Академический Документы

Профессиональный Документы

Культура Документы

HW #8

Загружено:

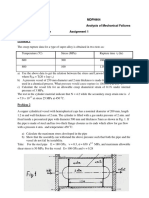

c_sierra34Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HW #8

Загружено:

c_sierra34Авторское право:

Доступные форматы

MCEN

2024: Materials Science

Fall

2014

Homework Assignment #8

Questions on Failure

(Due Monday, December 1st at the start of class)

1. A

specimen

of

4340

steel

alloy

having

a

plane

strain

fracture

toughness

of

45

MPa

m

is

exposed

to

a

stress

of

1000

MPa.

a) What

is

the

composition

of

4340

steel

alloy?

b) Will

this

specimen

experience

fracture

if

the

largest

surface

crack

is

0.75

mm

long?

Why

or

why

not?

Assume

that

the

parameter

Y

has

a

value

of

1.0.

2. a)

Calculate

the

maximum

internal

crack

length

allowable

for

a

7075-T651

aluminum

alloy

component

that

is

loaded

to

a

stress

one-half

its

yield

strength.

Assume

that

the

value

of

Y

is

1.35.

b) What

is

the

composition

of

a

7075-T651

aluminum

alloy?

3. The

tensile

strength

of

brittle

materials

may

be

determined

using

a

variation

of

1

!a$2

m = 2 0 # &

" t %

Compute

the

critical

crack

tip

radius

for

an

Al2O3

specimen

that

experiences

tensile

fracture

at

an

applied

stress

of

275

MPa.

Assume

a

critical

surface

crack

length

of

2x10-3

mm

and

a

theoretical

fracture

strength

of

E/10,

where

E

is

the

modulus

of

elasticity.

4. The

following

tabulated

data

were

gathered

from

a

series

of

Charpy

impact

tests

on

a

tempered

4140

steel

alloy.

a) What

is

the

difference

between

4140

and

4340

steel

alloys?

MCEN 2024: Materials Science

Fall

2014

b) Plot

the

data

as

impact

energy

vs.

temperature.

c) Determine

a

ductile-to-brittle

transition

temperature

as

the

temperature

corresponding

to

the

average

of

the

maximum

and

minimum

impact

energies.

d) Determine

a

ductile-to-brittle

transition

temperature

as

the

temperature

at

which

the

impact

energy

is

70

J.

5. The

fatigue

data

for

a

ductile

cast

iron

are

given

as

follows:

a)

b)

c)

d)

Make

an

S-N

plot

(stress

amplitude

vs.

logarithm

of

cycles

to

failure)

using

these

data.

What

is

the

fatigue

limit

for

this

alloy?

Determine

fatigue

lifetimes

at

stress

amplitudes

of

230

MPa

and

175

MPa.

Estimate

fatigue

strengths

at

2x105

and

6x106

cycles.

Вам также может понравиться

- Dme QP Series 1 2019Документ1 страницаDme QP Series 1 2019AADARS M SОценок пока нет

- Problems 4012 PDFДокумент8 страницProblems 4012 PDFjonthemesОценок пока нет

- Assignment 1Документ3 страницыAssignment 1Anand DevОценок пока нет

- M.D-I Final Tutorial and AssignmentДокумент16 страницM.D-I Final Tutorial and AssignmentnageshОценок пока нет

- Ashok Dmm1Документ4 страницыAshok Dmm1Praveen KumarОценок пока нет

- Sheet1 2nd PDFДокумент3 страницыSheet1 2nd PDFMahmoud Hashem SultanОценок пока нет

- Materials Science 2018Документ1 страницаMaterials Science 2018ParthibanОценок пока нет

- Unit-I: S.N0 Appeared in (R05, R07, R09, R13) Marks AssignedДокумент7 страницUnit-I: S.N0 Appeared in (R05, R07, R09, R13) Marks AssignedJeeevaОценок пока нет

- ENG782S2Документ8 страницENG782S2Emperor RocaОценок пока нет

- Failure Analysis of A 4340 Steel Locking BoltДокумент10 страницFailure Analysis of A 4340 Steel Locking BoltMarcos MontezumaОценок пока нет

- Design of Machine Elements Exam QuestionsДокумент8 страницDesign of Machine Elements Exam Questionsslv_prasaadОценок пока нет

- APSC 278 Midterm Feb 13 2013 SolutionsДокумент9 страницAPSC 278 Midterm Feb 13 2013 SolutionsykfungОценок пока нет

- Assignment 01Документ3 страницыAssignment 01RamNocturnalОценок пока нет

- Materials Science Homework on Plastic Deformation, Impact TestingДокумент2 страницыMaterials Science Homework on Plastic Deformation, Impact Testingcassandra_wittenОценок пока нет

- Design of Machine Members QuestionsДокумент3 страницыDesign of Machine Members Questionschinnapa reddy reddyОценок пока нет

- Design of Machine Elements IДокумент8 страницDesign of Machine Elements Imesab100Оценок пока нет

- Solution Tuto 6Документ13 страницSolution Tuto 6Abood AtiyatОценок пока нет

- Machine Design I - ME501 - Sup 011Документ2 страницыMachine Design I - ME501 - Sup 011Saurav JainОценок пока нет

