Академический Документы

Профессиональный Документы

Культура Документы

Tank Baffles Design Calc

Загружено:

Jorge Alberto Martinez OrtizАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tank Baffles Design Calc

Загружено:

Jorge Alberto Martinez OrtizАвторское право:

Доступные форматы

Tank baffles Design Calc

Version 1.0

by Daniel de la Torre

Process Engineer

Intro

This template contains a series of calculation sheets to assist you in calculating the baffles dimen

Please note that if agitator is off-centered normally is not needed to install the baffles, as the ef

The main objectives are to provide a reference about baffles dimension and installation distance

Setup

1. There are 2 worksheets, one with Metric units (SI) and one with Imperial units

2. Individual worksheets are protected against inadvertant data entry. Unlocked cells appears with

3. To change any other cells, unlock the workbook (from the Tools/Protection pull-down menu)

4. The baffle size is calculated according to 2 methods, the one called cal 1 using the viscosity of th

See Calculations point for more details

Data Entry

5. Input data appears with blue text color

Results

6. Results appear in black text with yellow backgound

Revisions

7. Version 1.0

Calculations

8. Calculations are based on following assumptions

First version

Calculation 1

alc

culating the baffles dimension and position in a tank, when the tank has a central agitator

stall the baffles, as the effect is relatively similar, with a more clean installation

n and installation distances details a compare results between more than one calculation method

locked cells appears with blue text color. No password needed to unlock

tion pull-down menu)

1 using the viscosity of the product, while the one called calc 2 not using it

Calculation 2

Calc sheet developed by

Daniel de la Torre

Project name

Project or Process Engineer

Project Manager

Description

Product

Case

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

DESCRIPTION

Process tank number 1

Process tank number 2

Process tank number 3

Process tank number 4

Comments to: DeLaTorreY.Eng@gmail.com

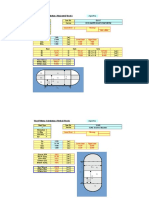

Diameter,

Dt

Height,

H

Viscosity

Ratio

mm

2600

mm

3000

cP

25

0.0805

Size of

Baffle acc.

calc 1

mm

209

Size of

Baffle acc.

calc 2 w/12

mm

217

Offset from

the Shell w/6

mm

36

Reference:

Min impeller & Max impeller

Diam

Diam

mm

780

mm

1560

Impeler

diameter d

Beginning of

baffle from

bottom - d/2

End of Baffle

from top of

Tank - H *10%

mm

1200

mm

600

mm

300

Calc sheet developed by

Daniel de la Torre

Project name

Project or Process Engineer

Project Manager

Description

Product

Case

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

Xxxxxxxxxxx

DESCRIPTION

Process tank number 1

Process tank number 2

Process tank number 3

Process tank number 4

Comments to: DeLaTorreY.Eng@gmail.com

Diameter,

Dt

Height,

H

Viscosity

Ratio

inch

102.0

inch

118.0

cP

25

0.0805

Size of

Size of Baffle

Baffle calc 2 calc 1

w/12

inch

8.2

inch

8.5

Offset from

the Shell w/6

inch

1.4

Reference:

Min impeller & Max impeller

Diam

Diam

inch

30.6

inch

61.2

Impeler

diameter d

Beginning of

baffle from

bottom - d/2

End of Baffle

from top of

Tank - H *10%

inch

47.2

inch

23.6

inch

11.8

Вам также может понравиться

- Tank Baffles Design CalcДокумент8 страницTank Baffles Design Calchamid vahedil larijani0% (1)

- Design of AgitatorДокумент3 страницыDesign of Agitatorkaps12Оценок пока нет

- Design of AgitatorДокумент3 страницыDesign of AgitatorManish PatelОценок пока нет

- 8KL FERMENTER DESIGN CALCULATIONSДокумент3 страницы8KL FERMENTER DESIGN CALCULATIONSkirandas_mullasseryОценок пока нет

- Agitator Guide for Mixing and Stirring Tank ProductsДокумент10 страницAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591Оценок пока нет

- AgitatorДокумент6 страницAgitatorSung Woong MoonОценок пока нет

- Sizing For Vaporiser/Flash Vessel: InputsДокумент3 страницыSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranОценок пока нет

- CycloneДокумент1 страницаCycloneEDUARDO100% (1)

- Allowable Nozzle LoadsДокумент7 страницAllowable Nozzle LoadsSiva baalanОценок пока нет

