Академический Документы

Профессиональный Документы

Культура Документы

Kiswire - Neptune

Загружено:

alphadingАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Kiswire - Neptune

Загружено:

alphadingАвторское право:

Доступные форматы

NEPTUNE

STEEL WIRE ROPES

MALAYSIA:

KISWIRE SDN. BHD. (OFFICE)

Address

Suite 1701, 17th Floor, City Plaza, Jalan

Tebrau, 80300 Johor Bahru, Johor, Malaysia

TEL | 60. 7. 333. 0178

FAX | 60. 7. 333. 2475

E-MAIL | ikpaik@kiswire.com

CHINA:

KISWIRE LTD.

(BEIJING REPRESENTATIVE OFFICE)

Address

Room 19-5A, Citic Building

19 Jianguomenwai Street, Beijing, China

TEL | 86. 21. 6593. 1833

FAX | 86. 21. 6593. 1876

E-MAIL | shulong@kiswire.com

KISWIRE LOCAL DISTRIBUTOR

EUROPE:

KISWIRE EUROPE BV

Kleine Landtong 21

4201 HL Gorinchem

E-MAIL | nordin@kiswire.com

The Netherlands

PO Box 364

4200 AJ Gorinchem

The Netherlands

TEL | +31 183 66 60 60

FAX | +31 183 66 50 21

E-MAIL | ruijter@kiswire-europe.com

KOREA :

KISWIRE LTD.

SEOUL OFFICE,

Jankyo Building 20th Floor,

Jankyo-dong 1,

Chung-ku, Seoul.

TEL | 82. 2. 316. 6114

FAX | 82. 2. 316. 6115

E-MAIL | webmaster@kiswire.com

USA:

KISWIRE WEST, INC.

Address

3450 Wilshire Boulevard. Suite #314

Los Angeles CA 90010. USA.

TEL | 1. 213. 386. 5420

FAX | 1. 213. 386. 6981

E-MAIL | jaemyung@kiswireusa.com

MALAYSIA:

KISWIRE SDN. BHD. (FACTORY)

Address

Plo 475, Jalan Keluli 2, Pasir Gudang,

81707, Johor, Malaysia

TEL | 60. 7. 251. 2475

FAX | 60. 7. 251. 0870

E-MAIL | nordin@kiswire.com

Providing strength to access oil and gas reserves

in the deepest waters

Kiswire

Features of Neptune

High strength wire rope for the

offshore oil & gas industry

The NEPTUNE product range includes:

Anchor Lines

A & R Winch Ropes

Drilling Lines

Marine Riser Tensioner Lines

Large Diameter Offshore Crane Ropes

KISWIRE LTD

The Worlds largest manufacturer of steel wire rope.

Kiswire was established in 1945 in Busan, Korea. The company has grown into a major international

operation with a global sales and marketing presence and manufacturing facilities in Korea, Malaysia,

China and the USA.

Key Product Features:

NEPTUNE Wire Ropes

In 1997 KISWIRE established a dedicated manufacturing operation in Johor, Malaysia for a complete range

of wire ropes for use by the oil and gas industry, with unit weights for 6-strand rope up to 120t.

Through continuous improvement, product development and expansion, NEPTUNE wire ropes have grown

into leading products for use Offshore

Planned investment will see NEPTUNE unit weights go beyond 300t. and its manufacturing

capacity double.

The highest breaking strengths and fatigue resistance in round and compacted strand rope made possible

by the use of special, high quality steel; high technology wire drawing machinery coupled with special die and

lubrication practices; optimum rope designs to minimise spinning loss.

Outstanding resistance to corrosion through heavy, uniform thickness zinc and zinc aluminium alloy

(ALUMAR) coatings in combination with highly effective water repellent blocking compounds developed

specifically for use with NEPTUNE products.

Excellent packaging and product protection by careful control of rope spooling and the use of strong steel

reels and protective wrapping.

Rigorous quality assurance through procedures and practices strictly applied according to Internationally

accredited standards.

Product Selection

Product Selection

Wire Rope Selection

When replacing a wire rope, refer to the relevant Original Equipment Manufacturers recommendation and rope test certification.

Rope Diameter

8 Strand - 8.5%

6 Strand - 7.1%

Multistrand - 1.9%

40

8 Strand

6 Strand

30

20

Multistrand

10

0

0

Correct and consistent rope diameter is essential for optimum

working performance. Ensure that the rope diameter is correctly

measured and that the resulting diameter is appropriate for the

working system.

100

200

300

400

500

600

Untwisting Effect in degrees/metre

Where an original wire rope is to be supplied, or where the required working conditions have changed, KISWIRE should be

consulted to obtain the best possible advice and recommendations.

Predicted Rope Rotation with Zero Restraining Torque

120

Torque Factors

Torque/Rope Diameter (tonnef)

To ensure safe and efficient operation, replacement ropes should conform to the specified nominal rope diameter and be at least

equal to the required strength originally specified. Additionally, the wire rope construction selected should provide similar or

improved working properties for resistance to rotation, bend fatigue, crushing, abrasion and corrosion.

Comparison of Rope Torques

50

100

8 Strand

80

6 Strand

60

40

20

Multistrand

Rope Tension (tonnef)

0

0

The torque generated is the torque factor (%) multiplied by

the rope diameter multiplied by the applied load.

10

15

Applied Load as % MBL

20

25

Incorrect diameter can reduce performance and cause unsafe

working conditions.

