Академический Документы

Профессиональный Документы

Культура Документы

SR50.37 FD: Double-Acting Swing Clamping Cylinder With Upper Flange

Загружено:

Vando SoaresИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SR50.37 FD: Double-Acting Swing Clamping Cylinder With Upper Flange

Загружено:

Vando SoaresАвторское право:

Доступные форматы

1

SR50.37 FD

DOUBLE-ACTING SWING CLAMPING CYLINDER WITH UPPER FLANGE

MAX.WORKINGPRESSURE=500BAR

Installation dimensions with

O-ring manifold mounting

A: Clamping

B: Unclamping

M45x1.5

M12

37

7 Max.

90

45

75

42

86

7 Max.

BSPP1/4"

14

72

15

208

40

ROD POSITION

AT STROKE END

TOTAL STROKE

11

CLAMPING

STROKE

82 -10

50

SWINGING

STROKE

26

(40)

25

TAPER 1:8

55

89.8

55

45

To use the O-ring ports, remove the plug and insert

the 3043 O-rings 10.78 x 2.62 (supplied)

B

42

55

125

Material:

> Piston/rod: Casehardened grinded steel.

> Body: Nitrided free machining steel.

75

70

72

95

In standard version, these cylinders are equipped with

the safety clutch against overload during rotation.

Supplied:

> TCEI M14x50 UNI 5931 12.9 mounting screws.

> 3043 O-rings 10.78 x 2.62

STROKE

mm

EFFECTIVE

CYLINDER AREA

TOTAL OIL

VOLUME

Cm2

Cm3

Total

37 Clamping Unclamping Clamping Unclamping

Swinging

11

Clamping

26

11.54

METAL WIPER

UPON

REQUEST!

31.17

42.70

115.30

I N N O VAT I V E E N G I N E E R I N G

Last update 01/2013

SR50.37 FD

DOUBLE-ACTING SWING CLAMPING CYLINDER WITH UPPER FLANGE

ORDERING CODE

0

0: Standard version with stroke 37 mm (11 + 26)

FD

FD: Double-acting version with upper ange

L

R

L: Left-hand swinging

R: Right-hand swinging

0 - 45 - 60- 90

0-45-60-90: Available swinging angles

M: Metal wiper (upon request)

TAPER 1 : 10

Clamping force/pressure ratio

The diagram shows the effective clamping force F as

a function of the operating pressure P and the recommended maximum clamping arm length L.

50

12x45

34

56

+0.1

-0

10

80

40

10

12x45

38

175

F - Effective clamping force (KN)

L - Recommended clamping arm length (mm)

50

220

150

120

95

80

65

60

100

150

200

250

300

350

400

40

35

30

25

20

15

10

5

10

50

450

500

P - Pressure (bar)

I N N O VAT I V E E N G I N E E R I N G

Last update 01/2013

SR50.37 PD

DOUBLE-ACTING SWING CLAMPING CYLINDER WITH LOWER FLANGE

Installation dimensions with

O-ring manifold mounting

A: Clamping

B: Unclamping

M45x1.5

37.5

06

/

M14

M90x2

11

BSPP1/4"

107

129

30

168

208

ROD POSITION

AT STROKE END

TOTAL STROKE

CLAMPING

STROKE

37

11

SWINGING

STROKE

26

TAPER 1:8

37.5

37.5

To use the O-ring ports, remove the plug and insert

the 3043 O-rings 10.78 x 2.62 (supplied)

115

16

Supplied:

> TCEI M14x50 UNI 5931 12.9 mounting screws.

> 3043 O-rings 10.78 x 2.62

90

68

In standard version, these cylinders are equipped with

the safety clutch against overload during rotation.

STROKE

mm

90

Material:

> Piston/rod: Casehardened grinded steel.

> Body: Nitrided free machining steel.

EFFECTIVE

CYLINDER AREA

TOTAL OIL

VOLUME

Cm2

Cm3

Total

37 Clamping Unclamping Clamping Unclamping

Swinging

11

Clamping

26

11.54

METAL WIPER

UPON

REQUEST!

