Академический Документы

Профессиональный Документы

Культура Документы

PL Dependence of ZnO Films Grown On Si With Various Buffer PDF

Загружено:

eid elsayedИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PL Dependence of ZnO Films Grown On Si With Various Buffer PDF

Загружено:

eid elsayedАвторское право:

Доступные форматы

Electrochemical and Solid-State Letters, 7 7 J20-J22 2004

J20

0013-4651/2004/77/J20/3/$7.00 The Electrochemical Society, Inc.

PL Dependence of ZnO Films Grown on Si with Various Buffer

Layers by RF Magnetron Sputtering

Chin-Ching Lin,a San-Yuan Chen,a,z and Syh-Yuh Chengb

a

Department of Materials Science and Engineering, National Chiao-Tung University, Hsinchu, Taiwan

Industrial Technology Research Institution, Materials Research Laboratories, Chutung, Taiwan

Peculiar photoluminescence PL emission properties of ZnO films on Si buffered with SiO2 and Si3 N4 were found. The ZnO films

deposited on SiO2 /Si substrate show two double peaks in the room-temperature PL spectra, one double 374 and 394 nm in the

ultraviolet region and the other double 495 and 605 nm located in the visible region. If the ZnO film was grown on Si3 N4 /Si,

a very strong UV along with invisible deep-level emission was detected because the Si3 N4 can effectively reduce the defect

formation of oxygen vacancies and Zn interstitials compared to ZnO on SiO2 /Si and Si.

2004 The Electrochemical Society. DOI: 10.1149/1.1736594 All rights reserved.

Manuscript submitted October 23, 2003; revised manuscript received November 21, 2003. Available electronically April 29, 2004.

Zinc oxide has received an enormous amount of attention because ZnO not only has a wide direct bandgap 3.37 eV at room

temperature but also shows a large exciton binding energy 60 meV

that is much larger than that of ZnSe 20 meV and GaN 25 meV.1

The ultraviolet UV emission of ZnO is attributed to exciton-related

activities, but for visible emissions, various mechanisms have been

proposed including the involvement of zinc interstitials,2,3 oxygen

interstitials,4,5 zinc vacancies,6,7 and oxygen vacancies.8,9 Recently,

a violet emission peaked at 401 nm 3.09 eV was observed in

low-temperature photoluminescence PL spectra of ZnO films

grown on p-type Si by radio-frequency rf magnetron sputtering

under oxygen-rich conditions. Jeong et al. considered that the emission was assigned to the electron transition from the bottom of the

conduction band to the zinc vacancies level.10 In addition, Jin et al.

also found another violet emission around 420 nm (2.95 eV) for

ZnO film grown on Si substrate and reported that the violet emission

is due to a defect level in the grain boundaries of the ZnOx

crystals.11 However, the exact origin of the special emission behavior of ZnO films is not yet well understood and is still debatable.

Recently, many studies have been focused on ZnO films deposited on silicon substrate because of the development for large-scale

electronic integration devices. However, a large lattice mismatch

between Si and ZnO affects the physical characteristics and emission properties of ZnO films. Therefore, it is important to understand

the substrate, especially interface microstructure, effect on defect

transition and PL properties of ZnO films.

In this article, we try to clarify the exact origin of the unique

emission behavior of ZnO films grown on Si substrate buffered with

SiO2 and Si3 N4 layers by rf magnetron sputtering. To the authors

knowledge, it was first reported that two double emissions, one in

the UV emission region and the other in deep-level emissions, were

observed in room-temperature PL spectra of ZnO films grown on

SiO2 /Si. Furthermore, the ZnO films deposited on Si3 N4 /Si presented excellent optical and electrical properties compared to those

on SiO2 /Si and Si substrates.

Experimental

ZnO thin films (125 nm) were deposited on 4 in. diameter Si

substrates buffered with SiO2 and Si3 N4 layers by rf magnetron

sputtering using 99.99% ZnO as a target. Sputtering conditions were

optimized at a substrate temperature of 50C, rf power of 50 W,

sputtering pressure of 10 mTorr, and sputtering time of 30 min at a

gas mole ratio of oxygen to argon of 5% condition. The buffer layers

were grown by electron evaporation and the thickness of the buffer

layers for Si3 N4 and SiO2 was about 10 and 20 nm, respectively.