- Gas Scrubbers: DescriptionДокумент14 страницGas Scrubbers: DescriptionPitiporn HasuankwanОценок пока нет

- PFS FWKO Tank EvaluationДокумент12 страницPFS FWKO Tank EvaluationkoyahassanОценок пока нет

- Shaft diameter calculation for stainless steelДокумент1 страницаShaft diameter calculation for stainless steelAhmad Ashshiddieqy60% (5)

- Blind Plate or Manhole Cover DesignДокумент2 страницыBlind Plate or Manhole Cover DesignHarish Kumar MahavarОценок пока нет

- Vessel DatasheetДокумент1 страницаVessel Datasheetsdrtfg100% (1)

- Design of AgitatorДокумент12 страницDesign of AgitatorPatil HemantОценок пока нет

- External Pressure CalculationsДокумент40 страницExternal Pressure Calculationsmisterdavi50% (2)

- Screw Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoДокумент2 страницыScrew Conveyor Size 350, Input Data SR No Description Metric Unit in Fts SrnoTheodoros AtheridisОценок пока нет

- Base Ring Fillet Size CalculationДокумент4 страницыBase Ring Fillet Size Calculationmiteshpatel191Оценок пока нет

- Manhole Davit ArmДокумент1 страницаManhole Davit ArmgaratetaОценок пока нет

- Digester Design2Документ16 страницDigester Design2Pragathees WaranОценок пока нет

- Beam Spreadsheet: Ignore Lateral Torsional BucklingДокумент5 страницBeam Spreadsheet: Ignore Lateral Torsional BucklingPurnima ArkalgudОценок пока нет

- Vdocuments - MX Rectangular Tank CalculationДокумент34 страницыVdocuments - MX Rectangular Tank CalculationAtilla TekinОценок пока нет

- Weir Plate Design OptimizationДокумент6 страницWeir Plate Design OptimizationPugel Yeremias50% (2)

- Stress at Junction of Shell & HeadДокумент13 страницStress at Junction of Shell & HeadRey Fiedacan100% (1)

- Design of HCL FRP Storage TANKДокумент21 страницаDesign of HCL FRP Storage TANKHaries Bugarin GarciaОценок пока нет

- Vessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumДокумент4 страницыVessel Volume Calculation (Horizontal Vessel) : Head Type Item No. D-1527 Service Hcu Amine Drain Sump DrumDongwon ShinОценок пока нет

- Boiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFДокумент4 страницыBoiler and Pressure Vessel Engineering - Lifting Trunnion Common Practices PDFAlexandru AsmarandeiОценок пока нет

- Agitator DesignДокумент5 страницAgitator DesignSaepul RochmanОценок пока нет

- Agitator DesignДокумент9 страницAgitator DesignDeepika100% (1)

- Tailing Lug Design FormulaДокумент2 страницыTailing Lug Design FormulaRajeshОценок пока нет

- Burner specification document summaryДокумент6 страницBurner specification document summaryHafiz Muhammad AbubakarОценок пока нет

- Power Calculation For AgitatorДокумент12 страницPower Calculation For AgitatorDeepikaОценок пока нет

- Flow Rate CalculationДокумент7 страницFlow Rate CalculationManish PatilОценок пока нет

- Shell Tube Heat Exchanger DesignДокумент7 страницShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiОценок пока нет

- Coil Heat CalculationДокумент2 страницыCoil Heat CalculationTarmana Antt100% (1)

- Skirt Support Analysis Per en 13445Документ13 страницSkirt Support Analysis Per en 13445karthik1amarОценок пока нет

- Design-Calculation Acid Wash TankДокумент5 страницDesign-Calculation Acid Wash TankWiz DomОценок пока нет

- Power Requirement (Agitator and High-Torque Stirrer)Документ8 страницPower Requirement (Agitator and High-Torque Stirrer)DozdiОценок пока нет

- Design of Agitator 8 Batch Volume PDFДокумент3 страницыDesign of Agitator 8 Batch Volume PDFakash kumarОценок пока нет

- Condensate Line SizingДокумент2 страницыCondensate Line SizingAnonymous oVRvsdWzfBОценок пока нет

- WRC-107 Lifting Lugs - Vert. Vessel Vertical LiftДокумент5 страницWRC-107 Lifting Lugs - Vert. Vessel Vertical LiftManoj MulikОценок пока нет

