Академический Документы

Профессиональный Документы

Культура Документы

Hilco Industrial

Загружено:

basuramanuelИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Hilco Industrial

Загружено:

basuramanuelАвторское право:

Доступные форматы

ONLINE AUCTION

CNC Woodworking Equipment from a

Contract Furniture and Table & Chair

Manufacturer

Online Bidding Open Now

Online Bidding Closes: Tuesday, June 3rd

Thomasville, North Carolina

31555 West Fourteen Mile Road, Suite 301

Farmington Hills, Michigan 48334 USA

Ph 248-254-9999 Fx 248-254-9995

www.hilcoind.com

A Hilco Global Company

Vested in Your Success

Hilco

TM

Industrial

ONLINE AUCTION

DIRECTIONS

LOCATION #1

FROM PIEDMONT TRIAD INTERNATIONAL AIRPORT: EXIT AIRPORT TO I-73 / I-85 S. TAKE

EXIT 106 AND MERGE ONTO FINCH FARM RD. CONTINUE ONTO TO UNITY STREET. TURN

LEFT ONTO E SUNRISE AVE, THEN TAKE THE 3RD RIGHT ONTO COUNTY LINE RD.

LOCATION #2

ONLINE BIDDINg OPENS

TH

TUESDAY, MAY 27

OPEN NOW

ONLINE BIDDINg CLOSES

RD

TUESDAY, JUNE 3

CHeCk www.HIlCoInd.Com For ClosInG tImes

PREVIEw

THURSDAY & FRIDAY, MAY 29TH & 30TH

8AM TO 4PM LOCAL TIME

to sCHedUle An eArlIer InspeCtIon, pleAse

ContACt tIm pFIster At 847-313-4747

or emAIl tpFIster@HIlCoGloBAl.Com

ASSET LOCATIONS

LOCATION #1

505 COUNTY LINE RD

THOMASVILLE, NC 27360

LOCATION #2

405 E. MAIN STREET PLANT C

THOMASVILLE, NC 27360

FROM PIEDMONT TRIAD INTERNATIONAL AIRPORT: EXIT AIRPORT TO I-73 / I-85 S. TAKE

EXIT 103 AND TURN RIGHT ONTO RANDOLPH STREET. CONTINUE ON TO JULIAN AVE, THEN

TURN LEFT ONTO E. MAIN STREET.

FURTHER INFORMATION

AN 18% BUYER'S PREMIUM WILL BE CHARGED ON ALL ASSETS. THE BUYERS

PREMIUM WILL BE REDUCED TO 16% FOR PAYMENTS MADE BY MEANS OF

CASH, CASHIERS CHECK, COMPANY CHECK (WITH BANK LETTER OF GUARANTEE) OR WIRE TRANSFER WITHIN 48 HOURS OF SALE CLOSE. AUCTION WILL BE

CONDUCTED IN ENGLISH, ACCEPTING U.S. CURRENCY ONLY.

REMOVAL DEADLINE IS THURSDAY, JUNE 19TH WITH HOURS OF REMOVAL BETWEEN 8AM

TO 4PM MONDAY THRU FRIDAY. BUYERS WITH ITEMS LEFT ON SITE AFTER DEADLINE

ARE SUBJECT TO FINES OF $500 PER DAY.

MACHINERY & EQUIPMENT

TIM PFISTER 847-313-4747 TPFISTER@HILCOGLOBAL.COM

PAYMENT INFORMATION

LESIA JOSEPH 616-328-6892 LJOSEPH@HILCOGLOBAL.COM

HILCO ACCOUNTS RECEIVABLE AT HIN_AR@HILCOGLOBAL.COM

CUSTOMER SERVICE

+1 877-37-HILCO +1 616-732-1800 INFO@HILCOIND.COM

SANDI NEELY 248-254-9999 X16 SNEELY@HILCOGLOBAL.COM

Information contained herein deemed to be accurate at time of printing and subject to change.

For updated information, please visit our website at www.hilcoind.com for any changes to

date, sale process, terms and conditions and list of available assets.

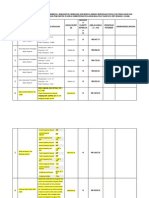

CNC PaNEl SaW

1 HOLZMA MODEL HFL 33/X/38/221

CNC ANGULAR PANEL SAW,

S/N 0-241-15-0878 (2000), 43 kW Saw

Motors, Power Side Load (Left & Right)

Infeed Conveyor, (4) Material Grippers,

Powered Rotationg Lift Feed Table,

144" Panel Saw, 23" Blade, 185mm

Projection, Exit Conveyor, Scrap

Conveyor, (10) Material Grippers, Right

Angle Transfer Conveyor, 96" Panel

Saw, Scrap Conveyor, Power Loc

Arbors on Main & Scoring Saw, Exit

Conveyor with (4) Bishamon 4,500 Lb.

Hydraulic Scissor Lift Tables with Roller

Tops, 37" x 84" Top, Bishamon 2,500

Lb. Hydraulic Lift Table with 24" x 84"

Top, Operators Platform, Control

Pendant, 480/3/60

To schedule an auction, please call Hilco Industrial at 1-877-37-HILCO (44526)

CNC PANEL SAW EDGEBANDERS

DOuBlE SiDED EDgEBaNDiNg liNE

1 BULK OFFER OF DOUBLE SIDED EDGEBANDING LINE,

Consisting of: Homag KF 20/10/QA/15 Double Sided

Edgebander, S/N 0-202-08-3935, (2000), Homag KF

20/13/QA/25, S/N 0-202-08-3937, (2000), Transfer Conveyor TD

31/20/08, S/N 0-205-08-3936, (2000), Bargstedt Entry Conveyor,

NC 21 CNC Control (BULK OFFERING SUBJECT TO PIECEMEAL BIDS PLEASE SEE INDIVIDUAL LISTINGS BELOW)

