Академический Документы

Профессиональный Документы

Культура Документы

JHA For Blasting Painting Works Final

Загружено:

rosevelvetОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

JHA For Blasting Painting Works Final

Загружено:

rosevelvetАвторское право:

Доступные форматы

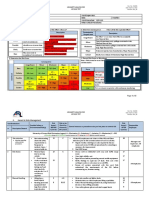

SMDS WAX PLANT EXPANSION PROJECT

JOB HAZARD ANALYSIS

(GENERIC JHA FOR BLASTING & PAINTING WORKS T 7502 HOT SLOPS STORAGE

TANK)

JOB TASK

NO.

S-0346-02

JOB TASK NAME :

BLASTING & PAINTING

WORKS

T-7504 HOT SLOPS

STORAGE TANK

FACILITY / EQUIPMENT NO. :

T-7502 HOT SLOPS STORAGE TANK

LOCATION

U-8400

COMPILED & PREPARED

BY

JHA TEAM MEMBERS :

INITIA

L

NAME

COM

THOMAS LEE

SMDS

BEAVEN ONADIA

AMAL

THIAN CHIN YAP

SMDS

MATIUS JOK

AMAL

STEPHEN GITA

SMDS

JAMRY WAN DING

AMAL

NAME

GENE YEE

JSGP

RUDI LIAI

THAN TUNG NAI

JSGP

TAN BEE SENG

TAIN TIMBAN

JSGP

IND

REVISION

:

JOB STEPS / S E Q U E N C E

1.

Transportation / Mobilization of Material & Equipment

2.

Preparatory Works Manual Loading & Unloading for Paint Cans

3.

General Facilities Works Blasting & Painting Equipment

4.

Blasting & Painting Activities

5.

Cleaning of steel plate with water

6.

Housekeeping

COM

AMALKGJ

AMALKGJ

LISTING

Page 1 Of 7

INITIAL

REVIEWED & APPROVED

BY

MEMBERS

JHA MEETING

DATE

13th June

2011

TIME

13:00 hours

VENUE

CONST. SITE

DISTRIBUTION

OFFICE LAY

ALL ATTENDEES

DOWN AREA

OF A C T I V I T I E S

SMDS WAX PLANT EXPANSION PROJECT

JOB HAZARD ANALYSIS

(GENERIC JHA FOR BLASTING & PAINTING WORKS T 7502 HOT SLOPS STORAGE

TANK)

RAM RATING

JOB

STEP

NO.

1.0.

DESCRIPTIONS

OF JOB TASK

Transportation

of Material &

Equipment

HAZARDS / THREAT

1.1 Vehicle Material /

goods falling

off during

loading,

transporting &

unloading

S

E

V

E

P

R

O

B

R

A

N

K

1.2 Vehicle entry

into tank farm

2.0.

Preparatory

Works

Manual

Loading &

Unloading for

Paint Cans

2.1. Manual

Confined

Space Entry

when Power

Brush Roof

Underside

2.2 Presence of

Do not overload

Secure all materials during

transportation

Notify operation before entry

Ensure vehicle entry under PTW

Carry gas test by operation

SMDS

JSGP

AMAL

CONSEQUENCES

Physical Injury /

Damage to

Property

Wear proper hand gloves

Hand & Finger

Injury

Continuous ventilation during entry

Continuous monitoring using gas

detector

Subsequence gas test by AGT

Unconscious /

Overcome by

gas

toxic gases /

CO Lack of

oxygen

2.3 Heat stress

illumination

RESP.

PARTY

Material

Handling

Hand / Fingers

Caught in

Between

2.4 Poor Visibility/

BARRIER / CONTROL MEASURE

Rotation of painters and blasters

Provide drinking water at resting

shade

Provide lighting with low voltage

explosion proof lighting

Sufficient lighting to be provided.

To be verified to the acceptance of

painting and JSGP inspector.

Page 2 Of 7

RECOVERY

MEASURES

Inform SMDS

PMT &

Operations

ACTION /

RESP.