Strength

Axial Stiffness (EA)

Flexural Stiffness (EI)

Rope strength should be specified as Minimum Breaking

Strength or Minimum Breaking Force.

Axial Stiffness (EA) is determined by E x A x 10-3, in MN,

where:

Flexural Stiffness (EI) is determined by E x I x 10-6, in N.m2,

where:

E - is the apparent modulus of the rope in kN/mm2, shown

below for 6x37 IWRC group constructions.

A - is the cross sectional area of the circumscribed circle

(mm2) based on the nominal rope diameter.

E - is the Stiffness Factor in N/mm2, shown below for

appropriate 6x37 IWRC group constructions.

I - is the Second Moment of Area of the rope (d4), using

Nominal Diameter d.

The breaking strength of the rope is determined by the wire

tensile strength and steel cross sectional area.

Grooves for Pulleys, Sheaves and Drums

The steel fill factor and rope construction can be varied to suit

the operating conditions.

Strand compaction can be used for increased rope strength

and service life.

Construction 6x37 IWRC API classification

Construction 6x37 IWRC API classification

kN/mm

Rope Torsion

All wire ropes have inherent rotation characteristics that

will produce a turning moment in the rope. With both rope ends

fixed and unable to rotate, the turning moment will generate a

TORQUE force at the fixed points. Whereas, if one end of the

rope is free to rotate, the generated force will result in rope

TURN and therefore load rotation.

58.86

6x36

15.6

6xK36, 6xK41 and 6xK49

63.77

6xK36

18.8

6x41

14.5

6xK41

17.6

6x49

12.6

6xK49

14.4

e.g. EI for 76.2mm dia. 6x36: 15.6 x 76.24 x 10-6 = 526 N.m2

Single Layer ropes such as the 6 and 8 strand have a much

greater tendency to rotate under load, whereas Multistrand

ropes, which depend upon the opposing torsional values of the

various layers of strands, offer much greater torsional stability.

As the wire rope construction options are numerous, KISWIRE

would be pleased to offer technical advice on rope selection.

N/mm

6x36, 6x41 and 6x49

e.g. EA for 76.2mm dia. 6x36: 58.86 x 4560 x 10-3 = 268 MN

Wire ropes can be designed to achieve the desired rotational

properties required by the application.

Stiffness Factor

N.B. In both cases the Stiffness values apply to new rope with little or no applied load.

On all technical queries and parameters, it is always best to verify your requirements with the KISWIRE QA Dept.

Single Layer

2 Layer

Neptune Alumar

Product Selection

Influence of rope lubricant on bend

fatigue performance

Rope Lubrication

All Neptune ropes are filled with an impermeable, semi

solid, anti corrosion blocking compound. This provides

lubrication for the rope which reduces internal abrasion

damage, as well as increasing rope service life through

resistance to penetration of the rope by seawater.

A range of manufacturing lubricants is available to

satisfy particular seawater salinity and temperature.

Neptune Alumar

(000s)

200

150,000 High performance lubricant

100,000 General lubricant

25,000 Dry rope

Neptune ALUMAR provided by the special zinc/aluminum alloy coating.

Neptune ALUMAR is an exciting new development, stemming from a major investment programme led by KISWIREs R&D Center.

Cycles to failure

Effective rope lubrication during manufacture by

the selection and application of the optimum lubricant

can increase fatigue life, minimise wear and provide

corrosion resistance to extend the service life of

wire rope.

150

100

50

Neptune ALUMAR has excellent corrosion resistance and superior rope fatigue performance compared to conventional

galvanising.

The special, ductile zinc/aluminum coating, combined with highly effective, water repellent blocking compounds, provide three

times greater life in sea water than the conventional product.

This powerful combination of corrosion resistance, durability and highest strength rope, significantly extends useful life of rope

in a marine environment.

Neptune ALUMAR provides a 21st century solution for the offshore oil and gas industry: Unparalleled high strength to weight ratio

Extended tension-tension and bend fatigue life

Remarkable corrosion resistance

A quality assured product from design through to installation.

Corrosion Induced Coat Weight Reduction Over Time

200

Coat Loss in g/m2/year

Coating

180

160

All information and data provided are for guidance only and it is recommended that individual requirements be discussed

with KISWIRE.

Loss in Coating (g/m2)

In applications such as Riser Lines, additional corrosion protection can be achieved by the use of a plastic impregnated core.

The plastic will give added protection to the centre wires and also offer greater support to the outer strands, resulting in

extended rope life.

Severe

Marine

ALUMAR

10

12

Galvanised

14

21

19

24

GALVANISED

Corrosion

Where the rope is working in a corrosive environment, protection of the individual wires should be considered, especially if the

rope life is expected to be in excess of 12 months. In such cases, it is essential to safeguard the integrity of the smaller, inner wires

of the rope in order to maintain the constructional stability and also the working safety of the rope. Zinc has been the conventional

coating on wire, but KISWIRE is now offering a much superior coating based on a Zinc/Aluminum alloy ALUMAR, (see the

details overleaf).

Rural Industrial Marine

140

120

100

80

60

ALUMAR

40

20

0

0

4

6

Exposure Period (years)

10

Neptune Factory

Neptune Factory

Dedicated inside rod storage provides protection against pitting corrosion and coil handling damage.

Durable reels for world wide transportation.

State-of-the-art ALUMAR coating line for Neptune products.

Support cradles to distribute weight.