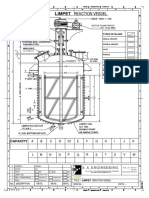

- Limpet Reaction Vessel PDFДокумент1 страницаLimpet Reaction Vessel PDFarajamani78Оценок пока нет

- Vertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010Документ16 страницVertical Storage Tank Heat Loss Calcs - Rev.1 31.12.2010jnmanivannanОценок пока нет

- Evaporator heat transfer and surface area calculationДокумент4 страницыEvaporator heat transfer and surface area calculationDaniyal HashmiОценок пока нет

- Calculation AgitatorДокумент3 страницыCalculation AgitatorKrishnaAgarwalОценок пока нет

- Agitator - Xls 0Документ2 страницыAgitator - Xls 0Prathmesh Gujarati100% (4)

- Half Pipe CalculationДокумент3 страницыHalf Pipe CalculationdhavaleshОценок пока нет

- Agitator DesignДокумент36 страницAgitator DesignnileshОценок пока нет

- Project : Agitator Power Calculations for 15L FermenterДокумент4 страницыProject : Agitator Power Calculations for 15L FermenterGunasekaranОценок пока нет

- Project Shell Entrance Area CalculationДокумент2 страницыProject Shell Entrance Area CalculationnagtummalaОценок пока нет

- Calculation Sheet: Design CodeДокумент1 страницаCalculation Sheet: Design CodeCak AndiОценок пока нет

- Agitator CalДокумент2 страницыAgitator Calvazzoleralex6884Оценок пока нет

- Coupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОт EverandCoupled CFD-DEM Modeling: Formulation, Implementation and Application to Multiphase FlowsОценок пока нет

- Tank Baffles Design CalcДокумент6 страницTank Baffles Design CalcnicolasОценок пока нет

- Smart Duct Sizer V 3.0Документ10 страницSmart Duct Sizer V 3.0ashishОценок пока нет

- Tutorial A Pipe System AnalysisДокумент38 страницTutorial A Pipe System AnalysisLuis OrtizОценок пока нет

- Manual For Stormwater Detention CalculatorДокумент10 страницManual For Stormwater Detention CalculatorgemotorresОценок пока нет

- CycloneДокумент22 страницыCyclonenaser hasan fauziОценок пока нет

- Thermal Analysis ExampleДокумент9 страницThermal Analysis ExampleTrung KiênОценок пока нет

- WAVE Tutorial 001Документ46 страницWAVE Tutorial 001Premkumarr SanthanammОценок пока нет

- Calcs For Pressure VesselДокумент4 страницыCalcs For Pressure VesselJorge Alberto Martinez OrtizОценок пока нет

- Calcs For Pressure VesselДокумент4 страницыCalcs For Pressure VesselJorge Alberto Martinez OrtizОценок пока нет

- Alfa Laval Pump Handbook PDFДокумент257 страницAlfa Laval Pump Handbook PDFkashifwarsiОценок пока нет

- Mechanical Engineer Jorge Martinez Design ServicesДокумент2 страницыMechanical Engineer Jorge Martinez Design ServicesJorge Alberto Martinez OrtizОценок пока нет

- Steam Table Chart with Pressure, Temperature and DensityДокумент122 страницыSteam Table Chart with Pressure, Temperature and DensityJorge Alberto Martinez OrtizОценок пока нет

- Business CardДокумент2 страницыBusiness CardJorge Alberto Martinez OrtizОценок пока нет

- Fire Protection Valves: Effective March 18, 2013 - Supercedes FPP-0312 of March 26, 2012Документ8 страницFire Protection Valves: Effective March 18, 2013 - Supercedes FPP-0312 of March 26, 2012Jorge Alberto Martinez OrtizОценок пока нет

- Distro TK SlopДокумент1 страницаDistro TK SlopJorge Alberto Martinez OrtizОценок пока нет

- Tablas Criterio de Selección CojinetesДокумент6 страницTablas Criterio de Selección CojinetesJorge Alberto Martinez OrtizОценок пока нет

- Ocean Out Fall Autumn 2010Документ2 страницыOcean Out Fall Autumn 2010Jorge Alberto Martinez OrtizОценок пока нет

- Specification For The Use of Steel Tanks in The Water Industry PDFДокумент15 страницSpecification For The Use of Steel Tanks in The Water Industry PDFJorge Alberto Martinez OrtizОценок пока нет

- Active Control Connected PlatesДокумент25 страницActive Control Connected PlatesJorge Alberto Martinez OrtizОценок пока нет