1 HOMAG MODEL KF 20/10/QA/15 CNC DOUBLE SIDED

EDGEBANDER, S/N 0-202-08-3937 (2000), with 30 mm

Overhang, 60m/min Feed, Trimming, 15 kW Hogger, 90 Deg

Swivel, Compact Double Hogger, Horizontal In/Out Adjustment,

6.6 kW Standard Trimming Unit, QA34 Hot Melt Gluing Unit, Top

& Bottom Trimming, Pneumatic Adjustment, 600mm Free Position

for Universal Trimming (NOT INCLUDED), Noise Protection, Top

& Bottom Edge Buffing with Oscillation, Outfeed Transport, NC 21

Controller

1 HOMAG MODEL KF 20/13/QA/25 CNC DOUBLE SIDED

EDGEBANDER, S/N 0-205-08-3937 (2000), with 60 m/min,

Compact Double Hogger, Horizontal In/Out Adjustment, 6.6 kW

Standard Trimming, Panel Blow Off, QA34 Hot Melt Gluing Unit, HL10 Magazine, 2-Rolls, 1.5 mm, Snipping Unit (Chamfer/Straight),

Snip Saw Collection Tray, Open Space for Rough Trimming, Top &

Bottom Trimming, 600 mm Open Space for Universal Trimming, Top

& Bottom Buffing with Oscillation, NC 21 Control

1 HOMAG MODEL TD 31/20/08 2000MM ROTARY TRANSFER

CONVEYOR, S/N 0-205-08-3936 (2000), with Second Feed

Control, Feed Interlock for Homag Double Edgebanders,

Motorized Follow Up Control for Top Pressure, (30) 48" Powered

Rolls, 2-1/2", Adjustable Leg Height, Side Transfer Conveyor with

(19) 34" Powered Rolls, 2-1/2", Crossover Platform, 250mm

2000mm Part Length, 220mm 800mm Part Width, 12-60 m/min

Infeed, 8-40 m/min Outfeed, 8-60mm Thickness, Infinitely

Adjustable Double Rotary Cone

1 BARGSTEDT 30" POWERED ROLLER ENTRY CONVEYOR,

with (27) 2-1/2" Rolls, 124" Length, Adjustable Leg Height

SiNglE SiDED EDgEBaNDErS

1 HOMAG MODEL KL76/A20/S2 SINGLE SIDED EDGEBANDER,

S/N 0-200-08-4016 (1999), with Pre-Mill/Joint Trim, Glue Section,

Temperature Controller, End Trim/Snipping, Top & Bottom

Trim/Rough Trim, Scraping, Open Section, Detail Trim, Buffing,

Single Coil Horizontal Uncoiler, 12-60mm Thickness, 30mm

Overhang, Pendant Control, (2) 6" x 10' Roller Conveyor Sections,

(1) 16" Expanding Roller Conveyor, NC21 CNC Control

1 FLETCHER MODEL SF2000CB SINGLE SIDE CONTOUR

EDGEBANDER, S/N 2000CB-1, with Band Length Counter

For more information, please visit us on the web at www.hilcoind.com

CNC MACHINING CENTERS CNC ROUTERS BORE & DOWEL EQUIPMENT

CNC MaChiNiNg CENTErS

1 BIESSE MODEL ROVER 37L 72" X 178" CNC MACHINING CENTER,

S/N 22101, with (8) Rails & Pods, 20-Position Automatic Tool Changer,

(10) Vertical Boring Spindles in X & Y Axis, (6) Horizontal Boring Spindles,

Safety Mats, 25.6 kW

1 BIESSE MODEL ROVER 346 PALLET 54" X 125" CNC MACHINING

CENTER, S/N 91310 (1999), with 15 kW, (19) Vertical Boring Spindles on

X Axis, (11) Vertical Boring Spindles on Y-Axis, (6) Horizontal Boring

Spindles, (2) ISO 30 Spindles, 12,000 RPM, (8) Rails & Pods, CNI XNC

Control, Safety Mats, 440/3/60

1 BIESSE MODEL ROVER 336 52" X 125" CNC MACHINING CENTER,

S/N 72956 (1997), with 14 kW, (8) Rail & Pods, (3) ISO 30 Spindles,

(6) Horizontal Boring Spindles, (12) Vertical Boring Spindles Y-Axis,

(14) Vertical Boring Spindles X-Axis, Biesse CNC Control, Vacuum Pump,

Wood Cabinet with Tooling & Manuals

CNC rOuTErS

1 SHODA MODEL NCW516-2156 4 HEAD CNC ROUTER, S/N 931303

(1993), with 37 kW Motor, (2) 82" x 102" Box Way Tables, Rear Dust

Collection Ports, Laser Align System, Pneumatic Front Table Guard,

Perimeter Barrier, (4) Main Routers, 12 kW, 18,000 RPM, (4) Piggy Back

Spindles, 2.2 kW, 18,000 RPM, (4) Shaper Spindles, 1.5 kW, (2) Vac U Flex

160 Sheet Lifters, (2) Sull-Air RSVS 12 Vacuum Pumps, Fanuc 15-M CNC

Control, 480-3-60 (NO DUST COLLECTION PIPING)

1 HEIAN MODEL ZR-442PF-R4-2616W 4 HEAD CNC ROUTER, S/N

9800583H26149 (1998), with (2) 63" x 103" Box Way Tables, (4) Main

Router Spindles, 7.5-8.8 kW, 17,400 RPM, (4) Piggy Back Spindles,

2.2 kW, 17,400 RPM, Dekker Vac-Tech Vacuum Pump, Fanuc 15-M CNC

Control, 460/3/60 (NO DUCT COLLECTION PIPING)

