Академический Документы

Профессиональный Документы

Культура Документы

Microstructure and Crystal Defects in Epitaxial Zno Film Grown On Ga Modified 0001 Sapphire Surface

Загружено:

eid elsayedИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Microstructure and Crystal Defects in Epitaxial Zno Film Grown On Ga Modified 0001 Sapphire Surface

Загружено:

eid elsayedАвторское право:

Доступные форматы

APPLIED PHYSICS LETTERS

VOLUME 85, NUMBER 19

8 NOVEMBER 2004

Microstructure and crystal defects in epitaxial ZnO film grown on Ga

modified (0001) sapphire surface

H. P. Sun and X. Q. Pana)

Department of Materials Science and Engineering, University of Michigan, Ann Arbor,

Michigan 48109-2136

X. L. Du, Z. X. Mei, Z. Q. Zeng, and Q. K. Xue

State Key Laboratory for Surface Physics, Institute of Physics, Chinese Academy of Sciences,

Beijing 100081, Peoples Republic of China

(Received 29 June 2004; accepted 7 September 2004)

Surface modification of sapphire (0001) by Ga can eliminate multiple rotation domains in ZnO

films. The existence of Ga at ZnO/sapphire interface was confirmed by x-ray energy dispersive

spectroscopy in a transmission electron microscope. Atomic detail of mismatch dislocations at

interface was imaged by high resolution transmission electron microscopy. Inside the ZnO film,

there is a high density of stacking fault. Both pure gliding of ZnO 0001 plane and condensation

of vacancies or interstatials are possible mechanisms to generate the stacking fault. 2004

American Institute of Physics. [DOI: 10.1063/1.1811393]

Wurtzite ZnO is a wide band gap 3.27 eV IIVI compound semiconductor with promising applications to UV

light emitters, spin functional devices, gas sensors, and transparent electronic devices. ZnO can be grown on cheap substrates such as glass at relatively low temperatures and it has

several potential advantages over GaN for some of these

applications because of a larger exciton binding energy

60 meV.1 Optically pumped excitonic lasing of ZnO thin

films at room temperature has been observed.2,3 Recently,

lasing effect of ZnO nanowire arrays was also

demonstrated.4 Epitaxial growth of ZnO has been carried out

on Si5,6 and mainly on sapphire711 using various techniques.

Efforts are also made to obtain ZnO film with controlled

electronic and optical properties, such as p-type ZnO by N

doping12 and magnetic ZnO by Mn doping.5

It was found that ZnO film was grown via island nucleation and then lateral extension on a substrate surface,2,13

which is particularly true for substrate with large lattice mismatch. This growth mode will produce a film with a columnar structure and incoherent grain boundaries, and introduce

high density of threading dislocations in the film.14,15 Stacking fault is another type of defect frequently observed in

ZnO films.16,17 Multiangle rotation domains can form when

ZnO is grown on sapphire (0001) surface (c-face), but pretreatment of the sapphire (0001) surface by Ga predeposition

can eliminate these rotation domains.7,8 This pretreatment

can also be used to suppress inversion domains which often

appear in ZnO films,18 and sole Zn polarity film was

obtained.19 In this letter, we report a transmission electron

microsocpy (TEM) study of the microstructure, interfacial

dislocations and antiphase boundaries in ZnO layers grown

on the Ga pretreated sapphire (0001) surface.

The ZnO films were prepared by using rf-plasma assisted molecular beam epitaxy. Substrate pretreatments were

performed in a sequence of chemical etching, annealing,

atomic hydrogen radiation, plasma-excited oxygen cleaning,

and finally Ga exposure for 22 s. A ZnO buffer layer was

then deposited at 400 C and annealed at 650 C for 5 min.

Finally a ZnO epilayer was grown at 650 C for 3 h. More

experimental details were described elsewhere.7,19 Crosssectional TEM samples were prepared by gluing the film

with Si, cutting to slices followed by mechanical polishing,

dimpling and ion-milling (Gatan PIPS, Model 691, Pleas 0

anton, CA). The sample was cut along the sapphire 101

prismatic face, so the electron beam in TEM is looking down

0 direction. A JEOL 2010F TEM was used

the sapphire 101

to investigate the morphology, crystal structure, interface,

and chemistry of the samples.

