Академический Документы

Профессиональный Документы

Культура Документы

Duxan 2C PDF

Загружено:

niroshniroshОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Duxan 2C PDF

Загружено:

niroshniroshАвторское право:

Доступные форматы

LANKEM KSTER

Deuxan 2C

film sealant for waterproofing of buildings according to DIN 18195, part 4 - 6

Features

determined exactly by the planner prior to the application. Even

KSTER Deuxan 2C is a two-component, polystyrene-foam-free,

though it is not anchored in the DIN 18195, KSTER Deuxan 2C

fibrated, polymer modified bitumen thick film sealant for safe

has proven itself successfully for many years also in

waterproofing of building structures according to DIN 18195, part 4

waterproofing against pressurised water (Consumption min.

- 6. The coating bridges cracks in the substrate safely and is

3kg/m). The coating is also suited for waterproofing under

resistant to pressurised water. KSTER Deuxan 2C is especially

screeds and for bonding of insulation- and drainage-boards.

suited to be applied with spraying machines.

Substrate preparation

Technical data

The substrate should be dry or slightly damp, frost-free, free of

Material base

Bitumen / rubber with a reactive powder

tar and oil and free of loose particles. Remove protruding mortar

1.07 g / cm

residues, break edges; corners and transitions should be rounded

Density of the mixture

Heat resistance

+ 70 C

Elongation at break

approx. 100 %

Water permeability after full cure

(according to DIN 1048, part 5)

Curing time at 20 C

approx. 24 hours

+ 2 C

min. 3 minutes

Pot life

Mineral substrates can be primed with KSTER Polysil TG 500

(approx. 100 130 g / m) by spray application. On polystyrene

waterproof at 5 bar

Min. temperature during curing

Mixing time

out by installing fillets.

approx. 90 minutes

Application temperature

+ 5 C to + 35 C

Substrate temperature

Field of application

+ 5 C to + 30 C

substrates, priming is not necessary.

Surface patterns and unevenness up to a depth of max. 5 mm are

closed with a scraped layer of KSTER Deuxan 2C

Open cavities which are deeper than 5 mm like e. g. mortar

pockets, open butt- and horizontal-joints must be closed level

beforehand with KSTER Repair Mortar. Prior to the application

of the waterproofing layer made of KSTER Deuxan 2C the

KSTER Deuxan 2C is designed for the safe and permanent

scraped layer must have dried far enough so that it is not

waterproofing of basement walls, foundations, floor slabs etc., for

damaged by the application of the next layer.

waterproofing of balconies and terraces under screed which do not

Fillets

have inhabited sub-structures as well as for wet- and damp-rooms.

Fillets (leg length: 4 6 cm) in the wall / floor junction must be

The relevant standard is DIN 18195:

applied at least 24 hours prior to the beginning of the application

- part 4: Waterproofing against ground moisture and non-retained

of the waterproofing using KSTER Repair Mortar (Consumption

seepage

per m: approx. 2 3 kg). When waterproofing polystyrene

- part 5: Waterproofing against non-pressurised water

materials, the fillet (leg length: 2 cm) is made from KSTER

- part 6: Waterproofing against retained seepage.

Deuxan 2C The subsequently applied area waterproofing can in

Since the application of the waterproofing is carried out depending

both cases be applied only after full cure of the fillet.

on the water-loading condition, the loading condition has to be

Application

LANKEM CEYLON PLC

(SPECIAL PROJECTS)

297 A, 1/1, Union Place, P. O. BOX 919, Colombo 2, Sri Lanka

+94 11 4627765/ +94 11 7766000, Fax: +94 11 2478796

Aruna: 0777005109 E-mail: arunae@lankem.lk Damith: 0777251715 E-mail: damitheran@lankem.lk

Regarding the application of KSTER Deuxan 2C, DIN 18195 has to

Glass Fibre Mesh into it. When waterproofing against non-

be observed. Further, the leaflet of the Deutsche Bauchemie e.V.