Efficient cooling in drawing to maximise ductility, aided by special drawing die technology and lubrication.

Robust polymer wrap protecting against corrosion

and mechanical damage.

Efficient, well controlled stranding for complex constructions.

Large rope closing machine provides options for 6, 8 and 9 strand constructions.

Take up unit capable of handling very large rope pieces enabling excellent package quality.

Clear customer ID and shipping documentation.

Products

Products

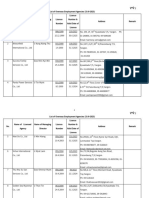

Anchor Lines

Rope construction:

Class 6x36 IWRC and greater.

Large diameter outer wires for optimum

resistance to wear and corrosion.

Wire protection by galvanising or ALUMAR.

Compact strand (CMP) for increased

strength, improved contact area, reduced

tread pressures and sheave wear.

Anchor Lines & A&R Winch Ropes

Nominal Rope Estimated Rope

Diameter

Mass in air

mm

ins

kg/m

lb/ft

EEIPS

kN

metric

tonnes

short

tons

kN

ALPHA

DELTA

Minimum Breaking Force

metric short

metric

kN

tonnes tons

tonnes

OMEGA

short

tons

kN

metric

tonnes

short

tons

2384

2578

2957

3612

3980

4394

4805

5276

5610

5992

6531

7090

7698

8554

9076

10089

11132

12226

243

263

302

369

406

448

490

538

572

611

666

723

785

873

926

1029

1136

1248

268

290

332

406

448

494

540

593

630

673

734

797

865

962

1021

1134

1252

1375

2575

2784

3193

3901

4299

4742

5186

5694

6055

6467

7049

7652

8308

9238

263

284

326

398

439

484

529

581

618

660

719

781

848

943

290

313

359

439

483

533

583

640

681

727

793

860

934

1039

Neptune Conventional - Large Diameter Six Strand Rope

A&R Winch Ropes

Optimum flexibility to allow efficient rope

operation around sheaves, drums and

capstans.

Effective protection of all wires by

galvanising/ALUMAR.

Appropriate lubrication during manufacture.

Rope selection should be determined through

consultation with KISWIRE.

50.8

54.0

57.2

63.5

66.7

69.9

73.0

76.2

79.4

82.6

85.7

88.9

95.3

102.0

108.0

114.0

121.0

127.0

2

218

214

212

258

234

278

3

318

314

338

312

334

4

414

412

434

5

11.3

12.8

14.3

17.8

19.7

21.4

23.5

25.4

27.6

29.9

32.2

34.8

39.9

45.3

51.1

57.4

63.9

70.8

7.6

8.6

9.6

11.9

13.2

14.4

15.8

17.1

18.5

20.1

21.6

23.4

26.8

30.5

34.3

38.6

42.9

47.5

1930

2160

2420

2950

3240

3530

3840

4170

4490

4840

5180

5520

6280

7060

7730

8590

9480

10430

197

220

247

301

330

360

392

425

458

494

528

563

640

720

788

876

967

1064

217

243

272

332

364

397

432

469

505

544

582

620

706

794

869

966

1066

1172

2216

2363

2697

3295

3629

4011

4384

4815

5119

5462

5953

6463

7002

7806

8287

9209

10160

11160

226

241

275

336

370

409

447

491

522

557

607

659

714

796

845

939

1036

1138

249

266

303

370

408

451

493

541

575

614

669

726

787

877

931

1035

1142

1254

2285

2471

2834

3462

3815

4207

4599

5060

5374

5737

6247

6786

7355

8199

8699

9670

10670

11719

233

252

289

353

389

429

469

516

548

585

637

692

750

836

887

986

1088

1195

257

278

319

389

429

473

517

569

604

645

702

763

827

922

978

1087

1199

1317

Neptune CMP - Large Diameter Six Strand Rope

50.8

54.0

57.2

63.5

66.7

69.9

73.0

76.2

79.4

82.6

85.7

88.9

95.3

102.0

2

218

214

212

258

234

278

3

318

314

338

312

334

4

12.1

13.8

15.5

19.1

21.1

23.1

25.2

27.4

29.8

32.3

34.8

37.6

43.0

48.9

8.1

9.3

10.4

12.8

14.2

15.5

16.9

18.4

20.0

21.7

23.4

25.3

28.9

32.9

2141

2396

2684

3272

3594

3916

4260

4626

4981

5369

5746

6123

6966

7831

218

244

274

334

367

400

435

472

508

548

586

625

711

799

241

269

302

368

404

440

479

520

560

604

646

689

783

881

Estimated Rope Mass in Sea Water = 0.87x Rope Mass in Air.

All Ropes manufactured in accordance with API Standards.

2458

2621

2992

3655

4025

4449

4863

5341

5678

6059

6603

7169

7767

8659

251

267

305

373

411

454

496

545

579

618

674

732

793

884

276

295

336

411

453

500

547

601

639

681

743

806

873

974

2535

2741

3144

3840

4232

4667

5101

5613

5961

6364

6929

7527

8159

9095

259

280

321

392

432

476

521

573

608

649

707

768

833

928

285

308

353

432

476

525

574

631

670

716

779

846

917

1023

Products

Products

Drilling Lines

Marine Riser Tensioner Lines

Rope construction:

6x19 and 6x26 for constructional stability.

Rope construction:

Flexible constructions (6x41 and 6x49) to

achieve optimum fatigue life.