Dense single crystal ZnO film was obtained for the

Ga-pretreated sample, as shown in Fig. 1(a). Some vertical

straight dark fringes in the film show the existence of stacking faults, inversion boundaries, and/or threading dislocations. The inset in Fig. 1(a) is a selected area electron diffraction pattern from a region including both the ZnO film

and

the

sapphire

substrate. It shows the orientation relationship between

10 sapphire

the film and the substrate: ZnO000121

0. This orientation relationship is called the main

0001101

domain as illustrated in Fig. 1(b). Corresponding atomic

arrangement can be found in Refs. 19 and 20. No 30

FIG. 1. (a) Cross-sectional TEM image showing the morphology of a ZnO

film grown on the (0001) sapphire. The inset is a corresponding selected

10

area electron diffraction pattern with electron beam parallel to the 21

zone axis of ZnO, in which 1 and 2 are ZnO0001 and 0110 reflections,

10. (b) Illustration of

and a and b are reflections of sapphire (0003) and 12

the main domain orientation relationship of ZnO on sapphire.

a)

Author to whom correspondence should be addressed; electronic mail:

panx@umich.edu

0003-6951/2004/85(19)/4385/3/$22.00

4385

2004 American Institute of Physics

4386

Appl. Phys. Lett., Vol. 85, No. 19, 8 November 2004

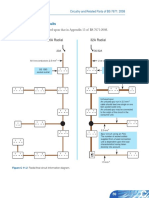

FIG. 2. (a) EDS spectra 1 and 2 are collected from the ZnO/sapphire interface [spot 1 marked in (b)] and the ZnO film [spot 2 in (b)], respectively,

using 1.0 nm beam size. (b) High resolution TEM image showing the periodic distribution of misfit dislocations along ZnO/sapphire interface. (c)

Fourier filtered image shows lattice distortion around dislocation cores.

10 sapphire (0001)

rotation domain, i.e. ZnO000121

10, was found in the films. This reveals that

ZnO000121

ZnO film with only one domain orientation can be obtained

by surface modification of the substrate with Ga.

The Ga O bond at the substrate surface is believed to

play a key role in eliminating other rotation domains. X-ray

energy dispersion spectroscopy (EDS) [Fig. 2(a)] shows the

existence of Ga at the interface. Line-profile analysis by EDS

across the film/substrate interface shows that the Ga distribution is limited to the first few atomic layers at the interface. More detailed mechanism of formation of bonding at

the interface and how surface modification changes the

nucleation behavior of ZnO are interesting topics for future

study.

Lattice mismatch between the ZnO film and the sapphire

substrate for the main domain orientation is about 18%,

which results in a high density of misfit dislocation at the

interface. The misfit dislocations can be observed by high

resolution transmission electron microscopy (HRTEM) imaging. Dislocation cores with an average spacing about 2 nm

are indicated in Fig. 2(b). Around the dislocation cores, the

atom positions in ZnO as well as in sapphire are highly displaced as shown in Fig. 2(c), suggesting the existence of a

high strain in the film.

Stacking faults in the (0001) plane were also observed in

the epitaxial ZnO film. As shown in Fig. 3(a), the density of

Sun et al.

FIG. 3. (a) High resolution TEM image showing a high density of stacking

fault. (b) High resolution image of stacking faults with Burger vector lying

in the (0001) plane.

stacking faults in the ZnO film is fairly high. Stacking faults

can easily be recognized because of a change in the stacking

sequence of the (0001) planes along the [0001] growth direction, as shown in Fig. 3(b), where the stacking faults are

indicated by dashed lines. These stacking faults consist of a

100 directions in

relative displacement of a / 3 along the 1

the (0001) plane. The displacement does not have a vertical

component along the [0001] direction, as illustrated by AD

in Fig. 4(b). Such stacking faults may originate from incoherent boundaries between adjacent columnar grains during

the growth.

FIG. 4. (a) High resolution TEM image of a partial dislocation around a

3. (b) Illusstacking fault in ZnO with the Burger vector b = AB= 1 / 6022

tration of possible Burger vector AB and AD in ZnO.

Sun et al.

