Академический Документы

Профессиональный Документы

Культура Документы

D 1

Загружено:

Tran Van DaiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

D 1

Загружено:

Tran Van DaiАвторское право:

Доступные форматы

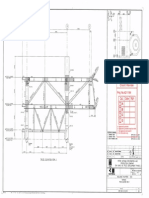

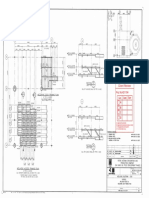

CALCULATION SHEET

JOB:

PROJECT:

SU TU VANG EXTENSION PLAN STV SOUTH WEST

DATE:

SUBJECT:

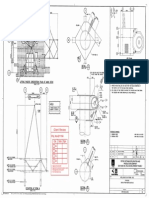

CONDUCTOR STICK UP

REVISION:

P1+P2

DESIGN CODE:

1.0 INPUT DATA

2.0 STICK UP CALCULATION

1.1 Dimension & section properties

2.1 Actual axial & bending stresses

D

- Diameter

-Wall Thickness

-Assuming freestanding length

-Apparent batter in X direction

-Apparent batter in Y direction

-Angle of pile lean with vertical

-Center of gravity of Hammer

-Eccentricity

iy

C.G

=

=

=

=

=

=

=

=

-Area of pile section

-Moment of inertia

-Section Modulus

-Radius of gyration

S

r

=

=

=

=

t

L

ix

0.914

1

1.00

4.76

0.532

m

0

m

:

:

deg

m

m

0.105

0.010

0.022

0.310

m2

m4

m3

m

0.038

25.71

1

0

0

- Axial load in pile

-Lateral deflection

-Moment from Hammer

-Moment from Pile lean

-Moment from enviromental load

-Total Moment

-Bending stress

-Axial stress

-Slenderness ratio

=

=

=

=

E

Fy

EI

Cc

208000

345

2090

109.091

MN/m2

MN/m2

MM.m2

-

-Euler buckling stress

-Allowable bending stresses

-Bending stress

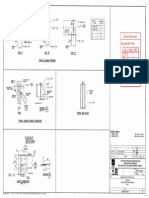

1.3 Loads

-Hammer type

-Hammer + falling Weigh

-Sleeve 72" + Anvil

-Contingency factor

Total hammer+falling+Helmet

-Weight

IHC-280

=

=

=

CF

WH

914.0

38.0

25,710.0

207.1

25.71

914.0

0.0

0.0

0.0

914.0

0.0

0.0

0.0

Total Weight (kN)

914.0

0.0

0.0

0.0

207.1

APPROVED

API RP2A - WSD, 21ST EDITION

(WH+WP)*Cos()

MH

MP

Me

M

fb

fa

=

=

=

=

=

=

=

=

669.00 kN

0.038 m

263.03 kNm

54.23 kNm

kNm

317.26 kNm

14426.66 kN/m2

6397.18 kN/m2

35.31

6.40

387.495

74.556

1.00

kN

kN

-

462.051

kN

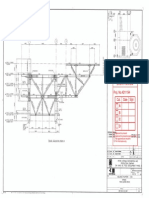

2.4 Driving Stress from GRLWeap

50% hammer efficiency

143.238

914.0

0.0

0.0

0.0

COG (m)

914.0

0.0

0.0

0.0

914.0

0.0

0.0

0.0

70% hammer efficiency

171.302

90% hammer efficiency

195.826

2.5 Combined stress (Static+Dynamic)

50% hammer efficiency

164.1

70% hammer efficiency

192.1

90% hammer efficiency

216.6

12.86

Page 1 of 4

MN/m2

MN/m2

=

174.16 kL/r

=

1.60

(kL/r)/Cc

( k = 2.1 as per API RP 21 edition CI 6.10.4)

