Академический Документы

Профессиональный Документы

Культура Документы

Lab7 Scotch Yoke Measurements

Загружено:

Ioan DorofteiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Lab7 Scotch Yoke Measurements

Загружено:

Ioan DorofteiАвторское право:

Доступные форматы

ELECTROMECHANICAL ANALYSIS LAB

EMET 3424_70

TUESDAY, MARCH 13, 2001

8:00 9:50AM, SET 363

LAB#7

SCOTCH YOKE MEASUREMENTS

PREPARER:

Scott Greenberg

Address: Mac S J5C4

Phone:

607-587-2615

E-mail:

greenbse@alfredstate.edu

INSTRUCTOR:

Nicholas Reitter III

Office:

SET 3668

Phone:

607-587-4670

E-mail:

reitten@alfredstate.edu

LAB PARTNERS:

Scott Nicastro

Jonathan Ewen

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 2

TABLE OF CONTENTS

Preparer: ........................................................................................... 1

Instructor:......................................................................................... 1

Lab partners:.................................................................................... 1

Table of Contents .......................................................................... 2

Lab Objective.................................................................................. 4

Scotch Yoke Measurements........................................................ 5

Theory............................................................................................... 5

Figure 1: Block Diagram Scotch Yoke.............................................. 5

Figure 2: Velocity Peak Equation................................................... 5

Figure 3: Block Diagram For Oscillioscope ...................................... 5

Figure 4: Velocity Peak Equation for Oscillioscope ........................ 5

Figure 5: Block Diagram For Tachometer........................................ 5

Figure 6: Velocity Peak Equation................................................... 6

Figure 7: Slope Equation................................................................... 6

Figure 9: Percent Error Equation..................................................... 6

Schematic ......................................................................................... 6

Figure 6: Mechanical Setup................................................................ 6

Procedure/Data Collection......................................................... 7

Calculations...................................................................................... 7

Results Summary............................................................................ 8

Table 1: ANGULAR DISPLACEMENT MEASURMENTS.........................................................................................8

Figure 11: Scotch Yoke MEASURMENTS Graph.................... 8

Figure 12: % Error Graph ............................................................... 8

Discussion........................................................................................ 9

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 3

Lab Sheet........................................................................................10

Notes...............................................................................................12

Orginal Data..................................................................................13

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 4

LAB OBJECTIVE

The objective of this laboratory experiment is to gain experience and practice working with electrical

devices. We will look at how a scotch yoke mechanism converts circular motion into linear motion. There

are many ways to measure velocity. We will look at three, tachometer, oscilloscope, and velocity transducer.

The equipment used in this lab is listed but limited to this list.

n

Tachometer

Linear Velocity Transducer (LVT), manufacture sensitivity: 500 mV/in/s

Tektronix TDS 310 Two Channel Oscilloscope, S/N: B040281, Instr. TDS310, Voltage

Range: 90 132 V, Frequency Range: 47 440 Hz

Hewlett Packard 34401A Multimeter, S/N 3146A29090

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 5

S C O T C H Y O K E M E A S U R E M ENTS

THEORY

Scotch yoke takes a revolution per minute and converts it to a linear velocity.

FIGURE 1: BLOCK DIAGRAM SCOTCH YOKE

RPMmeasured

Conversion

Volcitiyout

The displacement motion of the scotch yoke is at a maximum velocity is zero. When velocity is a t a

maximum, displacement is zero. Velocity max is equal to output voltage divided by sensitivity of the linear

velocity transducer (LVT).

FIGURE 2: VELOCITY PEAK EQUATION

V peak

Volts

Sensitvity

With the use of an oscilloscope, we can convert time in to angler acceleration.

FIGURE 3: BLOCK DIAGRAM FOR OSCILLIOSCOPE

Tmeasured

Conversion

Volcitiyout

We divided two pi by time, times a thousand for unit conversion to get angler acceleration.

FIGURE 4: VELOCITY PEAK EQUATION FOR OSCILLIOSCOPE

2.

Time . 1000

With the use of a Tachometer, we can convert time in to linear velocity.

FIGURE 5: BLOCK DIAGRAM FOR TACHOMETER

Voltagepeak-peak

Conversionsensitivity

Volcitiyout

We divided two pi by time, times a thousand for unit conversion to get angler acceleration.