31.17

42.70

115.30

I N N O VAT I V E E N G I N E E R I N G

Last update 01/2013

SR50.37 PD

DOUBLE-ACTING SWING CLAMPING CYLINDER WITH LOWER FLANGE

ORDERING CODE

0

0: Standard version with stroke 37 mm (11 + 26)

PD

PD: Double-acting version with lower ange

L

R

L: Left-hand swinging

R: Right-hand swinging

0 - 45 - 60- 90

0-45-60-90: Available swinging angles

M: Metal wiper (upon request)

TAPER 1 : 10

Clamping force/pressure ratio

The diagram shows the effective clamping force F as

a function of the operating pressure P and the recommended maximum clamping arm length L.

.

50

12x45

34

56

+0.1

-0

10

80

40

10

12x45

38

175

F - Effective clamping force (KN)

L - Recommended clamping arm length (mm)

50

220

150

120

95

80

65

60

100

150

200

250

300

350

400

40

35

30

25

20

15

10

5

10

50

450

500

P - Pressure (bar)

I N N O VAT I V E E N G I N E E R I N G

Last update 01/2013

SR50.62 PD

DOUBLE-ACTING SWING CLAMPING CYLINDER WITH LOWER FLANGE

MAX.WORKINGPRESSURE=500BAR

A: Clamping

B: Unclamping

Installation dimensions with

O-ring manifold mounting

M45x1.5

CLAMPING

STROKE

62 -TOTAL STROKE

11

SWINGING

STROKE

51

TAPER 1:8

ROD POSITION

AT STROKE END

30

218

258

37.5

BSPP1/4"

154

132

M14

M90x2

11

B

37.5

To use the O-ring ports, remove the plug and insert

the 3043 O-rings 10.78 x 2.62 (supplied)

37.5

115

In standard version, these cylinders are equipped with

the safety clutch against overload during rotation.

Supplied:

> TCEI M14x50 UNI 5931 12.9 mounting screws.

> 3043 O-rings 10.78 x 2.62

68

90

16

STROKE

mm

90

Material:

> Piston/rod: Casehardened grinded steel.

> Body: Nitrided free machining steel.

EFFECTIVE

CYLINDER AREA

TOTAL OIL

VOLUME

Cm2

Cm3

Total

62 Clamping Unclamping Clamping Unclamping

Swinging

11

Clamping

51

11.54

METAL WIPER

UPON

REQUEST!

31.17

71.55

193.2

I N N O VAT I V E E N G I N E E R I N G

Last update 01/2013

SR50.62 PD

DOUBLE-ACTING SWING CLAMPING CYLINDER WITH LOWER FLANGE

ORDERING CODE

0

0: Standard version with stroke 62 mm (11 + 51)

PD

PD: Double-acting version with lower ange

L

R

L: Left-hand swinging

R: Right-hand swinging

0 - 45 - 60- 90

0-45-60-90: Available swinging angles

M: Metal wiper (upon request)

TAPER 1 : 10

Clamping force/pressure ratio

The diagram shows the effective clamping force F as

a function of the operating pressure P and the recommended maximum clamping arm length L.

50

12x45

34

56

+0.1

-0

10

80

40

10

12x45

38

175

F - Effective clamping force (KN)

L - Recommended clamping arm length (mm)

50

220

150

120

95

80

65

60

100

150

200

250

300

350

400

40

35

30

25

20

15

10

5

10

50

450

500

P - Pressure (bar)

MAQUINARIA INTERNACIONAL

(679 47 12 12)

I N N O VAT I V E E N G I N E E R I N G

Last update 01/2013

Вам также может понравиться

- Connecting Rod: EspecificacionesДокумент3 страницыConnecting Rod: Especificacioneseldiego1790Оценок пока нет

- ProductDetailzoCLD ScAd8AAAFTVK00II.LДокумент7 страницProductDetailzoCLD ScAd8AAAFTVK00II.Ljacob_scribdОценок пока нет

- STANDARD CHUCKS Technical SpecificationsДокумент8 страницSTANDARD CHUCKS Technical SpecificationshungОценок пока нет

- KGE1000Ti Service ManualДокумент41 страницаKGE1000Ti Service Manualmarksmods100% (1)

- H1000e K FJДокумент8 страницH1000e K FJSyarif HidayatullahОценок пока нет

- Hydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Документ6 страницHydraulic Cylinders CH: - Big Bore Sizes To Iso 6020-3 - Nominal Pressure 16 Mpa (160 Bar) - Max 25 Mpa (250 Bar)Stoianovici CristianОценок пока нет

- Fuel Injection Equipment: EspecificacionesДокумент29 страницFuel Injection Equipment: EspecificacionesSergio Ricardo IbañezОценок пока нет