pressurised water and retained seepage (DIN 18195, part 5 6),

Guideline for the design and the application of waterproofing of

generally lose- / fixed-flange systems should be used. It is

construction members with ground contact using polymer

necessary to make sure that the material of the installed parts is

modified bitumen thick film sealants has to be observed.

compatible with the waterproofing material. The same applies

Add the powder to the liquid component in portions and use a

when waterproofing against pressurised water.

slow rotating mixing machine to intensively mix the components

Protection and drainage layer

with each other until a paste-like, lump-free, homogeneous

Prior to backfilling, the fully cured coating must be protected

consistency is reached (mixing time: min. 3 minutes).

from mechanical damages. We recommend use of our KSTER SD

The waterproofing layer must be free of defects, uniform and in

Protection and Drainage Sheet. Polystyrene drainage boards,

the required layer thickness. The actual layer thickness must

perimeter insulation, etc. can be spot-bonded in case of ground

nowhere be less than the required minimum layer thickness and

moisture and non-retained seepage. A full surface bonding is

must in no case exceed it by more than 100 %. The waterproofing

required if the waterproofing is subjected to retained seepage

layer of the wall area has to extend at least 10 cm onto the front of

and pressurised water. In order to avoid vertical movement

the floor slab or foundation. The external waterproofing must in all

during filling of the excavation pit, the surface of the protection-

areas be connected to the existing horizontal waterproofing. Do

or respectively drainage boards should be covered with a gliding

not expose the material to frost, rain and water until it has fully

layer of e.g. polyethylene. All cases allow for bonding with

cured.

KSTER Deuxan 2C. Avoid stress at single spots only. Bumpy foils,

The minimum dry layer thickness must be:

corrugated boards or the like are not suited as protection layers.

1.

2mm thick in case of waterproofing against ground moisture

A drainage according to DIN 4095 or similar is required.

and non-retained seepage as well as non-pressurised water

Make sure that the fillet is not damaged when backfilling and

(wet layer thickness 3.0 mm = 3.0 kg / m). Embed KSTER

compacting with cohesionless soil.

Glass Fibre Mesh into the first layer while it is still fresh at

Cleaning of tools

corners, fillets and areas strongly in danger of cracking.

Clean tools with water immediately after use. If the material has

3mm thick in case of waterproofing against retained seepage

already started to dry, clean tools with KSTER Bitumen Remover.

(wet layer thickness 4 mm = 4.0 kg / m). Embed KSTER

Consumption

Glass Fibre Mesh into the first layer while it is still fresh at

Loading condition

Ground moisture, non-retained seepage and non-pressurised

2.

corners, fillets and areas strongly in danger of cracking.

Seal expansion joints by applying KSTER Special Joint Tape in the

water

Retained seepage

joint areas of the thick film sealant. Avoid water seeping in behind

the coating. Allow the waterproofing to cure fully before stressing

the material (depends on the weather, but at the earliest after 24

Packaging

32 kg hobbock (powder component is inside the packaging)

Storage

hours).

Store in a cool and frost free place; in closed originally sealed

Feed throughs / penetrations

In case of waterproofing against ground moisture and non-retained

seepage (DIN 18195, part 4), apply KSTER Deuxan 2C in a fillet

shape around the feed through or penetration and embed KSTER

packages, the material can be stored for approx. 6 month.

Safety instructions

The powder component contains cement.

Avoid contact with the skin.

LANKEM CEYLON PLC

(SPECIAL PROJECTS)

297 A, 1/1, Union Place, P. O. BOX 919, Colombo 2, Sri Lanka

+94 11 4627765/ +94 11 7766000, Fax: +94 11 2478796

Aruna: 0777005109 E-mail: arunae@lankem.lk Damith: 0777251715 E-mail: damitheran@lankem.lk

Вам также может понравиться

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoОт EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoОценок пока нет

- Uzin Ke 2000 S: Product Data SheetДокумент4 страницыUzin Ke 2000 S: Product Data SheetFloorkitОценок пока нет