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 6

FIGURE 6: VELOCITY PEAK EQUATION

2.

Time . 1000

FIGURE 7: SLOPE EQUATION

ScaleFactor

CalibratedResult

RawData

We find the percent error by finding the difference of calibrated result and true value divided by full-scale

value.

FIGURE 9: PERCENT ERROR EQUATION

%Error

CalibratedResult

TrueValue .

100

FullScaleValue

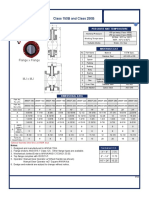

SCHEMATIC

FIGURE 6: MECHANICAL SETUP

Tachometer

Velocity

Transducer

Oscilloscope

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 7

PROCEDURE/DATA COLLE CTION

To calibrate the system we first connect a potentiometer on the output of the velocity transducer.

We set the motor to 150 RPM. We then adjusted the pot such that the output voltage peak was 150mV. We

then speed up the motor up to 500 RPM. This will give us an output voltage reading of 500 mV.

We can calibrate the system to linear velocity by adjusting the pot to the time on the oscilloscope.

CALCULATIONS

Oscilloscope

Time

Tachometer

RPM

298

2.

Time

1000

2 . . RPM

60

200

= 31.416

= 31.206

So

.108173

V scope

S o .

V scope = 3.376

So

.108173

V scope

S o .

V scope = 3.398

Transducer

Volts

1.7

Sensitvity

V peak

.500

Volts

Sensitvity

V peak = 3.4

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 8

RESULTS SUMMARY

TABLE 1: ANGULAR DISPLACEMENT MEASURMENTS

Tachometer

RPM

152.7

199.7

249.1

298.0

350.7

400.0

449.9

498.3

Oscilloscope

Tech

VTech

(rad/s) (in/sec)

16.04

1.74

20.98

2.27

26.17

2.83

31.31

3.39

36.84

3.99

42.02

4.55

47.26

5.11

52.35

5.66

scope

(rad/s)

15.91

20.94

26.18

31.42

36.74

41.89

47.60

52.14

T

(s)

395

300

240

200

171

150

132

121

Velocity Transducer

Vscope

(in/sec)

1.72

2.27

2.83

3.40

3.97

4.53

5.15

5.64

Vpp

1.76

2.28

2.84

3.40

3.92

4.52

5.12

5.68

% Error

VTransducer

(in/sec)

1.76

2.28

2.84

3.40

3.92

4.52

5.12

5.68

0.44%

0.19%

0.16%

0.24%

-1.15%

-0.45%

0.13%

0.31%

FIGURE 11: SCOTCH YOKE MEASURMENTS GRAPH

Velcity (in/sec)

6.00

5.00

4.00

3.00

2.00

1.00

150

200

250

300

350

400

450

500

RPM

Tachometer

Oscilloscope

Velocity Transducer

FIGURE 12: % ERROR GRAPH

5.00%

3.00%

1.00%

-1.00%150

200

250

300

350

-3.00%

-5.00%

RPM

400

450

500

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 9

DISCUSSION

We can see that all configurations used to find the linear velocity are very accurate. However there are

some drawbacks. The biggest is human error. When this lab was first conducted, the So, total travel of the

stock yoke was incorrectly reported. As a result, all data that included this figure we off. Once the mistake

was corrected, we were able to see the true results. In all configurations, it comes down to what equipment is

available. In addition, from our percent error we can see that there is no significant difference of reads due to

speed.

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 10

LAB SHEET

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 11

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 12

NOTES

LAB #7 -SCOTCH YOKE MEASUREMENTS.DOC GREENBERG: 13

ORGINAL DATA

Вам также может понравиться

- Locomotion Methods of Pipe Climbing Robots: A ReviewДокумент13 страницLocomotion Methods of Pipe Climbing Robots: A ReviewIoan DorofteiОценок пока нет

- Design and Control of A Novel Compliant Differential Shape Memory Alloy Actuator (SAAP)Документ11 страницDesign and Control of A Novel Compliant Differential Shape Memory Alloy Actuator (SAAP)Ioan DorofteiОценок пока нет

- Preliminary Mechanical Analysis of An Improved Amphibious Spherical Father RobotДокумент16 страницPreliminary Mechanical Analysis of An Improved Amphibious Spherical Father RobotIoan DorofteiОценок пока нет