Compacted strand (CMP) provides:

Langs lay to provide improved wear

resistance to rope and sheaves.

Improved spooling on the drawworks

Corrosion protection by galvanising or

ALUMAR.

Greater contact area for reduced sheave

and groove wear

High resistance to abrasion and pressure

The IWRC can be Plastic impregnated to:

Higher strength

Protect the inner small wires

Improved fatigue life

Improve strand support and reduce internal

wire stresses

Compact Strand (CMP) offers:

Greater contact area

Reduced tread pressures and sheave wear

Nominal Rope

Diameter

Estimated Rope

Mass in air

mm

kg/m

ins

lb/ft

EIPS

kN

metric

tonnes

short

tons

EEIPS

Minimum Breaking Force

metric

short

kN

tonnes

tons

ALPHA

kN

metric

tonnes

short

tons

575

723

889

1072

1259

1471

1697

1932

2216

2363

2697

3295

59

74

91

109

128

150

173

197

226

241

275

336

65

81

100

120

142

165

191

217

249

266

303

370

594

747

919

1108

1301

1520

1812

2104

2414

2733

3061

3734

61

76

94

113

133

155

185

215

246

279

325

418

67

84

103

124

146

171

204

237

271

307

358

461

Nominal Rope

Diameter

Estimated Rope

Mass in air

mm

ins

kg/m

44.5

50.8

54.0

57.2

63.5

66.7

69.9

73.0

76.2

1 4

2

218

214

212

258

234

278

3

44.5

50.8

54.0

57.2

63.5

66.7

69.9

73.0

76.2

1 4

2

218

214

212

258

234

278

3

Neptune Conventional - Class 6x19 Steel Core

25.4

28.6

31.8

34.9

38.1

41.3

44.5

47.6

50.8

54.0

57.2

63.5

1

118

114

138

112

158

134

178

2

218

214

212

2.8

3.6

4.4

5.3

6.4

7.5

8.7

9.9

11.3

12.8

14.3

17.8

1.91

2.41

2.98

3.59

4.28

5.03

5.83

6.68

7.61

8.59

9.63

11.95

460

578

711

854

1010

1170

1360

1550

1760

1970

2200

2655

47

59

73

87

103

119

139

158

180

201

224

271

52

65

80

96

114

132

153

174

198

221

247

298

506

636

782

943

1110

1300

1500

1710

1930

2160

2420

2950

52

65

80

96

113

133

153

174

197

220

247

301

57

71

88

106

125

146

169

192

217

243

272

332

1

118

114

138

112

158

134

178

2

218

214

212

3.05

3.79

4.85

5.90

6.64

7.90

9.20

10.60

12.10

13.70

15.50

19.10

2.05

2.54

3.25

3.96

4.45

5.30

6.17

7.11

8.12

9.19

10.40

12.82

475

597

734

882

1043

1211

1454

1688

1948

2206

2463

2974

All Ropes manufactured in accordance with API Standards.

48

61

75

90

106

123

148

172

199

225

251

303

53

67

83

99

117

136

163

190

219

248

277

334

523

657

808

974

1147

1345

1604

1862

2136

2419

2709

3304

53

67

82

99

117

137

164

190

218

247

276

337

59

74

91

109

129

151

180

209

240

272

304

371

kN

metric

tonnes

short

tons

EEIPS

Minimum Breaking Force

metric

short

kN

tonnes

tons

ALPHA

kN

metric

tonnes

short

tons

1695

2216

2363

2697

3295

3629

4011

4384

4815

173

226

241

275

336

370

409

447

491

191

249

266

303

370

408

451

493

541

1812

2414

2733

3061

3734

4088

4452

4814

5195

185

246

279

312

381

417

454

491

530

204

271

307

344

420

459

500

541

584

Neptune Conventional - Class 6x36 Steel Core

Neptune CMP - Class 6x19 Steel Core

25.4

28.6

31.8

34.9

38.1

41.3

44.5

47.6

50.8

54.0

57.2

63.5

lb/ft

EIPS

8.7

11.3

12.8

14.3

17.8

19.6

21.5

23.5

25.4

5.83

7.61

8.59

9.63

11.95

13.18

14.42

15.76

17.10

1360

1760

1970

2200

2682

2945

3209

3491

3782

138.7

179.5

200.9

224.4

273.5

300.4

327.3

356.1

385.7

153

198

221

247

301

331

361

392

425

1500

1930

2160

2420

2950

3240

3530

3840

4160

153.0

196.9

220.3

246.8

300.9

330.5

360.0

391.7

424.3

169

217

243

272

332

364

397

432

468

Neptune CMP - Class 6x36 Steel Core

3

9.2

12.1

13.8

15.5

19.1

21.1

23.1

25.2

27.4

6.0

7.9

9.0

10.1

12.4

13.7

15.0

16.4

17.8

1448

1924

2180

2436

2974

3257

3548

3831

4140

All Ropes manufactured in accordance with API Standards.

147.6

196.2

222.3

248.4

303.3

332.1

361.8

390.6

422.1

163

216

245

274

334

366

399

430

465

1608

2138

2422

2707

3305

3619

3942

4256

4599

164

218

247

276

337

369

402

434

469

181

240

272

304

371

407

443

478

517

Products

Quality Assurance

Large Diameter Crane Ropes

Appropriate rope constructions to achieve

optimum fatigue life.

Where the expected working life is in excess of

1 year, ALUMAR protection is recommended.