- Assignment 4Документ3 страницыAssignment 4hustlingisthewayОценок пока нет

- Draw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IДокумент9 страницDraw The Stress - Strain Diagram For Mild Steel. Explain.: Unit - IKomma Hema100% (1)

- DMM - I Question Bank For StudentsДокумент11 страницDMM - I Question Bank For StudentsDushyanthkumar DasariОценок пока нет

- DMM - I Question Bank For StudentsДокумент11 страницDMM - I Question Bank For StudentsDushyanthkumar DasariОценок пока нет

- Iat 1 DmeДокумент3 страницыIat 1 DmesathishskymechОценок пока нет

- Eng Failure Analysis - Digital Assignment IIДокумент4 страницыEng Failure Analysis - Digital Assignment IIAnish ChakrabartiОценок пока нет

- Question Bank: Module 1:design For Static StrengthДокумент22 страницыQuestion Bank: Module 1:design For Static Strengthcrazy hjОценок пока нет

- DMM 1Документ9 страницDMM 1andhracollegesОценок пока нет

- DME - 1 One Mark Q's (KDR)Документ13 страницDME - 1 One Mark Q's (KDR)durgaraokamireddyОценок пока нет

- Machine Design Question PaperДокумент2 страницыMachine Design Question Papersushil.vgi100% (1)

- DMM1 Important QuestionsДокумент2 страницыDMM1 Important QuestionsChand Basha Shaik100% (1)

- Assignment 1Документ3 страницыAssignment 1154 ahmed ehabОценок пока нет

- NR-310305-Design of Machine ElementsДокумент9 страницNR-310305-Design of Machine ElementsSrinivasa Rao GОценок пока нет

- ME 352 - All Problem Class - 14-18 BatchДокумент125 страницME 352 - All Problem Class - 14-18 BatchEntertainment GamingОценок пока нет

- IFS Mechanical Engineering 2015 Part 1Документ4 страницыIFS Mechanical Engineering 2015 Part 1Saurabh BhardwajОценок пока нет

- Dme Mid1 Question PaperДокумент2 страницыDme Mid1 Question PaperPavaniОценок пока нет

- Som Assignments PDFДокумент12 страницSom Assignments PDFLaxmi HattiholiОценок пока нет

- Machine Design Question BankДокумент4 страницыMachine Design Question BankManivannanОценок пока нет

- Dme Home Assignment 2019-20Документ4 страницыDme Home Assignment 2019-20VenkateshОценок пока нет

- Sheet#8Документ7 страницSheet#8oreaby05Оценок пока нет

- Dme Lab Sheets Ii Iii IvДокумент4 страницыDme Lab Sheets Ii Iii IvA58Vikas UbovejaОценок пока нет

- Mem-402-Mos Final QB-2015Документ9 страницMem-402-Mos Final QB-2015Rohit DiwakarОценок пока нет

- H W #6 D: W 3/3/2010: Ne/mse 409 / 509Документ1 страницаH W #6 D: W 3/3/2010: Ne/mse 409 / 509azizieh5701Оценок пока нет

- Tutorial 1Документ3 страницыTutorial 1Raiham EffendyОценок пока нет

- A Study On Mechanical Properties of Dissimilar Steels Welded With Electric Arc WELDING KAYNAKДокумент6 страницA Study On Mechanical Properties of Dissimilar Steels Welded With Electric Arc WELDING KAYNAKgokhan-altntas-9106Оценок пока нет

- Machine Design MCQsДокумент10 страницMachine Design MCQssureshm_raj5434Оценок пока нет

- Assignment 3 IEMДокумент1 страницаAssignment 3 IEMHareesha N GОценок пока нет

- TUGAS Sifat MEKANISДокумент10 страницTUGAS Sifat MEKANISHelmi FuadiОценок пока нет

- Code: 13A03505: (Mechanical Engineering)Документ2 страницыCode: 13A03505: (Mechanical Engineering)MrHEMAMAHEHОценок пока нет

- DME 1-SupplyДокумент3 страницыDME 1-SupplyAmal SОценок пока нет

- Material Yr1 - Tutorial 6Документ16 страницMaterial Yr1 - Tutorial 6Ahmed TahaОценок пока нет

- QB Unit-1,2Документ5 страницQB Unit-1,2Agranshu BhardwajОценок пока нет

- SDSS 2022 Paper 43 - RevisedДокумент6 страницSDSS 2022 Paper 43 - RevisedBatuhan DerОценок пока нет

- CE8402/Strength of Materials II: J.N.N Institute of Engineering Class Test-IДокумент1 страницаCE8402/Strength of Materials II: J.N.N Institute of Engineering Class Test-IManohar MathialaganОценок пока нет

- Dynamics of Machinery r10 May-2016Документ20 страницDynamics of Machinery r10 May-2016Srimanthula SrikanthОценок пока нет

- Eng Mat Chapter 3Документ155 страницEng Mat Chapter 3VC Chua Yee Leong0% (1)