- Building A Line Following RobotДокумент31 страницаBuilding A Line Following RobotfarhanshakeelОценок пока нет

- Line Follower Tutorial v1.1Документ34 страницыLine Follower Tutorial v1.1zanluphzahОценок пока нет

- Bristled In-Pipe Machine Inside Pipe With Geometric DeviationsДокумент8 страницBristled In-Pipe Machine Inside Pipe With Geometric DeviationsIoan DorofteiОценок пока нет

- Line Follwer Robot Using LM324Документ11 страницLine Follwer Robot Using LM324Ioan DorofteiОценок пока нет

- 9 15 Su J H PDFДокумент7 страниц9 15 Su J H PDFIoan DorofteiОценок пока нет

- Line Following Robot DocumentДокумент27 страницLine Following Robot DocumentAsif AliОценок пока нет

- Line Follower ATMEGA16 WWW - Robotechno.usДокумент17 страницLine Follower ATMEGA16 WWW - Robotechno.usSarang WadekarОценок пока нет

- Line Follwer Robot Using LM324Документ11 страницLine Follwer Robot Using LM324Ioan DorofteiОценок пока нет

- LFR ReportДокумент91 страницаLFR ReportRahul Salim NarayananОценок пока нет

- Quadcopters PDFДокумент30 страницQuadcopters PDFIoan DorofteiОценок пока нет

- 1 s2.0 S0921889014002115 MainДокумент11 страниц1 s2.0 S0921889014002115 MainIoan DorofteiОценок пока нет

- A Line Follower Robot-ICCAE 2010Документ6 страницA Line Follower Robot-ICCAE 2010Ioan DorofteiОценок пока нет

- 03 LocomotionДокумент24 страницы03 LocomotionIoan DorofteiОценок пока нет

- Design Optimization of Parallel Manipulators For High-Speed Precision Machining ApplicationsДокумент6 страницDesign Optimization of Parallel Manipulators For High-Speed Precision Machining ApplicationsIoan DorofteiОценок пока нет

- GearsДокумент156 страницGearsIoan DorofteiОценок пока нет

- Luis Paulo Reis Waf2014Документ15 страницLuis Paulo Reis Waf2014Ioan DorofteiОценок пока нет

- 3 ChariotДокумент8 страниц3 ChariotIoan DorofteiОценок пока нет

- Quadcopters PDFДокумент30 страницQuadcopters PDFIoan DorofteiОценок пока нет

- Robot LocomotionДокумент25 страницRobot LocomotionChaitanya Raghav SharmaОценок пока нет

- Quadcopter PDFДокумент14 страницQuadcopter PDFabhiarora4100% (1)

- Stroe Ioan-Elastic and Safety Clutch With Radial Tapered Roller and Metallic Elastic Elements Axially ArrangedДокумент4 страницыStroe Ioan-Elastic and Safety Clutch With Radial Tapered Roller and Metallic Elastic Elements Axially ArrangedIoan DorofteiОценок пока нет

- Technical Cognitive Systems: Michael BeetzДокумент54 страницыTechnical Cognitive Systems: Michael BeetzIoan DorofteiОценок пока нет

- (ICIT-2010) FAMPER - A Fully Autonomous Mobile Robot For Pipeline ExplorationДокумент7 страниц(ICIT-2010) FAMPER - A Fully Autonomous Mobile Robot For Pipeline ExplorationIoan DorofteiОценок пока нет

- 04b OkamuraДокумент37 страниц04b OkamuraIoan DorofteiОценок пока нет

- Two-Dimensional Lubrication Analysis and Design Optimization of A Scotch Yoke Engine Linear BearingДокумент13 страницTwo-Dimensional Lubrication Analysis and Design Optimization of A Scotch Yoke Engine Linear Bearinggarbage94Оценок пока нет

- Elementele Imaginii UrbaneДокумент19 страницElementele Imaginii UrbaneIoan DorofteiОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- EasyLogic APF - EZAPF05044W20Документ4 страницыEasyLogic APF - EZAPF05044W20Marie LucyОценок пока нет

- Spotify Premium Method #Noob FriendlyДокумент5 страницSpotify Premium Method #Noob FriendlyJulian SuitsОценок пока нет

- HOW TO DO FAKE Video CallДокумент4 страницыHOW TO DO FAKE Video CallOfficial Coolest kid100% (3)

