resulted in an effective and cost saving system. Supports to a massive

5000mm in height have been successfully installed using Sea-Struct

ROV installation system.

Grouting Equipment

In the field, Sea-Struct can supply all of the equipment required for the

installation of its Groutbags including silo bulk cement storage and

shipping containers. Please refer to Sea-Struct equipment flyers for

further information.

Contact Details

MPE Lindung Sdn Bhd

Suite 19.01, Level 19, The Gardens North Tower,

Mid Valley City, Lingkaran Syed Putra,

59200 Kuala Lumpur, Malaysia

Telephone +603 2685 6800

Fax +603 2685 6999

product

www.wascoenergy.com | mpe.sales@wascoenergy.com

www.wascoenergy.com | m p e. sa l es @ wa sco e n e rg y.co m

Sea-Struct Groutbags

Sea-Struct Groutbags

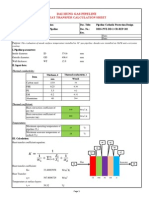

SBP Series Groutbags

GM Series Groutbags

Specification

SBP 250 SERIES SUITABLE FOR EXTERNAL PIPELINE DIAMETER: 10mm to 250mm

MODEL

FREESPAN HEIGHT A

B

C

D

E

F

Form

MIN

MAX

Vol (m3)

SBP 250/750

500

750

550 1120 630 250 200 1620 0.91

SBP 250/1000 750

1000

550 1320 880 250 200 1820 1.42

SBP 250/1250 1000

1250

550 1520 1130 250 200 2020 2.97

SBP 250/1500 1250

1500

550 1720 1380 250 200 2220 4.05

SBP 250/1750 1500

1750

550 1920 1630 250 200 2420 5.38

SBP 250/2000 1750

2000

550 2120 1880 250 200 2620 6.98

SBP 250/2250 2000

2250

550 2320 2130 250 200 2820 8.89

SBP 250/2500 2250

2500

550 2520 2380 250 200 3020 11.13

SBP 500 SERIES SUITABLE FOR EXTERNAL PIPELINE DIAMETER: 250mm to 500mm

MODEL

FREESPAN HEIGHT A

B

C

D

E

F

Form

MIN

MAX

Vol (m3)

SBP 500/750

500

750

920 1520 680 250 200 2020 2.69

SBP 500/1000 750

1000

920 1720 930 250 200 2220 3.67

SBP 500/1250 1000

1250

920 1920 1180 250 200 2420 4.90

SBP 500/1500 1250

1500

920 2120 1430 250 200 2620 6.38

SBP 500/1750 1500

1750

920 2320 1680 250 200 2820 8.16

SBP 500/2000 1750

2000

920 2520 1930 250 200 3020 10.26

SBP 500/2250 2000

2250

920 2720 2180 250 200 3220 12.70

SBP 500/2500 2250

2500

920 2920 2430 250 200 3420 15.52

Stabilised Base Pyramids provide an enlarged base, high

payload, stable support for pipeline freespan correction.

The standard SBP design provides clients with time and

cost savings associated with positioning and filling the

forms and the cement required. In addition, the SBP form

also provides:

Improved load bearing characteristics

Improved lateral stability

Scour reduction

Application on sloping seabed

The SBP form construction comprises multiple

compartments with internal structural partitioning and

base height limiting straps to provide form shape during

inflation.

SBP 750 SERIES SUITABLE FOR EXTERNAL PIPELINE DIAMETER: 500mm to 750mm

MODEL

FREESPAN HEIGHT A

B

C

D

E

F

Form

MIN

MAX

Vol (m3)

SBP 750/750

500

750

1220 1920 780 250 200 2420 2.69

SBP 750/1000 750

1000

1220 2120 1030 250 200 2620 3.77

SBP 750/1250 1000

1250

1220 2320 1280 250 200 2820 5.09

SBP 750/1500 1250

1500

1220 2520 1530 250 200 3020 6.70

SBP 750/1750 1500

1750

1220 2720 1780 250 200 3220 8.61

SBP 750/2000 1750

2000

1220 2920 3030 250 200 3420 10.85

SBP 750/2250 2000

2250

1220 3120 2280 250 200 3620 13.45

SBP 750/2500 2250

2500

1220 3320 2530 250 200 3820 16.44

SBP 1000 SERIES SUITABLE FOR EXTERNAL PIPELINE DIAMETER: 750mm to 1000mm

MODEL

FREESPAN HEIGHT A

B

C

D

E

F

Form

MIN

MAX

Vol (m3)

