Академический Документы

Профессиональный Документы

Культура Документы

Standard Test Method For Slump of Hydraulic Cement Concrete

Загружено:

JonathanCuzcoZuñigaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Standard Test Method For Slump of Hydraulic Cement Concrete

Загружено:

JonathanCuzcoZuñigaАвторское право:

Доступные форматы

WSDOT FOP for AASHTO T1191

Standard Test Method for Slump of Hydraulic-Cement Concrete

1. Scope

2.

3.

1.1

This test method covers determination of slump of concrete, both in the laboratory and

inthe field.

1.2

The values stated in either inch-pound units or SI units are to be regarded separately as

standard. Within the text, the SI units are shown in brackets. The values stated in each

system are not exact equivalents; therefore, each system shall be used independently of

the other. Combining values from the two systems may result in nonconformance with

thestandard.

1.3

The text of the standard reference notes and footnotes provide explanatory material.

Thesenotes and footnotes (excluding those in tables and figures) shall not be considered

asrequirements of thestandard.

1.4

This standard does not purport to address all of the safety problems associated with its

use. It is the responsibility of the user of this standard to establish appropriate safety

andhealth practices and determine the applicability of regulatory limitations prior touse.

(Warning: Fresh Hydraulic cementitious mixtures are caustic and may cause chemical

burns to skin and tissue upon prolonged exposure.)

Referenced Documents

2.1

AASHTO Standards

T141 Sampling Freshly Mixed Concrete

2.2

ASTM Standards

C 172 Practice for Sampling Freshly Mixed Concrete

Summary of Test Method

3.1

4.

1This

A sample of freshly mixed concrete is placed and compacted by rodding in a mold

shaped as the frustum of a cone. The mold is raised and the concrete allowed to subside.

Thedistance between the original and displaced position of the center of the top surface

of the concrete is measured and reported as the slump of the concrete.

Significance and Use

4.1

This test method is intended to provide the user with a procedure to determine slump of

plastic hydraulic-cement concretes.

Note 1: This test method was originally developed to provide a technique to monitor the

consistency of unhardened concrete. Under laboratory conditions, with strict control of

allconcrete materials, the slump is generally found to increase proportionally with the

water content of a given concrete mixture, and thus to be inversely related to concrete

FOP is based on AASHTO T 119-11.

WSDOT Materials Manual M 46-01.15

January 2013

Page 1 of 8

T119

Standard Test Method for Slump of Hydraulic-Cement Concrete

strength. Under field conditions, however, such a strength relationship is not clearly and

consistently shown. Care should therefore be taken in relating slump results obtained

under field conditions tostrength.

4.2

This test method is considered applicable to plastic concrete having coarse aggregate up

to 1in (37.5mm) in size. If the coarse aggregate is larger than 1in (37.5mm) insize,

remove per FOP for WAQTC TM2.

4.3

This test method is not considered applicable to non-plastic and non-cohesive concrete.

Note 2: Concretes having slumps less than 0.5in (15mm) may not be adequately plastic

and concretes having slumps greater than about 9in (230mm) may not be adequately

cohesive for this test to have significance. Caution should be exercised in interpreting

such results.

5. Apparatus

5.1

Mold The test specimen shall be formed in a mold made of metal not readily attacked

by the cement paste. The metal shall not be thinner than 0.060in (1.5mm) and if formed

by thespinning process, there shall be no point on the mold at which the thickness is

less than 0.045in (1.15mm). The mold shall be in the form of the lateral surface of

the frustum of a cone with the base 8in (200mm) in diameter, the top 4in (100mm)

in diameter, and the height 12in (300mm). Individual diameters and heights shall be

within in (3.2mm) ofthe prescribed dimensions. The base and the top shall be open

and parallel to each other andat right angles to the axis of the cone. The mold shall be

provided with foot pieces and handles similar to those shown in Figure1. The mold shall

be constructed without a seam. The interior ofthe mold shall be relatively smooth and

free from projections. The mold shall be free from projections. A mold which clamps to a

nonabsorbent base plate is acceptable instead of the one illustrated provided the clamping

arrangement is such that it can be fully released without movement of the mold and the

base is large enough to contain all of the slumped concrete in an acceptable test.