Appl. Phys. Lett., Vol. 85, No. 19, 8 November 2004

Another way to form a stacking fault is by condensation

of vacancies or interstitials, so that a missing or an extra

(0001) plane will be introduced into the lattice. This type of

SF is bounded by partial dislocations with Burgers vector

3, as shown in Fig. 4. A more detailed discusb = 1 / 6022

sion of this type of stacking fault can be found in a recent

paper by Gerthsen et al.,16 in which they attribute the formation of stacking faults to the precipitation and condensation

of Zn interstitials. In this case, the density of stacking fault is

growth-condition related and oxygen vacancies have to be

generated in the film. Distribution of oxygen vacancies in the

ZnO layer has not been very well studied yet. Vacancy clustering and ordering is likely to occur in this hexagonal material, and may affect the film properties.

In conclusion, our TEM observations show that the ZnO

thin film grows epitaxially on the (0001) sapphire substrates

by molecular beam epitaxy with a Ga pretreatment, which is

free of 30 in-plane rotation domains. Local bonding configuration at the ZnO/sapphire interface with the existence of

Ga determines the nucleation mechanism and hence the domain structure of the ZnO layer. HRTEM image reveals a

detailed structure of misfit dislocation cores at the interface.

In the ZnO film there is a high density of stacking faults

which are introduced either by a translation of the crystal

lattice along three equivalent close-packing directions in the

(0001) plane or by condensation of vacancies or interstitials

to form dislocation loop accompanied with partial dislocations. More efforts are needed to control the formation of

stacking fault and to understand its effect on the properties of

the ZnO layer.

This work was supported by the National Science Foundation (NSF) through Grant No. NSF/DMR 0308012. The

TEM work was performed by using a JEOL 2010F field

emission gun TEM with NSF Award No. DMR-9871177 in

the Electron Microbeam Analysis Laboratory (EMAL) at the

University of Michigan. The work at the Institute of Physics

4387

was supported by National Science Foundation of China under Grant No. 60376004, and Ministry of Science and Technology of China under Grant No. 2002CB613500.

1

Y. Chen, D. Bagnall, and T. Yao, Mater. Sci. Eng., B 75, 190 (2000).

M. Kawasaki, A. Ohtomo, I. Ohkubo, H. Koinuma, Z. K. Tang, P. Yu, G.

K. L. Wong, B. P. Zhang, and Y. Segawa, Mater. Sci. Eng., B 56, 239

(1999).

3

D. M. Bagnall, Y. F. Chen, Z. Zhu, T. Yao, S. Koyama, M. Y. Shen, and T.

Goto, Appl. Phys. Lett. 70, 2230 (1997).

4

M. H. Huang, S. Mao, H. Feick, H. Yan, Y. Wu, H. Kind, E. Weber, R.

Russo, and P. Yang, Science 292, 1897 (2001).

5

A. Tiwari, M. Park, C. Jin, H. Wang, D. Kumar, and J. Narayan, J. Mater.

Res. 17, 2480 (2002).

6

A. Nahhas, H. K. Kim, and J. Blachere, Appl. Phys. Lett. 78, 1511 (2001).

7

X. L. Du, M. Murakami, H. Iwaki, and A. Yoshikawa, Phys. Status Solidi

A 192, 183 (2002).

8

X. L. Du, M. Murakami, H. Iwaki, Y. Ishitani, and A. Yoshikawa, Jpn. J.

Appl. Phys., Part 2 41, 1 (2002).

9

I. Ohkubo, Y. Matsumoto, A. Ohtomo, T. Ohnishi, A. Tsukazaki, M. Lippmaa, H. Koinuma, and M. Kawasaki, Appl. Surf. Sci. 159160, 514

(2000).

10

P. Fons, K. Iwata, S. Niki, A. Yamada, and K. Matsubara, J. Cryst. Growth

201202, 627 (1999).

11

P. Fons, K. Iwata, A. Yamada, K. Matsubara, S. Niki, K. Nakahara, T.

Tanabe, and H. Takasu, Appl. Phys. Lett. 77, 1801 (2000).

12

D. C. Look, D. C. Reynolds, C. W. Litton, R. L. Jones, D. B. Eason, and

G. Cantwell, Appl. Phys. Lett. 81, 1830 (2002).

13

P. M. Verghese and D. R. Clarke, J. Mater. Res. 14, 1039 (1999).

14

F. Vigue, P. Vennegues, S. Vezian, M. Laugt, and J.-P. Faurie, Appl. Phys.

Lett. 79, 194 (2001).

15

S.-H. Lim, D. Shindo, H.-B. Kang, and K. Nakamura, J. Vac. Sci. Technol.

B 19, 506 (2001).