=

35.31 MN/m2

Fe

D/t

24.05

>

29.97

D/t

10340/Fy

<

59.94

D/t

20680/Fy

=

Fb

258.75 MN/m2

=

fb

14.43 MN/m2

2.3 Combined axial compression and bending (API RP 21 edition)

Stability Utilisation

=

0.249

fa/Fa + Cm.fb/(1-fa/Fa)*Fb

( Cm =1 as per API RP 21 edition CI 6.10.4)

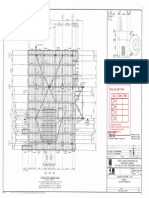

1.4 Pipe Weight detail

Sec. Dia

Sec. Thk

Sec. Length

Sec. Weight (kN)

Total Length (m)

2.2 Allowable axial & bending stresses (API RP 21 edition)

-Allowable axial stresses

=

Fa

-Axial stress

=

fa

1.2 Material properties

-Youngs modulus of pile material

-Yield stress of pile material

-Modulus of rigidity

-Coefficient

PREPARED

12/03/2014 15:31 CHECKED

<

OK

OK

OK

0.8Fy

0.8Fy

0.8Fy

=

=

=

276

<

<

276

276

OK

OK

OK

<

<

<

Fy

Fy

Fy

=

=

=

345.00

345.00

345.00

OK

OK

OK

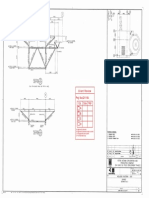

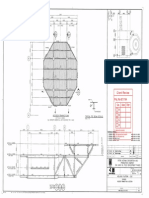

CALCULATION SHEET

JOB:

PROJECT:

SU TU VANG EXTENSION PLAN STV SOUTH WEST

DATE:

SUBJECT:

CONDUCTOR STICK UP

REVISION:

P1+P2+P3

12/03/2014 15:31 CHECKED

A

DESIGN CODE:

1.0 INPUT DATA

2.0 STICK UP CALCULATION

1.1 Dimension & section properties

2.1 Actual axial & bending stresses

D

- Diameter

-Wall Thickness

-Assuming freestanding length

-Apparent batter in X direction

-Apparent batter in Y direction

-Angle of pile lean with vertical

-Center of gravity of Hammer

-Eccentricity

iy

C.G

=

=

=

=

=

=

=

=

-Area of pile section

-Moment of inertia

-Section Modulus

-Radius of gyration

S

r

=

=

=

=

t

L

ix

0.914

1

1.00

4.76

0.648

m

0

m

:

:

deg

m

m

0.105

0.010

0.022

0.310

m2

m4

m3

m

0.038

32.4

1

0

0

- Axial load in pile

-Lateral deflection

-Moment from Hammer

-Moment from Pile lean

-Moment from enviromental load

-Total Moment

-Bending stress

-Axial stress

-Slenderness ratio

=

=

=

=

E

Fy

EI

Cc

208000

345

2090

109.091

MN/m2

MN/m2

MM.m2

-

-Euler buckling stress

-Allowable bending stresses

-Bending stress

1.3 Loads

-Hammer type

-Hammer + falling Weigh

-Sleeve 72" + Anvil

-Contingency factor

Total hammer+falling+Helmet

-Weight

IHC-280

=

=

=

CF

WH

914.0

914.0

38.0

38.0

4,400.0 28,000.0

35.4

225.5

32.4

914.0

0.0

0.0

0.0

Total Weight (kN)

914.0

0.0

0.0

0.0

260.9

API RP2A - WSD, 21ST EDITION

(WH+WP)*Cos()

MH

MP

Me

M

fb

fa

=

=

=

=

=

=

=

=

722.87 kN

0.069 m

331.51 kN

91.79 kN

0

423.30

19248.36

6912.29

kN

kN

kN/m2

kN/m2

22.23

6.91

MN/m2

MN/m2

=

219.48 kL/r

=

2.01

(kL/r)/Cc

( k = 2.1 as per API RP 21 edition CI 6.10.4)