After sputtering, the as-grown ZnO films were annealed at 850C

for 20 min under pure oxygen and nitrogen atmospheres. The sur-

E-mail: sychen@cc.nctu.edu.tw

face morphology was examined by field-emission scanning electron

microscopy FESEM, S-4100. The crystal structure was determined

using Siemens D5000 X-ray diffraction XRD with Cu K radiation and a Ni filter. Transmission electron microscopy TEM Philips

TECNAI 20 attached with energy-dispersive X-ray spectroscopy

EDS operated at 200 keV was also used for microstructure analysis of cross-sectional interface. PL measurement was performed by

the excitation from 325 nm He-Cd laser at various temperatures.

Results and Discussion

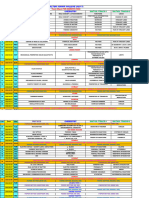

Figure 1 shows the XRD patterns of ZnO films sputtered at Si,

SiO2 /Si, and Si3 N4 /Si, and then annealed at 850C in O2 atmosphere. Only a sharp diffraction peak of 002 at 2 34.5 can be

detected for all the films, indicating that well-defined and oriented

ZnO films have been obtained. However, the peak intensity of ZnO

film grown on SiO2 /Si substrate is much weaker compared with that

on Si3 N4 /Si substrate. This reveals that the amorphous SiO2 buffer

layer has a strong negative affect on the crystalline characteristics of

the ZnO films. The values of full width at half-maximum fwhm are

0.18, 0.16, and 0.33 for the ZnO films grown on Si, Si3 N4 /Si, and

SiO2 /Si substrates, respectively. In addition, it was observed that

the ZnO films annealed at 850C in nitrogen (N2 ) exhibit a similar

trend to that annealed in O2 atmosphere but the corresponding values 0.20, 0.19, and 0.45 of fwhm are larger in N2 atmosphere. It

implies that O2 annealing presents a more positive effect on crystalline characteristics of ZnO films than N2 annealing.

Figure 2 shows the bright-field TEM images of the ZnO films

deposited on various substrates and then annealed at 850C in O2

atmosphere. The cross-sectional microstructure of all the ZnO films

can be clearly divided into two regions: crystalline columnar shape

and interlayer flat belt. The columnar structure was grown along c

axis orientation but the interlayer forms a disorder structure that may

play a crucial important role in reducing stress due to lattice mismatch between ZnO and Si substrate. Both ZnO films deposited on

Si and Si3 N4 /Si substrates present similar cross-sectional microstructure as can be seen in Fig. 2a. However, as the ZnO film was

deposited on SiO2 /Si substrate, a large variation appears on the

microstructure as shown in Fig. 2b. A thicker disordered ZnO interlayer with rougher interface was identified for ZnO film grown on

SiO2 /Si compared to that on Si3 N4 /Si and Si. The formation of the

thicker disordered ZnO interlayer in ZnO/SiO2 /Si structure was believed to be strongly dependent on the crystal characteristics of the

SiO2 buffered layer. Some researchers reported that as the SiO2 film

was annealed at a high temperature exceeding 700C, many defects such as oxygen vacancies were easily produced and it became

the nonstoichiometric composition.12,13 As illustrated in Fig. 2c,

more oxygen vacancies are induced in the ZnO film deposited on the

SiO2 buffered layer. Furthermore, the diffusivity of the oxygen vacancies is faster than other defects in ceramic oxides. Therefore, in

Electrochemical and Solid-State Letters, 7 7 J20-J22 2004

J21

Figure 1. XRD patterns and fwhm inset of ZnO films sputtered at Si,

SiO2 /Si, and Si3 N4 /Si after annealing at 850C in oxygen atmospheres.

this condition, a thicker ZnO interlayer was formed on SiO2 buffered layer compared to Si3 N4 buffered layer. X-ray photoelectron

spectroscopy XPS was further used to investigate the depth profile

of element composition from columnar ZnO shape through disordered ZnO interlayer. As shown in Fig. 2c, the relative Zn/O ratio

obviously increases around the interlayer ZnO region in all cases,

implying that the ZnO interlayer disordered layer is nonstoichio

metric and contains more oxygen vacancies (VO

). Moreover, the

defect concentration of oxygen vacancy in ZnO/SiO2 /Si films was

apparently more than that in ZnO/Si3 N4 /Si films as confirmed by

XPS analysis, O 1s peak at 531.25 0.2 eV. In addition, a higher

VO

concentration was also detected in ZnO/SiO2 /Si films than that

in ZnO/Si that could be due to the diffusion of more extra defects

oxygen vacancies from the SiO2 buffered layer into ZnO films

during later thermal annealing. In contrast to SiO2 /Si and Si substrates, the diffusion of oxygen vacancies from Si3 N4 /Si into ZnO

was almost undetected.