PARTY

SMDS

Operation

s

JSGP

AMAL

Stop Work &

inform

Operations

Inform SMDS

PMT &

Operations

Fainted /

unconscious

Tripping

hazards /

personal injury

SMDS WAX PLANT EXPANSION PROJECT

JOB HAZARD ANALYSIS

(GENERIC JHA FOR BLASTING & PAINTING WORKS T 7502 HOT SLOPS STORAGE

TANK)

RAM RATING

JOB

STEP

NO.

3.0

4.0

DESCRIPTIONS

OF JOB TASK

General

Facilities

Works

Blasting &

Painting

Equipment

Blasting /

Painting

Activities

S

E

V

E

P

R

O

B

R

A

N

K

3.1 Spillage of

diesel during

refueling of

equipment

3.2 Emission of

black smoke &

source of

ignition

3.3 Generation of

Noise from

Running

Equipment

4.1 Exposure to

HAZARDS / THREAT

BARRIER / CONTROL MEASURE

CONSEQUENCES

RECOVERY

MEASURES

ACTION /

RESP.

PARTY

Provide drip tray and appropriate

facility all diesel driven machine

All contaminated material to clean

spill to be dispose at waste station

Soil

contamination

Station at up wind direction at all

time

Station equipment at least 15m

from the ventilation point

Air pollution

Wear ear plug /muff

Noise pollution

SMDS

Project

Team &

SMDS

Operation

s

To use proper PPE as required for

blasting & painting activities Full

dispose Coverall, gloves, visor,

dust mask, fume mask, goggle, etc

Unauthorized personnel to keep

clear from the area of painting /

blasting

Only experience painter/ blaster

shall carry out the works

Only bring sufficient painting

materials at site for the days work

Practise personal hygiene at all

time (drinking water only at resting

shed along road 4

Produce manufacturer data and to

ensure compatible and new filters

are installed and valid for use

verified by AMAL/JSGP safety.

Gas detector to be provided at all

time during operation

Personnel injury /

Unconscious

/suffocation/ skin

irritation/ Eye

Irritation

SMDS

Operation

s

JSGP

AMAL

RESP.

PARTY

toxic fumes /

dust

Page 3 Of 7

SMDS WAX PLANT EXPANSION PROJECT

JOB HAZARD ANALYSIS

(GENERIC JHA FOR BLASTING & PAINTING WORKS T 7502 HOT SLOPS STORAGE

TANK)

RAM RATING

JOB

STEP

NO.

DESCRIPTIONS

OF JOB TASK

HAZARDS / THREAT

4.2 High speed grit

blast

S

E

V

E

P

R

O

B

R

A

N

K

BARRIER / CONTROL MEASURE

4.3 Working at

heights

4.4 Hearing

damaged

4.5 Exposed to

Compressed Air

RESP.

PARTY

CONSEQUENCES

RECOVERY

MEASURES

ACTION /

RESP.

PARTY

Personal Injury

First aid

trained

person to

attend to the

injured

person and to

contact

Operations or

call SMDS

Clinic

SMDS

Operation

s

JSGP

AMAL

To wear ear plug/muff while carried

out the work

Install warning sign at worksite/

manhole entrance.

Hearing loss

Contact

Operations or

call SMDS

Clinic

SMDS

Operation

s

JSGP

AMAL

All pressured equipment //hoses to

inspected at SMDS workshop

All connecter must attached with

whip check

Pre-use inspection of equipment

daily by AMAL-KGJ approved

personnel

Fire watcher available at site

No using of compressed air for

body cleaning

Personal Injury

First aid

trained

person to

attend to the

injured

person and to

contact

Operations or

call SMDS

Clinic

SMDS

Operation

s

JSGP

AMAL

To wear safety glasses and face

shield / blasting hood

All hoses are to be fitted with whip

lash

Dead mans trigger not to tempered

(illegal tying of trigger)

Nozzle of blast gun should not be

pointed to any direction of common

access/ladders/ potential presence

of personnel

Full body harness to be used when

working at height except for

blasterer to be reviewed and

advise

Ensure scaffold ladders access

openings are guarded

Page 4 Of 7

SMDS WAX PLANT EXPANSION PROJECT

JOB HAZARD ANALYSIS

(GENERIC JHA FOR BLASTING & PAINTING WORKS T 7502 HOT SLOPS STORAGE

TANK)

RAM RATING

JOB

STEP

NO.