2012

BOrE & DOWEl EquiPMENT

1 WEEKE MODEL ABD 050 OPTIMAT CNC DRILL AND DOWEL INSERTER, S/N 0-253-17-2092

(2012), with 0.79" 49" Part Length, 1.97" 31.5" Part Width, 2.36" Max Part Thickness, (1) 7,500

RPM Horizontal Drilling Aggregate, (1) Doweling Tool, Glue Injector, Adjustable Glue Amount,

8x30 & 8x35mm Dowel Dimensions, Vibrating Hopper for Dowel Feeding, 10mm Drill Shank

Diameter, 70mm Drill Bit Length, 8mm Dowel Driver, PC Based CNC Control, PC 85 Hardware

2 BIESSE MODEL TECHNO LOGIC FEED THROUGH WOODWORKING BORING MACHINES,

S/Ns 2593 (2000), S/N 64577 (1997), with 49.3 / 46.4 kW, (3 / 2) 22-Spindle Up Acting Vertical

Boring, (2) 20-Spindle Horizontal Boring, Mechanical Readouts, (1) 11-Spindle / (2) 16-Spindle

Down Acting Boring, RT 483 Control, Approx. 120" Width Capacity

1 CUSTOM FEED THROUGH WOODWORKING BORING MACHINE, for Drawers and Fronts,

with (2) 4-Spindle Down Acting Vertical Boring, (2) 5-Spindle Up Acting Vertical Boring, Right

Angle Discharge Conveyor, Bottom Grooving Saw, 33" x 96" Belt Conveyor

1 MACOSER MODEL BPB1600 BED POST WOODWORKING BORING MACHINE, (2)

Opposed Drills, Pecking, Rotation, Push Button Controls

1 NICHOLS CLEAT CUT OFF, DRILLING AND WOODWORKING BORING MACHINE, 7" Cut

Off Saw, (8) Drilling Spindles, Magazine Feed, 18" Stroke

1 MCKNIGHT 3-SPINDLE HORIZONTAL WOODWORKING BORING MACHINES, S/Ns 9215,

N/A, 44" x 10" / 20 x 30" Table

1 FOREST CITY 2-SPINDLE VERTICAL WOODWORKING BORING MACHINE, with 3500

RPM, 16" x 30" Table, Auto-Cycle, Electric Foot Switch

1 MULTI-HEAD HORIZONTAL WOODWORKING BORING MACHINE, with (2) 3-Spindle Drills,

2 HP, (2) Offset Spindles, 1 HP, (2) Pneumatic Hold Downs, 20" x 59" Table

To schedule an auction, please call Hilco Industrial at 1-877-37-HILCO (44526)

DOUBLE END TENONERS FOIL MACHINES CASE CLAMP MOULDER

CaSE ClaMP

1 C-MOORE 108" X 70" PNEUMATIC CASE CLAMP, with (4) Horizontal Clamps,

Allen Bradley Panel View 550 Control, 24" x 24' Belt Conveyor, (2) 24" x 15' Roller

Conveyor, 24" x 10'' Belt Conveyor, 28" x 10' Roller Conveyor

1 CUSTOM 80" X 30" CASE TURNER, with (5) Belts, (2) 24" x 15' Roller Conveyor

MOulDEr

1 WEINIG MODEL UNIMAT 22 A 7-HEAD MOULDER, S/N 222-774 (1986), with EM4

Magazine Feed, Bottom, Right, Left, Right, Top, Bottom, & Top Head Configuration,

(3) GP Machine UA -2 Pedestal End Brush Machines, 1,200 RPM, Cabinet of Parts

& Tooling

DOuBlE END TENONErS

1 MEREEN-JOHNSON MODEL 600 DET DOUBLE END TENONER, S/N MJ4154,

with 1st Station Jump Score, 1st Station Trim, 2nd Station Lower Score, 2nd Station

Upper Score, 3rd Station Lower Tenoner, 3rd Station Upper Tenoner, 4th Station

Cope, (6) Digital Controls

1 CHALLONER MODEL 720 DOUBLE END TENONER, S/N 6333R1, with L&R Saw,

L&R Upper & Lower Scoring, L&R Cope, L&R Trim, L&R Tenoner, Push Button

Control (NOT IN SERVICE)

2 CHALLONER MODEL 723 DOUBLE END TENONERS, S/Ns 405210, 407360, with

L&R Saw, L&R Cope, Push Button Control

FOil MaChiNES

1 FLETCHER MODEL FT-200D DOUBLE SIDED FOIL APPLICATION MACHINE,

S/N 83200D6, with R&L Scoring, R&L Trim/Hogg, R&L 2nd Station Scoring, R&L

Shaper, (2) R&L Sanding Belts Stations, Air Brush, Dual 4-Head Foil Sections, Dado,

R&L Rear Brush, Tosvert 130G2+ Transistor Invertor, 6" 80" Width Capacity

1 FLETCHER MODEL FT-75S SINGLE SIDED FOIL APPLICATION MACHINE, S/N

8375SI, with Trim Station, Shaper, (2) Sanding Belt Stations, Air Brush, 3 Head Foiler,

Air Brush, 2nd 3 Head Foiler, Rear Trim, 18" x 48' Hytrol Belt Conveyor, Push Button