Figure 3 illustrates the room-temperature PL spectra of ZnO

films deposited on various substrates and then annealed at 850C in

O2 atmosphere. From the spectra, note that the peak intensity of the

UV emission depends markedly on the substrates used. The ZnO

films deposited on Si substrate show a sharp free exciton peak

around 379 nm and a broad peak in the visible region between 550

and 650 nm. The PL emission peak corresponding to the UV emission appears around 377-379 nm 3.29-3.27 eV that should be a

near bandedge emission of ZnO films due to an exciton-related

activity.14 Concerning the visible emission, it should result from

deep-level emission which is generally associated with zinc interstitialsand oxygen vacancies in ZnO lattice. However, the PL spectra

of ZnO deposited on SiO2 /Si substrate are apparently different from

others. The PL spectra present two UV emissions peaked at 377 nm

3.29 eV and 394 nm 3.15 eV. The former one is the normally

observed UV peak and the latter one is similar to the one 401 nm

reported by Jeong et al. in low-temperature PL spectra of ZnO films

grown on p-type Si under oxygen-rich conditions. According to the

observation of Jeong et al., the emission band was assigned to the

electron transition from the bottom of the conduction band to the

zinc vacancies level.10 However, in our case, it may suggest that the

UV emission peak at 394 nm 3.15 eV results from the variation in

microstructure and is assigned to the transition form oxygen va

cancy (VO

) level to valence band, positioned approximately 0.20 eV

below the conduction bandedge.15 In addition to the UV emission,

the visible emission is also changed. The spectra corresponding to

the visible emission region also exhibit two broad peaks around 495

(2.50 eV) and 605 nm (2.05 eV). It implies that there may be

Figure 2. XTEM images of the ZnO grown on a Si3 N4 /Si and b SiO2 /Si

substrates after annealing at 850C in oxygen atmospheres. c Atomic ratio

(0.10) of zinc and oxygen at different depths form the surface of the ZnO

film on Si with various buffer layers.

two different defect transitions occurring at the same time. According to the defect model proposed by Lima,16 the green luminescence

(2.5 eV) corresponds to a transition from Zn to Zn and the red

).

luminescence (2.0 eV) is attributed to the oxygen vacancies (VO

It was believed that the variation of PL spectra in ZnO/SiO2 /Si was

influenced by the change of crystal characteristics thicker ZnO interlayer and rough interface between columnar ZnO and ZnO interlayer and defect concentration nonstoichiometric. According to

the investigation of Zhao et al. for asymmetric double GaAs/

AlGaAs quantum well, it was reported that the peak splitting in the

PL spectra may result from two transitions probably due to the geometric fluctuations layer-thickness fluctuation.17 Therefore, a

thicker ZnO interlayer could effectively relieve the stress to assist

the crystal growth but the disordered ZnO interlayer may induce

many defects to change the PL spectra. In contrast, ZnO/Si3 N4 /Si

structure does not exhibit those double emission peaks. Only a

strongly sharp UV peak centered at 377 nm 3.29 eV was detected.

It was believed that the ZnO film grown on Si3 N4 /Si substrate has

improved stoichiometry with few oxygen vacancies and Zn intersti-

J22

Electrochemical and Solid-State Letters, 7 7 J20-J22 2004

slightly compressed in low-temperature environment and the local

defect transition may be thermally quenched as evidenced from the

variation in the emission peak at 394 nm. The double peaks in the

UV region coexist in the whole temperature between 10 and 300 K

but show different intensities. This indicates that there are thermal

transfer effects. It seems that the local defect transition may be thermally quenched at low temperature and a large amount of oxygen

vacancies to induce defects transfer from oxygen vacancies (VO )

level to valence band was confined due to microstructure fluctuations. Further investigations for the temperature dependence on PL

are in progress and the results will be reported in the near future.

Moreover, although all the specimens were n-type ZnO films, the

carrier concentration of ZnO/Si3 N4 /Si sample is very close to intrinsic ZnO (1.40 1014 cm3 ) and can be increased by posttreatment. Thus, it may offer an alternative route to develop p-type

ZnO films on Si3 N4 /Si.