=

22.23 MN/m2

Fe

D/t

24.05

>

29.97

D/t

10340/Fy

<

59.94

D/t

20680/Fy

=

Fb

258.75 MN/m2

=

fb

19.25 MN/m2

387.495

74.556

1.00

kN

kN

-

2.3 Combined axial compression and bending (API RP 21 edition)

Stability Utilisation

=

0.419

fa/Fa + Cm.fb/(1-fa/Fa)*Fb

( Cm =1 as per API RP 21 edition CI 6.10.4)

462.051

kN

2.4 Driving Stress from GRLWeap

50% hammer efficiency

143.238

1.4 Pipe Weight detail

Sec. Dia

Sec. Thk

Sec. Length

Sec. Weight (kN)

Total Length (m)

APPROVED

2.2 Allowable axial & bending stresses (API RP 21 edition)

-Allowable axial stresses

=

Fa

-Axial stress

=

fa

1.2 Material properties

-Youngs modulus of pile material

-Yield stress of pile material

-Modulus of rigidity

-Coefficient

PREPARED

914.0

0.0

0.0

0.0

COG (m)

914.0

0.0

0.0

0.0

914.0

0.0

0.0

0.0

70% hammer efficiency

171.302

90% hammer efficiency

195.826

2.5 Combined stress (Static+Dynamic)

50% hammer efficiency

169.4

70% hammer efficiency

197.5

90% hammer efficiency

222.0

16.20

Page 2 of 4

<

OK

OK

OK

0.8Fy

0.8Fy

0.8Fy

=

=

=

276

<

<

276

276

OK

OK

OK

<

<

<

Fy

Fy

Fy

=

=

=

345.00

345.00

345.00

OK

OK

OK

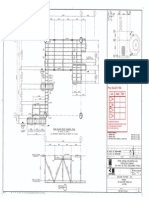

CALCULATION SHEET

JOB:

PROJECT:

SU TU VANG EXTENSION PLAN STV SOUTH WEST

DATE:

SUBJECT:

CONDUCTOR STICK UP

REVISION:

P1+P2+P3+P4

DESIGN CODE:

1.0 INPUT DATA

2.0 STICK UP CALCULATION

1.1 Dimension & section properties

2.1 Actual axial & bending stresses

D

- Diameter

-Wall Thickness

-Assuming freestanding length

-Apparent batter in X direction

-Apparent batter in Y direction

-Angle of pile lean with vertical

-Center of gravity of Hammer

-Eccentricity

iy

C.G

=

=

=

=

=

=

=

=

-Area of pile section

-Moment of inertia

-Section Modulus

-Radius of gyration

S

r

=

=

=

=

t

L

ix

0.914

1

1.00

4.76

0.437

m

0

m

:

:

deg

m

m

0.105

0.010

0.022

0.310

m2

m4

m3

m

0.038

20.3

1

0

0

- Axial load in pile

-Lateral deflection

-Moment from Hammer

-Moment from Pile lean

-Moment from enviromental load

-Total Moment

-Bending stress

-Axial stress

-Slenderness ratio

=

=

=

=

E

Fy

EI

Cc

208000

345

2090

109.091

MN/m2

MN/m2

MM.m2

-

-Euler buckling stress

-Allowable bending stresses

-Bending stress

1.3 Loads

-Hammer type

-Hammer + falling Weigh

-Sleeve 72" + Anvil

-Contingency factor

Total hammer+falling+Helmet

-Weight

IHC-280

=

=

=

CF

WH

914.0

914.0

38.0

38.0

4,400.0 15,900.0

35.4

128.0

20.3

914.0

0.0

0.0

0.0

Total Weight (kN)

914.0

0.0

0.0

0.0

163.5

APPROVED

API RP2A - WSD, 21ST EDITION

(WH+WP)*Cos()

MH

MP

Me

M

fb

fa

=

=

=

=

=

=

=

=

625.44 kN

0.021 m

211.61 kN

32.34 kN

0

243.95

11092.86

5980.63

kN

kN

kN/m2

kN/m2

56.64

5.98

MN/m2

MN/m2

=

137.51 kL/r

=

1.26

(kL/r)/Cc

( k = 2.1 as per API RP 21 edition CI 6.10.4)