DESCRIPTIONS

OF JOB TASK

HAZARDS / THREAT

Performing

multiple (2)

blaster (due to

time element)

4.6 Accidental

being shot /

blast by

another blaster

S

E

V

E

P

R

O

B

R

A

N

K

BARRIER / CONTROL MEASURE

Ensure safe distance by

maintaining the following

movement

o Maintained diagonally opposite

direction movement

o Maintained clockwise direction

movement only

o Maintained same direction

elevation of area to blast

Barrier tape to be installed

assuring no crossing over between

blasterer

Only one blaster is required when

performing blasting at manhole

(bottom) level

Cut off blasting line (by fire

watcher) to communicate with

blasterer during emergency

6.0

Cleaning of

steel plate

using Water

Cleaning

6.1 sudden

increase of

pressure

from fire

hydrant

All pressured equipment

//hoses to inspected at SMDS

workshop

All connecter must attached

with whip check

Pre-use inspection of

equipment daily

Fire watcher available at site

Wear proper hand gloves

6.2 Handling

water hose

with slippery

surface

Page 5 Of 7

RESP.

PARTY

SMDS

JSGP

AMAL

ACTION /

RESP.

PARTY

CONSEQUENCES

RECOVERY

MEASURES

Personal Injury

First aid

trained

person to

attend to

the injured

person and

to contact

Operations

or call SMDS

Clinic

SMDS

Operatio

ns

JSGP

AMAL

Hand injury

First aid

trained

person to

attend to

the injured

person and

JSGP

AMAL

SMDS

Operatio

ns

SMDS WAX PLANT EXPANSION PROJECT

JOB HAZARD ANALYSIS

(GENERIC JHA FOR BLASTING & PAINTING WORKS T 7502 HOT SLOPS STORAGE

TANK)

RAM RATING

JOB

STEP

NO.

DESCRIPTIONS

OF JOB TASK

HAZARDS / THREAT

S

E

V

E

P

R

O

B

R

A

N

K

BARRIER / CONTROL MEASURE

RESP.

PARTY

CONSEQUENCES

RECOVERY

MEASURES

ACTION /

RESP.

PARTY

to contact

Operations

or call SMDS

Clinic

6.3 Polluted

Waste Water

6.4

6.0

Housekeeping

Send water sample to SMDS

Laboratory

Depending on the laboratory

result, dispose the waste water

accordingly

SMDS

JSGP

AMAL

Environmental

Pollution

6.1 Handling object

with slippery

surface

Wear proper hand gloves

SMDS

JSGP

AMAL

Hand injury

First aid

trained

person to

attend to the

injured

person and to

contact

Operations or

call SMDS

Clinic

JSGP

AMAL

SMDS

Operation

s

6.2 Sharp object /

Pinch point

Wear proper hand gloves

Hand injury

Inform SMDS

PMT &

Operations

JGC

/Contractor to

provide

assistant

when needed

by respond

team

6.3 Waste

Segregate all waste accordingly

Spent metal grits to be disposed to

Wrongly

disposed of

Notify JGC /

SMDS Project

Page 6 Of 7

SMDS WAX PLANT EXPANSION PROJECT

JOB HAZARD ANALYSIS

(GENERIC JHA FOR BLASTING & PAINTING WORKS T 7502 HOT SLOPS STORAGE

TANK)

RAM RATING

JOB

STEP

NO.