Conclusion

Figure 3. Room temperature PL spectra of the ZnO films deposited on various substrates after annealing at 850C in oxygen and nitrogen inset atmospheres.

tials concentration as shown in Fig. 2c because the PL emission

characteristics of ZnO films are strongly dependent on both the film

stoichiometry and the crystal quality of the film. Especially, as the

buffer layer (SiO2 ) becomes thicker in ZnO/SiO2 /Si structure, the

physical and optical properties of ZnO films become poor because a

thicker SiO2 layer induces more extra defects during annealing. In

contrast, in ZnO/Si3 N4 /Si structure, a thicker buffer layer (Si3 N4 )

prevents the formation and diffusion of extra defects and, thus, the

film stoichiometry of ZnO is improved. Therefore, ZnO films grown

on Si3 N4 /Si substrate present better physical and optical properties

than those on other substrates.

Low-temperature PL measurement was performed for a more

detailed investigation of the emission characteristics. As shown in

Fig. 4, the PL spectra obtained were measured at 10 K from the

same samples as shown in Fig. 3. The ZnO films grown on Si3 N4 /Si

substrate still show the strongest exciton-related emission peak at

374 nm (3.32 eV) along with blue shift. For the ZnO film grown

on SiO2 /Si, the PL peak centered at 394 nm becomes weak and

more broadening as compared with Fig. 3 butthe deep-level emission remains unchanged. Generally, the lattice distance would be

We have shown that the emission characteristics of ZnO films

grown on Si by rf magnetron sputtering are strongly influenced by

the buffer layer. Although all the ZnO films have strong c axis

orientation and present similar columnar-like crystal structure, the

PL results in this study apparently reveal that the buffer layer plays

a crucial role in crystal quality and film stoichiometry of the disordered ZnO interlayer. In the room-temperature PL spectra, the ZnO

films deposited on SiO2 /Si substrate show two double peaks, one

double 374 nm and 394 nm near the UV peak and the other one

495 nm and 605 nm located in the visible region. In addition to the

UV emission peak at 374 nm, the peak at 394 nm 3.15 eV in the

UV region was assigned to the transition from oxygen vacancies

(Vo ) level to valence band, positioned approximately 0.20 eV below the conduction bandedge, due to the variation of the type and

concentration of intrinsic defects in the local microstructure of

ZnO/SiO2 /Si. If the ZnO film was grown on Si3 N4 /Si, a very

strong UV along with invisible deep-level emission was detected

because the Si3 N4 can effectively improve film stoichiometry and

reduce the defect formation of oxygen vacancies and Zn interstitials

compared to SiO2 on Si. Moreover, the carrier concentration of the

ZnO/Si3 N4 /Si sample is very close to that of intrinsic ZnO

(1.40 1014 cm3 ) and can be increased by post-treatment.

Therefore, the ZnO deposited on Si3 N4 /Si substrate can be used as

a potential method to develop p-type ZnO film for optoelectronic

devices.

Acknowledgment

The authors gratefully acknowledge the National Science Council of the Republic of China for its financial support through contract

NSC-92-2216-E-009-014.

References

Figure 4. Low-temperature PL spectra measured at 10 K for the ZnO films

grown at various substrates after annealing at 850C in oxygen atmospheres.

1. K. Hummer, Phys. Status Solidi, 56, 249 1973.

2. S. Cho, J. Ma, Y. Kim, Y. Sun, G. K. L. Wang, and J. B. Ketterson, Appl. Phys.

Lett., 75, 2761 1999.

3. E. G. Bylander, J. Appl. Phys., 49, 1188 1978.

4. D. Hahn and R. Nink, Phys. Condens. Mater., 3, 311 1965.

5. M. Liu, A. H. Kitai, and P. Mascher, J. Lumin., 54, 35 1992.

6. Y. Zhang, G. Du, D. Liu, X. Wang, Y. Ma, J. Wang, J. Yin, X. Yang, X. Hou, and

S. Yang, J. Cryst. Growth, 243, 439 2002.

7. B. J. Jin, S. Im, and S. Y. Lee, Thin Solid Films, 366, 107 2000.

8. P. H. Kasai, Phys. Rev., 130, 989 1963.

9. F. A. Kroger and H. J. Vink, J. Chem. Phys., 22, 250 1954.

10. S. H. Jeong, B. S. Kim, and B. T. Lee, Appl. Phys. Lett., 82, 2625 2003.

11. B. J. Jin, S. Im, and S. Y. Lee, Thin Solid Films, 366, 107 2000.

12. E. Fogarassy, A. Siaoul, C. Fuchs, and J. L. Regolini, Appl. Phys. Lett., 51, 337

1987.

