Академический Документы

Профессиональный Документы

Культура Документы

Seamless Supply Chain

Загружено:

RupeshKumarАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Seamless Supply Chain

Загружено:

RupeshKumarАвторское право:

Доступные форматы

Supply Chain Management: An International Journal

A seamless supply chain management model for construction

Peter E.D. LoveZahir IraniDavid J. Edwards

Article information:

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

To cite this document:

Peter E.D. LoveZahir IraniDavid J. Edwards, (2004),"A seamless supply chain management model for construction", Supply

Chain Management: An International Journal, Vol. 9 Iss 1 pp. 43 - 56

Permanent link to this document:

http://dx.doi.org/10.1108/13598540410517575

Downloaded on: 28 August 2014, At: 08:41 (PT)

References: this document contains references to 71 other documents.

To copy this document: permissions@emeraldinsight.com

The fulltext of this document has been downloaded 6403 times since 2006*

Access to this document was granted through an Emerald subscription provided by 563455 []

For Authors

If you would like to write for this, or any other Emerald publication, then please use our Emerald for Authors service

information about how to choose which publication to write for and submission guidelines are available for all. Please visit

www.emeraldinsight.com/authors for more information.

About Emerald www.emeraldinsight.com

Emerald is a global publisher linking research and practice to the benefit of society. The company manages a portfolio of

more than 290 journals and over 2,350 books and book series volumes, as well as providing an extensive range of online

products and additional customer resources and services.

Emerald is both COUNTER 4 and TRANSFER compliant. The organization is a partner of the Committee on Publication Ethics

(COPE) and also works with Portico and the LOCKSS initiative for digital archive preservation.

*Related content and download information correct at time of download.

Introduction

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Research paper

A seamless supply chain

management model for

construction

Time and schedule overruns, quality deviations

and poor health and safety continually plague

projects in the Australian construction industry

(CIDA, 1995; DIST, 1998). The habitual

nature of these aforementioned problems has

spurned numerous government-initiated

investigations. Findings emanating from these

investigations have been critical of the

industry's fragmented nature, lack of

coordination and communication between

participants, adversarial contractual

relationships, lack of a customer-supplier focus,

price-based selection, and ineffective use of

technology (e.g. APCC, 1997; DISR, 1999).

Such inadequate organizational and

management practices have contributed to

unnecessary costs, time waste, increased errors,

and misunderstandings between design

consultants and contractors (Love and Sohal,

2002). Ultimately, this has resulted in conflict,

rework, and in some instances litigation

occurring. The Australian government in close

consultation with various professional bodies

have recommended that the industry requires

reform, if improvements in quality, productivity

and performance are to be achieved (CIDA,

1994; DISR, 1999). This need for radical

improvement is not restricted to Australia

alone, as several other countries have received

similar calls, for example, Finland (KTM,

1996; Silen, 1997), Hong Kong (Grove, 1998;

Tang, 2001), Norway (Haugen, 1999), Sweden

(Kommerskollegium, 1996), Singapore

(Construct 21 Steering Committee, 1999) and

the UK (Latham, 1994; Egan, 1998).

Fundamentally, calls for improved

collaboration, integration, communication and

coordination between customers and suppliers

throughout the project supply chain have been

the leitmotiv of the published reports. Although

reports were critical of the industry, problems

encountered are not insuperable.

Several supply chain management (SCM)

initiatives such as alliancing/partnering, and

Peter E.D. Love

Zahir Irani and

David J. Edwards

The authors

Peter E.D. Love is a Professor in the We-B Centre, School of

Management Information Systems, Edith Cowan University,

Perth, Australia.

Zahir Irani is a Professor in the Department of Information

Systems and Computing, Brunel University, Uxbridge, UK.

David J. Edwards is a Lecturer in the Department of Civil

and Building Engineering, Loughborough University,

Loughborough, UK.

Keywords

Construction industry, Supply chain management,

Integration, Team working

Abstract

Presents a holistic approach to construction project SCM.

Specifically, a seamless project supply chain management

(SCM) model is proposed that integrates the design and

production processes of construction projects. The proposed

model was subjected to validation by a sample of industry

practitioners and their comments are presented and

reflected upon. Direction for future research is provided and

such work aims to: explore the legalities of implementing

the model; develop an appropriate benchmarking framework; explore the use of quality function development; and

probity issues when selecting project team members.

