Академический Документы

Профессиональный Документы

Культура Документы

575 Drag Valve For Fossil Power Plants

Загружено:

shashikanth79Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

575 Drag Valve For Fossil Power Plants

Загружено:

shashikanth79Авторское право:

Доступные форматы

Save Energy

Save Money

Save Time

CCI DRAG 100DSV for

Attemperator Spraywater Control

CCI DRAG Technology for Boiler

Feedpump Recirculation

CCI DRAG Technology for Boiler

Feedwater Regulator

Features

Features

n

n

n

n

n

n

n

n

n

n

n

DRAG disk stack control element

Repeatable Class V shutoff

Equal percentage trim characteristic

Quick change trim

Angle and globe configuration

Benefits

Features

DRAG disk stack control element

Pressurized seat trim

MSS-SP 61 shutoff

Snap-acting relay

Quick change trim

Angle and globe configuration

n

n

n

n

n

DRAG disk stack control element

Equal-percentage trim characteristic

High rangeability

Long valve stroke

Quick change trim

Angle and globe configuration

Benefits

Benefits

Fuel cost savings

Eliminate costly and damaging leakage

Easy maintenance

Heat rate improvement

Repeatable and reliable shutoff

Maintenance cycle reduction

Erosion and cavitation elimination

n

n

n

n

n

n

Feedpump output increase

Operating cost reduction

Erosion and cavitation elimination

Maintenance cycle reduction

Reliable pump protection

Avoid plant shutdowns

n

n

n

n

n

n

n

Precise low end temperature control

Combine startup and main valves

Precise flow control

Startup time reduction

Plant efficiency improvement

Erosion and cavitation elimination

Maintenance cycle reduction

System reliability improvement

CCI quality and performance products

Throughout the world, companies rely

on CCI to solve their severe service

control valve problems. CCI has provided

custom solutions for these and other

industry applications for more than

80 years.

CCI locations worldwide.

Fossil Fuel

Pulp & Paper

DRAG trim equal

percentage characteristic

for attemperator spray and

feedwater regulator for

precise flow water control

CCI DRAG valves meet the control valve fluid velocity limits

published in the ISA Guide, Control Valves, Practical Guides for

Measurement and Control.

Nuclear

Velocity (H20)

ft/s

m/s

Continuous service single phase fluids

100

30

Cavitating & multi-phase fluid outlet

75

23

How many pressure reducing stages are required?

Delta P

Psi

Fluid velocity vs. stages of

pressure drop

1 stage

ft / sec

Recommended velocity

/ stages

3 stages

ft / sec

velocity

ft / sec

stages

500

155

105

100

1400

259

172

100

10

2300

331

233

100

12

4100

441

302

100

16

CCI Austria

(Spectris Components

GmbH)

Telephone: 43 1 869

27 40

Fax: 43 1 865 36 03

Lembockgasse 63

1230 Wien

AT-1233 Vienna

Austria

CCI China

Telephone: 86 10 6501

0350

Fax: 86 10 6501 0286

Room 567/569

Office Tower, Poly Plaza

14 Dongzhimen South

Avenue

Beijing 100027

China

Service conditions

CCI World

Headquarters

California

Telephone: (949) 8581877

Fax: (949) 858-1878

22591 Avenida Empresa

Rancho Santa

Margarita,

California 92688

USA

Oil & Gas

CCI FK

(Fluid Kinetics)

Telephone: 805 644

5587

Fax: 805 644 1080

2368 Eastman Avenue,

Suite 8

Ventura

California 93003

USA

CCI Japan

Telephone: 81 726 41

7197

Fax: 81 726 41 7198

4-15-20 Shukunosho

Ibaraki-City, Osaka

567-0051

Japan

CCI Korea

Telephone: 82 31 980

9800

Fax: 82 31 985 0552

26-17, Pungmu-Dong

Kimpo City

Kyunggi-Do 415-070

Republic of Korea

CCI Sweden

(BTG Valves)

Telephone: 46 533

689 600

Fax: 46 533 689 601

Box 603

SE-661 29 Sffle

Sweden

CCI Switzerland

(Sulzer Valves)

Telephone: 41 52 264

95 00

Fax: 41 52 264 95 01

Im Link 11

P.O. Box 65

8404 Winterthur

Switzerland

CCI DRAG

Valves for

Fossil

Power Plants

n

Temperature Control

Pump Protection

Feedwater Level Control

Contact us at:

info@ccivalve.com

Visit us online for

sales and service

locations at:

www.ccivalve.com

CCI Italy

(STI)

Telephone: 39 035

29282

Fax: 39 035 2928247

Via G. Pascoli 10 A-B

24020 Gorle, Bergamo

Italy

Example: ambient temperature water

DRAG is a registered trademark of CCI.