DESCRIPTIONS

OF JOB TASK

HAZARDS / THREAT

S

E

V

E

P

R

O

B

R

A

N

K

BARRIER / CONTROL MEASURE

RESP.

PARTY

AMAL- KGJ workshop

6.4 Heavy Objects

Do not do manual lifting more that

25 kg, use mechanical

support/lifting

CONSEQUENCES

RECOVERY

MEASURES

material

Team for

further

respond

Muscle strained.

Lower back

injury

Contact

Control room

for medical

assistant /

First aid

trained

person

ACTION /

RESP.

PARTY

GENERAL NOTES

A.

B.

C.

D.

E.

F.

G.

H.

I.

J.

K.

L.

M.

PPE shall be worn at all times.

Set up barricades around work area and display warning signs.

All equipment inspected by SMDS must have a valid inspection stickers attached on the equipment

All PTW and supporting permits must be valid before any work begins.

All jobs must be closely supervised and contractors PTW HOLDER must be on site at all times.

Valid vehicle entry permit is required for entering into restricted area. Only SMDS operations can open road barrier to allow entry into restricted area.

On hearing fire alarm siren, stop all works, machinery & source of ignition and walk on foot to the nearest muster point.

Vehicle to exit immediately to designated parking area after delivery of material.

No eating and resting on site. Use designated eating and resting area.

All pressure gauges used must be calibrated and tagged with valid calibration sticker.

All scaffolding must have a green safe to use tag before put into service.

Maintain good housekeeping daily at all the work places.

Tool box talk specific on work instruction and briefing on hazards and control measures to be conducted before start of work.

Personnel to be briefed with respond and hazards from the plant as follows :

Hazardous (toxic and flammable) Gas Potential released of hazardous gas

Contact control for any emergency cases All workers need to be familiar with emergency facilities

Noisy Surrounding and work location

Hearing protection need to be worn at all times

Protection against possible contact with hot pipe surface

The use of hand protection is required when entering the process area.

Page 7 Of 7

Вам также может понравиться

- JSA G20 Scaffolding (Erection, Dismantling)Документ4 страницыJSA G20 Scaffolding (Erection, Dismantling)Kanchalida Champathong92% (12)

- Risk Assesment For Sand Blasting and PaintingДокумент6 страницRisk Assesment For Sand Blasting and PaintingRochdi Bahiri100% (10)

- JSA Blasting and Coating KP 69.4Документ5 страницJSA Blasting and Coating KP 69.4shinto Lawrence100% (6)

- Job Safety Analysis (Rolling For MS Plates)Документ1 страницаJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Jsa Grit BlastingДокумент2 страницыJsa Grit BlastingHenryOdoh100% (3)

- JSA For Painting Works-Hazards ControlДокумент4 страницыJSA For Painting Works-Hazards Controlkaleem0% (2)

- Job Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00Документ6 страницJob Hazard Analysis (Jha) : Contractor: Date: Doc. No. & Rev. No.: 00poovazhaganОценок пока нет

- Jha of PaintingДокумент3 страницыJha of PaintingAllan Camacho Regalado100% (1)

- Manual Tig Welding (RRC) - Job ProcedureДокумент3 страницыManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Jsa-Jha For Using of Hand ToolsДокумент2 страницыJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JSA HandToolsДокумент2 страницыJSA HandToolsCristina Rican100% (3)

- JSA For Painting Inside TankДокумент2 страницыJSA For Painting Inside TankDilshad aliОценок пока нет

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkДокумент4 страницыMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- 1installation of Steel Structures JHA 1 (06!06!2015)Документ33 страницы1installation of Steel Structures JHA 1 (06!06!2015)Karthik babu100% (2)

- QP Blasting JSAДокумент6 страницQP Blasting JSAMohammed Mujahid100% (1)

- Jsa For Complete Erection of Tank-001Документ52 страницыJsa For Complete Erection of Tank-001Ashutosh80% (10)

- Safe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisДокумент17 страницSafe Work Method Statement (SWMS) - : Incorporating Job Safety AnalysisKhuda Buksh0% (1)