Committed to supplying the

highest possible quality across

the full product range

Compact Strand (CMP) offers:

Higher strength and improved spooling

properties

Greater contact area for reduced

sheave wear

Improved fatigue performance

Nominal Rope Estimated Rope

Diameter

Mass in air

mm

ins

41.3

44.5

47.6

50.8

54.0

57.2

63.5

66.7

69.9

73.0

76.2

1 8

134

178

2

218

214

212

258

234

278

3

kg/m

lb/ft

EEIPS

kN

metric

tonnes

short

tons

kN

ALPHA

DELTA

Minimum Breaking Force

metric short

metric

kN

tonnes tons

tonnes

OMEGA

short

tons

kN

metric

tonnes

short

tons

1612

1860

2120

2381

2575

2953

3607

3975

4394

4805

5276

164

190

216

243

263

301

368

405

448

490

538

181

209

238

268

289

332

405

447

494

540

593

Neptune Conventional Rope - Class 6x36 Steel Core

5

7.5

8.7

9.9

11.3

12.8

14.3

17.8

19.7

21.4

23.5

25.4

5.0

5.8

6.7

7.6

8.6

9.6

11.9

13.2

14.4

15.8

17.1

1300

1500

1710

1930

2160

2420

2950

3240

3530

3840

4170

133

153

174

197

220

247

301

330

360

392

425

146

169

192

217

243

272

332

364

397

432

469

1469

1695

1932

2216

2363

2697

3295

3629

4011

4384

4815

150

173

197

226

241

275

336

370

409

447

491

165

191

217

249

266

303

370

408

451

493

541

1547

1785

2035

2285

2471

2834

3462

3815

4207

4599

5060

158

182

208

233

252

289

353

389

429

469

516

174

201

229

257

278

319

389

429

473

517

569

Neptune CMP Rope - Class 6x36 Steel Core

41.3

44.5

47.6

50.8

54.0

57.2

63.5

66.7

69.9

73.0

76.2

158

134

178

2

218

214

212

258

234

278

3

7.9

9.2

10.6

12.2

13.7

15.5

19.0

21.0

23.1

25.2

27.4

5.3

6.2

7.1

8.2

9.2

10.4

12.8

14.1

15.5

16.9

18.4

1345

1604

1862

2136

2419

2709

3304

3618

3940

4260

4598

137

164

190

218

247

276

337

369

402

434

469

All Ropes manufactured in accordance with API Standards.

151

181

209

240

272

305

371

407

443

479

517

1520

1812

2104

2414

2733

3061

3734

4088

4452

4814

5195

155

185

215

246

279

312

381

417

454

491

530

171

204

237

271

307

344

420

460

500

541

584

1601

1909

2216

2542

2878

3224

3932

4306

4689

5069

5471

163

195

226

259

293

329

401

439

478

517

558

180

215

249

286

324

362

442

484

527

570

615

1668

1989

2309

2649

2999

3359

4097

4486

4886

5282

5701

170

203

235

270

306

343

418

457

498

539

581

187

224

260

298

337

378

461

504

549

594

641

KISWIRE is committed to supplying the highest possible

quality across its full product range. This is achieved by strict

adherence to ISO 9001 to which the whole of KISWIREs

operations are accredited.

ISO 9001 Det Norske Veritas Management System

API Certificate of Approval to use the official API Monogram

Korean Register of Shipping

KISWIRE maintains its QA programmes throughout its

operations to ensure that products are manufactured under

a documented and controlled system for consistency in

workmanship standards.

The following quality systems have been integrated into

KISWIREs manufacturing operations and process control

programmes:

ABS Certificate of Manufacturing Assessment

ABS Certificate of Design Assessment

ABS Certificate of Type Approval (AQS)

Det Norske Veritas Approval of Manufacturer Certificate

Вам также может понравиться

- Weld Like a Pro: Beginning to Advanced TechniquesОт EverandWeld Like a Pro: Beginning to Advanced TechniquesРейтинг: 4.5 из 5 звезд4.5/5 (6)

- NDT Handbook Vol 9 Visual Testing Handbook-3Ed-ASNTДокумент347 страницNDT Handbook Vol 9 Visual Testing Handbook-3Ed-ASNTDavid Andres Cañas Suarez87% (30)

- Aluminum Alloy Casting Properties Processes Applications ASM 2004 PDFДокумент322 страницыAluminum Alloy Casting Properties Processes Applications ASM 2004 PDFmikeav18b100% (1)

- BDO Network Bank List of Branches As of December 16 2020Документ2 страницыBDO Network Bank List of Branches As of December 16 2020Giessen Fran RamosОценок пока нет

- Company ListДокумент19 страницCompany ListikaaОценок пока нет

- Bearing damage classification ISO standardДокумент6 страницBearing damage classification ISO standardPraveen PaviОценок пока нет

- External Floating Roof Tank - WikipediaДокумент2 страницыExternal Floating Roof Tank - WikipediaalphadingОценок пока нет

- The Calibration of Flow Meters PDFДокумент35 страницThe Calibration of Flow Meters PDFRené Mora-CasalОценок пока нет

- Construction Solutions for EngineersДокумент16 страницConstruction Solutions for EngineersFida GОценок пока нет

- Basf Masterflow 980 TdsДокумент4 страницыBasf Masterflow 980 TdsVijayaraghavan Srinivasamurthi100% (1)