SBP 1000/750 500

750

1580 2320 830 250 200 2820 4.21

SBP 1000/1000 750

1000

1580 2520 1080 250 200 3020 5.68

SBP 1000/1250 1000

1250

1580 2720 1330 250 200 3220 7.45

SBP 1000/1500 1250

1500

1580 2920 1580 250 200 3420 9.54

SBP 1000/1750 1500

1750

1580 3120 1830 250 200 3620 11.97

SBP 1000/2000 1750

2000

1580 3320 2080 250 200 3820 14.78

SBP 1000/2250 2000

2250

1580 3520 2330 250 200 4020 17.99

SBP 1000/2500 2250

2500

1580 3720 2580 250 200 4220 21.63

SBP 1250 SERIES SUITABLE FOR EXTERNAL PIPELINE DIAMETER: 1000mm to 1250mm

MODEL

FREESPAN HEIGHT A

B

C

D

E

F

Form

MIN

MAX

Vol (m3)

SBP 1250/750 500

750

1920 2720 930 250 200 3220 6.36

SBP 1250/1000 750

1000

1920 2920 1180 250 200 3420 8.34

SBP 1250/1250 1000

1250

1920 3120 1430 250 200 3620 10.66

SBP 1250/1500 1250

1500

1920 3320 1680 250 200 3820 13.34

SBP 1250/1750 1500

1750

1920 3520 1930 250 200 4020 16.42

SBP 1250/2000 1750

2000

1920 3720 2180 250 200 4220 19.91

SBP 1250/2250 2000

2250

1920 3920 2430 250 200 4420 23.86

SBP 1250/2500 2250

2500

1920 4120 2680 250 200 4620 28.28

product

GM Series Groutbags provide an economical solution to

pipeline support and are used for small spans. GM forms can

also be used in conjunction with SBP forms to support

pipeline crossovers and can be applied, in various sizes, to a

pipeline adding weight for stability.

Typical examples of Grout Mat stability:

In shallow water where a vessel that is capable of handling

pre-cast concrete mattresses cannot access the pipe

Where there are concerns that the application of

Sea-Structs pre-cast concrete mattresses may cause

damage to a cable or umbilical.

Specification

MODEL

LENGTH

WIDTH

(mm)

(mm)

(m3)

GM 300/1250

GM 300/1750

GM 300/2250

GM 500/1250

GM 500/1750

GM 500/2250

1250

1750

2250

1250

1750

2250

1250

1750

2250

1250

1750

2250

300

300

300

500

500

500

0.63

1.23

2.00

0.94

1.84

3.00

(mm)

HEIGHT

VOLUME

www.wascoenergy.com | m p e. sa l es @ wa sco e n e rg y.co m

Вам также может понравиться

- Reality Show PacketДокумент19 страницReality Show PacketCourtney Grace100% (8)

- ANSYS TutorialДокумент44 страницыANSYS Tutorialsauravc88Оценок пока нет

- Underwater InspectionДокумент26 страницUnderwater InspectionAchmad Afif Wijayanto100% (2)

- (GRE) Installation Manual For MarineДокумент37 страниц(GRE) Installation Manual For MarineQuy RomОценок пока нет

- US Army - Engineer Diving Operations FM 5-490Документ38 страницUS Army - Engineer Diving Operations FM 5-490Jared A. Lang100% (3)

- ABS MODU Part3-Hull Const & EquipДокумент64 страницыABS MODU Part3-Hull Const & EquipGoodD11Оценок пока нет

- Europe's Longest Marine PE Pipe ProjectДокумент8 страницEurope's Longest Marine PE Pipe Projectmidhun1986Оценок пока нет

- Perform3d User GuideДокумент336 страницPerform3d User Guidepechak1Оценок пока нет

- Seaflex Product LiteratureДокумент8 страницSeaflex Product LiteratureKen Tang100% (1)

- ITP For Pressure Vessel PDFДокумент4 страницыITP For Pressure Vessel PDFErica MartinОценок пока нет

- U Drain SpecДокумент4 страницыU Drain Speckenji_sanОценок пока нет

- SAA DeeP-Stop Diving For AllДокумент7 страницSAA DeeP-Stop Diving For AllGrym1Оценок пока нет

- 00.1.corrosion Control Jetty PileДокумент48 страниц00.1.corrosion Control Jetty PileSyafrudin MegnumzОценок пока нет