- Jsa For Civil Confined Space EntryДокумент11 страницJsa For Civil Confined Space EntryKhuda BukshОценок пока нет

- QP Painting JSAДокумент6 страницQP Painting JSAMohammed Mujahid100% (2)

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingДокумент4 страницыJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- JSA - Repair-Coating and Finition WorkДокумент3 страницыJSA - Repair-Coating and Finition WorkAMIN100% (1)

- Jsa For HydrotestДокумент10 страницJsa For HydrotestAnonymous CcGYhZb080% (5)

- Jsa Grinding Welding Gas CuttingДокумент3 страницыJsa Grinding Welding Gas CuttingRyanОценок пока нет

- JSA-055 Hydro-TestДокумент24 страницыJSA-055 Hydro-TestOmar Dhieb100% (7)

- JHA-011 (Power Brush & Touch-Up Painting Activities 1)Документ1 страницаJHA-011 (Power Brush & Touch-Up Painting Activities 1)shaiful annuar50% (2)

- JOB HAZARD ANALYSIS (Pipe Laying)Документ9 страницJOB HAZARD ANALYSIS (Pipe Laying)jay R100% (3)

- JSA Hydro TestingДокумент1 страницаJSA Hydro TestingZeyad RezkОценок пока нет

- JHA PaintingДокумент9 страницJHA Paintingperquino oasan100% (1)

- JHA For Tie-In at PCR14-02Документ7 страницJHA For Tie-In at PCR14-02Francis Enriquez TanОценок пока нет

- Risk Assessment For Sand BlastingДокумент8 страницRisk Assessment For Sand BlastingRochdi Bahiri71% (17)

- JSA-Construction Right of WayДокумент3 страницыJSA-Construction Right of Wayfrancis_e_tan100% (6)

- Abrasive Blasting S.O.P.7AДокумент7 страницAbrasive Blasting S.O.P.7AFerlie Indrapati100% (1)

- JSA For Cutting, Grinding and WeldingДокумент4 страницыJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA Welding Confined SpaceДокумент2 страницыJSA Welding Confined Spacegkmlal100% (4)

- JSA - Dismantling CM ShedДокумент4 страницыJSA - Dismantling CM ShedvivekaramanaОценок пока нет

- #15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsДокумент14 страниц#15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsSathish Insmile100% (1)

- JSA006 - Vacuum Box TestingДокумент5 страницJSA006 - Vacuum Box TestingLaohan LiuОценок пока нет

- JSA - Sand Blasting & PaintingДокумент4 страницыJSA - Sand Blasting & Paintingsurendra behera100% (4)

- Jsa For Piping and Erection RevisedДокумент1 страницаJsa For Piping and Erection RevisedDr AnwarОценок пока нет

- JSA WeldingДокумент2 страницыJSA WeldingSigint Sides0% (3)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleДокумент7 страницJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanОценок пока нет

- Column Lifting & Erection JSAДокумент7 страницColumn Lifting & Erection JSAAli Mohsin100% (3)

- Demolition PDFДокумент2 страницыDemolition PDFvinothОценок пока нет

- Lifting Operatio in Progress PDFДокумент1 страницаLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- JHA Civil WorksДокумент2 страницыJHA Civil Worksethelchudi100% (11)

- Jsa Hydro JettingДокумент4 страницыJsa Hydro Jettingyelsa otrebla100% (2)

- Job Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralДокумент2 страницыJob Safety Analysis: Pipe Cutting Cleaning and Flushing GeneralNico Raharjo60% (5)

- 0017 JS A Hot Job (Welding, Grinding & Cutting)Документ4 страницы0017 JS A Hot Job (Welding, Grinding & Cutting)Positivesolution100% (2)

- JSA of MPI InspectionДокумент1 страницаJSA of MPI Inspectionengmuhmud100% (1)

- JSA Shut Down and Tie in Work PDFДокумент6 страницJSA Shut Down and Tie in Work PDFpjosesm80% (5)