16

D. Gerthsen, D. Litvinov, Th. Gruber, C. Kirchner, and A. Waag, Appl.

Phys. Lett. 81, 3972 (2002).

17

L. Sagalowicz and G. R. Fox, J. Mater. Res. 14, 1876 (1999).

18

I. Ohkubo, A. Ohtomo, T. Ohnishi, Y. Mastumoto, H. Koinuma, and M.

Kawasaki, Surf. Sci. 443, L1043 (1999).

19

Q. Y. Xu, Y. Wang, Y. G. Wang, X. L. Du, Q. K. Xue, and Z. Zhang, Appl.

Phys. Lett. 84, 2069 (2004).

20

H. B. Kang, K. Nakamura, S. H. Lim, and D. Shindo, Jpn. J. Appl. Phys.,

Part 1 37, 781 (1998).

2

Вам также может понравиться

- SEM Micrograph of The Diamond Film Surface Deposited Under High Perpendicularity ConditionsДокумент2 страницыSEM Micrograph of The Diamond Film Surface Deposited Under High Perpendicularity ConditionsJeanne Kamille Evangelista PiniliОценок пока нет

- 1997, Srikant Et Al, JAPДокумент11 страниц1997, Srikant Et Al, JAPAbheek BardhanОценок пока нет

- ApplPhysLett 82 742 PDFДокумент3 страницыApplPhysLett 82 742 PDFEidelsayedОценок пока нет

- ApplPhysLett 84 502 PDFДокумент3 страницыApplPhysLett 84 502 PDFEidelsayedОценок пока нет

- Optoelectronic Properties of Three-Dimensional Zno Hybrid StructureДокумент3 страницыOptoelectronic Properties of Three-Dimensional Zno Hybrid StructureEidelsayedОценок пока нет

- Strejn U BFO Filmu - Ujimoto2011Документ5 страницStrejn U BFO Filmu - Ujimoto2011Bojan StojadinovićОценок пока нет

- Thickness-Dependent Structure-Property Relationships in Strained (110) Srruo Thin FilmsДокумент8 страницThickness-Dependent Structure-Property Relationships in Strained (110) Srruo Thin FilmsBhabani Sankar SwainОценок пока нет

- ApplPhysLett 87 051901 PDFДокумент3 страницыApplPhysLett 87 051901 PDFEidelsayedОценок пока нет

- TMP 6 EC5Документ4 страницыTMP 6 EC5FrontiersОценок пока нет

- tmp3B0E TMPДокумент5 страницtmp3B0E TMPFrontiersОценок пока нет

- High Transparency of Zno:In Coated Glass SubstratesДокумент6 страницHigh Transparency of Zno:In Coated Glass SubstratesСара ОрхидеяОценок пока нет

- Journal of Science of Hnue-2016 - 1Документ6 страницJournal of Science of Hnue-2016 - 1Vinh PhamОценок пока нет

- Chen 2011 Nanotechnology LSM CeO2Документ7 страницChen 2011 Nanotechnology LSM CeO2antonello tebanoОценок пока нет

- ApplPhysLett 83 2784 PDFДокумент3 страницыApplPhysLett 83 2784 PDFEidelsayedОценок пока нет

- Structural Defects and Their RelationshipДокумент12 страницStructural Defects and Their RelationshipbirhangebrieОценок пока нет

- Structural and Optical Characterization of Cu DopeДокумент5 страницStructural and Optical Characterization of Cu DopeSyahrul MuchlisОценок пока нет

- Mughal Et Al. - 2017 - Structural and Optical Properties of Group III Doped Hydrothermal ZnO Thin Films - Journal of Electronic MaterialsДокумент5 страницMughal Et Al. - 2017 - Structural and Optical Properties of Group III Doped Hydrothermal ZnO Thin Films - Journal of Electronic MaterialsAsadОценок пока нет

- Structure of Interface in Directionally Solidified Oxide Eutectic SystemsДокумент18 страницStructure of Interface in Directionally Solidified Oxide Eutectic SystemsAzizur RahmanОценок пока нет

- Yusof2020 Merged OrganizedДокумент9 страницYusof2020 Merged Organized069 Sharathkumar V G EEОценок пока нет