- WT Property Table Dimensions and SpecificationsДокумент5 страницWT Property Table Dimensions and SpecificationsJorge Alberto Martinez OrtizОценок пока нет

- Analysis of Nonlinear Steady State VibrationДокумент10 страницAnalysis of Nonlinear Steady State VibrationJorge Alberto Martinez OrtizОценок пока нет

- Kray-Leading Through Negotiation - CMR 2007Документ16 страницKray-Leading Through Negotiation - CMR 2007Rishita Rai0% (2)

- Board of Education Meeting Observation ReportДокумент3 страницыBoard of Education Meeting Observation ReportBidita RahmanОценок пока нет

- Introduction To Political PhilosophyДокумент6 страницIntroduction To Political PhilosophyMartina MartyОценок пока нет

- Heritage Tourism in IndiaДокумент13 страницHeritage Tourism in Indiavinay narneОценок пока нет

- Dosha NakshatrasДокумент3 страницыDosha NakshatrasNeo RagОценок пока нет

- Aho - Indexed GrammarsДокумент25 страницAho - Indexed GrammarsgizliiiiОценок пока нет

- PT 2 Pracba1Документ2 страницыPT 2 Pracba1LORNA GUIWANОценок пока нет

- UC Autism PDFДокумент7 страницUC Autism PDFcarlosОценок пока нет

- Ebook PDFДокумент55 страницEbook PDFrahul vivekОценок пока нет

- Robot Framework LatestДокумент410 страницRobot Framework LatestKei RxОценок пока нет

- Exercises in Structural DynamicsДокумент13 страницExercises in Structural DynamicsObinna ObiefuleОценок пока нет

- Happy Startup EbookДокумент72 страницыHappy Startup EbookLucca CinquarolliОценок пока нет

- Aral2019 Program PortraitДокумент8 страницAral2019 Program PortraitAldrich OОценок пока нет

- Apache Reverse ProxyДокумент14 страницApache Reverse ProxybripradОценок пока нет

- Higher Education Catalogue 2017Документ59 страницHigher Education Catalogue 2017AtifNazОценок пока нет

- Collecting Information & Forecasting DemandДокумент34 страницыCollecting Information & Forecasting DemandCinta NastasyaОценок пока нет

- ROHR2 InterfacesДокумент16 страницROHR2 InterfacesMarcia Akutsu MainardiОценок пока нет

- Standard Equations of Motion For Submarine Simulation: Graul R. LhgenДокумент42 страницыStandard Equations of Motion For Submarine Simulation: Graul R. LhgenVamsi GuptaОценок пока нет

- VP Supply Chain in Columbus OH Resume Belinda SalsbureyДокумент2 страницыVP Supply Chain in Columbus OH Resume Belinda SalsbureyBelinda Salsburey100% (1)

- Yogesh Kumar Garg Resume Mechanical EngineerДокумент3 страницыYogesh Kumar Garg Resume Mechanical EngineerYogeshGargОценок пока нет

- Dynamic Workload Console Installation GuideДокумент245 страницDynamic Workload Console Installation GuideGeetha Power100% (1)

- Phywe Tess Che Lec enДокумент108 страницPhywe Tess Che Lec enOlga Viviana Cardenas LunaОценок пока нет

- Instrumentation in Earthquake Seismology PDFДокумент365 страницInstrumentation in Earthquake Seismology PDFKumar PallavОценок пока нет

- Hosford W.F. Materials For Engineers (CUP, 2008) (ISBN 9780521899970) (O) (298s) - EMДокумент298 страницHosford W.F. Materials For Engineers (CUP, 2008) (ISBN 9780521899970) (O) (298s) - EMZeeshan AliОценок пока нет

- HemeДокумент9 страницHemeCadenzaОценок пока нет

- Ampac Xp95 DetectorДокумент4 страницыAmpac Xp95 DetectortinduongОценок пока нет

- Mario Tamitles Coloma JR.: POSITION DESIRE: Structural Welder/S.M.A.W/F.C.A.W ObjectivesДокумент3 страницыMario Tamitles Coloma JR.: POSITION DESIRE: Structural Welder/S.M.A.W/F.C.A.W ObjectivesJune Kenneth MarivelesОценок пока нет

- For The Sidereal Zodiac - Kenneth BowserДокумент3 страницыFor The Sidereal Zodiac - Kenneth BowserGuilherme Alves PereiraОценок пока нет