Controls, 480/3/60

1 FLETCHER MODEL FT-86 SINGLE SIDED PROFILE FOIL MACHINE, S/N 8686BT2, with 21" Belt, Roll Heat, Tilting, 240-3-60

1 VOORWOOD CO. MODEL P78ARM SINGLE SIDED PLOUGH EDGE FOIL

MACHINE, S/N 6158, with Toshiba Tosvert 130 Invertor, Score, Shape, Sand 1&2,

Finish/Foil, Temperature Controller, 480-3-60

1 5 HP FOIL WHEEL DRESSER, with 1 HP Wheel Indexer

Partial Listing Only, Please Visit Our Website

www.hilcoind.com

For Complete Lot Catalog

For more information, please visit us on the web at www.hilcoind.com

PLANERS LATHES ROUTERS SANDERS SAWS SHAPERS

PlaNErS

1 WHITNEY MODEL 97 36" DOUBLE HEAD PLANER, S/N 15488, with Helical Top & Bottom

Cutter Heads, 6" Thickness Capacity, Grinder Attachment, Bottom Grinder Attachment, Allen

Bradley 1336 Plus Sensorless Vector Drive, Push Button Controls, Dust Collection Hood,

30HP & 40HP Motors (NO DUCTWORK)

1 WHITNEY MODEL S-290 36" SINGLE HEAD PLANER, S/N 18878, with Newman Quiet Cut

Helical Carbide Cutterhead, 8" Thickness Capacity, 40HP (NO DUCTWORK)

laThES

2 DIEHL MODEL TL-41 24" TURNING LATHES, S/Ns 68M-2124-1405, N/A, Hydraulic Unit,

Controls, (1) with Magazine Feed

1 CENTAURO MODEL T6/1200 1200 MM TURNING LATHE, S/N 94542 (1994), with 8" Swing,

5" Swing over Carriage, 900-3000 RPM, Copy Attachment, 240-3-60

3 MATTISON MODEL 69 TURNING LATHES, (1) S/N 21384, 48; (2) S/Ns 21391, 21525, 36, 15 HP

1 MATTISON MODEL 57-D 36" TURNING LATHE, S/N 10166

OVErarM rOuTErS

1 SCMI MODEL R9N OVERARM ROUTER, S/N AA1/001239, 30" x 36" Table, 10,000-20,000 RPM

2 ONSRUD MODEL W1136-A OVERARM ROUTERS, S/N 907911-01, with 26" x 36" Table,

S/N 937988-01, with 36" x 48" Table

3 PORTER MODEL 920 OVERARM ROUTERS, S/Ns 66-4118, 66-4110, 66-4123, 40" x 48" Table

1 EKSTROM-CARLSON MODEL 327 OVERARM ROUTER, with 36" x 72" Table, 20,000 RPM

SaNDErS

1 TIMESAVERS MODEL 52-40 52" ORBITAL SANDER, S/N 26214, with (4) 5 HP Sanding

Heads, 5 HP Table Motor, ProScale ABS Scale, Push Button Control (NO DUCTWORK)

1 TIMESAVERS MODEL 337-4 36" 4-HEAD SANDER, S/N 20511, with (2) Drum Sanding

Units, (2) Platen Sanding Unit, (2) 25 HP Motors, (1) 30 HP Motor, (1) 40 HP Motor

1 TIMESAVERS MODEL 337-3 36" 3-HEAD SANDER, S/N 17257, with (2) Drum Sanding

Units, (1) Platen Sanding Unit, (1) 20 HP Motor, (1) 30 HP Motor, (1) 40 HP

1 SHIMURA MODEL SR-100W-PJ EDGE PROFILE SANDER, S/N 1501 (1986), with (2) 1 kW

Motors, (2) 3" Belts, (1) Flap Wheel, 480-3-60

1 CROUCH MODEL 245-48 7" HORIZONTAL DEAD HEAD BELT SANDER, S/N 121094, with

Spare Roller Belt Drum, Side Table, Radius Table

1 TIMESAVERS MODEL 52-30B 52" ORBITAL SANDER, S/N 22085, with (2) Orbital Heads

(NOT IN SERVICE)

1 WYSONG & MILES CO. 10" HORIZONTAL BELT SANDER, Side Table, Radius Table, 7" Belt

1 FLETCHER MODEL FT-30 7" HORIZONTAL BELT SANDER, S/N 68184, with Side Table,

Radius Table, 7" Belt

QUANTITY OF SANDERS, Including: 1-Spindle / 2-Spindle Pedestal, Horizontal Belt to 10,

Horizontal Dead Head Belt to 12, and Ribbon Sanders

SaWS

1 DIEHL MODEL 750 STRAIGHT LINE RIP SAW, with 60" x 80" Table, 15 HP & 3 HP Motors

1 OMGA MODEL T50-350 350 MM MITRE SAW, S/N 280446, with Trigger Control, Wood

Extension Table

1 PORTER MODEL 43-20K1 18" TRAVERSING CUT OFF SAW, S/N 663974, with 15' x 18"

Roller Conveyor

1 BELL 14" DOUBLE MITRE SAW, with Tilting Heads, Swivel Base, Adjustable Length,

Opposed Spindle Boring Heads. Power Clamping, Push Button Controls, 5 HP Hydraulic Unit

1 NEWMAN MODEL K-72 7" DOUBLE MITRE SAW, with 72" Adjustable Track, 16" x 96" Table

8 TANNEWITZ 42" CAST IRON WOODWORKING VERTICAL BAND SAWS, (1) Model R1: S/N

10251, with 36" x 51" Table, (4) Model RH: S/Ns 3939, 14609, 13904, 15536, 36 x 46 Tilting

Table, (3) Model RHS: S/Ns 13850, 13851, 13852, 36" x 46" Tilting Table, 10 HP, 685 RPM