- Forms of Corrosion Corrosion-Fatigue Erosion-CorrosionДокумент105 страницForms of Corrosion Corrosion-Fatigue Erosion-CorrosionAnupam Chowdhury100% (1)

- Chapter 7 - Destructive and Non Destructive Testing of MaterialДокумент33 страницыChapter 7 - Destructive and Non Destructive Testing of MaterialzainonayraОценок пока нет

- Storage Tank: Storage Tanks Are Containers That Hold LiquidsДокумент7 страницStorage Tank: Storage Tanks Are Containers That Hold LiquidsalphadingОценок пока нет

- 0028-4 GL Guidelines For Transport and Install of Steel JacketsДокумент38 страниц0028-4 GL Guidelines For Transport and Install of Steel Jacketsdamnaged100% (1)

- Process Safety Metrics: Guide For Selecting Leading and Lagging IndicatorsДокумент63 страницыProcess Safety Metrics: Guide For Selecting Leading and Lagging IndicatorsDiego100% (1)

- FittingsДокумент15 страницFittingsAjith MohandasОценок пока нет

- Penang FactoryДокумент30 страницPenang Factorytsl0% (1)

- Singapore Real Estate Developer Contact ListДокумент4 страницыSingapore Real Estate Developer Contact ListFrancis TaduranОценок пока нет

- Where to Purchase Vapor Pins WorldwideДокумент2 страницыWhere to Purchase Vapor Pins WorldwideLautaro RissoОценок пока нет

- List of IndustryДокумент2 страницыList of IndustryMohamad AzmeerОценок пока нет

- Crash Cushion, End Treatments and Barrier Selection Guide List of ManufacturersДокумент2 страницыCrash Cushion, End Treatments and Barrier Selection Guide List of ManufacturersFaisal MohammedОценок пока нет

- List 3 Approved Manufacturers of Steel Forgings: As at 06 November 2012Документ51 страницаList 3 Approved Manufacturers of Steel Forgings: As at 06 November 2012wyvren88Оценок пока нет

- Macalloy Cable StructuresДокумент12 страницMacalloy Cable Structuresjmcc2Оценок пока нет

- MPMA Ordinary MembersДокумент14 страницMPMA Ordinary MembersSK NgОценок пока нет

- Calculating The Service Life of Running Steel Wire RopesДокумент33 страницыCalculating The Service Life of Running Steel Wire RopesAbdellah El Barkany100% (1)

- Fixed Roof TankДокумент2 страницыFixed Roof TankalphadingОценок пока нет

- Fracture Mechanics and Fatigue CourseДокумент8 страницFracture Mechanics and Fatigue CoursekalirajgurusamyОценок пока нет

- 0 Letter ITTДокумент2 страницы0 Letter ITTalphadingОценок пока нет

- Senarai Pusat Kitar Semula Di MalaysiaДокумент18 страницSenarai Pusat Kitar Semula Di MalaysiabiscodylОценок пока нет

- Construction Products ASTM A416 ASTM A421Документ3 страницыConstruction Products ASTM A416 ASTM A421heruОценок пока нет

- Johor Branches: Tasek Maju GroupДокумент14 страницJohor Branches: Tasek Maju GroupPuspita Leriana100% (1)

- List of Wire Manufacturer WorldДокумент13 страницList of Wire Manufacturer WorldSANGHVI OVERSEASОценок пока нет

- List 4 Approved Manufacturers of Steel Pipes and Tubes: © Lloyd's Register Group Limited 2015. All Rights ReservedДокумент28 страницList 4 Approved Manufacturers of Steel Pipes and Tubes: © Lloyd's Register Group Limited 2015. All Rights ReservedEricОценок пока нет

- Update Agencies List English 468 31.8.2023 UpdateДокумент266 страницUpdate Agencies List English 468 31.8.2023 Updatekyawkanthlaing.dev100% (1)

- Approved List of Manufacturers: CategoryДокумент5 страницApproved List of Manufacturers: CategoryBernard SolisОценок пока нет

- Senarai Kontraktor Untuk Perniagaan Futsal - Penting!Документ2 страницыSenarai Kontraktor Untuk Perniagaan Futsal - Penting!Afandi EberahimОценок пока нет

- 2016CompositeList Web 161Документ1 страница2016CompositeList Web 161AnuranjanОценок пока нет

- List of Utility Providers (170316)Документ4 страницыList of Utility Providers (170316)rahmanОценок пока нет

- Registered Employment Agentf 3 e 106 DДокумент4 страницыRegistered Employment Agentf 3 e 106 DChrisОценок пока нет

- Auc List SG Serai 13032011Документ6 страницAuc List SG Serai 13032011mazelanyОценок пока нет

- Customer AgingДокумент55 страницCustomer AgingRahul KumarОценок пока нет

- SEO-Optimized Titles for 15 Company DocumentsДокумент135 страницSEO-Optimized Titles for 15 Company DocumentsizwanОценок пока нет

- UK Security Firm DirectoryДокумент16 страницUK Security Firm DirectoryErasmus Rassie Van JaarsveldОценок пока нет

- KOREAN EXHIBITORS. September 18-23, 2017, Hannover Germany PDFДокумент74 страницыKOREAN EXHIBITORS. September 18-23, 2017, Hannover Germany PDFGnwantt RajputОценок пока нет

- Vendor List 2012 MarchДокумент8 страницVendor List 2012 MarchNye LavalleОценок пока нет