13. E. P. OReilly and J. Robertson, Phys. Rev. B, 27, 3780 1983.

14. Y. Chen, D. M. Bagnall, Z. Zhu, T. Sekiuchi, K.-T. Park, K. Hiraga, T. Yao, S.

Koyama, M. Y. Shen, and T. Goto, J. Cryst. Growth, 181, 165 1997.

15. W. Gopel, J. Vac. Sci. Technol., 16, 1229 1979.

16. S. A. M. Lima, F. A. Sigoli, M. Jafelicci, Jr., and M. R. Davolos, Inorg. Mater., 3,

749 2001.

17. Q. X. Zhao, M. Willander, W. Lu, X. Q. Liu, S. C. Shen, H. H. Tan, C. Jagadish, J.

Zou, and D. J. H. Cockayne, J. Appl. Phys., 88, 2519 2000.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- 8136 (1857) Ultraviolet-Visible Spectroscopy-Theory and PracticeДокумент10 страниц8136 (1857) Ultraviolet-Visible Spectroscopy-Theory and PracticeCristian GomezОценок пока нет

- Lecture - 2&3 - Direct DyesДокумент41 страницаLecture - 2&3 - Direct Dyesmlg54100% (1)

- Recovered PDF 3 PDFДокумент7 страницRecovered PDF 3 PDFeid elsayedОценок пока нет

- Recovered PDF 3 PDFДокумент7 страницRecovered PDF 3 PDFeid elsayedОценок пока нет

- Recovered PDF 7 PDFДокумент6 страницRecovered PDF 7 PDFeid elsayedОценок пока нет

- Recovered PDF 10 PDFДокумент9 страницRecovered PDF 10 PDFeid elsayedОценок пока нет

- Determination of The Elastic Properties of Au5Sn and AuSn PDFДокумент7 страницDetermination of The Elastic Properties of Au5Sn and AuSn PDFeid elsayedОценок пока нет

- Ab-Initio Investigation of Electronic Properties and Magnetism of Half-Heusler Alloys XCrAl (X Fe, Co, Ni) PDFДокумент7 страницAb-Initio Investigation of Electronic Properties and Magnetism of Half-Heusler Alloys XCrAl (X Fe, Co, Ni) PDFEidelsayedОценок пока нет

- Acta 2004 52 14 4121 PDFДокумент11 страницActa 2004 52 14 4121 PDFeid elsayedОценок пока нет

- 1 s2.0 S0925838806011017 Main PDFДокумент5 страниц1 s2.0 S0925838806011017 Main PDFeid elsayedОценок пока нет

- A Thermodynamic Theory of Short-Term and Creep RuptureДокумент6 страницA Thermodynamic Theory of Short-Term and Creep Ruptureeid elsayedОценок пока нет

- 215-cbh 2011 PDFДокумент9 страниц215-cbh 2011 PDFeid elsayedОценок пока нет

- 163-Leejh Jap PDFДокумент3 страницы163-Leejh Jap PDFeid elsayedОценок пока нет

- Tensile, Creep, and ABI Tests On Sn5%Sb Solder PDFДокумент8 страницTensile, Creep, and ABI Tests On Sn5%Sb Solder PDFeid elsayedОценок пока нет

- Study On The Properties of Sn-9Zn-Xcr Lead-Free Solder: Xi Chen, Anmin Hu, Ming Li, Dali MaoДокумент7 страницStudy On The Properties of Sn-9Zn-Xcr Lead-Free Solder: Xi Chen, Anmin Hu, Ming Li, Dali Maoeid elsayedОценок пока нет

- Materials Science and Engineering BДокумент7 страницMaterials Science and Engineering Beid elsayedОценок пока нет

- Materials Science & Engineering A: A.A. El-Daly, A. Fawzy, S.F. Mansour, M.J. YounisДокумент10 страницMaterials Science & Engineering A: A.A. El-Daly, A. Fawzy, S.F. Mansour, M.J. Youniseid elsayedОценок пока нет

- Materials Science & Engineering A: Lu Shen, Zheng Yu Tan, Zhong ChenДокумент7 страницMaterials Science & Engineering A: Lu Shen, Zheng Yu Tan, Zhong Cheneid elsayedОценок пока нет

- Pretreatment Training-EngДокумент62 страницыPretreatment Training-EngNethaji Mett100% (1)