1 TANNEWITZ MODEL R3 40" CAST IRON WOODWORKING VERTICAL BAND SAW,

S/N 5264, with 36" x 46" Tilting Table, 220-3-60

1 DELTA 16" RADIAL ARM SAW, Dual Side Table Extensions, 20" x 112" Overall Table, 7.5 HP

1 TRI-STATE 10" UP CUT SAW, with Entry & Exit Conveyor

ShaPErS

1 ONSRUD MODEL WT2-1284H 84" PROFILE SHAPER, S/N 797388-01, with (9) Pneumatic

Hold Downs, (2) Vertical Shaper Heads, 30 HP

1 WHITNEY MODEL 138 2-SPINDLE SHAPER, S/N 13940, with 42" x 66" Table

1 PORTER MODEL 165 2-SPINDLE HORIZONTAL SHAPER, S/N 64-226, with Opposed

Heads, (2) 48" x 10" Tables

1 POWERMATIC MODEL 28 SINGLE SPINDLE SHAPER, with 4" Spindle Travel, 3300-9500

RPM, 7.5 HP, 8" Max Dia. Cutter @ 3000 RPM, Delta VFO-B Variable Frequency Drive

1 ONSRUD MODEL WB86H 2-SPINDLE AUTOMATIC ROTARY PROFILE SHAPER,

S/N 787296-01, with (6) Pneumatic Hold Downs

3 RYE ROTARY SHAPERS, Model R80SM Speed Max, S/N 146/79, Model R100E-CSM-MS,

S/N 235-2C-89 (1989), 68; Model R52, S/N 982 (1989), 52, All with Shaper Heads, Push

Button Control

1 WHITNEY MODEL 182 1-SPINDLE SHAPER, S/N 13191, with 40" x 56" Table, Forest

CityFCT-8 Power Feed

2 ONSRUD MODEL W-684H 1-SPINDLE PROFILE SHAPERS, S/Ns 9892, 9040, Pneumatic

Hold Downs, Hydraulic Unit, 84" Table, 20 HP

1 GREENLEE MODEL 180 2-SPINDLE SHAPER, with 66" x 42" Table

1 PORTER SINGLE SPINDLE SHAPER

To schedule an auction, please call Hilco Industrial at 1-877-37-HILCO (44526)

TABLE SAWS RF GLUING FRAME CLAMPING SHOP EQUIPMENT MATERIAL

TaBlE SaWS

2 WHITNEY MODEL 177 12" TILTING ARBOR TABLE SAWS, S/Ns 17460, 17648,

Power Feed, 5 HP / 7.5 HP

2 TANNEWITZ 14" TILTING ARBOR TABLE SAWS, S/Ns 12312, 73271, (1) with

Powermatic New PH-3 3-Roll Power Feed

1 TANNEWITZ MODEL 50 12" TILTING ARBOR TABLE SAW, S/N 10061, with

Biesemeyer Rip Fence

1 14" TILTING ARBOR TABLE SAW, with 48" Rip Fence

2 GREENLEE TILTING ARBOR TABLE SAWS, S/N 44810 12, S/N 41212 14

rF gluiNg

3 L & L MODEL DU-ALL DA-50 60" X 64" PLATEN RF GLUE SYSTEMS, S/Ns 82614, 85-712, 85-711, with Pneumatic Lid Opening, (14) Pneumatic Squaring

Cylinders, Inclined Bed

FraME ClaMPiNg

2 JLT INCLINED FRAME CLAMPING MACHINE, Model 78A-CDFC-2, S/N 217,

Model LCMP S/N 209, (Both 2000), with Approx 4' x 7' Working Area

1 JM LANCASTER 4-WAY DRAWER CLAMP, S/N 1400-C-24, with Approx 40" x 50"

Working Area, Pneumatic Foot Pedal

1 JM LANCASTER 48" X 84" FLAT TABLE FRAME CLAMP, S/N 100-F-158

1 48" X 90" FLAT TABLE FRAME CLAMPING MACHINE, with Pneumatic Foot Pedal

1 18" X 36" PNEUMATIC DRAWER CLAMP

WOODWOrkiNg SuPPOrT EquiPMENT

1 ADJUSTABLE BASE DOUBLE HEAD HAUNCHER, with 8' Travel, 15" Stroke,

(2) Hold Downs, (2) 10 HP Motors, Hydraulic Unit, Electric Foot Pedal, Control

Cabinet, (2) Short Stop SS-5G-10 Electric Motor Brake

1 BELL 7-HEAD ADJUSTABLE BASE VERTICAL MORTISER, S/N 110480, with

20" x 84" Table, 102" Adjustable Base, (6) 2 HP Motors, (1) 2.5 HP Motor, 480-3-60

1 NEWMAN MODEL 30 MANUAL TENONER, with (2) 2 HP Cutter Heads, Upper

Tilting Adjustment, Manual Table, Pneumatic Clamping, 2 HP Cut Off Saw

1 7.5 KW SINGLE HEAD HAUNCHER, with 20" x 48" Table, Foot Pedal, 480-3-60

1 WYSONG & MILES CO. MODEL 601 15-SPINDLE DOVETAIL MACHINE

1 CUSTOM SCREW CLEAT MACHINE (2000), with Pedestal Control, 30" Vibratory

Bowl Feeder, Prox. Sensors, (2) Side Drills, (1) End Bore Drill

1 MAGGI MODEL STEFF 2034 3-ROLL POWER FEED SYSTEM, S/N 1270701829 (2007)

1 MASTERWOOD MODEL EUROMEC 3-ROLL POWER FEED SYSTEM, S/N

02090065 (2002)

QUANTITY OF WOODWORKING SUPPORT EQUIPMENT Including: Jointers to 12,

Pocket Hole Machine, Dovetail Machines, Pneumatic Miter Joint Nailing Machines, Lag

Bolt Insertion Machines, Etc.