Electronic access

The Emerald Research Register for this journal is available at

www.emeraldinsight.com/researchregister

The current issue and full text archive of this journal is

available at

www.emeraldinsight.com/1359-8546.htm

The authors are most grateful to the two anonymous

referees and the editor, Dr Andrew Fearne, for their

helpful constructive comments, which helped

improve this manuscript. Finally, we would like to

acknowledge the financial support provided by the

Australian Research Council.

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . pp. 43-56

# Emerald Group Publishing Limited . ISSN 1359-8546

DOI 10.1108/13598540410517575

43

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

incentive-based contracting have been

sporadically implemented to ameliorate

construction project performance. Such

initiatives have often been used in conjunction

with traditional practices for managing and

controlling the project supply chain and as a

result, performance improvements have been

limited to the sub-process level (Vrijhoef and

Koskela, 2000). Moreover, as total quality

management (TQM) has not been practiced as

a philosophy by construction organizations

(specifically in Australia), many have been

unable to develop the vernacular skill and

experience required to effectively utilize the

tools and techniques needed to improve SCM

(Love and Sohal, 2002). Rather than apply

specific SCM initiatives in a fragmented ad hoc

manner to address project-orientated problems,

it is proposed that a holistic approach to project

SCM in construction is needed. Bearing this in

mind, a seamless project SCM model that

integrates the design and production processes

of a construction project is presented and

discussed.

Defining project SCM in construction

While many retail and manufacturing

organizations are capitalizing on implementing

SCM by attaining maximum business process

efficiency and effectiveness through intra and

inter organizational relations, the construction

industry has been slow, or perhaps even

reluctant, to employ the concept (Love, 2000).

The reasoning for the poor up-take of SCM in

construction is outside the scope of this paper.

However, longstanding efficient

supplier-contractor relations that are subject to

vulnerability due to the temporariness of

projects and the one-off nature of the product

are considered to be a major contributing factor

(Akintoye et al., 2000).

Consequently, construction project SCM

definitions have not been forthcoming in the

literature (Agapiou et al., 1998; Akintoye et al.,

2000; Love, 2000). Though Vollman et al.

(1998) have suggested that construction SCM

should be seen as an integrated set of practices

aimed at managing and co-ordinating the entire

chain from raw materials to end customers. As

no definition for project SCM in construction

exists, the following is proffered:

. . . the network of facilities and activities that

provide customer and economic value to the

functions of design development, contract

management, service and material procurement,

materials manufacture and delivery, and facilities

management.

Overview of supply chain management in

construction

Definitions of SCM applicable to general

industry (particularly retail and manufacturing)

abound in the literature. For example, Johnston

(1995) defines SCM as:

If the construction industry is to move from an

adversarial environment to one that is founded

on collaboration then it should openly embrace

SCM (e.g. Barker et al., 2000).

. . . the process of strategically managing the

movement and storage of materials, parts and

finished inventory from suppliers, through the firm

to customers.

SCM practice in construction

Whilst the application of SCM philosophies is

embryonic within the construction industry,

organizations are beginning to comprehend its

intrinsic value (Akintoye et al., 2000; Vrijhoef

and Koskela, 2000; Love, 2000; Dainty et al.,

2001). Pearson (1999) suggests that SCM has

replaced partnering in the UK construction

industry. However, Pearson (1999) reports that

only a few UK clients (BAA, the Ministry of

Defence, and Tesco) and contractors (Balfour

Beatty, and Tarmac) use SCM as an integrative

part of their business strategy for procuring

their projects. Furthermore, Pearson (1999)

notes that these clients and contractors have

Kranz (1996), on the other hand, suggests that

SCM is:

. . . the effort involved in producing and delivering

a final product from a supplier's supplier to the

customers' customer.

Fundamentally, SCM aims to increase the

transparency and alignment of a supply chain's

coordination and configuration, regardless of

functional or organisational boundaries

(Cooper and Ellram, 1993). Therefore, SCM

recognizes interdependency in the supply chain

and seeks to improve its configuration and

control base by integrating inter and intra

organizational business processes.