- Prolemario 2Документ4 страницыProlemario 2Emiliano LozanoОценок пока нет

- Assignment No 2Документ2 страницыAssignment No 2Abhishek BordoloiОценок пока нет

- DME1 Question BankДокумент4 страницыDME1 Question BankJinto Joy ManjalyОценок пока нет

- Resistance WeldingДокумент7 страницResistance Weldingswaroop_exlncОценок пока нет

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesОт EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášОценок пока нет

- HW #7Документ4 страницыHW #7c_sierra34Оценок пока нет

- HW #6Документ2 страницыHW #6c_sierra340% (1)

- HW #5Документ2 страницыHW #5c_sierra340% (1)

- HW #3Документ3 страницыHW #3c_sierra34Оценок пока нет

- HW #4Документ2 страницыHW #4c_sierra34Оценок пока нет

- Homework Assignment #2Документ1 страницаHomework Assignment #2c_sierra34Оценок пока нет

- Tabelas Normativas DinДокумент2 страницыTabelas Normativas DinDeimos PhobosОценок пока нет

- Royal DSMДокумент16 страницRoyal DSMSree100% (2)

- Manual For The MCPL Programming LanguageДокумент74 страницыManual For The MCPL Programming Languagechri1753Оценок пока нет

- Radical Candor: Fully Revised and Updated Edition: How To Get What You Want by Saying What You Mean - Kim ScottДокумент5 страницRadical Candor: Fully Revised and Updated Edition: How To Get What You Want by Saying What You Mean - Kim Scottzafytuwa17% (12)

- Nektar Impact LX25 (En)Документ32 страницыNektar Impact LX25 (En)Camila Gonzalez PiatОценок пока нет

- Research ProposalДокумент2 страницыResearch ProposalHo Manh LinhОценок пока нет

- Grillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종Документ8 страницGrillage Method Applied to the Planning of Ship Docking 150-157 - JAROE - 2016-017 - JangHyunLee - - 최종tyuОценок пока нет

- Math Curriculum Overview Grades 1 8Документ1 страницаMath Curriculum Overview Grades 1 8GuiselleОценок пока нет

- TheMindReader TeaserA WhatДокумент7 страницTheMindReader TeaserA WhatnakulshenoyОценок пока нет

- Worksheet 9-2 - Math 7Документ2 страницыWorksheet 9-2 - Math 7bfbrfvlfrerОценок пока нет

- Omega Fluid PDFДокумент2 страницыOmega Fluid PDFapatzinfedОценок пока нет

- Procedural Text Unit Plan OverviewДокумент3 страницыProcedural Text Unit Plan Overviewapi-361274406Оценок пока нет

- Past Papers - A Levels - Geography (9696) - 2018 - GCE GuideДокумент9 страницPast Papers - A Levels - Geography (9696) - 2018 - GCE GuideLee AsaОценок пока нет

- Vocabulary Prefixes ExercisesДокумент2 страницыVocabulary Prefixes ExercisesMarina García CarrascoОценок пока нет

- Date ValidationДокумент9 страницDate ValidationAnonymous 9B0VdTWiОценок пока нет

- ArrayList QuestionsДокумент3 страницыArrayList QuestionsHUCHU PUCHUОценок пока нет

- Chapter 2: Science, Technology, and Society in Human Condition Lesson 1: Human FlourishingДокумент5 страницChapter 2: Science, Technology, and Society in Human Condition Lesson 1: Human FlourishingJcОценок пока нет

- Bluehill BrochureДокумент24 страницыBluehill BrochureGeorge SingerОценок пока нет

- Space Gass 12 5 Help Manual PDFДокумент841 страницаSpace Gass 12 5 Help Manual PDFNita NabanitaОценок пока нет

- Lenovo IdeaPad U350 UserGuide V1.0Документ138 страницLenovo IdeaPad U350 UserGuide V1.0Marc BengtssonОценок пока нет

- Db2 Compatibility PDFДокумент23 страницыDb2 Compatibility PDFMuhammed Abdul QaderОценок пока нет

- Advance Control Systems LabДокумент2 страницыAdvance Control Systems Labpadmajasiva100% (1)

- MySQL Cursor With ExampleДокумент7 страницMySQL Cursor With ExampleNizar AchmadОценок пока нет

- PSPO I Question AnswerДокумент11 страницPSPO I Question AnswerAurélie ROUEОценок пока нет

- Imports System - data.SqlClient Imports System - Data Imports System PartialДокумент2 страницыImports System - data.SqlClient Imports System - Data Imports System PartialStuart_Lonnon_1068Оценок пока нет

- Консп 1Документ48 страницКонсп 1VadymОценок пока нет

- BUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyДокумент34 страницыBUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyThe Bartlett Development Planning Unit - UCLОценок пока нет

- How To Prepare Squash Specimen Samples For Microscopic ObservationДокумент3 страницыHow To Prepare Squash Specimen Samples For Microscopic ObservationSAMMYОценок пока нет

- Sprite Graphics For The Commodore 64Документ200 страницSprite Graphics For The Commodore 64scottmac67Оценок пока нет

- 5.mpob - LeadershipДокумент21 страница5.mpob - LeadershipChaitanya PillalaОценок пока нет