- RepairStats Marine M100 M150 P3D32N003 Mar06Документ20 страницRepairStats Marine M100 M150 P3D32N003 Mar06Avi GoldmanОценок пока нет

- Apron Feeder Spare Part ListДокумент17 страницApron Feeder Spare Part ListParmeshwar Nath TripathiОценок пока нет

- Stihl 034 Parts ManualДокумент58 страницStihl 034 Parts ManualSonnie Ledbetter100% (2)

- Sab 163mk3 PartsДокумент15 страницSab 163mk3 PartsYacine MaricheОценок пока нет

- Caterpillar c6.6Документ23 страницыCaterpillar c6.6Marcos Astete Egoavil75% (4)

- JKV-2300 Series Hydraulic Cylinders Technical SpecificationsДокумент44 страницыJKV-2300 Series Hydraulic Cylinders Technical Specificationsmedi38Оценок пока нет

- Optimize CT2436 Jaw Crusher ManualДокумент13 страницOptimize CT2436 Jaw Crusher ManualVladimir Illich Pinzon100% (1)

- Yanmar 4tne88 TNE Series PDFДокумент15 страницYanmar 4tne88 TNE Series PDFluna281068Оценок пока нет

- Slit Type Rodless Cylinders 10: Actuators General CatalogДокумент6 страницSlit Type Rodless Cylinders 10: Actuators General CatalogSamik MukherjeeОценок пока нет

- Frenos de Servicio Cat 950H K5KДокумент19 страницFrenos de Servicio Cat 950H K5KhectorОценок пока нет

- Cylinder Liner ProjectionДокумент4 страницыCylinder Liner ProjectionFernando Daniel Saez VillarrealОценок пока нет

- Alpha Drives Eaton PTO BOMДокумент2 страницыAlpha Drives Eaton PTO BOMacconutОценок пока нет

- JДокумент32 страницыJlutherblackОценок пока нет

- Picture No - 3 Top Table GroupДокумент3 страницыPicture No - 3 Top Table Groupنعيم سلمانОценок пока нет

- 12 - Generator ReplacementДокумент2 страницы12 - Generator ReplacementAsimoОценок пока нет

- Service Information No. 990209 GBДокумент2 страницыService Information No. 990209 GBAndrei 26Оценок пока нет

- DR-MV1 PartДокумент19 страницDR-MV1 PartLuis TorcattОценок пока нет

- 3406e SpecificationsДокумент126 страниц3406e Specificationsnacho100% (6)

- Ancla Hidraulica D&L PDFДокумент5 страницAncla Hidraulica D&L PDFWLOPEZPAОценок пока нет

- WTI UK Screw Thread Inserts and Kits CatalogueДокумент16 страницWTI UK Screw Thread Inserts and Kits CatalogueThor InternationalОценок пока нет

- 04 550 Ver2Документ8 страниц04 550 Ver2Maria Gabriela BusteloОценок пока нет

- Datos de Reparacion de Motor Caterpillar c6.6Документ21 страницаDatos de Reparacion de Motor Caterpillar c6.6Marcos Astete EgoavilОценок пока нет

- Steam TrapДокумент2 страницыSteam TrapAmpornchai PhupolОценок пока нет

- Rotork 300 Quarter TurnДокумент4 страницыRotork 300 Quarter TurngullenariОценок пока нет

- DSL135 Power Swivel Drawing and Part ListДокумент33 страницыDSL135 Power Swivel Drawing and Part ListJIN WANGОценок пока нет

- Drawing A Crankcase - Concise for engine part diagramДокумент46 страницDrawing A Crankcase - Concise for engine part diagramManuel PedrosaОценок пока нет

- Suspension diagrams and parts list for 2009-2012 Top Fuel aluminum suspensionДокумент35 страницSuspension diagrams and parts list for 2009-2012 Top Fuel aluminum suspensionakti gonzo100% (1)

- Mazda B2500, 1999, 2.5L-SpecsДокумент4 страницыMazda B2500, 1999, 2.5L-SpecsAdiel Alexis Pérez100% (3)

- Chain CouplingДокумент3 страницыChain CouplingJong JavaОценок пока нет

- MK4 Posttensioning SpecificationsДокумент28 страницMK4 Posttensioning SpecificationsshashireshОценок пока нет

- Dolmar 116si 120si ServiceДокумент20 страницDolmar 116si 120si ServiceslickattitudewiОценок пока нет

