Академический Документы

Профессиональный Документы

Культура Документы

Dashboard Digital Voltmeter

Загружено:

crashoveriteАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Dashboard Digital Voltmeter

Загружено:

crashoveriteАвторское право:

Доступные форматы

Dashboard Digital Voltmeter

This project is helpful to anyone who drives an automobile. I had found this project at

the local libary... in an old publication. I made it and it worked fine.

Below are the complete text and schematic of the Dashboard Digital Voltmeter. I retyped the text and re-drew the schematic...as the printing from the book was old and

faded. Sit back and read the story why this LED display might just save you from

being stranded on the road!

Your making time down the interstate at three in the morning...all of a sudden you

become aware that the lights on the dash seem kind of dim, and that the headlights

don't seem to be reaching out as far ahead to warn you of darkened 18-wheelers'

parked on the shoulder. Are your eyes just playing tricks on you, or is there

something the matter with your car's electrical system? A quick glance down at the

three glowing LED numerals on the dash gives your the instant answer. Either you

pull into a rest area and grab a few hours of shuteye, or you pull into a service area

and have the battery, alternator and voltage regulator given a good scrutinizing by

the mechanic.

In either case, your car's digital voltmeter has given you the information that was

needed about the car's electrical system; and maybe saved you either a headache, a

smashup, or a king-sized repair and towing bill. Maybe all three...

Recent advances in the design and availability of industrial integrated circuits have

opened up many doors to the electronic hobbyist. Analog-to-digital devices have

become more complex internally, thus making the portions of the circuitry that have

to be assembled by the hobbyist that much more simple. The Dashboard Digital

Voltmeter takes advantage of these advances, utilizing three IC's and a small handful

of discrete components to give you an instrument capable of better than +/- 1%

accuracy in reading the voltage level delivered by your vehical's

(car/boat/motorcycle) electrical system.

If this project has interest to you...we shall begin!

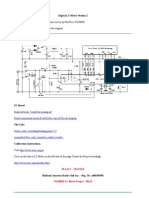

The Dashboard Digital Voltmeter Schematic

Parts List for the Dashboard Digital Voltmeter

1. 1N4002 Diode

11. 1K ohm resistor (1/4 watt)

2. 1N4002 Diode

12. 100K ohm resistor (1/4 watt)

3. 47uF/25v (Electrolytic

capacitor)

U1 LM340-T-5 (5vdc voltage regulator)

4. 10uF/16v (Tantalum

capacitor)

U2 NTE2054 or CA3162E (Analog to Digital

Converter)

5. 50K Potentiometer

U3 NTE2032 or CA3161E (BCD Display Driver)

6. .33uF /35v (Tantalum

capacitor)

Q1, Q2, Q3 PNP - 2N2907 or MPS2907 (3 are

needed)

*7. LED #2 has the decimal

point lite.

LED - NTE3078 or ECG3078 Common Anode (3

are needed)

8. Omitted

IC Sockets - For the LED's and IC's.

9. 10K Potentiometer

10. 10uF/16v (Tantalum

capacitor)

The PCB

Placement of Components on the PCB

Identification of Lettering With Respect to Components

A. 1N4002 Diode (Observe Polarity)

Q. Terminal connection for 'G' of LED #1,

#2, #3

B. 47uF/25v Electrolytic Capacitor

(Observe Polarity)

R. Terminal connection for 'F' of LED #1,

#2, #3

C. LM340T-5 Voltage Regulator

S. This is the +5v line coming from the

Voltage Regulator.

D. 10uF/16v Tantalum Capacitor

(Observe Polarity)

T. This is where a 'cross-over' wire needs

to be put. It must be put on the opposite

side of the copper routing, in order for it not

to interfere with the copper routing coming

in to Pin #7 of the CA3161E.

E. 10K Potentiometer (The Yellow

terminal is for the center leg on the

potentiometer)

U. Terminal connection for the 'decimal

point' on LED #2.

F. 2N2907 1st Transistor - Purple (E)

Brown (B) Lt. Blue (C)

V. 100 ohm resistor, 1/4 watt

G. 2N2907 2nd Transistor - Purple (E)

Brown (B) Lt. Blue (C)

W.