- Chapter 16 Quality Assurance and Implementation: Systems, Roles, and Development Methodologies, 8e (Kendall/Kendall)Документ12 страницChapter 16 Quality Assurance and Implementation: Systems, Roles, and Development Methodologies, 8e (Kendall/Kendall)Matin OdoomОценок пока нет

- MKT4009 Dissertation Proposal Form: KV176@Live - Mdx.ac - UkДокумент18 страницMKT4009 Dissertation Proposal Form: KV176@Live - Mdx.ac - UkniravОценок пока нет

- Flyer - 12nd IEM Design CompetitionДокумент2 страницыFlyer - 12nd IEM Design CompetitionNarayanaan SupurmaniamОценок пока нет

- GCSE Maths Revision Race (Grades 6 9)Документ21 страницаGCSE Maths Revision Race (Grades 6 9)Ricky JacobОценок пока нет

- TheNewStack GuideToCloudNativeMicroservices PDFДокумент125 страницTheNewStack GuideToCloudNativeMicroservices PDFanon_609690202Оценок пока нет

- ShahДокумент17 страницShahSaeed AliОценок пока нет

- CoVE - Projects - 2023 - Ver 06Документ26 страницCoVE - Projects - 2023 - Ver 06tazmania82Оценок пока нет

- Advanced PM2000B Patient Monitor USER MANUALДокумент243 страницыAdvanced PM2000B Patient Monitor USER MANUALNur Adam Abd RahmanОценок пока нет

- 110105139Документ946 страниц110105139BapudayroОценок пока нет

- WiFi TechnologyДокумент35 страницWiFi TechnologySmitesh MukaneОценок пока нет

- Fourier Series Beku 2431 Laboratory ReportДокумент5 страницFourier Series Beku 2431 Laboratory ReportAzrul NizarОценок пока нет

- Lab 02 - Boolean Function Implementation PDFДокумент10 страницLab 02 - Boolean Function Implementation PDFNashowan Gamal AlhadrmiОценок пока нет

- Course Details & Program SyllabusДокумент7 страницCourse Details & Program SyllabusParitosh SinghОценок пока нет

- Terex Rough Terrain Cranes Spec 77ad4a PDFДокумент212 страницTerex Rough Terrain Cranes Spec 77ad4a PDFGunawan WijayaОценок пока нет

- 5 Roll's Theorem.Документ5 страниц5 Roll's Theorem.Kavi SanjaiОценок пока нет

- Dell™ Ultrasharp™ 2001Fp LCD Display: QualityДокумент1 страницаDell™ Ultrasharp™ 2001Fp LCD Display: QualityAnonymous GBge2ED1OОценок пока нет

- AFROZEДокумент11 страницAFROZEtaimoor hasanОценок пока нет

- BSBPMG430 Project Management Learner WorkbookДокумент58 страницBSBPMG430 Project Management Learner WorkbookAkriti DangolОценок пока нет

- Space Resources: An IntroductionДокумент4 страницыSpace Resources: An Introductionnaela abdullaОценок пока нет

- Introduction To Control SystemДокумент48 страницIntroduction To Control SystemRogelioB.AlobIIОценок пока нет

- BIM Ex PlanДокумент40 страницBIM Ex PlancoidoianhОценок пока нет

- 6 Dimensions of Data Quality Examples and Measurement iCEDQДокумент17 страниц6 Dimensions of Data Quality Examples and Measurement iCEDQArizalОценок пока нет

- Wheat Crop Yield Prediction Using Deep LSTM ModelДокумент8 страницWheat Crop Yield Prediction Using Deep LSTM ModelEndalew SimieОценок пока нет

- Track and Trace Your Delivery StatusДокумент1 страницаTrack and Trace Your Delivery StatusCrissy NonОценок пока нет

- Introduction To Java Questions Answers - MyCSTutorial - in - The Path To Success in Exam..Документ25 страницIntroduction To Java Questions Answers - MyCSTutorial - in - The Path To Success in Exam..Abhinav PauranikОценок пока нет

- AWWA C-504: Model 3900F & Model 3900MДокумент2 страницыAWWA C-504: Model 3900F & Model 3900MPriyanka rajpurohitОценок пока нет

- RegreenExcel Company Profile EthanolДокумент20 страницRegreenExcel Company Profile EthanolHarsh GutgutiaОценок пока нет