2004 CCI

575

3/04

The Valve Doctor Solution

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Globe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12Документ1 страницаGlobe Valve: No Material 1 2 3 4 6 7 8 9 10 11 12shashikanth79Оценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Globe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12Документ1 страницаGlobe Valve: No Material 1 2 4 5 6 7 8 9 10 11 12shashikanth79Оценок пока нет

- Gate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12Документ1 страницаGate Valve: No Material 1 2 3 4 5 6 7 8 9 10 11 12shashikanth79Оценок пока нет

- Ball Check Valve: 4740 47401 PN 16 PN 10Документ1 страницаBall Check Valve: 4740 47401 PN 16 PN 10shashikanth79Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Globe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12Документ1 страницаGlobe Valve: No Material 1 2 3 5 6 7 8 9 10 11 12shashikanth79Оценок пока нет

- Ball Valve Full Bore - Flanged End: 1 No MaterialДокумент1 страницаBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79Оценок пока нет

- Ball Check Valve: 472452 472451 PN 16 PN 10Документ1 страницаBall Check Valve: 472452 472451 PN 16 PN 10shashikanth79Оценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Ball Valve Full Bore - Flanged End: No MaterialДокумент1 страницаBall Valve Full Bore - Flanged End: No Materialshashikanth79Оценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Ball Valve Full Bore - Flanged End: 1 Body No MaterialДокумент1 страницаBall Valve Full Bore - Flanged End: 1 Body No Materialshashikanth79Оценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Resilient Seated Gate Valve: 620302 620301 PN 16 PN 10Документ1 страницаResilient Seated Gate Valve: 620302 620301 PN 16 PN 10shashikanth79Оценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Ball Valve Full Bore - Compact: No MaterialДокумент1 страницаBall Valve Full Bore - Compact: No Materialshashikanth79Оценок пока нет

- Ball Valve Full Bore - Flanged End: 1 No MaterialДокумент1 страницаBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79Оценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 3-Way Ball Valve Full Bore - Screwed End: No MaterialДокумент1 страница3-Way Ball Valve Full Bore - Screwed End: No Materialshashikanth79Оценок пока нет

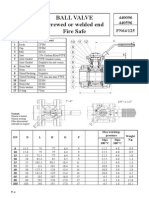

- Ball Valve Screwed or Welded End Fire SafeДокумент1 страницаBall Valve Screwed or Welded End Fire Safeshashikanth79Оценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Ball Valve Full Bore - Screwed End: 442013 PN 30 PN 20Документ1 страницаBall Valve Full Bore - Screwed End: 442013 PN 30 PN 20shashikanth79Оценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Ball Valve Full Bore - Screwed End: 1 No MaterialДокумент1 страницаBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79Оценок пока нет

- Ball Valve Full Bore - Butt Weld End: No MaterialДокумент1 страницаBall Valve Full Bore - Butt Weld End: No Materialshashikanth79Оценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Ball Valve Full Bore - Butt Weld End: 1 No MaterialДокумент1 страницаBall Valve Full Bore - Butt Weld End: 1 No Materialshashikanth79Оценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Ball Valve Full Bore - Screwed End: No MaterialДокумент1 страницаBall Valve Full Bore - Screwed End: No Materialshashikanth79Оценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Ball Valve Full Bore - Flanged End: 1 No MaterialДокумент1 страницаBall Valve Full Bore - Flanged End: 1 No Materialshashikanth79Оценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Ball Valve Full Bore - Screwed End: 1 No MaterialДокумент1 страницаBall Valve Full Bore - Screwed End: 1 No Materialshashikanth79Оценок пока нет

- 3-Way Gland Cock: 1 No MaterialДокумент1 страница3-Way Gland Cock: 1 No Materialshashikanth79Оценок пока нет

- 3-Way Gland Cock: 1 No MaterialДокумент1 страница3-Way Gland Cock: 1 No Materialshashikanth79Оценок пока нет

- Strainer: 483492 483491 PN 16 PN 10Документ1 страницаStrainer: 483492 483491 PN 16 PN 10shashikanth79Оценок пока нет

- 3-Way Gland Cock: No Material 1Документ1 страница3-Way Gland Cock: No Material 1shashikanth79Оценок пока нет

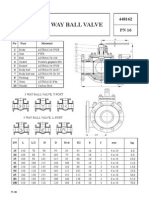

- 3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10Документ1 страница3 Way Ball Valve With Gear: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79Оценок пока нет

- 3-Way Ball Valve Full Bore - Flanged End: 1 No MaterialДокумент1 страница3-Way Ball Valve Full Bore - Flanged End: 1 No Materialshashikanth79Оценок пока нет