H. 2N2907 3rd Transistor - Purple (E)

Brown (B) Lt. Blue (C)

X. 50K ohm Potentiometer (The Yellow

terminal is for the center leg on the

potentiometer)

I. Terminal connection for Anode of

LED #1

Y. .33uF/35v Tantalum Capacitor (Observe

Polarity)

J. Terminal connection for Anode of

LED #2

Z. 10uF/16v Tantalum Capacitor (Observe

Polarity)

K. Terminal connection for Anode of

LED #3

AA. 1K Resistor, 1/4 Watt

L. Terminal connection for 'E' of LED

#1, #2, #3

BB. 100K Resistor, 1/4 Watt

M. Terminal connection for 'D' of LED

#1, #2 #3

CC. 1N4002 Diode (Observe Polarity)

N. Terminal connection for 'C' of LED

#1, #2, #3

DD. INPUT - From automobile battery (-)

side

O. Terminal connection for 'B' of LED

#1, #2, #3

EE. INPUT - From automobile battery (+)

side

FF. This is where another 'cross-over' wire

needs to be put. It must be put on the

P. Terminal connection for 'A' of LED

opposite side of the copper routing, in

#1, #2,

order for it not to interfere with the copper

#3............................................................

routing coming from Pin #2, Pin #6 and Pin

#8 of the CA3161E.

Finding The Parts To Begin The Project

Mouser Electronics (toll free 1-800-346-6873) here in the USA does carry the LED's

and IC's as well as insert sockets..and the rest of the components for the project.

Your local Radio Shack store would carry the more common items, such as...

resistors, capacitors, diodes, voltage regulator and transistors. Also insert sockets for

the LED's and IC's.

Let us begin...

The ICs

The system is built around three ICs: the LM340T-5 (a 5-volt regulator); a NTE2054;

a NTE2032; and a support combination of diodes, resistors and capacitors. It is the

NTE2032 and NTE2054 that is at the heart of the system.

Circuit Function

Analog voltage from 000 mV's to 999 mV's can be applied between pins 11 (+) and

10 (-) of the CA3162E (U2). That IC converts the voltage into a Binary Coded

Decimal (BCD) equivalent. The BCD leaves pins 2, 1, 15 and 16 (the group

represents the 1's, 2's, 4's, and 8's) and enters pins 7, 1, 2 and 6 respecitvely of the

CA3161E (U3). The latter IC takes the BCD code, converts the output, then uses it

(in conjunction with the 7-segment display) to generate (form) the number that

correlates to the BCD input of the CA3161E. The multiplexing driver pins 5, 3 and 4

(5 being the least significant and 4 the most significant) turn on that display by means

of the PNP switching transistors (Q1, Q2 and Q3). Concurrently, the CA3162E is

providing the BCD information to the CA3161E driver/decoder.

The maximum input differential between pins 11 and 10 of the CA3162E is 999 mV's.

A resistor network (R1, R2) is used to attenuate the applied 13.8 volts to 138 mV's.

An Ohm's Law calculation would give a result of 136.6 mV's. The gain-adjust

potentiometer compensates for the slight drop. The The three LED's display this as

13.8 volts.

Note the point marked "Obtion" in the schematic. With Pin 6 of the CA3162E

grounded or disconnected, there are four conversions or comparisons made each

second. Tying pin 6 to the 5-volt line will result in 96 conversions or comparisons per

second. The 96/second rate moves with excessive rapidity and is not appealing to

the eye, and usually results in the least significant digit appearing to be blurred. Of

the two rates, the 4/second conversion (4 Hz) is by far the more pleasing to the eye,

is easier for the eye to focus on quickly, and is the recommended rate.

Assembling the Voltmeter

Do as you would any other project by soldering all of the components on the board

once the PCB has been made. There is no right way of routing the electrical circuitry.

Any route you may choose to use should be OK.

Hooking it up and Calibration

Before accurate calibration can be done, you need to have a functional DVM on hand

to check the exact voltage of the battery (with engine off) in relation to calibrating

your Dashboard Digital Voltmeter.

Let's assume that your battery was checked with a DVM and gave a reading of

13.8vdc. Now you may proceed to the calibration of the Dashboard Digital Voltmeter.