- PERFORADORA MONTABERT HC50 RESEMIN S MAINTENANCE GUIDEДокумент12 страницPERFORADORA MONTABERT HC50 RESEMIN S MAINTENANCE GUIDERaphael Ruiz RamosОценок пока нет

- SAB163 MK4 SparesДокумент7 страницSAB163 MK4 SparesYutt WattОценок пока нет

- Hydraulic Cylinders CHДокумент8 страницHydraulic Cylinders CHStoianovici CristianОценок пока нет

- Drawing A Engine Housing: MS 231, MS 231 C, MS 251, MS 251 C 1 SCS 01-2011 3.33Документ26 страницDrawing A Engine Housing: MS 231, MS 231 C, MS 251, MS 251 C 1 SCS 01-2011 3.33Matthew100% (1)

- Manual for SAB 128 and SAB 163 Mk4 spare partsДокумент56 страницManual for SAB 128 and SAB 163 Mk4 spare partsyoye1968100% (3)

- Spare Part Manual bp350d Part 2 PDFДокумент35 страницSpare Part Manual bp350d Part 2 PDFnirmalОценок пока нет

- General mould components guideДокумент7 страницGeneral mould components guideНикола МедићОценок пока нет

- F640-5-1 459/10267 LAYSHAFT CLUTCH ASSEMBLY Parts CatalogДокумент3 страницыF640-5-1 459/10267 LAYSHAFT CLUTCH ASSEMBLY Parts CatalogMarcial Jr. MilitanteОценок пока нет

- Wind World W2700Документ60 страницWind World W2700paolosementa100% (1)

- Sab 163 MK2 ManДокумент6 страницSab 163 MK2 ManManuel perezОценок пока нет

- Parts Manual: Taurulift T 276 HДокумент115 страницParts Manual: Taurulift T 276 HMiguel ViegasОценок пока нет

- Modular Dual Line SystemДокумент6 страницModular Dual Line Systemangela_draguОценок пока нет

- Podizna Osovina SAFДокумент9 страницPodizna Osovina SAFPavle StevanovicОценок пока нет

- CS-315 Service DataДокумент4 страницыCS-315 Service DatamealysrОценок пока нет

- Turbo Nozzle Operating InstructionsДокумент3 страницыTurbo Nozzle Operating InstructionssailbirdОценок пока нет

- Toyo Rubber CouplingДокумент14 страницToyo Rubber CouplingGreg SanjayaОценок пока нет

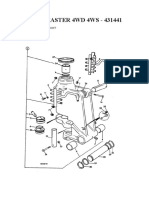

- 4CX SITEMASTER 4WD 4WS - 431441 Parts ListДокумент12 страниц4CX SITEMASTER 4WD 4WS - 431441 Parts ListHusi NihaОценок пока нет

- 11 - Perforadora Montabert Hc50Документ12 страниц11 - Perforadora Montabert Hc50Raphael Ruiz RamosОценок пока нет

- Crankshaft AssemblyДокумент80 страницCrankshaft AssemblyGreg HannaОценок пока нет

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОт EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceОценок пока нет

- SalerioДокумент28 страницSalerioRizqaFebrilianyОценок пока нет

- GER 3695e GE Aeroderivative Gas Turbines Design and Operating FeaturesДокумент24 страницыGER 3695e GE Aeroderivative Gas Turbines Design and Operating FeaturesTony AppsОценок пока нет

- Solar Turbines 2Документ12 страницSolar Turbines 2josethompson0% (1)

- Capitulo 04 Anexo 03 AlstomДокумент8 страницCapitulo 04 Anexo 03 AlstomJosue Fernandez MarquezОценок пока нет

- Technology Experience Innovation: GE Power SystemsДокумент20 страницTechnology Experience Innovation: GE Power SystemsVando SoaresОценок пока нет

- Capitulo 04 Anexo 01 SiemensДокумент8 страницCapitulo 04 Anexo 01 Siemensjfher87Оценок пока нет

- EUROPART Inter Catalog Bus Spare Parts 2014-09 EN PDFДокумент778 страницEUROPART Inter Catalog Bus Spare Parts 2014-09 EN PDFludiloliku67% (3)

- Centrifugal Chiller Brochure Daikin ASP 31-435LRДокумент6 страницCentrifugal Chiller Brochure Daikin ASP 31-435LREmilio PachecoОценок пока нет