- SEALINE Catalog 2021Документ20 страницSEALINE Catalog 2021ddОценок пока нет

- Pipeline Heat Transfer CalculationДокумент2 страницыPipeline Heat Transfer CalculationErica MartinОценок пока нет

- PLEM Design Methodology: StructureДокумент4 страницыPLEM Design Methodology: StructureErik AlfiandyОценок пока нет

- Neptune Subsea Stabilisation - Products and Services (V10) PDFДокумент56 страницNeptune Subsea Stabilisation - Products and Services (V10) PDFPablo Ignacio Cortés AguileraОценок пока нет

- History and Development of Scuba DivingДокумент43 страницыHistory and Development of Scuba DivingAngie AugustineОценок пока нет

- Larsen & Toubro Limited Grouting SpecificationДокумент11 страницLarsen & Toubro Limited Grouting Specificationirshad khanОценок пока нет

- HSS80 Heat Shrink Sleeve: Features & BenefitsДокумент2 страницыHSS80 Heat Shrink Sleeve: Features & BenefitsAnonymous eEJDOR2100% (1)

- 4 Kinds of Stroke and Kick in Swimming Techniques ExplainedДокумент4 страницы4 Kinds of Stroke and Kick in Swimming Techniques ExplainedTrichia ZabaloОценок пока нет

- Walkway GratingДокумент7 страницWalkway GratingdaniarsyafrilianОценок пока нет

- 50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierДокумент9 страниц50037-ME-DOC-001 - Marine Spread Specifications and Certifications DossierseehariОценок пока нет

- Concrete Mattresses FlysheetДокумент3 страницыConcrete Mattresses FlysheetDave M MichaelОценок пока нет

- ISES CP Report 5Документ17 страницISES CP Report 5Tamer Hesham AhmedОценок пока нет

- 028120-SPL-002 CRA Lined Carbon Steel Linepipe (Rev. C)Документ13 страниц028120-SPL-002 CRA Lined Carbon Steel Linepipe (Rev. C)Rokan PipelineОценок пока нет

- Underwater Submarine Pipe LineДокумент30 страницUnderwater Submarine Pipe LinevillanuevamarkdОценок пока нет

- Deltabeam Brochure EngДокумент20 страницDeltabeam Brochure EngymitevОценок пока нет

- CN Scrubber Dn3500 Rev04Документ58 страницCN Scrubber Dn3500 Rev04becemОценок пока нет

- Pipe Mill and Coating Yard - Qualification: Offshore Service Specification DNV-OSS-313Документ22 страницыPipe Mill and Coating Yard - Qualification: Offshore Service Specification DNV-OSS-313learsipi061Оценок пока нет

- Catalogue 2014 en HDДокумент58 страницCatalogue 2014 en HDBrad BarnesОценок пока нет

- Technical Specifications TSHD Jan de NulДокумент4 страницыTechnical Specifications TSHD Jan de NulRavael SimanjuntakОценок пока нет

- KLELINE hoses for offshore vertical installation and CALM buoy configurationsДокумент24 страницыKLELINE hoses for offshore vertical installation and CALM buoy configurationsJorge GonzalezОценок пока нет

- DNV Structural OS C201Документ78 страницDNV Structural OS C201nse mcxОценок пока нет

- Bollard Catalogue PDFДокумент16 страницBollard Catalogue PDFHaris PrasetiyoОценок пока нет

- Tyfo SW-1 EpoxyДокумент2 страницыTyfo SW-1 EpoxyJeje AjrОценок пока нет

- FRP Repair of Corrosion-Damaged Concrete BeamsДокумент13 страницFRP Repair of Corrosion-Damaged Concrete BeamsahmadlieОценок пока нет

- OceanTools Video Overlay TutorialДокумент10 страницOceanTools Video Overlay TutorialFilip EmОценок пока нет

- BS 5480-2 (1982) Design and Performance RequirementsДокумент24 страницыBS 5480-2 (1982) Design and Performance RequirementsGregory Simmon100% (1)

- 0-3670R Hydrosure Msds Eng AIP 30112010-2Документ5 страниц0-3670R Hydrosure Msds Eng AIP 30112010-2Michael MaldonadoОценок пока нет

- WW 11 Corrosion Prevention of Steel Pipe 2012Документ100 страницWW 11 Corrosion Prevention of Steel Pipe 2012daskirОценок пока нет