- Muru Crane CV WordДокумент6 страницMuru Crane CV WordMURUGESAN PONNIAHОценок пока нет

- Customs Brokers Prohibited From Re-Activating Expired Customs AccreditationДокумент26 страницCustoms Brokers Prohibited From Re-Activating Expired Customs AccreditationPortCallsОценок пока нет

- International Magnesium Association (IMA) - Current Members - Buyers' GuideДокумент56 страницInternational Magnesium Association (IMA) - Current Members - Buyers' GuideVishav SharmaОценок пока нет

- # 13 Local Indents Area Wise 2011 - 2012Документ166 страниц# 13 Local Indents Area Wise 2011 - 2012shani55730% (1)

- FEET Recruitment Agencies Oxford Only 2 PDFДокумент8 страницFEET Recruitment Agencies Oxford Only 2 PDFCatalina ElenaОценок пока нет

- Is 278 2009 PDFДокумент11 страницIs 278 2009 PDFjaianit89Оценок пока нет

- Azeeta Company ProfileДокумент36 страницAzeeta Company ProfileNurul AkmaОценок пока нет

- Network For Social Computing ResearchДокумент30 страницNetwork For Social Computing ResearchUNITED NATIONS PAYMENT APPROVALS.Оценок пока нет

- 2016-10-08 SWGDE Best Practices For Forensic Audio - v2-2 PDFДокумент28 страниц2016-10-08 SWGDE Best Practices For Forensic Audio - v2-2 PDFLuis Demetrio Martinez RuizОценок пока нет

- Iranian Oil, Gas and Petrochemical CompaniesДокумент6 страницIranian Oil, Gas and Petrochemical CompaniesEbiОценок пока нет

- STIHL Authorized DealerДокумент1 страницаSTIHL Authorized DealerBrian DuelaОценок пока нет

- Electrical Works-1Документ86 страницElectrical Works-1Sharafat AliОценок пока нет

- New YorkДокумент9 страницNew YorkrashidasmiОценок пока нет

- Internal Wiring Contractor SarikeiДокумент18 страницInternal Wiring Contractor SarikeiVlyn HyeОценок пока нет

- World Airliner Census DataДокумент21 страницаWorld Airliner Census DataGiovanni EspositoОценок пока нет

- Tokyou MOU Detention List 2018Документ343 страницыTokyou MOU Detention List 2018Hai Le Tran0% (1)

- Sarawak RДокумент21 страницаSarawak RMel VinzОценок пока нет

- Interpon D1036 Gloss 85Документ3 страницыInterpon D1036 Gloss 85ptopic10Оценок пока нет

- Textile ImportYeti SuppliersДокумент108 страницTextile ImportYeti SuppliersSay KhaОценок пока нет

- SCANDINAVIAN INDUSTRIAL EQUIPMENTДокумент77 страницSCANDINAVIAN INDUSTRIAL EQUIPMENTsahirprojectsОценок пока нет

- High Court Writ LawsuitДокумент5 страницHigh Court Writ LawsuitNur ImanОценок пока нет

- Andina FreightДокумент73 страницыAndina FreightReynolds TorresОценок пока нет

- 01 Brochure - Plants For Tire Cord - Bead Wire - Hose Wire - Staple Wire - Wire RopeДокумент12 страниц01 Brochure - Plants For Tire Cord - Bead Wire - Hose Wire - Staple Wire - Wire RopeYahyaMoummouОценок пока нет

- List of Building and Electrical Contractors in South AfricaДокумент10 страницList of Building and Electrical Contractors in South AfricaMike MatshonaОценок пока нет

- Manhole Cover, Steel Marine Cover, Watertight Manhole Cover Product On AlibabaДокумент5 страницManhole Cover, Steel Marine Cover, Watertight Manhole Cover Product On AlibabapaulsonОценок пока нет

- CATALOGUE Coprosider SRLДокумент64 страницыCATALOGUE Coprosider SRLwlmОценок пока нет

- Metal Comany Products DiscreptionДокумент22 страницыMetal Comany Products DiscreptionAjinkya BhujbalОценок пока нет

- Indcert Jan 2020 PDFДокумент23 страницыIndcert Jan 2020 PDFAsyraf NordinОценок пока нет

- Leaflet SPM and SOPДокумент4 страницыLeaflet SPM and SOPAbdullah Al-ZahraniОценок пока нет

- Copper Weld BrochureДокумент4 страницыCopper Weld Brochurefarfugliare100% (1)

- Corrosion Under InsulationДокумент7 страницCorrosion Under InsulationalphadingОценок пока нет

- Corrosion AllowanceДокумент9 страницCorrosion AllowancealphadingОценок пока нет

- Microbiologically Induced CorrosionДокумент11 страницMicrobiologically Induced CorrosionalphadingОценок пока нет

- Blowout PreventerДокумент7 страницBlowout PreventeralphadingОценок пока нет

- Gear Pump: Gear Pumps Which Use An External and An InternalДокумент4 страницыGear Pump: Gear Pumps Which Use An External and An InternalalphadingОценок пока нет

- What Is CorrosionДокумент8 страницWhat Is CorrosionalphadingОценок пока нет

- White RustДокумент5 страницWhite RustalphadingОценок пока нет

- Guided Wave TestingДокумент4 страницыGuided Wave TestingalphadingОценок пока нет