=

56.64 MN/m2

Fe

D/t

24.05

>

29.97

D/t

10340/Fy

<

59.94

D/t

20680/Fy

=

Fb

258.75 MN/m2

=

fb

11.09 MN/m2

387.495

74.556

1.00

kN

kN

-

2.3 Combined axial compression and bending (API RP 21 edition)

Stability Utilisation

=

0.154

fa/Fa + Cm.fb/(1-fa/Fa)*Fb

( Cm =1 as per API RP 21 edition CI 6.10.4)

462.051

kN

2.4 Driving Stress from GRLWeap

50% hammer efficiency

143.238

1.4 Pipe Weight detail

Sec. Dia

Sec. Thk

Sec. Length

Sec. Weight (kN)

Total Length (m)

2.2 Allowable axial & bending stresses (API RP 21 edition)

-Allowable axial stresses

=

Fa

-Axial stress

=

fa

1.2 Material properties

-Youngs modulus of pile material

-Yield stress of pile material

-Modulus of rigidity

-Coefficient

PREPARED

12/03/2014 15:31 CHECKED

914.0

0.0

0.0

0.0

COG (m)

914.0

0.0

0.0

0.0

914.0

0.0

0.0

0.0

70% hammer efficiency

171.302

90% hammer efficiency

195.826

2.5 Combined stress (Static+Dynamic)

50% hammer efficiency

160.3

70% hammer efficiency

188.4

90% hammer efficiency

212.9

10.15

Page 3 of 4

<

OK

OK

OK

0.8Fy

0.8Fy

0.8Fy

=

=

=

276

<

<

276

276

OK

OK

OK

<

<

<

Fy

Fy

Fy

=

=

=

345.00

345.00

345.00

OK

OK

OK

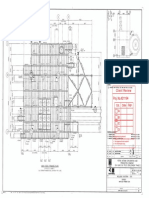

CALCULATION SHEET

JOB:

PROJECT:

SU TU VANG EXTENSION PLAN STV SOUTH WEST

DATE:

SUBJECT:

CONDUCTOR STICK UP

REVISION:

P1+P2+P3+P4+P5

DESIGN CODE:

1.0 INPUT DATA

2.0 STICK UP CALCULATION

1.1 Dimension & section properties

2.1 Actual axial & bending stresses

D

- Diameter

-Wall Thickness

-Assuming freestanding length

-Apparent batter in X direction

-Apparent batter in Y direction

-Angle of pile lean with vertical

-Center of gravity of Hammer

-Eccentricity

iy

C.G

=

=

=

=

=

=

=

=

-Area of pile section

-Moment of inertia

-Section Modulus

-Radius of gyration

S

r

=

=

=

=

t

L

ix

0.914

1

1.00

4.76

0.505

m

0

m

:

:

deg

m

m

0.105

0.010

0.022

0.310

m2

m4

m3

m

0.038

24.2

1

0

0

- Axial load in pile

-Lateral deflection

-Moment from Hammer

-Moment from Pile lean

-Moment from enviromental load

-Total Moment

-Bending stress

-Axial stress

-Slenderness ratio

=

=

=

=

E

Fy

EI

Cc

208000

345

2090

109.091

MN/m2

MN/m2

MM.m2

-

-Euler buckling stress

-Allowable bending stresses

-Bending stress

1.3 Loads

-Hammer type

-Hammer + falling Weigh

-Sleeve 72" + Anvil

-Contingency factor

Total hammer+falling+Helmet

-Weight

IHC-280

=

=

=

CF

WH

914.0

914.0

38.0

38.0

4,400.0 19,800.0

35.4

159.5

24.2

914.0

0.0

0.0

0.0

Total Weight (kN)