- TMP 7645Документ3 страницыTMP 7645FrontiersОценок пока нет

- Lawrence E Murr (Editor) - Electron and Ion Microscopy and Microanalysis - Principles and Applications, Second Edition,-CRC Press (1991)Документ54 страницыLawrence E Murr (Editor) - Electron and Ion Microscopy and Microanalysis - Principles and Applications, Second Edition,-CRC Press (1991)Elkin ZapataОценок пока нет

- Michea-Enhanced Hall Effect in Co-Pd Multilayered Nanodomes With Perpendicular anisotropy-2017-AIP AdvancesДокумент7 страницMichea-Enhanced Hall Effect in Co-Pd Multilayered Nanodomes With Perpendicular anisotropy-2017-AIP AdvancessebaheadОценок пока нет

- Computer Modeling Zinc OxideSilicon Heterojunction Solar CellsДокумент6 страницComputer Modeling Zinc OxideSilicon Heterojunction Solar Cellskhannoussi kamiliaОценок пока нет

- ZnO Deposited by RFДокумент4 страницыZnO Deposited by RFHoon Jian WeiОценок пока нет

- On The Roughness of Single-And Bi-Layer Graphene MembranesДокумент9 страницOn The Roughness of Single-And Bi-Layer Graphene MembranesMateo BallestaОценок пока нет

- Determination of Crystallographic Polarity of Zno LayersДокумент3 страницыDetermination of Crystallographic Polarity of Zno Layerseid elsayedОценок пока нет

- Synthesis, Optical and Electrochemical Properties of Zno Nanowires/Graphene Oxide HeterostructuresДокумент6 страницSynthesis, Optical and Electrochemical Properties of Zno Nanowires/Graphene Oxide HeterostructuresAbdul Karim KhanОценок пока нет

- Magnetic Anisotropy of Epitaxial Cobalt Ferrite Thin Films: Y. Suzuki, G. Hu, R.B. Van Dover, R.J. CavaДокумент8 страницMagnetic Anisotropy of Epitaxial Cobalt Ferrite Thin Films: Y. Suzuki, G. Hu, R.B. Van Dover, R.J. Cavaイワン D AОценок пока нет

- JApplPhys 93 3837 PDFДокумент7 страницJApplPhys 93 3837 PDFEidelsayedОценок пока нет

- Thin Solid Films, 196: (1991) 35-46 Electronics and OpticsДокумент12 страницThin Solid Films, 196: (1991) 35-46 Electronics and OpticsPaul AsturbiarisОценок пока нет

- Surface TopographyДокумент11 страницSurface TopographyPathik ShahОценок пока нет

- J Vacuum 2018 03 050Документ14 страницJ Vacuum 2018 03 050Vinita ChoudharyОценок пока нет

- Reading2 Nanostructures ZnO PDFДокумент8 страницReading2 Nanostructures ZnO PDFJhon Barzola PalominoОценок пока нет

- Strain Dependence of Lasing Mechanisms in Zno EpilayersДокумент3 страницыStrain Dependence of Lasing Mechanisms in Zno Epilayerseid elsayedОценок пока нет

- 18-Shape-Induced Anisotropy in Antidot Arrays IEEE Trans Magn 2005Документ3 страницы18-Shape-Induced Anisotropy in Antidot Arrays IEEE Trans Magn 2005iaia367Оценок пока нет

- Modeling and Simulation of Polycrystalline Zno Thin-Film TransistorsДокумент10 страницModeling and Simulation of Polycrystalline Zno Thin-Film Transistorsck maitiОценок пока нет

- Scientific Reports 2010Документ6 страницScientific Reports 2010angelomalachiasОценок пока нет

- Optical and Electronic Properties of Mo:Zno Thin Films Deposited Using RF Magnetron Sputtering With Different Process ParametersДокумент10 страницOptical and Electronic Properties of Mo:Zno Thin Films Deposited Using RF Magnetron Sputtering With Different Process ParametersTun Thu LinОценок пока нет

- Fundamental and Experimental Aspects of Difraction For Characterizin Dislocations in STEMДокумент8 страницFundamental and Experimental Aspects of Difraction For Characterizin Dislocations in STEM5935b0a41dОценок пока нет

- Influence of Substrate Temperature On Structural, Electrical and Optical Properties of Zno:Al Thin FilmsДокумент11 страницInfluence of Substrate Temperature On Structural, Electrical and Optical Properties of Zno:Al Thin FilmsMuhammad Sahlan RidwanОценок пока нет