- Strainer: 483422 483421 PN 16 PN 10Документ1 страницаStrainer: 483422 483421 PN 16 PN 10shashikanth79Оценок пока нет

- 3-Way Ball Valve Screwed End: No MaterialДокумент1 страница3-Way Ball Valve Screwed End: No Materialshashikanth79Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- 3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10Документ1 страница3 Way Ball Valve: No Part Material 1 2 3 4 5 6 7 8 9 10shashikanth79Оценок пока нет

- Introduccion To PhysicsДокумент475 страницIntroduccion To PhysicsLyvsОценок пока нет

- Cover Letter Mechanical Engineering Nondestructive TestingДокумент1 страницаCover Letter Mechanical Engineering Nondestructive TestingGagandeep SinghОценок пока нет

- Scarifier 9 Piecies Tooth TypeДокумент2 страницыScarifier 9 Piecies Tooth Typeangga setyawanОценок пока нет

- Fracture in Concrete and Reinforced ConcreteДокумент23 страницыFracture in Concrete and Reinforced ConcreteNilay GandhiОценок пока нет

- Plumbing Fixture CatalogueДокумент10 страницPlumbing Fixture CatalogueNoemi D. BreñaОценок пока нет

- Case Study 11 Centralia Underground Mine FireДокумент11 страницCase Study 11 Centralia Underground Mine Firemigire kennedyОценок пока нет

- XRD ProcedureДокумент2 страницыXRD Procedurepullo123Оценок пока нет

- 9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PДокумент6 страниц9.16. Prepare A Plot of Work Per Pound Mole Versus The Pressue Ratio PttussenoОценок пока нет

- Refining Mechanical PulpingДокумент12 страницRefining Mechanical PulpingMahdia MahmudОценок пока нет

- Pace Power System Presentation - 0Документ15 страницPace Power System Presentation - 0everetteОценок пока нет

- BX-74 / BX-78: Sliding Gate Operator BX SeriesДокумент24 страницыBX-74 / BX-78: Sliding Gate Operator BX SeriesStefce PetrovОценок пока нет

- Sample Electrical LayoutДокумент1 страницаSample Electrical LayoutBentesais Bente UnoОценок пока нет

- 545 ELP-ES-2011 - Catálogo de DisipadoresДокумент24 страницы545 ELP-ES-2011 - Catálogo de DisipadoresrichkidОценок пока нет

- 11i APC Imp GuideДокумент108 страниц11i APC Imp GuidePrashanth ReddyОценок пока нет

- Parameters by Functional CategoryДокумент6 страницParameters by Functional Categoryapi-3819698Оценок пока нет

- Wheels & BrakesДокумент14 страницWheels & BrakesJoshua Saldana VélezОценок пока нет

- Software Hardware ListДокумент2 страницыSoftware Hardware ListjackОценок пока нет

- Ncomputing VSpace Server Management Console User ManualДокумент34 страницыNcomputing VSpace Server Management Console User ManualJeff IvanОценок пока нет

- 29L0054805FДокумент49 страниц29L0054805FszОценок пока нет

- Home,: A Solace To Which A Journey Is Never Too Long..Документ25 страницHome,: A Solace To Which A Journey Is Never Too Long..Duvonto RealtyОценок пока нет

- Lube-Tech: Lubricants For Wind TurbinesДокумент6 страницLube-Tech: Lubricants For Wind TurbinesMC AОценок пока нет

- NCERT Class 7 Geography WaterДокумент9 страницNCERT Class 7 Geography Waterbalamurali_aОценок пока нет

- Graco Pumps Catalog 300435EN MДокумент76 страницGraco Pumps Catalog 300435EN MAlbu MihaiОценок пока нет

- Electrochemical Measurement of Diffusible Hydrogen in Steels (Barnacle Electrode)Документ6 страницElectrochemical Measurement of Diffusible Hydrogen in Steels (Barnacle Electrode)Faiber AndrésОценок пока нет

- Cfw300 Manual 1Документ124 страницыCfw300 Manual 1maurilioОценок пока нет

- Welding ProceduresДокумент11 страницWelding ProceduresnamasralОценок пока нет

- Tutorial Questions and Answers - 2011Документ10 страницTutorial Questions and Answers - 2011Jan ScarОценок пока нет

- Textile AssignmentДокумент8 страницTextile AssignmentMahmudul Hasan Khan40% (5)

- Manufacturing Layout Analysis - Comparing Flexsim With Excel SpreadsheetsДокумент2 страницыManufacturing Layout Analysis - Comparing Flexsim With Excel Spreadsheetsmano7428Оценок пока нет

- FM-200 Alpha Series SystemsДокумент6 страницFM-200 Alpha Series SystemsGurusumiОценок пока нет