914.0

0.0

0.0

0.0

194.9

APPROVED

API RP2A - WSD, 21ST EDITION

(WH+WP)*Cos()

MH

MP

Me

M

fb

fa

=

=

=

=

=

=

=

=

656.84 kN

0.032 m

248.36 kN

47.43 kN

0

295.78

13449.87

6280.92

kN

kN

kN/m2

kN/m2

39.85

6.28

MN/m2

MN/m2

=

163.93 kL/r

=

1.50

(kL/r)/Cc

( k = 2.1 as per API RP 21 edition CI 6.10.4)

=

39.85 MN/m2

Fe

D/t

24.05

>

29.97

D/t

10340/Fy

<

59.94

D/t

20680/Fy

=

Fb

258.75 MN/m2

=

fb

13.45 MN/m2

387.495

74.556

1.00

kN

kN

-

2.3 Combined axial compression and bending (API RP 21 edition)

Stability Utilisation

=

0.219

fa/Fa + Cm.fb/(1-fa/Fa)*Fb

( Cm =1 as per API RP 21 edition CI 6.10.4)

462.051

kN

2.4 Driving Stress from GRLWeap

50% hammer efficiency

143.238

1.4 Pipe Weight detail

Sec. Dia

Sec. Thk

Sec. Length

Sec. Weight (kN)

Total Length (m)

2.2 Allowable axial & bending stresses (API RP 21 edition)

-Allowable axial stresses

=

Fa

-Axial stress

=

fa

1.2 Material properties

-Youngs modulus of pile material

-Yield stress of pile material

-Modulus of rigidity

-Coefficient

PREPARED

12/03/2014 15:31 CHECKED

914.0

0.0

0.0

0.0

COG (m)

914.0

0.0

0.0

0.0

914.0

0.0

0.0

0.0

70% hammer efficiency

171.302

90% hammer efficiency

195.826

2.5 Combined stress (Static+Dynamic)

50% hammer efficiency

163.0

70% hammer efficiency

191.0

90% hammer efficiency

215.6

12.10

Page 4 of 4

<

OK

OK

OK

0.8Fy

0.8Fy

0.8Fy

=

=

=

276

<

<

276

276

OK

OK

OK

<

<

<

Fy

Fy

Fy

=

=

=

345.00

345.00

345.00

OK

OK

OK

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Calculation Report For Monorail and Hatch Cover REV.0Документ15 страницCalculation Report For Monorail and Hatch Cover REV.0Tran Van DaiОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 2013-3289!62!0100 - Rev.0 - Jacket Elevations at Row AДокумент2 страницы2013-3289!62!0100 - Rev.0 - Jacket Elevations at Row ATran Van DaiОценок пока нет

- Bk10lq ST d10 A 001 Rev.0 Structural Design BriefДокумент14 страницBk10lq ST d10 A 001 Rev.0 Structural Design BriefTran Van DaiОценок пока нет

- List of Deliverabls-Aker ProposalДокумент4 страницыList of Deliverabls-Aker ProposalTran Van DaiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- CD ListДокумент1 страницаCD ListTran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Client Review: Proj. No.4211194Документ1 страницаClient Review: Proj. No.4211194Tran Van DaiОценок пока нет

- SMK Techno ProjectДокумент36 страницSMK Techno Projectpraburaj619Оценок пока нет

- The Finley ReportДокумент46 страницThe Finley ReportToronto StarОценок пока нет

- Case Notes All Cases Family II TermДокумент20 страницCase Notes All Cases Family II TermRishi Aneja100% (1)

- La Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanДокумент4 страницыLa Salle Lipa Integrated School Senior High School Community 1 Quarter Summative Assessment Earth Science AY 2021-2022 Household Conservation PlanKarlle ObviarОценок пока нет

- AutoCAD Dinamicki Blokovi Tutorijal PDFДокумент18 страницAutoCAD Dinamicki Blokovi Tutorijal PDFMilan JovicicОценок пока нет