- Sika® Tite WPU: Product Data SheetДокумент3 страницыSika® Tite WPU: Product Data SheetZèlia FláviaОценок пока нет

- Boscoseal Torch OnДокумент3 страницыBoscoseal Torch OnjbonvierОценок пока нет

- Shower Waterproofing SystemДокумент2 страницыShower Waterproofing SystemLoz101Оценок пока нет

- 599 PDFДокумент2 страницы599 PDFbizottsagОценок пока нет

- MYK Aquafin 2CДокумент2 страницыMYK Aquafin 2Cnarmad_anil100% (1)

- CeresitWV UK400 TM 11 0816Документ3 страницыCeresitWV UK400 TM 11 0816gabira_Оценок пока нет

- List of Icons: Product InfoДокумент11 страницList of Icons: Product InfoniroОценок пока нет

- Abe DIY BookletДокумент89 страницAbe DIY BookletFrancois-Оценок пока нет

- The Anydron Manual - Working With PU Waterproof CoatingsДокумент5 страницThe Anydron Manual - Working With PU Waterproof Coatingsakis5375Оценок пока нет

- Renovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationsДокумент1 страницаRenovating Plaster: A Pre-Mixed Lightweight Plaster For Damp Proofing ApplicationswassimmahfouzОценок пока нет

- Construction MethodologyДокумент4 страницыConstruction MethodologyMica VerayeОценок пока нет

- MR Fix Itumat Plus 502Документ2 страницыMR Fix Itumat Plus 502Israel ExporterОценок пока нет

- Sikafill®-300 Thermic: Product Data SheetДокумент4 страницыSikafill®-300 Thermic: Product Data Sheetmaga2292Оценок пока нет

- PSOW2 - MS For Waterproofing Dated 04.11.2023Документ5 страницPSOW2 - MS For Waterproofing Dated 04.11.2023projectsОценок пока нет

- UP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Документ3 страницыUP210 Lime/cement Basecoat Render: Data Sheet Sept 2014Francesco FanaraОценок пока нет

- Cresit CR 72-HenkelДокумент4 страницыCresit CR 72-HenkelJoun SmithОценок пока нет

- Uzin KE 2428Документ2 страницыUzin KE 2428FloorkitОценок пока нет

- 4650 Aquastop FlexibleДокумент4 страницы4650 Aquastop Flexiblewawen03Оценок пока нет

- Uzin NC 150 New: Product Data SheetДокумент2 страницыUzin NC 150 New: Product Data SheetFloorkitОценок пока нет

- WaterproofingДокумент23 страницыWaterproofingKenneth Ituralde BesmonteОценок пока нет

- Tds - Emaco s88c TДокумент2 страницыTds - Emaco s88c TVenkata RaoОценок пока нет

- Waterproofing MethodologyДокумент16 страницWaterproofing MethodologyGaurav Nijhawan100% (1)

- TDS - Emaco S88 PlusДокумент2 страницыTDS - Emaco S88 PlusVenkata RaoОценок пока нет

- Uzin NC 152Документ2 страницыUzin NC 152FloorkitОценок пока нет

- 7GS 5000Документ5 страниц7GS 5000subhaschandraОценок пока нет

- WaterproofingДокумент7 страницWaterproofingNeda Shakil100% (1)

- Building Materials and ConstructionДокумент7 страницBuilding Materials and ConstructionKavya 7Оценок пока нет

- Case StudyДокумент7 страницCase StudyKavya 7Оценок пока нет

- 82 Ultraflex s2 Quick GB NoRestrictionДокумент4 страницы82 Ultraflex s2 Quick GB NoRestrictionFloorkitОценок пока нет

- Pekay 835 Acryl-Seal Seamless Waterproofing SystemДокумент7 страницPekay 835 Acryl-Seal Seamless Waterproofing SystemMmamoraka Christopher MakhafolaОценок пока нет

- WP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Документ2 страницыWP - Brochure - Sika Davco Bitkote - 3 - Jan - 20Ade KurniawanОценок пока нет