- Confined Space Entry For Painting Inside PontoonДокумент4 страницыConfined Space Entry For Painting Inside PontoonAchalere Shekhar KashinathОценок пока нет

- Jsa For Ut TestДокумент2 страницыJsa For Ut Testnasar_mahsood50% (2)

- Grinding Equipment Risk AssessmentДокумент3 страницыGrinding Equipment Risk Assessmentdroffilcz270% (1)

- JSA UT TestДокумент1 страницаJSA UT TestIksan Adityo MulyoОценок пока нет

- RA 002 - LPSG Steam Pipe Hot Work in ERДокумент6 страницRA 002 - LPSG Steam Pipe Hot Work in ERdassi99Оценок пока нет

- 3.jsa - Arc Welding-NДокумент5 страниц3.jsa - Arc Welding-NVivek NaikОценок пока нет

- Please Print or Type Project Management Contractor Near-Miss at Worksite ReportДокумент17 страницPlease Print or Type Project Management Contractor Near-Miss at Worksite ReportPeshteenОценок пока нет

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteДокумент3 страницыJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteganeshkanthОценок пока нет

- RA 002 - Engine Casing Exhaust Funnel - Hot WorkДокумент6 страницRA 002 - Engine Casing Exhaust Funnel - Hot Workdassi99Оценок пока нет

- Job Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity NoteДокумент2 страницыJob Hazard Analysis (Jha) Worksheet: Installation/Facility Job Activity Location Description of Activity Noteganeshkanth100% (1)

- Transmission Corridor Vs Transmission RouteДокумент1 страницаTransmission Corridor Vs Transmission RouterosevelvetОценок пока нет

- Kumwell Exothermic WeldДокумент137 страницKumwell Exothermic WeldThanThanscc100% (9)

- MSDS SieveДокумент4 страницыMSDS SieverosevelvetОценок пока нет

- JHA Valve Leak Test and RepairДокумент16 страницJHA Valve Leak Test and Repairrosevelvet100% (1)

- Jha Hot Tapping WorkДокумент6 страницJha Hot Tapping Workrosevelvet100% (1)

- U See U ActДокумент2 страницыU See U Actrosevelvet100% (1)

- Jha Tank Erection NDTДокумент3 страницыJha Tank Erection NDTrosevelvet100% (1)

- Project Safety Management SystemДокумент16 страницProject Safety Management SystemrosevelvetОценок пока нет

- Unsafe Act Unsafe ConditionДокумент1 страницаUnsafe Act Unsafe ConditionrosevelvetОценок пока нет

- Crane Lift Work PlatformДокумент13 страницCrane Lift Work PlatformsheqarayzanОценок пока нет

- Water Safety Plan Participant Workbook With CoverДокумент65 страницWater Safety Plan Participant Workbook With CoverrosevelvetОценок пока нет

- Safety Netting ComparisonДокумент2 страницыSafety Netting ComparisonrosevelvetОценок пока нет

- JSA For Filter Cleaning by Steam and Water ManuallyДокумент22 страницыJSA For Filter Cleaning by Steam and Water ManuallyThái Đạo Phạm LêОценок пока нет

- John ZinkДокумент4 страницыJohn ZinkbilororisalОценок пока нет

- RA For Cs Bar Welding 4F280 #3CDUДокумент16 страницRA For Cs Bar Welding 4F280 #3CDUJaison JosephОценок пока нет

- Report Project Osha PDFДокумент27 страницReport Project Osha PDFSky FireОценок пока нет

- Shell Crude Oil - MSDSДокумент16 страницShell Crude Oil - MSDSspurscoukОценок пока нет

- Collection and Processing of Human Amniotic Fluid: Manual of Procedures The GAPPS Repository April 2014Документ4 страницыCollection and Processing of Human Amniotic Fluid: Manual of Procedures The GAPPS Repository April 2014Rhianny PierceОценок пока нет