- Continuous Mesoporous Silica Films With Highly Ordered Large Pore StructuresДокумент6 страницContinuous Mesoporous Silica Films With Highly Ordered Large Pore Structurestrandafir16Оценок пока нет

- CCL GD MeP 3Документ14 страницCCL GD MeP 3dgg3565Оценок пока нет

- Stoichiometry - Anisotropy Connections in Epitaxial L1 Fept (001) FilmsДокумент8 страницStoichiometry - Anisotropy Connections in Epitaxial L1 Fept (001) FilmsarslansaeedarslanОценок пока нет

- 2016 - APL - Surface and Interface States by THZ EmissionДокумент6 страниц2016 - APL - Surface and Interface States by THZ Emissionbansal.namzОценок пока нет

- Thin Film Iit DelhiДокумент4 страницыThin Film Iit DelhiChandra ShettyОценок пока нет

- Como É A AmostraДокумент4 страницыComo É A AmostraLeandro CapraraОценок пока нет

- Residual Stress Measurement in Thin Films Using The Semi-Destructive Ring-Core Drilling Method Using Focused Ion BeamДокумент6 страницResidual Stress Measurement in Thin Films Using The Semi-Destructive Ring-Core Drilling Method Using Focused Ion BeamGabriel Vazquez VegaОценок пока нет

- Raman Study of Structural Disorder in ZnO NanopowdersДокумент8 страницRaman Study of Structural Disorder in ZnO NanopowdersMaja ScepanovicОценок пока нет

- 073-076 Reilly, E.KДокумент4 страницы073-076 Reilly, E.KDebnath MajiОценок пока нет

- Study of Dislocations in Znse and Zns by Scanning Force MicrosДокумент8 страницStudy of Dislocations in Znse and Zns by Scanning Force MicrosReuven BallabanОценок пока нет

- Lecture 2 7 Atomic - Force - MicrosДокумент51 страницаLecture 2 7 Atomic - Force - MicrosMudzakkir DioktyantoОценок пока нет

- 2001 Slab-Modulated Sidewall Bragg Gratings in Silicon-On-Insulator Ridge WaveguidesДокумент3 страницы2001 Slab-Modulated Sidewall Bragg Gratings in Silicon-On-Insulator Ridge WaveguidesP wОценок пока нет

- Fib/Sem and Sem/Edx: A New Dawn For The Sem in The Core Lab?Документ12 страницFib/Sem and Sem/Edx: A New Dawn For The Sem in The Core Lab?Rosa K Chang HОценок пока нет

- Study of The Wettability of Zno NanofilmsДокумент4 страницыStudy of The Wettability of Zno NanofilmsMausam ShresthaОценок пока нет

- Barnes 1978Документ15 страницBarnes 1978ismail.bliamsiОценок пока нет

- Safi ASS 12Документ6 страницSafi ASS 12Safiul MollickОценок пока нет

- Kim 2009Документ5 страницKim 2009Petru ApostolОценок пока нет

- Enhanced Light Absorption in Thin Film Solar Cells With Embedded Dielectric Nanoparticles: Induced Texture Dominates Mie ScatteringДокумент4 страницыEnhanced Light Absorption in Thin Film Solar Cells With Embedded Dielectric Nanoparticles: Induced Texture Dominates Mie Scatteringbaljit6111Оценок пока нет

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: FundamentalsОт EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: FundamentalsОценок пока нет

- Subduction Dynamics: From Mantle Flow to Mega DisastersОт EverandSubduction Dynamics: From Mantle Flow to Mega DisastersGabriele MorraОценок пока нет

- Recovered PDF 7 PDFДокумент6 страницRecovered PDF 7 PDFeid elsayedОценок пока нет

- 1 s2.0 S0921509300013514 Main1 PDFДокумент9 страниц1 s2.0 S0921509300013514 Main1 PDFEidelsayedОценок пока нет

- Recovered PDF 10 PDFДокумент9 страницRecovered PDF 10 PDFeid elsayedОценок пока нет

- Recovered PDF 3 PDFДокумент7 страницRecovered PDF 3 PDFeid elsayedОценок пока нет

- Recovered PDF 3 PDFДокумент7 страницRecovered PDF 3 PDFeid elsayedОценок пока нет

- Recovered PDF 1 PDFДокумент15 страницRecovered PDF 1 PDFeid elsayedОценок пока нет