44

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

service quality (Hoxley, 2001), and purchasing

behaviour (Dubios and Gadde, 2000). Yet,

there is a clear dearth in research that takes a

holistic approach to SCM as applied to

construction projects (e.g. Barker et al., 2000).

reduced their supplier base; established and

nurtured relationships with suppliers; organized

training programmes to encourage a

cooperative approach to problem solving; and

developed systems for rating suppliers

performance on quality, speed and prices. In

doing so, clients and contractors hope to derive

greater discounts from a smaller number of

firms by supplying each with a greater volume

of work. In particular, Pearson (1999) states

that these firms involve suppliers at an early

stage in the project so as to acquire their

expertise about design and procurement issues.

In particular, Wong and Kanji (1998) have

suggested that when SCM is adopted in

conjunction with partnering and TQM, major

misailments that often plague construction

projects can be successfully addressed.

Similarly, Wong and Fung (1998) indicate that

SCM must be an integral part of a quality

management objective (and that the main

contractor must develop an enabling structure

and efficient communication system for

effective relationship management within their

projects. This is because the contractor is

invariably at the interface of the design and

production process.

The separation of the design and production

process in projects has been widely criticised

during the last 50 years or so (e.g. Simon

Report, 1944; Banwell, 1964; Latham, 1994;

and Egan, 1998). Consequently, there have

been endless calls to ``bridge this gap'' by

creating a seamless supply chain whereby the

interface between various phases of the project's

life cycle are integrated with one another. Love

et al. (2000) have suggested that each

organization involved with a project is both a

customer and supplier and therefore

consideration should be given as to how each

party can add value throughout the supply

chain (Figure 1). Indeed, according to

Lamming (1996), value should be given more

attention in a process rather than its cost.

Most research has tended to focus on specific

operational and tactical aspects of the supply

chain such as client-contractor relations

(Akintoye et al., 2000), contractor

subcontractor/supplier interface (Vrijhoef and

Koskela, 2000), rework (Love et al., 1999),

environmental performance (Ofori, 2000),

design management (Khalfan et al.., 2001),

Propagation of a seamless project SCM

model

To improve communication and minimize the

barriers to information flow in projects, Love

et al. (1998a) proposed that traditional project

structures, used for procuring projects, should

be replaced with a horizontal organization

structure founded on a multi-disciplinary team

approach. This implies that individuals and

groups work together concurrently rather than

sequentially, to design and develop both

product and process, and to ``jointly'' identify

materials and equipment required for

production.

In Figure 2 each team member maintains a

direct contact with the client throughout the

design development process. In addition, the

project SCM model has been designed to

stimulate collective learning, teamwork and

influence the development of a vibrant

psychosocial system. A fundamental

presupposition is that each organization

implements a form of TQM philosophy and

strives toward attaining ``industry best

practice''. The proposed project SCM model

illustrated in Figure 2 offers a collaborative

working arrangement where the design and

conflict resolution solutions are developed in a

concurrent style. Essentially, team members

perform better when the responsibility for

project development is shared (Nesan and Holt,

1999). This may have a positive effect on

reducing overall development time by limiting

design iterations, variations and sacrifices in

quality. The proposed model attempts to bring

together, in a holistic and integrated framework,

various design management and procurement

practices that are being implemented in a

piecemeal fashion within the construction

industry.

The project facilitator

A project facilitator (also often referred to as a

project manager) should oversee negotiations,

45

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Peter E.D. Love, Zahir Irani and David J. Edwards

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

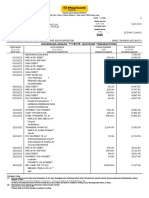

Figure 1 Customer-supplier interface in the project supply chain

2000). As the leader of the project, the

facilitator faces the challenge of realising

maximum team potential without implying

any hierarchical authority (Graham, 1996).

This can be, however, a difficult and

demanding task to undertake, especially

when strict time and cost schedules must be

adhered to.

Value management should be undertaken

prior to the production of the project's detailed

design and documentation stage so as to

minimise the impact of any change orders or

design rework that may be initiated by the

client, at a later stage. While some best

practice projects have demonstrated the

benefits of embracing value management

(Green, 1996), Australian clients have tended

not to embrace it because it is considered an

additional cost (Love, 2002a, b). Needless to

say, value management can enable the project

team (e.g. design consultants, quantity

surveyor (QS), main contractor and service

subcontractors) to evaluate the project's

functionality, cost, constructability and

method of construction.