5.1.1 Check and record conformance to the molds specified dimensions when it is

purchased or first placed in service and at least annually thereafter.

5.1.2 Mold With Alternative Materials

5.1.2.1 Molds other than metal are permitted if the following requirements are

met: The mold shall meet the shape, height, and internal dimensional

requirements of Section 5.1. The mold shall be sufficiently rigid

to maintain the specified dimensions and tolerances during use,

resistant to impact forces, and shall be nonabsorbent. The mold shall

be demonstrated to provide test results comparable to those obtained

when using a metal mold meeting the requirements of Section 5.1.

Comparability shall be demonstrated on behalf of the manufacturer by

an independent testing laboratory. Test for comparability shall consist

of not less than 10consecutive pairs of comparisons performed at

each of three different slumps ranging from 50to200mm (2 to 8in).

Noindividual test results shall vary by more than 15 mm (0.50in)

fromthat obtained using the metal mold. The average test results of

Page 2 of 8

WSDOT Materials Manual M 46-01.15

January 2013

Standard Test Method for Slump of Hydraulic-Cement Concrete

T119

each slump range obtained using the mold constructed of alternative

material shall not vary by more than 0.25in (6mm) from the average of

test results obtained using the metal mold. Manufacturer comparability

test data shall be available to users and laboratory inspection authorities

(Note4). If any changes in material or method of manufacture are made,

tests for comparability shall be repeated.

Note 3: The phrase consecutive pairs of comparisons does not mean

without interruption or all in one day. At a schedule selected by the

testing entity, the pairs of tests leading to 10 consecutive pairs may be

accomplished in small groups. The word consecutive prevents ignoring

pairs of tests which may not meet criteria.

Note 4: Because the slump of concrete decreases with time and higher

temperatures, it will be advantageous for the comparability tests to be

performed by alternating the use of metal cones and alternative material

cones, to utilize several technicians, and to minimize the time between

test procedures.

5.1.2.2 If the condition of any individual mold is suspected of being out of

tolerance from the as manufactured condition, a single comparative

test shall be performed. If the test results differ by more than 0.50in

(15mm) from that obtained using the metal mold, the mold shall be

removed fromservice.

5.2

Tamping Rod The tamping rod shall be a round, straight steel rod in (16mm)

in diameter and approximately 24in (600mm) in length, having the tamping end

orbothendsrounded to a hemispherical tip, the diameter of which is in (16mm).

5.3

Measuring Device A ruler, metal roll-up measuring tape, or similar rigid or semirigid length measuring instrument marked in increments of 5mm (in) or smaller.

Theinstrument length shall be at least 300mm (12in).

5.4

Torpedo level.

5.5

Base Flat, nonabsorbent, rigid surface.

6. Sample

6.1

The sample of concrete from which test specimens are made shall be representative

of the entire batch. It shall be obtained in accordance with FOP for WAQTC TM2.

With concrete using 1in (37.5mm) or larger aggregate, the aggregate larger than

1in (37.5mm) must be removed per FOP for WAQTC TM2. Contact the Materials

Laboratory fordirections.

WSDOT Materials Manual M 46-01.15

January 2013

Page 3 of 8

T119

Standard Test Method for Slump of Hydraulic-Cement Concrete

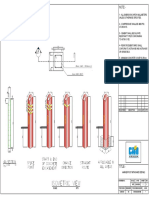

Mold for Slump Test

Figure 1

Page 4 of 8

WSDOT Materials Manual M 46-01.15

January 2013

Standard Test Method for Slump of Hydraulic-Cement Concrete

T119

7. Procedure

7.1

Dampen the mold and place it on a flat, level, moist, nonabsorbent rigid horizontal

surface, free from vibration and other disturbances, such as a pre-moistened concrete

floor or a base plate on a rigid surface. It shall be held firmly in place during filling

and perimeter cleaning by the operator standing on the two foot pieces, or by clamping

arrangements to a base plate as described in Section 5.1. From the sample of concrete

obtained in accordance with Section 6, immediately fill the mold in three layers, each

approximately one-third the volume of the mold.

Note 5: One-third of the volume of the slump mold fills it to a depth of 2in (67mm);

two-thirds of the volume fills it to a depth of 6in (155mm).