- Tyfo SEH 51A CompositeДокумент2 страницыTyfo SEH 51A CompositeThanongsak ImjaiОценок пока нет

- SPECIALISED DREDGING SERVICES FOR OFFSHORE PROJECTSДокумент5 страницSPECIALISED DREDGING SERVICES FOR OFFSHORE PROJECTSUyavie ObonnaОценок пока нет

- PMS12 Baltim ITP Offshore Pipelay ActivitiesДокумент15 страницPMS12 Baltim ITP Offshore Pipelay ActivitiesyehiaОценок пока нет

- Comparisons of Materials Between JIS and Foreign StdsДокумент1 страницаComparisons of Materials Between JIS and Foreign StdsChenthil KumarОценок пока нет

- CementДокумент19 страницCementSaqib RanaОценок пока нет

- List of Referenced Codes and StandardsДокумент1 страницаList of Referenced Codes and StandardsHaridevОценок пока нет

- GREДокумент12 страницGREadvis79Оценок пока нет

- MGP-i For Jetties (Final)Документ2 страницыMGP-i For Jetties (Final)Eddie TaiОценок пока нет

- Stainless Steel Ball Valves and Industrial Valves ManufacturerДокумент57 страницStainless Steel Ball Valves and Industrial Valves ManufacturerLuqman Elhanif0% (1)

- Ductile Iron Pipes FittingsДокумент44 страницыDuctile Iron Pipes FittingsSaifur RahmanОценок пока нет

- Bottcher UV Roller Maintenance RecommendationsДокумент3 страницыBottcher UV Roller Maintenance RecommendationsMadonna del CastilloОценок пока нет

- Technical Enquiry and Price Quote for ILT 42Документ2 страницыTechnical Enquiry and Price Quote for ILT 42dungrelОценок пока нет

- U BoltsДокумент14 страницU BoltsLuz DuarteОценок пока нет

- PVC CPVC Physical Properties and Astm Specifications For Piping PDFДокумент1 страницаPVC CPVC Physical Properties and Astm Specifications For Piping PDFShahfaraz AhmadОценок пока нет

- Zinc (Hot-Dip Galvanized) Coatings On Iron and Steel ProductsДокумент8 страницZinc (Hot-Dip Galvanized) Coatings On Iron and Steel ProductssenthilkumarОценок пока нет

- Jis g3456 Grade STPT 410 Pipes PDFДокумент1 страницаJis g3456 Grade STPT 410 Pipes PDFMitul MehtaОценок пока нет

- In Line Sled (Ils)Документ6 страницIn Line Sled (Ils)xonepotОценок пока нет

- Simulasi Tes TOEICДокумент16 страницSimulasi Tes TOEICAlfi CahyaОценок пока нет

- Introducing Hengtong MarineДокумент25 страницIntroducing Hengtong MarineJuan R. López BetanzosОценок пока нет

- Long Radius Steel Elbows - 3D, 5D and 6D: Product DescriptionДокумент3 страницыLong Radius Steel Elbows - 3D, 5D and 6D: Product Descriptionbadesharamk100% (2)

- Nace Table 3Документ2 страницыNace Table 3gana_1783100% (1)

- Iscar Grade ChartДокумент1 страницаIscar Grade ChartsmarjanОценок пока нет

- Setting The Standard: We Find Out Why Shell Shipping Is The Industry LeaderДокумент28 страницSetting The Standard: We Find Out Why Shell Shipping Is The Industry Leadershihabjamaan8205Оценок пока нет

- Tyfo SEH-51AДокумент2 страницыTyfo SEH-51AgammankОценок пока нет

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsДокумент2 страницыEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaОценок пока нет

- AV GasketsДокумент2 страницыAV GasketsAliОценок пока нет

- Defensas Maritimas - Complete FlotationДокумент32 страницыDefensas Maritimas - Complete FlotationFelipe FernandesОценок пока нет

- Tank Ft4 KKCДокумент1 страницаTank Ft4 KKCErica MartinОценок пока нет

- Tank Ft4 KKCДокумент1 страницаTank Ft4 KKCErica MartinОценок пока нет

- Tank FT4 KKC PDFДокумент1 страницаTank FT4 KKC PDFErica MartinОценок пока нет

- ITP For Pressure VesselДокумент48 страницITP For Pressure VesselErica MartinОценок пока нет

- Swiber PJW3000 Crane Lift Chart - FIДокумент1 страницаSwiber PJW3000 Crane Lift Chart - FIErica MartinОценок пока нет