- MC Stradale enДокумент58 страницMC Stradale enaiigee100% (2)

- Soils and Foundations - Failure behavior of soil nail reinforced slopesДокумент13 страницSoils and Foundations - Failure behavior of soil nail reinforced slopesRivaiОценок пока нет

- Non-Uniform Torsional Behavior and Stability of Thin-Walled Elastic Beams With Arbitrary Cross SectionsДокумент25 страницNon-Uniform Torsional Behavior and Stability of Thin-Walled Elastic Beams With Arbitrary Cross SectionsSimon TileОценок пока нет

- Mechanical Engineer Muhammad Ibtisam's ResumeДокумент1 страницаMechanical Engineer Muhammad Ibtisam's ResumeshoaibОценок пока нет

- AS4041 PresurecontainmentДокумент5 страницAS4041 PresurecontainmentJOHNKОценок пока нет

- Lectu 14Документ4 страницыLectu 14YeviraArinDiyanaОценок пока нет

- 207ACBH-2-SS Parker Brass FittingДокумент24 страницы207ACBH-2-SS Parker Brass FittingMROstop.comОценок пока нет

- User Munual For DENAIR Diesel Portable Air CompressorДокумент25 страницUser Munual For DENAIR Diesel Portable Air CompressorBoumediene CHIKHAOUIОценок пока нет

- Manual Controlador Lae MTR 6Документ3 страницыManual Controlador Lae MTR 6Anonymous 6VCG1YRd100% (2)

- Weekly Report TemplateДокумент14 страницWeekly Report TemplateOmar DhiebОценок пока нет

- ASTM A106 GR.B Steel Tube PDFДокумент2 страницыASTM A106 GR.B Steel Tube PDFKader KaderОценок пока нет

- Bottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofДокумент8 страницBottom Blowdown: Download The (295 KB) Try Answering The For This Tutorial View The Complete Collection ofsenaОценок пока нет

- Equipment Sizing Criteria TDEДокумент32 страницыEquipment Sizing Criteria TDEEngr. Anees Ahmad100% (1)

- Naza Ria Rover KV6 Engine Cam Marking Manual PDFДокумент7 страницNaza Ria Rover KV6 Engine Cam Marking Manual PDFAdrian PhillipsОценок пока нет

- Keckley - Control Valves mm2Документ23 страницыKeckley - Control Valves mm2DEVОценок пока нет

- Assignment 06Документ1 страницаAssignment 06anurag kumarОценок пока нет

- Section D Grilles and RegistersДокумент227 страницSection D Grilles and RegistersacrisostoОценок пока нет

- Introduction To Risk Based Inspection (RBI)Документ7 страницIntroduction To Risk Based Inspection (RBI)Alejandro LopezОценок пока нет

- Cup 04 HSP Uk Web PDFДокумент2 страницыCup 04 HSP Uk Web PDFcasda73Оценок пока нет

- TOTO MRP Price List - 01-04-2019Документ65 страницTOTO MRP Price List - 01-04-2019Joshua Gnanaraj100% (1)

- Honda Gs390 Owners Manual (Powerwasher)Документ60 страницHonda Gs390 Owners Manual (Powerwasher)Nate SpaydОценок пока нет

- BMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)Документ2 страницыBMQ 30m-Min - 1500mm (SK92172.1AD-IEC71-71LP)YeisonОценок пока нет

- Lecture 3 Pressure Measuring InstrumentsДокумент47 страницLecture 3 Pressure Measuring InstrumentsChristian Patrice100% (1)

- 114-3 Unit Assembling Check Sheet KOMATSU ENGINE 114-3-87874Документ12 страниц114-3 Unit Assembling Check Sheet KOMATSU ENGINE 114-3-87874เชิดศักดิ์ สอาดศรีОценок пока нет

- VOLVO AT2412D IshiftДокумент16 страницVOLVO AT2412D IshiftSaray Aljure Ospino100% (1)

- Design of Deck Girder BridgesДокумент65 страницDesign of Deck Girder BridgesEna Mie CambaОценок пока нет

- 1 - NDT Basics Ut, MT.,PT, RiДокумент20 страниц1 - NDT Basics Ut, MT.,PT, RiGMОценок пока нет

- 2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualДокумент382 страницы2000 BMW Z3 - M Roadster - Z3 - M Coupe Electrical Troubleshooting ManualShelli Godfrey100% (1)