- FLEXIPRO - BrochureДокумент2 страницыFLEXIPRO - Brochurebeck.26Оценок пока нет

- Expoband Plus PDFДокумент4 страницыExpoband Plus PDFmilanbrasinaОценок пока нет

- K13 High-Flex Waterproofing SlurryДокумент3 страницыK13 High-Flex Waterproofing SlurryAmila SampathОценок пока нет

- Uzin KE 603Документ2 страницыUzin KE 603FloorkitОценок пока нет

- FloArm Screed Eco Ver7Документ4 страницыFloArm Screed Eco Ver7imsОценок пока нет

- 07131Документ11 страниц07131bravo deltafoxОценок пока нет

- Cemtop 250T PDFДокумент4 страницыCemtop 250T PDFriverwilliamsОценок пока нет

- Zentrifix F 92Документ2 страницыZentrifix F 92Roberto_PrrОценок пока нет

- Quicseal 119: AquapoxyДокумент4 страницыQuicseal 119: AquapoxyRenaldo BunaidiОценок пока нет

- Lavatex 2000...Документ2 страницыLavatex 2000...ArifОценок пока нет

- Proofex GPДокумент2 страницыProofex GPSyed ShahbazОценок пока нет

- Method Statement - Terrace WP - 08.07Документ4 страницыMethod Statement - Terrace WP - 08.07Treon Ajmera100% (2)

- MoyaProof WS2 PDFДокумент2 страницыMoyaProof WS2 PDFChristian Nicolaus Mbise100% (4)

- BOQ WaterproofingДокумент6 страницBOQ Waterproofinghareshkp100% (1)

- Boscoseal Ac2 PDFДокумент3 страницыBoscoseal Ac2 PDFVincentОценок пока нет

- Waterproof Planiseal 288Документ3 страницыWaterproof Planiseal 288Chezy629Оценок пока нет

- GCPAT Bituthene 3000 and Bituthene Low Temperature Membranes Us 65576Документ7 страницGCPAT Bituthene 3000 and Bituthene Low Temperature Membranes Us 65576sameerace.kolonОценок пока нет

- Damp Proofing and Water Proofing: Athira. P. R 101116007 Third Year B-ArchДокумент9 страницDamp Proofing and Water Proofing: Athira. P. R 101116007 Third Year B-ArchAshrutha HarshiniОценок пока нет

- Plio CureДокумент2 страницыPlio Curepravi3434Оценок пока нет

- Sikatop® Seal-107 In: Product Data SheetДокумент4 страницыSikatop® Seal-107 In: Product Data SheetMukesh RajОценок пока нет

- Nitomortar ELДокумент4 страницыNitomortar ELmilanbrasinaОценок пока нет

- Flexcrete 500: Epoxy Polysulfide Waterproofing CoatingДокумент2 страницыFlexcrete 500: Epoxy Polysulfide Waterproofing CoatingSuresh YadavОценок пока нет

- Platinum Star: Very High Polymer Modified AdhesiveДокумент3 страницыPlatinum Star: Very High Polymer Modified AdhesiveParashuram ChauhanОценок пока нет

- Branz Appraisal Dampfix 2 & 3 581 2015Документ5 страницBranz Appraisal Dampfix 2 & 3 581 2015DanielCarletonОценок пока нет

- Seal FlexДокумент2 страницыSeal Flexpravi3434Оценок пока нет

- Mariseal 250Документ2 страницыMariseal 250acsimonОценок пока нет

- Letter of Intent ArticleДокумент9 страницLetter of Intent ArticleniroshniroshОценок пока нет

- Fastening Systems: GLAMET Fastening CUTEC FasteningДокумент1 страницаFastening Systems: GLAMET Fastening CUTEC FasteningniroshniroshОценок пока нет