Correct calibration determines the accuracy of your Dashboard Digital Voltmeter.

Follow these steps carefully and sequentially. First, connect the inputs of the

Dashboard Digital Voltmeter straight to the battery. Next, for zero adjustment, ground

pins 11 and 10 to the circuit board ground momentarily. Using a small screwdriver,

slowly rotate the wiper arm on R3 until there is a reading of 000. Now remove the

ground from pins 10 and 11. Set the gain control (R4) by rotating the wiper arm until

the displays are displaying 13.8 .... which should be the same voltage as is being

applied. Now you have calibrated it and are ready to mount the project somewhere

you can visually see the LED's at all times.

Well, that concludes the project! Should you have any concerns or questions

regarding this venture, please do not hesitate to e-mail me!

...your friend, Patrick

mailto:braincambre500@yahoo.com

Вам также может понравиться

- Book Hollow City The Graphic NovelДокумент3 страницыBook Hollow City The Graphic NovelSuravi Kusuma PradhanОценок пока нет

- Fabric-by-Fabric One-Yard WondersДокумент4 страницыFabric-by-Fabric One-Yard WondersStorey Publishing20% (5)

- Electronics - Schematic Circuits For The HobbyistДокумент159 страницElectronics - Schematic Circuits For The HobbyistrispОценок пока нет

- The Basics of Analog SensorДокумент6 страницThe Basics of Analog Sensormatrixworld20Оценок пока нет

- Handbook On Navaratri - Kanchi ForumДокумент31 страницаHandbook On Navaratri - Kanchi Forumthapas100% (4)

- Time Loop Hunter 0.38.00 - Walktrhough: by KamelkidoДокумент101 страницаTime Loop Hunter 0.38.00 - Walktrhough: by KamelkidoFrancois IsabelleОценок пока нет

- Max Challenge NutritionДокумент14 страницMax Challenge NutritionAmber 'Bambi' Dench100% (1)

- This Is 20 Watt Power Audio Amplifier Which Use IC LM1875 As Main ComponentДокумент14 страницThis Is 20 Watt Power Audio Amplifier Which Use IC LM1875 As Main ComponentJc LastaОценок пока нет

- Circuit Study BOUBEGHEL RimaДокумент8 страницCircuit Study BOUBEGHEL RimawlabiodОценок пока нет

- PWMcircuit 08Документ10 страницPWMcircuit 08kcarringОценок пока нет

- Tacometro Motocicleta PDFДокумент4 страницыTacometro Motocicleta PDFciguaОценок пока нет

- 1.5v Battery ChargerДокумент25 страниц1.5v Battery ChargerJOHN BRICCO A. MATACSILОценок пока нет

- Design: IdeasДокумент6 страницDesign: IdeasSamantha EwingОценок пока нет

- A Low Cost Automatic Curve TracerДокумент5 страницA Low Cost Automatic Curve Tracerbill1022100% (2)

- Oxygen Sensor Simulator - JumperДокумент7 страницOxygen Sensor Simulator - JumperBrianssrt4100% (2)

- Digital Stop WatchДокумент54 страницыDigital Stop WatchAshishОценок пока нет

- Interfacing ADC To 8051. Circuit For Interfacing ADC 0804 To AT89S51 MicrocontrollerДокумент8 страницInterfacing ADC To 8051. Circuit For Interfacing ADC 0804 To AT89S51 Microcontrollerdanitranoster8512Оценок пока нет

- Chapter 3Документ11 страницChapter 3Aung MyatОценок пока нет

- Hardware InterfacingДокумент65 страницHardware Interfacingrajan palaОценок пока нет

- Building An AnalogДокумент10 страницBuilding An AnalogRosita AzzamОценок пока нет

- Power Failure AlarmДокумент17 страницPower Failure AlarmPurva Patil33% (3)

- 70 Interesting CircuitsДокумент21 страница70 Interesting CircuitsHasitha Suneth100% (4)

- Trailer Stop & Turn Signal ConverterДокумент5 страницTrailer Stop & Turn Signal ConverterTim schroderОценок пока нет

- This Project in PDF: Construction-1 Construction-2 Construction-3 CalibrationДокумент15 страницThis Project in PDF: Construction-1 Construction-2 Construction-3 CalibrationPravin MevadaОценок пока нет