- WPR AnswerДокумент40 страницWPR Answerதெய்வேந்திரன் கிருஷ்ணன்100% (5)

- Instalaltion, Testing and Commissioning For The Clean Agent Syste..Документ15 страницInstalaltion, Testing and Commissioning For The Clean Agent Syste..Ahmad Omar100% (1)

- Cara Christ Resignation PetitionДокумент26 страницCara Christ Resignation PetitionJoshua MoralesОценок пока нет

- Sample-Risk Assessment & Safe Work Method StatementДокумент4 страницыSample-Risk Assessment & Safe Work Method StatementioanchiОценок пока нет

- Journal Pre-Proof: American Journal of Obstetrics & Gynecology MFMДокумент8 страницJournal Pre-Proof: American Journal of Obstetrics & Gynecology MFMsameer sahaanОценок пока нет

- Epimastic 7200: Product DescriptionДокумент2 страницыEpimastic 7200: Product DescriptionSu KaОценок пока нет

- Saudi Arabian Oil Company (Saudi Aramco) : General Instruction ManualДокумент5 страницSaudi Arabian Oil Company (Saudi Aramco) : General Instruction ManualElie Aouad100% (1)

- Question List Chalta BoltaДокумент14 страницQuestion List Chalta BoltaRajesh Kumar SinghОценок пока нет

- L3 QualificationДокумент126 страницL3 QualificationmajaklipaОценок пока нет

- PHE Preparation of Samples and Dilutions Plating and Sub-CultureДокумент21 страницаPHE Preparation of Samples and Dilutions Plating and Sub-Culturedr Alex stanОценок пока нет

- Lab Activity KKA - Biological Hazard-Student. 2021Документ8 страницLab Activity KKA - Biological Hazard-Student. 2021refimaya arlitaОценок пока нет

- DMDS Data SheetДокумент7 страницDMDS Data Sheetfarooq798100% (1)

- Final Specific Guidelines For 2024 Nfot TechnolympicsДокумент15 страницFinal Specific Guidelines For 2024 Nfot Technolympicscristianjay.escarpeОценок пока нет

- Risk Assisment For Fence WorkДокумент2 страницыRisk Assisment For Fence Workashishakare100% (1)

- Chain Washing System Mod.635 18/16 ALUPRESSДокумент88 страницChain Washing System Mod.635 18/16 ALUPRESSAlamin SiddiqueОценок пока нет

- Cbof Full Framework Transmission LineworkerДокумент45 страницCbof Full Framework Transmission LineworkerDanial2296Оценок пока нет

- Uni PX-30 Paint Marker SDSДокумент31 страницаUni PX-30 Paint Marker SDShamdany danyОценок пока нет

- Lesson VIII Occupational Health and Safety PracticesДокумент42 страницыLesson VIII Occupational Health and Safety PracticesRoss Armyr GeliОценок пока нет

- Health, Safety & Environmental (Hse) Plan: Rotating Offsore Solutions Pte LTDДокумент35 страницHealth, Safety & Environmental (Hse) Plan: Rotating Offsore Solutions Pte LTDRajendraОценок пока нет

- Daftar Produk Tayang E-Catalog GenmedДокумент10 страницDaftar Produk Tayang E-Catalog GenmedAnggra AragonОценок пока нет

- 80-1310-21 Tech Manual REV SEPT2017Документ117 страниц80-1310-21 Tech Manual REV SEPT2017Edgar Alberto Sanchez PОценок пока нет

- National Chemical Laboratories, Inc.: Safety Data SheetДокумент6 страницNational Chemical Laboratories, Inc.: Safety Data SheeteadriesОценок пока нет

- Mee 235: Engineering Technology: H.A. Ajimotokan (PHD)Документ233 страницыMee 235: Engineering Technology: H.A. Ajimotokan (PHD)Ajiboye Mubarak100% (1)

- Continuous Sealer: User ManualДокумент59 страницContinuous Sealer: User ManualFreddy SuleimanОценок пока нет