- ADRAct SLДокумент3 страницыADRAct SLniroshniroshОценок пока нет

- Angle BarДокумент3 страницыAngle BaraselabollegalaОценок пока нет

- 781 2987 1 PBДокумент3 страницы781 2987 1 PBniroshniroshОценок пока нет

- ADRAct SLДокумент3 страницыADRAct SLniroshniroshОценок пока нет

- Hilti Concrete RepairДокумент4 страницыHilti Concrete RepairniroshniroshОценок пока нет

- Speak English in A WeekДокумент32 страницыSpeak English in A Weekniroshnirosh100% (14)

- Bird in BluesДокумент1 страницаBird in BluesniroshniroshОценок пока нет

- G33T MainboardДокумент54 страницыG33T MainboardniroshniroshОценок пока нет

- BS en Iso 4066Документ17 страницBS en Iso 4066niroshniroshОценок пока нет

- Color Management Made EasyДокумент2 страницыColor Management Made EasyPaicu Alexandru BogdanОценок пока нет

- IIESl Membership Guideline PDFДокумент60 страницIIESl Membership Guideline PDFniroshnirosh100% (1)

- IELTS Visuals Writing About Graphs, Tables and Diagrams PDFДокумент68 страницIELTS Visuals Writing About Graphs, Tables and Diagrams PDFSaleh KhalidОценок пока нет

- Tactics Forlistening Expanding PDFДокумент72 страницыTactics Forlistening Expanding PDFniroshniroshОценок пока нет

- FLWRДокумент1 страницаFLWRniroshniroshОценок пока нет

- Ucf - Tutorial of Modal AnalysisДокумент13 страницUcf - Tutorial of Modal AnalysisemelrapchanОценок пока нет

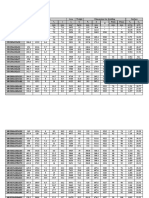

- Universal Beam PropertiesДокумент4 страницыUniversal Beam PropertiesniroshniroshОценок пока нет

- IELTS Visuals Writing About Graphs, Tables and Diagrams PDFДокумент68 страницIELTS Visuals Writing About Graphs, Tables and Diagrams PDFSaleh KhalidОценок пока нет

- CRB Jan 08 EarleyДокумент4 страницыCRB Jan 08 EarleyKhairuddin IsmailОценок пока нет

- Book - Reinforced Concrete Mechanics & Design 3rd Ed (James G Mc. Gregor) Chapter12aДокумент0 страницBook - Reinforced Concrete Mechanics & Design 3rd Ed (James G Mc. Gregor) Chapter12aSana UllahОценок пока нет

- Measurement Sheet TemleteДокумент1 страницаMeasurement Sheet TemleteniroshniroshОценок пока нет

- ImationLOCKv20 E ManualДокумент17 страницImationLOCKv20 E ManualDabz ViajanteОценок пока нет

- Some Tecnologies UsedДокумент7 страницSome Tecnologies UsedniroshniroshОценок пока нет

- Peng - Rules v1Документ8 страницPeng - Rules v1niroshniroshОценок пока нет

- Sgs Ind Construction CMT A4 en 10Документ8 страницSgs Ind Construction CMT A4 en 10niroshniroshОценок пока нет

- Drilling Shallow WellsДокумент8 страницDrilling Shallow WellsniroshniroshОценок пока нет

- Foundation DesignДокумент70 страницFoundation Designprabhu81100% (2)

- Steel Work Engineering QuestionsДокумент18 страницSteel Work Engineering QuestionsniroshniroshОценок пока нет

- Mosquito Control: Department of Zoology University of PeradeniyaДокумент4 страницыMosquito Control: Department of Zoology University of PeradeniyaniroshniroshОценок пока нет

- TG Chap. 10Документ7 страницTG Chap. 10Gissele AbolucionОценок пока нет

- Jis C 8156-2017, EngДокумент32 страницыJis C 8156-2017, Eng7620383tlОценок пока нет

- Eim s2000 Series Brochure PDFДокумент16 страницEim s2000 Series Brochure PDFHumbertoOtaloraОценок пока нет

- The Stony Brook Press - Volume 11, Issue 4Документ28 страницThe Stony Brook Press - Volume 11, Issue 4The Stony Brook PressОценок пока нет