- A Metal-Metal Bonding Process Using Metallic Copper PDFДокумент8 страницA Metal-Metal Bonding Process Using Metallic Copper PDFeid elsayedОценок пока нет

- Cluster Algorithms of The Monte Carlo Method, Finite-Size PDFДокумент8 страницCluster Algorithms of The Monte Carlo Method, Finite-Size PDFeid elsayedОценок пока нет

- Mechanical Properties of Lead Free Solder Alloys PDFДокумент100 страницMechanical Properties of Lead Free Solder Alloys PDFeid elsayedОценок пока нет

- 1 s2.0 S1226086X13003912 Main PDFДокумент15 страниц1 s2.0 S1226086X13003912 Main PDFeid elsayedОценок пока нет

- Determination of The Elastic Properties of Au5Sn and AuSn PDFДокумент7 страницDetermination of The Elastic Properties of Au5Sn and AuSn PDFeid elsayedОценок пока нет

- Comparative PDFДокумент6 страницComparative PDFeid elsayedОценок пока нет

- Effect of ZnO Nanoparticles Addition PDFДокумент11 страницEffect of ZnO Nanoparticles Addition PDFeid elsayedОценок пока нет

- Acta 2007 55 9 3059 PDFДокумент13 страницActa 2007 55 9 3059 PDFeid elsayedОценок пока нет

- Acta 2004 52 14 4121 PDFДокумент11 страницActa 2004 52 14 4121 PDFeid elsayedОценок пока нет

- 182-Grain Geometry Induced Reversal Behaviour Alteration PDFДокумент6 страниц182-Grain Geometry Induced Reversal Behaviour Alteration PDFeid elsayedОценок пока нет

- A Thermodynamic Theory of Short-Term and Creep RuptureДокумент6 страницA Thermodynamic Theory of Short-Term and Creep Ruptureeid elsayedОценок пока нет

- 215-cbh 2011 PDFДокумент9 страниц215-cbh 2011 PDFeid elsayedОценок пока нет

- Ab-Initio Investigation of Electronic Properties and Magnetism of Half-Heusler Alloys XCrAl (X Fe, Co, Ni) PDFДокумент7 страницAb-Initio Investigation of Electronic Properties and Magnetism of Half-Heusler Alloys XCrAl (X Fe, Co, Ni) PDFEidelsayedОценок пока нет

- Magnetic Characteristics of Ferromagnetic Nanotube PDFДокумент3 страницыMagnetic Characteristics of Ferromagnetic Nanotube PDFeid elsayedОценок пока нет

- 1 s2.0 S0167577X08006988 Main PDFДокумент3 страницы1 s2.0 S0167577X08006988 Main PDFEidelsayedОценок пока нет

- 195-Ahn - Mat Sci A PDFДокумент6 страниц195-Ahn - Mat Sci A PDFeid elsayedОценок пока нет

- 163-Leejh Jap PDFДокумент3 страницы163-Leejh Jap PDFeid elsayedОценок пока нет

- 150-Paper (DRS) PDFДокумент16 страниц150-Paper (DRS) PDFeid elsayedОценок пока нет

- Characterization of The Crystallographic Microstructure of The Stress-Induced Void in Cu InterconnectsДокумент3 страницыCharacterization of The Crystallographic Microstructure of The Stress-Induced Void in Cu Interconnectseid elsayedОценок пока нет

- 165-Bang-Study of Fracture Mechanics in Testing Interfacial Fracture of Solder Joints PDFДокумент12 страниц165-Bang-Study of Fracture Mechanics in Testing Interfacial Fracture of Solder Joints PDFeid elsayedОценок пока нет

- Thermal Diffusivity of Sn-Ag-Cu-based, Pb-Free, Micro - and Nano-Sized Solder PDFДокумент4 страницыThermal Diffusivity of Sn-Ag-Cu-based, Pb-Free, Micro - and Nano-Sized Solder PDFeid elsayedОценок пока нет

- Wear Resistant Electrically Conductive Au-ZnO Nanocomposite PDFДокумент8 страницWear Resistant Electrically Conductive Au-ZnO Nanocomposite PDFeid elsayedОценок пока нет

- Microstructure, Mechanical Properties, and Deformation Behavior 2 PDFДокумент10 страницMicrostructure, Mechanical Properties, and Deformation Behavior 2 PDFeid elsayedОценок пока нет