ShOP EquiPMENT

1 RUTLAND MODEL 26491236 12" X 35" TOOLROOM LATHE, S/N 9807 (1993),

with 70-1500 RPM, Inch/Metric Threading, Tool Post, Tail Stock, 6" 3-Jaw Chuck, 8"

4-Jaw Chuck, 10" Face Plate, 1-1/2" Through Hole

1 MILLER MODEL MILLERMATIC 250 200 AMP MIG WELDER, S/N XD635930, with

Spoolmatic 30 Air Cooled Spool Gun, 50-650 fpm Wire Speed, Manual Wire Feed

Gun, Cart Base

1 POWERMATIC MODEL 1150 PEDESTAL DRILL PRESS, S/N 315S068, with

255-5300 RPM, 1/2" Jacobs Chuck, 4" Wilton Vise, 16" x 21" Table, 110-1-60

1 CAROLINA MODEL HV20 8" X 15" HORIZONTAL BAND SAW, S/N 8257, 1 HP,

10' x 8" Entry Roller Conveyor

1 RIDGID MODEL 535 PIPE THREADER, (2) Universal Threading Heads, Reamer, Pipe Cutoff

1 WORTHINGTON MODEL 15EW12 10 HP HORIZONTAL TANK MOUNTED AIR

COMPRESSOR, with Baldor Motor

QUANTITY OF SHOP EQUIPMENT Including: Hydraulic Shop Press, Pedestal Bench

Grinders, Drill Presses, Vertical Boring Machine, Etc.

MaTErial haNDliNg

2 INFRAPAK 90" ROTARY PALLET STRETCH WRAPPERS, Model Sidewinder

S/N S025H95A, Model SWHP S/N SH10057A

1 SOUTHWORTH 24" X 60" ELECTRIC SCISSOR LIFT TABLE, with 4,000 Lb.

Capacity, Roller Conveyor Table-Top

1 ROLLER CONVEYOR SYSTEM, including (4) 24" x 60" Roller Transfer Carts,

(5) 25" x 15' Roller Conveyor Sections, (1) 25" x 13' Roller Conveyor Section,

(58) 25" x 10' Roller Conveyor Sections

1 FACTORY CAT MODEL 48 RIDING FLOOR SWEEPER, S/N 48-6518

QUANTITY OF MATERIAL HANDLING EQUIPMENT Including: Scissor Lift Tables

36/24" x 72", 30" Steel Mesh Assembly Conveyor, 58" x 78" Steel Turntables, Pallet

Racking, Etc.

Bid Online Only at

www.hilcoind.com

For more information, please visit us on the web at www.hilcoind.com

OVER 35 OFFICES THROUGHOUT NORTH, CENTRAL & SOUTH AMERICA, EUROPE, MIDDLE EAST, ASIA, AUSTRALIA

Hilco

TM

Industrial

ONLINE AUCTION

Terms of Sale

CNC Woodworking Equipment from a

Contract Furniture and Table & Chair

Manufacturer

An 18% buyer's premium will be charged on all assets. The

buyer's premium will be reduced to 16% for all payments made by

means of cash, cashiers check, company check (with bank letter

of guarantee) or wire transfer within 48 hours of sale close.

Everything will be sold online to the highest bidder for cash, in

accordance with the Auctioneers customary Terms of Sale,

copies of which will be posted online. All items will be sold as is,

where-is without any warranties, expressed or implied. Although

obtained from sources deemed reliable, the Auctioneer makes no

warranty or guarantee to the accuracy of the information herein

contained. Bidders are encouraged to thoroughly inspect the

items on which they intend to bid prior to sale. Absolutely no items

will be removed until the day after the conclusion of the sale and

payment is made in full. Subject to additions, deletions and prior

sale. For updated information, please visit our website at

www.hilcoind.com for any changes to date, sale process, terms

and conditions and list of available assets.

Payment: ALL PURCHASES MUST BE PAID IN FULL ON THE

DAY OF THE AUCTION. If you intend to pay by wire transfer, we

will accept payment the day after the sale ONLY IF a deposit of

25% of total purchases is made on the day of the sale. Contact

our office for wire transfer instructions. Only cash, wire transfer or

certified check, payable to Hilco Industrial will be accepted.

Company checks payable to Hilco Industrial will be accepted only

if accompanied by a bank letter of guarantee, (see sample letter

below). All sales are subject to sales tax. Purchasers claiming

exemptions from taxes must provide proof satisfactory to the

Auctioneer of their entitlement to claim such exemptions.

Sample Bank Letter

(Bank Name) unconditionally guarantees payment

to Hilco Industrial from (Company Name). This guarantee will

be valid for purchases made at the Auction of A Major

Furniture Manufacturer on May 27-June 3, 2014.

Online Bidding Open Now

Online Bidding Closes: Tuesday, June 3rd

Thomasville, North Carolina

HILCO Industrial is a division of Hilco Global Headquarters 5 Revere Drive, Ste. 206 Northbrook, IL 60062 All rights reserved

Hilco Industrial, LLC North Carolina Auctioneer & License: Tim Pfister License #NCAL-9334 NC License #7506 IL License #444.000215

Printed in USA THO2693 IL License #444.000215 Please visit our website at www.hilcoind.com to review our complete terms and conditions.

Follow

Us on:

A Hilco Global Company

Vested in Your Success

Вам также может понравиться

- How to Rebuild & Modify Rochester Quadrajet CarburetorsОт EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsРейтинг: 5 из 5 звезд5/5 (2)

- Axion DatabaseДокумент25 страницAxion Databasemacy williamsОценок пока нет

- SCOUT 700: Technical DescriptionДокумент4 страницыSCOUT 700: Technical DescriptionGerko Berrios GarcíaОценок пока нет

- Multi-Function CNC Lathe: FCL-18/25 SERIESДокумент10 страницMulti-Function CNC Lathe: FCL-18/25 SERIESBhargav SaiОценок пока нет

- D800 BrochureДокумент4 страницыD800 BrochurefrankОценок пока нет

- Groover Fundamentos Manual Soluciones C22Документ10 страницGroover Fundamentos Manual Soluciones C22Ayush BhadauriaОценок пока нет