7.2

Rod each layer with 25strokes of the tamping rod. Uniformly distribute the strokes

over the cross section of each layer. For the bottom layer, this will necessitate inclining

the rod slightly and making approximately half of the strokes near the perimeter, and

then progressing with vertical strokes spirally toward the center. Rod the bottom layer

throughout its depth. Rod the second layer and the top layer each throughout its depth,

sothat the strokes just penetrate into the underlying layer.

7.3

In filling and rodding the top layer, heap the concrete above the mold before rodding

is started. If the rodding operation results in subsidence of the concrete below the top

edge of themold, add additional concrete to keep an excess of concrete above the top

of the mold at all times. After the top layer has been rodded, strike off the surface of the

concrete by means of a screeding and rolling motion of the tamping rod. Continue to

holdthe mold down firmly and remove concrete from the area surrounding the base of

the mold to preclude interface with the movement of slumping concrete.

Remove the mold from the concrete by raising it carefully in a vertical direction. Raise

the mold a distance of approximately 12in (300mm) in 52 seconds by a steady

upward lift with no lateral or torsional motion. Complete the entire test from the start

ofthe filling through removal of the mold without interruption and complete it within

anelapsed time of 2min.

7.4

Immediately measure the slump by determining the vertical difference between the top

ofthe mold and the displaced original center of the top surface of the specimen. If a

decidedfalling away or shearing off of concrete from one side or portion of the mass

occurs (Note6), disregard the test and make a new test on another portion of thesample.

Note 6: If two consecutive tests on a sample of concrete show a falling away or shearing

offof a portion of the concrete from the mass of the specimen, the concrete probably

lacks necessary plasticity and cohesiveness for the slump test to be applicable. Report

material cannot be slumped due to shearing or falling away.

WSDOT Materials Manual M 46-01.15

January 2013

Page 5 of 8

T119

Standard Test Method for Slump of Hydraulic-Cement Concrete

8. Report

8.1

Report the slump in terms of inches (millimeters) to the nearest in (5mm) of

subsidence of the specimen during the test.

Report results on concrete delivery ticket (i.e., Certificate of Compliance).

The name of the tester who performed the field acceptance test isrequired on concrete

delivery tickets containing test results.

9.

Precision and Bias

9.1

Page 6 of 8

Precision See AASHTO T119 for precision and bias.

WSDOT Materials Manual M 46-01.15

January 2013

Performance Exam Checklist

Slump of Hydraulic Cement Concrete

FOP for AASHTO T 119

Participant Name

Exam Date

Procedure Element

1. The tester has a copy of the current procedure on hand?

2.

3.

4.

All equipment is functioning according to the test procedure, and if required,

hasthecurrent calibration/verification tags present?

Cone and floor or base plate dampened?

5.

Cone held firmly against the base by standing on the two foot pieces?

Cone not allowed to move in any way during filling?

Representative samples scooped into the cone?

6.

Cone filled in three approximately equal layers by volume?

7.

8.

Each layer rodded throughout its depth 25 times with hemispherical end of rod,

uniformly distributing strokes?

Middle and top layers rodded to just penetrate into the underlying layer?

9.

When rodding the top layer, excess concrete kept above the mold at all times?

10. Concrete struck off level with top of cone using tamping rod?

11. Excess concrete removed from around the base?

12. Cone lifted upward approximately 12in (300mm) in one smooth motion,

withouttwisting the cone, in 5 2 seconds?

13. Slump measured to the nearest in (5mm) from the top of the cone to the

displacedoriginal center of the top surface of the specimen?