- Centrifugal PumpДокумент8 страницCentrifugal PumpalphadingОценок пока нет

- Bostik Seal N Flex 1 Tds 26102017Документ3 страницыBostik Seal N Flex 1 Tds 26102017Francis BoeyОценок пока нет

- Rotary Vane PumpДокумент3 страницыRotary Vane PumpalphadingОценок пока нет

- Submersible Pump: Pump (ESP) ) Is A Device Which Has A Hermetically Sealed MotorДокумент5 страницSubmersible Pump: Pump (ESP) ) Is A Device Which Has A Hermetically Sealed MotoralphadingОценок пока нет

- Pipeline TransportДокумент20 страницPipeline TransportalphadingОценок пока нет

- Pipeline: Pipeline May Refer ToДокумент3 страницыPipeline: Pipeline May Refer ToalphadingОценок пока нет

- Sulfate Reducing MicroorganismsДокумент5 страницSulfate Reducing MicroorganismsalphadingОценок пока нет

- MSDS - GlobalpreneДокумент5 страницMSDS - GlobalprenealphadingОценок пока нет

- MSDS - Kraton SBS PolymersДокумент8 страницMSDS - Kraton SBS PolymersalphadingОценок пока нет

- Assentech - IFR Shoe Seal VS Wiper SealДокумент7 страницAssentech - IFR Shoe Seal VS Wiper SealalphadingОценок пока нет

- Ferrite Testing: Accurate Measurement of Stainless SteelsДокумент2 страницыFerrite Testing: Accurate Measurement of Stainless SteelsalphadingОценок пока нет

- Red Dye SDSДокумент20 страницRed Dye SDSalphadingОценок пока нет

- Understanding ATEXДокумент14 страницUnderstanding ATEXFavas KvpОценок пока нет

- Bostik Seal N Flex 1 Tds 26102017Документ3 страницыBostik Seal N Flex 1 Tds 26102017Francis BoeyОценок пока нет

- Contract Form Subsea Skid - 20131017Документ95 страницContract Form Subsea Skid - 20131017alphadingОценок пока нет

- Diaphragm ClosureДокумент1 страницаDiaphragm ClosurealphadingОценок пока нет

- MD-1 Presentation 1Документ25 страницMD-1 Presentation 1Furqan AhmadОценок пока нет

- Metallic Angled Orthopedic Fracture Fixation Devices: Standard Specifications and Test Methods ForДокумент12 страницMetallic Angled Orthopedic Fracture Fixation Devices: Standard Specifications and Test Methods ForRed RedОценок пока нет

- Machine Component Failure AnalysisДокумент9 страницMachine Component Failure Analysiskanakarao1Оценок пока нет

- Flexible Riser Fatigue Design and Testing: Carlos Alberto Duarte de Lemos Murilo Augusto VazДокумент1 страницаFlexible Riser Fatigue Design and Testing: Carlos Alberto Duarte de Lemos Murilo Augusto VazsiswoutОценок пока нет

- Arabian Journal For Science and Engineering: Manufacture and Testing of Air Springs Used in Railway VehiclesДокумент27 страницArabian Journal For Science and Engineering: Manufacture and Testing of Air Springs Used in Railway VehiclesHtc OneОценок пока нет

- Equivalence of Four-Point and Three-Point Rainflow Cycle Counting AlgorithmsДокумент14 страницEquivalence of Four-Point and Three-Point Rainflow Cycle Counting Algorithmsmahaprabhu78Оценок пока нет

- Exp 4 Buckling AnalysisДокумент10 страницExp 4 Buckling Analysissmg26thmayОценок пока нет

- MIL-HDBK-733 Composite NDTДокумент44 страницыMIL-HDBK-733 Composite NDTMClarkОценок пока нет

- Perpetual Pavement Design ConceptsДокумент4 страницыPerpetual Pavement Design Conceptschaudhari prajaktaОценок пока нет

- Ada199171 PDFДокумент311 страницAda199171 PDFsathiyasuthanОценок пока нет

- Rekabentuk Jalan Konkrit P37PendДокумент14 страницRekabentuk Jalan Konkrit P37PendSayuti YusofОценок пока нет

- Steel Bridge DesignДокумент9 страницSteel Bridge DesignĴetzaa Barragán ChávezОценок пока нет

- MSC Nastran 2013 Release GuideДокумент168 страницMSC Nastran 2013 Release GuideMSC Nastran BeginnerОценок пока нет

- Zero Breakdown Maintenance ContentДокумент4 страницыZero Breakdown Maintenance ContentVinoth KumarОценок пока нет

- Introduction To Fe SafeДокумент22 страницыIntroduction To Fe SafeGeralfОценок пока нет

- Unbrako Technical BrochureДокумент24 страницыUnbrako Technical BrochureAmirul ShamОценок пока нет

- Destructive and Non-Destructive Testing of The Weldment of Dissimilar MetalsДокумент9 страницDestructive and Non-Destructive Testing of The Weldment of Dissimilar MetalsAlbertОценок пока нет

- Fatigue Analysis and Design FundamentalsДокумент13 страницFatigue Analysis and Design FundamentalsKalidoss DossОценок пока нет

- Fatigue of Rivet Joints in Aircraft StructuresДокумент11 страницFatigue of Rivet Joints in Aircraft StructuresJosue NietoОценок пока нет

- Material Science and Metallurgy Question BankДокумент3 страницыMaterial Science and Metallurgy Question BankVinay KorekarОценок пока нет

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFДокумент23 страницыAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasОценок пока нет