- 2.4 2.5 2.6 Assessed HomeworkДокумент7 страниц2.4 2.5 2.6 Assessed HomeworkRabia Rafique100% (1)

- Eamcet Track Sheet (2024)Документ2 страницыEamcet Track Sheet (2024)MAHESWARA RAO ThotaОценок пока нет

- Concept of PH and BufferДокумент27 страницConcept of PH and BufferRolling Coast100% (1)

- Exam Jan 2007Документ5 страницExam Jan 2007Sam RutherfordОценок пока нет

- Removal of Water From Industrial Ammonia Systems PDFДокумент10 страницRemoval of Water From Industrial Ammonia Systems PDFMTOLОценок пока нет

- SolarControl enДокумент109 страницSolarControl enberymoОценок пока нет

- Material Property Charts-W4Документ15 страницMaterial Property Charts-W4Fara AsilaОценок пока нет

- VL2022230501086 DaДокумент2 страницыVL2022230501086 DabihbugvОценок пока нет

- Chem. SOC.: Single-Crystal Raman and Far-Infrared Spectra Tetrakis (Thiourea) - Nickel (Ii) DichlorideДокумент3 страницыChem. SOC.: Single-Crystal Raman and Far-Infrared Spectra Tetrakis (Thiourea) - Nickel (Ii) DichlorideFernandaIbarraVázquezОценок пока нет

- Unit 5 Electrogravimetry and CoulometryДокумент36 страницUnit 5 Electrogravimetry and CoulometryAzzah Dyah Pramata67% (3)

- 11th Chemistry Chapter 4 PDF Notes - Unlocked - OCRДокумент27 страниц11th Chemistry Chapter 4 PDF Notes - Unlocked - OCRamirbadshahОценок пока нет

- To Determine % Purity of The Given Sample of Mefenamic Acid by Titrimetric Method. Chemicals RequiredДокумент4 страницыTo Determine % Purity of The Given Sample of Mefenamic Acid by Titrimetric Method. Chemicals RequiredjerritОценок пока нет

- Jee Main 2021 Mar 18 First Shift PaperДокумент15 страницJee Main 2021 Mar 18 First Shift Papershivam singhОценок пока нет

- Chemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus) Chemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus)Документ20 страницChemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus) Chemistry Revision Guide For CIE IGCSE Coordinated Science (2012 Syllabus)Laura FidarovaОценок пока нет

- Synthesis of Fly Ash-Based Self-Supported Zeolites Foam Geopolymer Via Saturated Steam TreatmentДокумент14 страницSynthesis of Fly Ash-Based Self-Supported Zeolites Foam Geopolymer Via Saturated Steam TreatmentShabrina RaedyОценок пока нет

- Tutorium Refrigeration SolutionДокумент20 страницTutorium Refrigeration SolutionwanpudinОценок пока нет

- Lecture Notes - PH 301 & PH 401 - MODULE - 6 (Statistical Mechanics) PDFДокумент31 страницаLecture Notes - PH 301 & PH 401 - MODULE - 6 (Statistical Mechanics) PDFMD HASANОценок пока нет

- Environmental Green Chemistry Applications of Nanoporous CarbonsДокумент24 страницыEnvironmental Green Chemistry Applications of Nanoporous CarbonsIvan AlcomendrasОценок пока нет

- NCHO Problems IIДокумент1 страницаNCHO Problems IIgraceОценок пока нет

- Nanostructures For Light Trapping in Thin Film Solar Cells: MicromachinesДокумент18 страницNanostructures For Light Trapping in Thin Film Solar Cells: MicromachinesПривет УлыбатьсяОценок пока нет

- CASCADE MINI-RINGS® Random PackingДокумент2 страницыCASCADE MINI-RINGS® Random PackingSyukri Abd RahmanОценок пока нет

- CALORIMETRYДокумент3 страницыCALORIMETRYqueenjoseОценок пока нет

- TUNNELLINGДокумент14 страницTUNNELLINGkumarmanojod010215Оценок пока нет

- Giant Molecule StructureДокумент5 страницGiant Molecule StructureNAURAH AISYAH NAWAWI ABDULLAHОценок пока нет

- (G9) All QuestionsДокумент11 страниц(G9) All QuestionsJacky VandarОценок пока нет

- Thermo Sheet7 NewДокумент3 страницыThermo Sheet7 NewRodney SalazarОценок пока нет

- Limit Tests (Autosaved)Документ53 страницыLimit Tests (Autosaved)Adithi ukОценок пока нет