- Catalog A 1 Filter Driers - 42015Документ32 страницыCatalog A 1 Filter Driers - 42015Erica MartinОценок пока нет

- Dynamics of Fixed Marine Structures N. D. P. Barltrop A. J. AdamsДокумент396 страницDynamics of Fixed Marine Structures N. D. P. Barltrop A. J. AdamsErica MartinОценок пока нет

- ANSYS-Mode for Emacs, an introductory tutorialДокумент27 страницANSYS-Mode for Emacs, an introductory tutorialvicksgeorge9750Оценок пока нет

- Ans Mod PDFДокумент250 страницAns Mod PDFErica MartinОценок пока нет

- Deshpande Uta 2502M 10951 PDFДокумент65 страницDeshpande Uta 2502M 10951 PDFErica MartinОценок пока нет

- L2 WinДокумент4 страницыL2 WinErica MartinОценок пока нет

- L2 WinДокумент4 страницыL2 WinErica MartinОценок пока нет

- Diving Take The PlungeДокумент9 страницDiving Take The Plunge12D1.04 .Nguyễn Doãn Ngân HàОценок пока нет

- Physics 90 Wizard Problems 1Документ28 страницPhysics 90 Wizard Problems 1francis bautistaОценок пока нет

- EWEelding SafetyДокумент3 страницыEWEelding SafetyHafiz SabriОценок пока нет

- Resource One 11.10Документ39 страницResource One 11.10Jongol LobakОценок пока нет

- JTF2 Pre-Selection Physical Fitness EvaluationДокумент9 страницJTF2 Pre-Selection Physical Fitness Evaluationscribd3991Оценок пока нет

- Level I Unseen Comprehension Practice-Beneath The Surface (SV)Документ7 страницLevel I Unseen Comprehension Practice-Beneath The Surface (SV)saudiОценок пока нет

- Soal Latihan FisikaДокумент54 страницыSoal Latihan FisikaGinanjar Dika100% (1)

- Subject Verb AgreementДокумент4 страницыSubject Verb AgreementMarvelle JeffersonОценок пока нет

- Bekic (Ed) - Potopljena Baština / Submerged Heritage 1, 2011Документ35 страницBekic (Ed) - Potopljena Baština / Submerged Heritage 1, 2011utvrdaОценок пока нет

- Evan Geiselman rescued from drowning at Pipeline surf breakДокумент6 страницEvan Geiselman rescued from drowning at Pipeline surf breakRafaelОценок пока нет

- Grammar ComprehensionДокумент8 страницGrammar ComprehensionЛогинов ДенисОценок пока нет

- BI 2015 IBC Amendments 01-25-2017Документ208 страницBI 2015 IBC Amendments 01-25-2017Carl CrowОценок пока нет

- A Review of Human Disturbance Impacts On WaterbirdsДокумент23 страницыA Review of Human Disturbance Impacts On WaterbirdsslavernovaОценок пока нет

- Sabah Malaysian Borneo March 2008Документ28 страницSabah Malaysian Borneo March 2008Sabah Tourism Board100% (3)

- SnorkelingДокумент43 страницыSnorkelingMoreno, John Gil F.Оценок пока нет

- Sea-Struct Groutbag PDFДокумент2 страницыSea-Struct Groutbag PDFErica MartinОценок пока нет

- Coral Reef Packages - LakshadweepДокумент31 страницаCoral Reef Packages - Lakshadweeparijit_ghosh_18Оценок пока нет

- Breakingmuscle-Frogman Workout Cycle 1Документ11 страницBreakingmuscle-Frogman Workout Cycle 1Soylo Amado RubioОценок пока нет

- Vectors and Projectiles - Problem SetДокумент7 страницVectors and Projectiles - Problem Setcpverma2811Оценок пока нет

- Inflatable Kayaks PresentationДокумент17 страницInflatable Kayaks PresentationSimon RobinsonОценок пока нет

- Town of Bristol Fire Department Standard Operating ProcedureДокумент7 страницTown of Bristol Fire Department Standard Operating ProcedureGyanendra Narayan NayakОценок пока нет

- Whale Shark NewДокумент37 страницWhale Shark NewDrew RodriguezОценок пока нет

- Week 1 History of SwimmingДокумент23 страницыWeek 1 History of SwimmingGhee CopinoОценок пока нет

- Region 2 2-Day ItineraryДокумент8 страницRegion 2 2-Day Itinerarytayrayrmp68Оценок пока нет