14. Test performed from start to finish within 2 minutes?

First Attempt: Pass Fail

Yes No

Second Attempt: Pass Fail

Signature of Examiner

Comments:

WSDOT Materials Manual M 46-01.15

January 2013

Page 7 of 8

T119

Page 8 of 8

Standard Test Method for Slump of Hydraulic-Cement Concrete

WSDOT Materials Manual M 46-01.15

January 2013

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Tunnel Support - Use of Lattice Girders in Sedimentary Rock PDFДокумент94 страницыTunnel Support - Use of Lattice Girders in Sedimentary Rock PDFjulio1051Оценок пока нет

- Astm C143 Slum TestДокумент4 страницыAstm C143 Slum Testjomer john estoneloОценок пока нет

- Concrete Mix DesignДокумент7 страницConcrete Mix Designadil271Оценок пока нет

- ESTIMATE NO Demo Stop DamДокумент4 страницыESTIMATE NO Demo Stop Damakshaymnnit50% (2)

- HCF PDFДокумент68 страницHCF PDFSushmit SharmaОценок пока нет

- MARKER POST-ISOMATRIC ModelДокумент1 страницаMARKER POST-ISOMATRIC Modelmostafa ibrahimОценок пока нет

- Precast FactoryДокумент25 страницPrecast Factoryamirsh78Оценок пока нет

- 12STEM3 G1 Research PaperДокумент14 страниц12STEM3 G1 Research PaperJaztyne Ribudal CabansagОценок пока нет

- Danley Keyjoint BrochureДокумент4 страницыDanley Keyjoint BrochureLance Zhengling YinОценок пока нет

- AERC8 Ramset-EpconC8 PDSДокумент11 страницAERC8 Ramset-EpconC8 PDSZilong ZhangОценок пока нет

- Shrinkage Compensating Concrete Floors: Thessen Concrete Contracting, IncДокумент21 страницаShrinkage Compensating Concrete Floors: Thessen Concrete Contracting, Incgava_1307Оценок пока нет

- Design of Precast Concrete Oors in Steel-Framed Buildings. Part 1: Slab DesignДокумент5 страницDesign of Precast Concrete Oors in Steel-Framed Buildings. Part 1: Slab DesignΤε ΧνηОценок пока нет

- Internship Report Sample 5Документ35 страницInternship Report Sample 5SUMIT KUMARОценок пока нет

- "Assets&liability Management"kesoramДокумент51 страница"Assets&liability Management"kesoramaurorashiva1Оценок пока нет

- Lecture 5 - Reinforced Concrete - ColumnДокумент52 страницыLecture 5 - Reinforced Concrete - ColumnChristopher PaladioОценок пока нет

- 3 Fibres and Matrices: 3.2.1 PropertiesДокумент10 страниц3 Fibres and Matrices: 3.2.1 PropertiesMiljan TrivicОценок пока нет

- Building Code Australia ComplianceДокумент24 страницыBuilding Code Australia ComplianceLampard ChenОценок пока нет

- Aggregate & SandДокумент2 страницыAggregate & SandNur Khairina Khairul HishamОценок пока нет

- A Project Report On BEHAVIOUR OF CONCRET PDFДокумент89 страницA Project Report On BEHAVIOUR OF CONCRET PDFRahul Singh PariharОценок пока нет

- Self Healing 4Документ9 страницSelf Healing 4Toni ArangelovskiОценок пока нет

- Ultrasonic Pulse Velocity TestДокумент4 страницыUltrasonic Pulse Velocity TestDeepak SahОценок пока нет

- List of Publications in The American Concrete Institute Kansas Chapter LibraryДокумент14 страницList of Publications in The American Concrete Institute Kansas Chapter LibraryGabriel Paolo CañeteОценок пока нет

- Asphaltic Concrete Mix DesignДокумент70 страницAsphaltic Concrete Mix DesignKumaran Balakrishnan100% (5)

- 4c578f202616448 - Ek #1Документ72 страницы4c578f202616448 - Ek #1Alek Al HadiОценок пока нет

- Specification - Catacutan GasolineДокумент5 страницSpecification - Catacutan GasolineKaren MunozОценок пока нет

- Sikaswell P - Pds enДокумент3 страницыSikaswell P - Pds enRegy StracyОценок пока нет

- Assignment Nicmar / Code Office: Site Organization & Management Reg. No. - 217-09-11-51049-2194Документ15 страницAssignment Nicmar / Code Office: Site Organization & Management Reg. No. - 217-09-11-51049-2194Manvendra singhОценок пока нет

- Architectural Building MaterialsДокумент239 страницArchitectural Building MaterialsLaurence CalpoturaОценок пока нет

- 1.chemical (V3) Web PDFДокумент88 страниц1.chemical (V3) Web PDFAlvin NimerОценок пока нет