- Chrysler BrochureДокумент8 страницChrysler BrochureAlfredo Anzures EearnОценок пока нет

- Large 2-Day Public Auction: Mfr. & Rebuilder of Hot-Section Aerospace / Industrial Engine ComponentsДокумент12 страницLarge 2-Day Public Auction: Mfr. & Rebuilder of Hot-Section Aerospace / Industrial Engine ComponentsJesus N RodriguezОценок пока нет

- Connectivity Brochure FinalДокумент16 страницConnectivity Brochure FinalsteveОценок пока нет

- Electro Motion 5th Edition BrochureДокумент20 страницElectro Motion 5th Edition BrochureElectro Motion UK (Export) LtdОценок пока нет

- Electro Motion Machine Tools Sheet Metal - Fabrication Brochure March 2012Документ16 страницElectro Motion Machine Tools Sheet Metal - Fabrication Brochure March 2012Electro Motion UK (Export) LtdОценок пока нет

- Webcast/Onsite Auction: IndustrialДокумент8 страницWebcast/Onsite Auction: IndustrialAhmet MetinОценок пока нет

- EeДокумент7 страницEejohnОценок пока нет

- Timbron International Webcast/Onsite Auction BrochureДокумент5 страницTimbron International Webcast/Onsite Auction BrochureHilco IndustrialОценок пока нет

- Tongil Gu SeriesДокумент3 страницыTongil Gu Seriesmatthew_k_kohОценок пока нет

- ListДокумент4 страницыListsaravanan_c1Оценок пока нет

- Machine Tools Stock ListДокумент12 страницMachine Tools Stock ListMuhammad NadeemОценок пока нет

- Electro Motion Machine Tools Sheet Metal - Fabrication Brochure September 2012Документ16 страницElectro Motion Machine Tools Sheet Metal - Fabrication Brochure September 2012Electro Motion UK (Export) LtdОценок пока нет

- Delta Graphics - Printing Equipment Auction CatalogДокумент3 страницыDelta Graphics - Printing Equipment Auction CatalogChristopher AllenОценок пока нет

- Name of Equipment Specification Date of PurchaseДокумент3 страницыName of Equipment Specification Date of PurchaseJoydev GangulyОценок пока нет

- Electro Motion Brochure Issue 4Документ20 страницElectro Motion Brochure Issue 4Electro Motion UK (Export) LtdОценок пока нет

- Used Machine Tools & Fabrication MachineryДокумент20 страницUsed Machine Tools & Fabrication MachineryElectro Motion UK (Export) LtdОценок пока нет

- HTTP WWW - Taigtools.com Mmill - HTMLДокумент5 страницHTTP WWW - Taigtools.com Mmill - HTMLCamarada RojoОценок пока нет

- Mesin BubutДокумент34 страницыMesin BubutAhmad Amril NurmanОценок пока нет

- Machine Tools Stock ListДокумент10 страницMachine Tools Stock ListElectro Motion UK (Export) LtdОценок пока нет

- Goss Community SSC Press - 22-3/4" Cut-Off: (1) Mobile StepДокумент2 страницыGoss Community SSC Press - 22-3/4" Cut-Off: (1) Mobile StepFRANCIS CОценок пока нет

- Turnkey Production Centers: Product Finder Home PageДокумент3 страницыTurnkey Production Centers: Product Finder Home PageawemetalОценок пока нет

- Curvadora de Perfiles DURMA PBH 180 240 300 360Документ3 страницыCurvadora de Perfiles DURMA PBH 180 240 300 360Fernando Rivas CortesОценок пока нет

- Plates 2012en p27ddДокумент8 страницPlates 2012en p27ddGinoocle OrihuelaОценок пока нет

- CNC002-CNC Cylindrical GrinderДокумент9 страницCNC002-CNC Cylindrical GrinderarashОценок пока нет

- Knuth Milling Machine VHF 3Документ5 страницKnuth Milling Machine VHF 3martin_jaitmanОценок пока нет

- Galtech Pumps MotorsДокумент0 страницGaltech Pumps MotorsWesame ShnodaОценок пока нет

- RH30 Spec Sep2007Документ7 страницRH30 Spec Sep2007gheoda8926Оценок пока нет

- Occasion!!: Vertical Lathe Romania Made Type Sc43 - CNC - 2SДокумент3 страницыOccasion!!: Vertical Lathe Romania Made Type Sc43 - CNC - 2SgeorgegvrОценок пока нет

- 1.spesifikasi Peralatan MesinДокумент4 страницы1.spesifikasi Peralatan MesinMuhammad Luthfi SonjayaОценок пока нет

- TC600 e PDFДокумент12 страницTC600 e PDFSalar SalahiОценок пока нет

- Rodney Hunt AuctionДокумент3 страницыRodney Hunt AuctionJim KinneyОценок пока нет

- Brochure PDFДокумент6 страницBrochure PDFArimbi GembiekОценок пока нет

- Petroland PL 11 OkДокумент10 страницPetroland PL 11 Okmantenimiento keruiОценок пока нет

- Machine Tools Stock ListДокумент10 страницMachine Tools Stock ListElectro Motion UK (Export) LtdОценок пока нет

- Dana Molded Products Webcast/Onsite Auction BrochureДокумент5 страницDana Molded Products Webcast/Onsite Auction BrochureHilco IndustrialОценок пока нет

- Knuth Lathe V-Turn 410 - 1000Документ5 страницKnuth Lathe V-Turn 410 - 1000martin_jaitmanОценок пока нет

- Spinning Training ReprotДокумент62 страницыSpinning Training ReprotPranav Sharma100% (2)

- 2009-11 Wood MagazineДокумент96 страниц2009-11 Wood MagazinePhebusMalbec100% (5)