- Pilot'S Operating Handbook: Robinson Helicopter CoДокумент200 страницPilot'S Operating Handbook: Robinson Helicopter CoJoseph BensonОценок пока нет

- A CMOS Current-Mode Operational Amplifier: Thomas KaulbergДокумент4 страницыA CMOS Current-Mode Operational Amplifier: Thomas KaulbergAbesamis RanmaОценок пока нет

- Purchases + Carriage Inwards + Other Expenses Incurred On Purchase of Materials - Closing Inventory of MaterialsДокумент4 страницыPurchases + Carriage Inwards + Other Expenses Incurred On Purchase of Materials - Closing Inventory of MaterialsSiva SankariОценок пока нет

- An Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)Документ18 страницAn Over View of Andhra Pradesh Water Sector Improvement Project (APWSIP)gurumurthy38Оценок пока нет

- Tate Modern London, Pay Congestion ChargeДокумент6 страницTate Modern London, Pay Congestion ChargeCongestionChargeОценок пока нет

- Fr-E700 Instruction Manual (Basic)Документ155 страницFr-E700 Instruction Manual (Basic)DeTiEnamoradoОценок пока нет

- CPE Cisco LTE Datasheet - c78-732744Документ17 страницCPE Cisco LTE Datasheet - c78-732744abds7Оценок пока нет

- Conflict WaiverДокумент2 страницыConflict WaiverjlurosОценок пока нет

- VISCOROL Series - Magnetic Level Indicators: DescriptionДокумент4 страницыVISCOROL Series - Magnetic Level Indicators: DescriptionRaduОценок пока нет

- XI STD Economics Vol-1 EM Combined 12.10.18 PDFДокумент288 страницXI STD Economics Vol-1 EM Combined 12.10.18 PDFFebin Kurian Francis0% (1)

- RCC Design of Toe-Slab: Input DataДокумент2 страницыRCC Design of Toe-Slab: Input DataAnkitaОценок пока нет

- Power For All - Myth or RealityДокумент11 страницPower For All - Myth or RealityAshutosh BhaktaОценок пока нет

- Admissibility of Whatsapp Messages in Court For Family MattersДокумент3 страницыAdmissibility of Whatsapp Messages in Court For Family Mattersnajihah adeliОценок пока нет

- Napoleon RXT425SIBPK Owner's ManualДокумент48 страницNapoleon RXT425SIBPK Owner's ManualFaraaz DamjiОценок пока нет

- MCS Valve: Minimizes Body Washout Problems and Provides Reliable Low-Pressure SealingДокумент4 страницыMCS Valve: Minimizes Body Washout Problems and Provides Reliable Low-Pressure SealingTerry SmithОценок пока нет

- Intelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseДокумент4 страницыIntelligent Smoke & Heat Detectors: Open, Digital Protocol Addressed by The Patented XPERT Card Electronics Free BaseBabali MedОценок пока нет

- 7Документ101 страница7Navindra JaggernauthОценок пока нет

- Jetweigh BrochureДокумент7 страницJetweigh BrochureYudi ErwantaОценок пока нет

- Gmo EssayДокумент4 страницыGmo Essayapi-270707439Оценок пока нет

- 1grade 9 Daily Lesson Log For Demo 1 4Документ5 страниц1grade 9 Daily Lesson Log For Demo 1 4cristy olivaОценок пока нет

- Brochure 2017Документ44 страницыBrochure 2017bibiana8593Оценок пока нет

- Danube Coin LaundryДокумент29 страницDanube Coin LaundrymjgosslerОценок пока нет

- PanasonicДокумент35 страницPanasonicAsif Shaikh0% (1)

- Payment of GratuityДокумент5 страницPayment of Gratuitypawan2225Оценок пока нет

- Ramp Footing "RF" Wall Footing-1 Detail: Blow-Up Detail "B"Документ2 страницыRamp Footing "RF" Wall Footing-1 Detail: Blow-Up Detail "B"Genevieve GayosoОценок пока нет