- Thermal Conductivity Variation With Temperature For Lead-Free PDFДокумент9 страницThermal Conductivity Variation With Temperature For Lead-Free PDFeid elsayedОценок пока нет

- Datasheet LM358Документ25 страницDatasheet LM358Erlina YanuariniОценок пока нет

- DC Machine61 74Документ3 страницыDC Machine61 74Charina PinlacОценок пока нет

- Principles of Computer Architecture: Miles Murdocca and Vincent HeuringДокумент11 страницPrinciples of Computer Architecture: Miles Murdocca and Vincent HeuringAlxndr ColumbaОценок пока нет

- LCD TV Repair Case HistoriesДокумент0 страницLCD TV Repair Case Historiesगणेश पराजुली76% (17)

- Vlsi System DesignДокумент12 страницVlsi System DesignMahender GoudОценок пока нет

- DEA 300, Digital Input Modules: Ordering DataДокумент13 страницDEA 300, Digital Input Modules: Ordering DataThien NguyenngocОценок пока нет

- Datasheet MDF 12N50 MagnachipsДокумент8 страницDatasheet MDF 12N50 MagnachipsJorgeОценок пока нет

- Zener zp27bДокумент3 страницыZener zp27bCamilo AldanaОценок пока нет

- Presentation 1Документ5 страницPresentation 1TinaabisheganОценок пока нет

- Electronic Engineering 23 March 2021Документ33 страницыElectronic Engineering 23 March 2021utkarsh mauryaОценок пока нет

- Ace Ahead .Physics Vol 2. Student. Practical GuideДокумент15 страницAce Ahead .Physics Vol 2. Student. Practical GuideJolyn May LingОценок пока нет

- Physics ProjectДокумент13 страницPhysics ProjectShubhrasmita Patel50% (2)

- Smartphone Repair CourseДокумент14 страницSmartphone Repair CourseKirsty Joy Bacali50% (2)

- ADu M3190Документ16 страницADu M3190Varun ThakurОценок пока нет

- 24-Scanning Tunneling Microscope-Sawlan (SAMPLE 1)Документ2 страницы24-Scanning Tunneling Microscope-Sawlan (SAMPLE 1)Muhammad Tayyab MalikОценок пока нет

- Curs Comunicare OrganizationalaДокумент59 страницCurs Comunicare OrganizationalaEleonora JelescuОценок пока нет

- (600 Volts Peak) : Semiconductor Technical DataДокумент6 страниц(600 Volts Peak) : Semiconductor Technical DataDario Amaris MarquezОценок пока нет

- RF To DC Converter 2.4GHzДокумент12 страницRF To DC Converter 2.4GHzViswa GopalОценок пока нет

- OC - Lect - 01 Aziz AlhaidariДокумент34 страницыOC - Lect - 01 Aziz Alhaidariabdulaziz saif ali mansoorОценок пока нет

- 3AH Catalog PDFДокумент75 страниц3AH Catalog PDFalsilva2014100% (1)

- Capacitance & DielectricsДокумент51 страницаCapacitance & DielectricsruОценок пока нет

- 3-Phase Switched Reluctance Motor Control With Encoder Using DSP56F80xДокумент56 страниц3-Phase Switched Reluctance Motor Control With Encoder Using DSP56F80xYusuf Ilker öztürkОценок пока нет

- Data Conditioning & Carrier Modulation Transmitter & Data Reconditioning & Carrier Demodulation ReceiverДокумент49 страницData Conditioning & Carrier Modulation Transmitter & Data Reconditioning & Carrier Demodulation ReceiverCauVong JustinОценок пока нет

- PFR40L60PTV40Документ6 страницPFR40L60PTV40Andre AnsyahОценок пока нет

- Solution MalvinoДокумент123 страницыSolution MalvinoMax MuñozcanoОценок пока нет

- SocketДокумент1 страницаSocketEngr Zain Ul AbaidinОценок пока нет

- Periodic Table ActivityДокумент1 страницаPeriodic Table ActivityRonaldGomezОценок пока нет

- Ring Amplifiers For Switched Capacitor CircuitsДокумент15 страницRing Amplifiers For Switched Capacitor CircuitsheqiОценок пока нет

- Stps 5 L 25Документ8 страницStps 5 L 25Gabriel LatiuОценок пока нет

- LM-K5530X (SM)Документ61 страницаLM-K5530X (SM)Robert 2005Оценок пока нет