- Line Follower ROBOT Micro Controller 8051Документ28 страницLine Follower ROBOT Micro Controller 8051Rohit XavierОценок пока нет

- Optical If SДокумент11 страницOptical If SHenry ChanОценок пока нет

- Thermal Overload ProtectorДокумент69 страницThermal Overload ProtectorSai Printers100% (1)

- Stereo VU MeterДокумент3 страницыStereo VU MeterGuillermo HernandezОценок пока нет

- EDN Design Ideas 2006Документ142 страницыEDN Design Ideas 2006chag1956100% (1)

- LC Filter For DC Motor Hum RemovalДокумент7 страницLC Filter For DC Motor Hum Removalbill_gator20059105Оценок пока нет

- Full Paper of Put Coin and Draw Power 2010Документ9 страницFull Paper of Put Coin and Draw Power 2010Biswajit SarkarОценок пока нет

- 3 Axis 4AUPC Rev0 Driver Board Kit InstructionsДокумент3 страницы3 Axis 4AUPC Rev0 Driver Board Kit InstructionsmarceloОценок пока нет

- A Versatile 12-Channel Infrared Remote ControlДокумент5 страницA Versatile 12-Channel Infrared Remote ControlMeraz AhmedОценок пока нет

- TheftДокумент12 страницTheftEmeka Nelson OffornedoОценок пока нет

- Auto Shut OffДокумент5 страницAuto Shut OffJuan Manuel Han MacОценок пока нет

- Digital TachometerДокумент11 страницDigital TachometerDwi Muhchamad YusufОценок пока нет

- Esr Meter Dick Smith Kit k7204 by Bob Parker AssemblyДокумент6 страницEsr Meter Dick Smith Kit k7204 by Bob Parker AssemblypsapwellОценок пока нет

- IRMC Transistor CheckДокумент7 страницIRMC Transistor ChecksebifuenteОценок пока нет

- EDN Design Ideas 2009Документ144 страницыEDN Design Ideas 2009chag195675% (4)

- Infrared Emitter From CMOS 555 Robot RoomДокумент6 страницInfrared Emitter From CMOS 555 Robot RoomnkimlevnОценок пока нет

- Inductance & Capacitance MeterДокумент4 страницыInductance & Capacitance MeterDiego García MedinaОценок пока нет

- Ecgr3156 Experiment 10 Analog To Digital and Digital To Analog ConversionДокумент7 страницEcgr3156 Experiment 10 Analog To Digital and Digital To Analog ConversionS SaranyaОценок пока нет

- Brake Failure IndicatorДокумент15 страницBrake Failure IndicatorSubham Chakraborty100% (2)

- Rbs Engineering Technical Campus Bichpuri, AgraДокумент20 страницRbs Engineering Technical Campus Bichpuri, AgraVipin KushwaОценок пока нет

- JulyДокумент5 страницJulyapi-3707767Оценок пока нет

- Transformer Less Power Supply For MicrocontrollersДокумент11 страницTransformer Less Power Supply For MicrocontrollersSentimental SagОценок пока нет

- Clap SwitchДокумент14 страницClap SwitchAkilesh ArigelaОценок пока нет

- A Low Cost Automatic Curve Tracer PDFДокумент5 страницA Low Cost Automatic Curve Tracer PDFuditagarwal1997Оценок пока нет

- Practical 2P12 Semiconductor Devices: What You Should Learn From This PracticalДокумент11 страницPractical 2P12 Semiconductor Devices: What You Should Learn From This PracticalDevesh GargОценок пока нет

- Reference Design Low Cost CompassДокумент4 страницыReference Design Low Cost CompassHany MaximousОценок пока нет

- Digital LC Meter Version 2Документ3 страницыDigital LC Meter Version 2geraldino250Оценок пока нет

- ECEN 1400 Lab 6 Counters PDFДокумент4 страницыECEN 1400 Lab 6 Counters PDFMK KhnОценок пока нет

- DiДокумент6 страницDipani256Оценок пока нет

- GBPPR 'Zine - Issue #38Документ70 страницGBPPR 'Zine - Issue #38GBPPRОценок пока нет