- Structral DatasheetДокумент254 страницыStructral DatasheetdeepakОценок пока нет

- PROJECT PROPOSAL AND PROJECT MANAGEMENT TOOLS GROUPWORK (Situation No. 3 - BSSW 3A)Документ21 страницаPROJECT PROPOSAL AND PROJECT MANAGEMENT TOOLS GROUPWORK (Situation No. 3 - BSSW 3A)Hermida Julia AlexandreaОценок пока нет

- 756S PDFДокумент248 страниц756S PDFShahzad FidaОценок пока нет

- COLLOIDAL GOLD RECIPE - CitrateДокумент9 страницCOLLOIDAL GOLD RECIPE - CitrateDevon Narok100% (4)

- Nepal Health Research CouncilДокумент15 страницNepal Health Research Councilnabin hamalОценок пока нет

- Exercise 6Документ2 страницыExercise 6Satyajeet PawarОценок пока нет

- 30356-Article Text-56848-1-10-20210201Документ14 страниц30356-Article Text-56848-1-10-20210201Mel FaithОценок пока нет

- Labor Case DigestДокумент2 страницыLabor Case DigestJhollinaОценок пока нет

- EV-H-A1R 54C - M - EN - 2014 - D - Heat Detector SalwicoДокумент2 страницыEV-H-A1R 54C - M - EN - 2014 - D - Heat Detector SalwicoCarolinaОценок пока нет

- (PDF) Books Toxic Parents Epub Popular Download - by Susan ForwardДокумент1 страница(PDF) Books Toxic Parents Epub Popular Download - by Susan Forwardmartagonzalezbordonaba0% (3)

- 936-Article Text-2359-1-10-20211003Документ6 страниц936-Article Text-2359-1-10-20211003Geka KusumoОценок пока нет

- GASESДокумент55 страницGASESja_QuinineОценок пока нет

- EC Type-Examination Certificate: Reg.-No.: 01/205/5192.02/18Документ11 страницEC Type-Examination Certificate: Reg.-No.: 01/205/5192.02/18Orlando Ortiz VillegasОценок пока нет

- Cardiac PacemakerДокумент25 страницCardiac PacemakerDhvij KmlОценок пока нет

- CA02 ParchamentoJVMДокумент6 страницCA02 ParchamentoJVMJohnrey ParchamentoОценок пока нет

- Tenses Các NămДокумент4 страницыTenses Các NămAnh MinhОценок пока нет

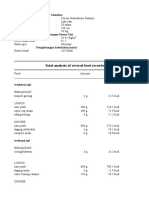

- Tugas Gizi Caesar Nurhadiono RДокумент2 страницыTugas Gizi Caesar Nurhadiono RCaesar 'nche' NurhadionoОценок пока нет

- Lecture 2 Types of Fluid FlowДокумент29 страницLecture 2 Types of Fluid FlowMilkias endashawОценок пока нет

- Difference Between Gram Positive and GramДокумент3 страницыDifference Between Gram Positive and Grambaraa aburassОценок пока нет

- Gastroschisis and Omphalocele PDFДокумент8 страницGastroschisis and Omphalocele PDFUtama puteraОценок пока нет

- 13 Unit 5 PainДокумент4 страницы13 Unit 5 PainAndres SalazarОценок пока нет

- Contoh Perhitungan DDD Excell - IRNAДокумент8 страницContoh Perhitungan DDD Excell - IRNAMaya DamanikОценок пока нет

- Cardiovascular SystemДокумент47 страницCardiovascular SystemAtnasiya GadisaОценок пока нет

- English Quarterly TestДокумент3 страницыEnglish Quarterly TestEdmon FabregasОценок пока нет

- Water Security STD 9th Textbook by Techy BagДокумент86 страницWater Security STD 9th Textbook by Techy Bagpooja TiwariОценок пока нет

- Book Report British Airways Flight 5390Документ7 страницBook Report British Airways Flight 5390KaruОценок пока нет