- CommScope2016 Brochure FinalДокумент8 страницCommScope2016 Brochure FinalsteveОценок пока нет

- Romi E280 Techspecs - UkДокумент12 страницRomi E280 Techspecs - UkDaiane CenaliОценок пока нет

- Petroland PL 02 OkДокумент9 страницPetroland PL 02 Okmantenimiento keruiОценок пока нет

- Petroland PL 21 OkДокумент10 страницPetroland PL 21 Okmantenimiento keruiОценок пока нет

- FInisor Lateral MIDLAND SPD-6Документ2 страницыFInisor Lateral MIDLAND SPD-6Dan TutaОценок пока нет

- Manual para Seleccion MaquinasДокумент8 страницManual para Seleccion MaquinasRicardo_CHES1986Оценок пока нет

- Model PM Series Three Axis Mills: ClimaxДокумент8 страницModel PM Series Three Axis Mills: ClimaxAntonius NataОценок пока нет

- Okuma Simul Turn 400Документ11 страницOkuma Simul Turn 400paulkupasОценок пока нет

- Hyperturn 65 Powermill en 01Документ16 страницHyperturn 65 Powermill en 01Mirko JovicОценок пока нет

- Knuth Ecoturn 650-1000Документ2 страницыKnuth Ecoturn 650-1000Iacob CornelОценок пока нет

- FP-30 - UadДокумент12 страницFP-30 - UadUday SharmaОценок пока нет

- Corporate ProfileДокумент24 страницыCorporate Profiletransiente2010Оценок пока нет

- Jadual Spesifikasi Dan Harga Tender MembekalДокумент12 страницJadual Spesifikasi Dan Harga Tender MembekalWak Tun0% (1)

- Okuma CNC LatheДокумент2 страницыOkuma CNC LatheRevolusiSoekarnoОценок пока нет

- HomgeДокумент80 страницHomgeRobert HarveyОценок пока нет

- Turning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.От EverandTurning and Boring A specialized treatise for machinists, students in the industrial and engineering schools, and apprentices, on turning and boring methods, etc.Оценок пока нет

- Mechanised Shaft SinkingДокумент12 страницMechanised Shaft Sinkingsauravsuman100% (2)

- 4732 Cylinder Block InspectionДокумент58 страниц4732 Cylinder Block InspectionShahzad Ahmad100% (3)

- Diploma Workshop Practice IIДокумент30 страницDiploma Workshop Practice IISagir Musa SaniОценок пока нет

- Unit II - MCMTДокумент50 страницUnit II - MCMTSai RamОценок пока нет

- MTM Lab Report..501Документ96 страницMTM Lab Report..501Usman BajwaОценок пока нет

- Machining: Workshop Practice ME-105Документ20 страницMachining: Workshop Practice ME-105Mazahir habibОценок пока нет

- MI-102Machining 2 PDFДокумент34 страницыMI-102Machining 2 PDFVaibhav GuptaОценок пока нет

- Sandvik EbookДокумент36 страницSandvik EbookvivianeОценок пока нет

- Automatic Bar Machine: Class VocabularyДокумент3 страницыAutomatic Bar Machine: Class VocabularyFadetwoОценок пока нет

- Turning and Boring ProcessesДокумент39 страницTurning and Boring ProcessesAdhanom G.Оценок пока нет

- A Project Report Submitted To in Partial Fulfillment of The Requirement For The Award of The Degree ofДокумент91 страницаA Project Report Submitted To in Partial Fulfillment of The Requirement For The Award of The Degree ofseelam manoj sai kumar100% (1)

- Experiment No. - 6Документ11 страницExperiment No. - 6jay_v9Оценок пока нет

- Mapal - Impulse - 51Документ24 страницыMapal - Impulse - 51sivanesanmailОценок пока нет

- MSTP Quiz2 ReviewerДокумент6 страницMSTP Quiz2 ReviewerChester Dave Bal-otОценок пока нет

- InternДокумент5 страницInternChushith NagandlaОценок пока нет

- Principles of General Chemistry 3rd Edition Silberberg Test Bank 1Документ36 страницPrinciples of General Chemistry 3rd Edition Silberberg Test Bank 1stacierossoxaqgpzmyc100% (25)

- CNC Programming & Machining PDFДокумент50 страницCNC Programming & Machining PDFSidhant Angural100% (1)

- MSTP Reviewer MidtermsДокумент9 страницMSTP Reviewer MidtermsCarl Jay R. IntacОценок пока нет

- CAD CAM - 2019-20 CompletedДокумент138 страницCAD CAM - 2019-20 CompletedMurugesan JeevaОценок пока нет

- B-64304en-1 - 02 (Manual Del Operador Torno) PDFДокумент446 страницB-64304en-1 - 02 (Manual Del Operador Torno) PDFIrineo Avalos MejiaОценок пока нет

- Jarret StructuresДокумент46 страницJarret StructuresBartoSimpsonОценок пока нет

- 08 TurningДокумент119 страниц08 Turningz19340543Оценок пока нет

- Lathe MachineДокумент91 страницаLathe MachineChandra NurikoОценок пока нет

- 10 1 1 1071 7012 PDFДокумент7 страниц10 1 1 1071 7012 PDFKombet 69Оценок пока нет

- DWT Babcock en MailingДокумент68 страницDWT Babcock en MailingMileОценок пока нет

- PCT Lathe 130929045829 Phpapp01Документ27 страницPCT Lathe 130929045829 Phpapp01Vivek Kumar SinghОценок пока нет

- Maa FactoryДокумент13 страницMaa FactoryRehan Raza100% (1)

- Gun ManufacturingДокумент11 страницGun ManufacturingTarun GuptaОценок пока нет

- Report KamcoДокумент17 страницReport Kamcoshamins123Оценок пока нет