- Digital CounterДокумент10 страницDigital Counterareej.fatima1298Оценок пока нет

- Troubleshooting VF DДокумент7 страницTroubleshooting VF DRichard BakerОценок пока нет

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Рейтинг: 2.5 из 5 звезд2.5/5 (3)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsОт EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsРейтинг: 3 из 5 звезд3/5 (2)

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1От EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Рейтинг: 4.5 из 5 звезд4.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Digital LED Thermometer with Microcontroller AVR ATtiny13От EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Рейтинг: 5 из 5 звезд5/5 (1)

- Re-Establishing SIC SecureInternalCommunications For CheckPointДокумент3 страницыRe-Establishing SIC SecureInternalCommunications For CheckPointgconusОценок пока нет

- Chess Magazine Chess Mai3Документ52 страницыChess Magazine Chess Mai3Francoise EithssenОценок пока нет

- Lucius Riccio Presentation, 2014 MIT Sloan Sports Analytics ConferenceДокумент47 страницLucius Riccio Presentation, 2014 MIT Sloan Sports Analytics ConferenceLuke Kerr-Dineen100% (1)

- Filipino Boxing World ChampionsДокумент5 страницFilipino Boxing World ChampionsGviller ApanОценок пока нет

- Tixati Language TemplateДокумент205 страницTixati Language TemplatePanchoОценок пока нет

- Anki DroidДокумент88 страницAnki DroidNestor Manuel Castillo BurgosОценок пока нет

- Billy Elliot Stage NotesДокумент29 страницBilly Elliot Stage NotesHilly McChef100% (2)

- 41 - Page 2 - WattpadДокумент8 страниц41 - Page 2 - Wattpadluhan143Оценок пока нет

- Chris Damito - Rough Living - An Urban Survival GuideДокумент175 страницChris Damito - Rough Living - An Urban Survival Guidesui pacha67% (3)

- Syllabus of Taekwondo PDFДокумент45 страницSyllabus of Taekwondo PDFEdho Pn100% (4)

- Head Gasket Replacement and Head Stud Install: Flopster843Документ26 страницHead Gasket Replacement and Head Stud Install: Flopster843fishhunter18Оценок пока нет

- A4Datasheet SMGДокумент1 страницаA4Datasheet SMGtimeport24Оценок пока нет

- Indian Weekender 3 April 2015Документ32 страницыIndian Weekender 3 April 2015Indian WeekenderОценок пока нет

- FMA Special Edition - MAMFMAДокумент45 страницFMA Special Edition - MAMFMAjeetlomarcoОценок пока нет

- Adrienne ClostreДокумент2 страницыAdrienne ClostrePaulaRiveroОценок пока нет

- CKD Air Unit FRL >>> นิวเมติกДокумент3 страницыCKD Air Unit FRL >>> นิวเมติกmon012Оценок пока нет

- DEVIALET ID PRICELIST 28062023Документ2 страницыDEVIALET ID PRICELIST 28062023M farhan alfariziОценок пока нет

- Cfe e 1631707075 All About Sea Turtles Differentiated Reading Comprehension Ver 2Документ17 страницCfe e 1631707075 All About Sea Turtles Differentiated Reading Comprehension Ver 2hanyОценок пока нет

- Air Sense HSSD-2 CommandДокумент2 страницыAir Sense HSSD-2 Commandportocala12Оценок пока нет

- Natural and Reinforced Grass, Experiences Learned and Shared, 2011 PDFДокумент48 страницNatural and Reinforced Grass, Experiences Learned and Shared, 2011 PDFEnacheAlin100% (1)

- Starcade Sidepanel PDFДокумент7 страницStarcade Sidepanel PDFJesusMoyaLopezОценок пока нет

- Sweet DreamДокумент2 страницыSweet DreamfatihsekerОценок пока нет

- English Grammar Placement Test - ILCДокумент6 страницEnglish Grammar Placement Test - ILCJIM GUIMACОценок пока нет

- Fields To PlayДокумент28 страницFields To Playstefi idlabОценок пока нет

- KING 2011: Parand Software GroupДокумент35 страницKING 2011: Parand Software GroupOmid ZamaniОценок пока нет