As the project progresses through the various

stages of design development, the project

facilitator should undertake an audit and sign-off

each design stage as they are completed so that

the client's expectations are met and are

documented accordingly. The auditing process

should also form an integral part of a

benchmarking process. The establishment of a

series of benchmarks at specific interfaces could

be used to enable empowered clients (i.e. those

who are experienced) and project participants to

compare pre-defined metrics, which may include

monitor resources used and periodically

evaluate design progression on the client's

behalf during the design development phase

(Smith and Jackson, 2000). Instead of assuming

single point responsibility, it is proffered that

accountability for the design development

process is divided equally among the project

team. Shared accountability should improve the

quality of contract documentation produced

because team members are encouraged to

ensure that changes, if any, are coordinated and

errors and omissions are identified earlier in the

development process.

The effective implementation of the model

in practice requires a leader who can

coordinate and integrate activities and

resources throughout the entire procurement

process. Previous research suggests that an

independent project facilitator can effectively

stimulate and develop inter-organizational

communication between project participants

and therefore improve project performance

(Ofori, 2000). In this instance, the project

facilitator acts as a conduit through which

two-way communications would flow between

project team and client. Responsibilities

would include identifying the client's strategic

needs, and initiating and managing the design

development process. As mentioned above, it

is during the design process that the most

important decisions are made. Therefore,

necessity dictates that the client commission

an experienced project facilitator to effectively

plan, organize, lead and control the project

from inception, where strategic needs are

defined through to completion and possible

operation of the facility (Smith and Jackson,

46

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Peter E.D. Love, Zahir Irani and David J. Edwards

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Figure 2 A seamless project supply chain management model

On completion of the audit, the client must

be given the opportunity to sign-off on a

complete set of project information. Once

reviewed and accepted, the decision to proceed

to the following stage is taken. At this juncture,

the client and project team will sign all the

drawings as the agreed set, and thus avoid any

unnecessary ambiguity of intention. In essence,

the client should be made aware that design

alterations are costly and could delay project

completion. If changes (variations) are required

the number of request for information (RFI)

raised, time to respond to RFIs, number of

rework incidences by value, etc. against what has

been found to be best practice performance.

However, effective benchmarking requires

organizations to view the exercise as a positive

process of improvement rather than one that

``negatively'' exposes organizational weakness (Li

et al., 2001). Benchmarking is after all a process

of continuous learning and adaptation that results

in the development of an improved organization.

47

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

their expertise was being sought at this point

and that their input would be remunerated. No

guarantee of being selected for the project

should be provided to any subcontractor and/or

supplier tendering for the works.

An empowered client could specify that

consultants will be benchmarked, especially for

documentation quality produced, so as to

provide a mechanism for monitoring their

performance (Li et al., 2001). Incentives, such

as repeat work or a possible share in cost savings

made could be used as a basis for encouraging

an improved level of service quality. By using

the same project team members where possible,

a ``partnering culture'' founded on cooperation

and teamwork would be allowed to flourish (Li

et al., 2000). Such a culture would also provide

a paradigm for collective learning to take place

within the project (Love et al., 2002). That is,

the project team would develop knowledge by

working collectively as a whole; a symbiotic

``cohesive'' mass of professionals working

towards a common objective. On an

inter-personal level, individuals within the team

could learn about themselves and their team

members' requirements. Over time, the project

team members would exchange learning

experiences and develop new skills and

capabilities as well as enhance existing ones. In

doing so, the project team would learn to learn

together.

then they should be reviewed and authorized

using a systematic and structured scope and

change programme.

Together with the client, the project

facilitator would develop a functional brief

before selecting other project members. The

brief then constitutes the basis for defining

project activities and acts as a basis for

appointing the architect, engineering

consultants and QS. Once the architect,

engineers and QS have been selected, a fully

augmented design brief, concept and schematic

drawings and cost plan would be developed in

conjunction with the client and project

facilitator.

Project team selection

Traditional price-driven selection procedures

would not be used as they can limit the

flexibility of designers and contractors to

explore innovative avenues that can result in

optimal performance. Furthermore, traditional

price-driven selection procedures are deemed to

be ineffective, when used to ensure that clients

procure their buildings for the least possible

cost for a less than best product (Holt et al.,

2000; Walker et al., 2002). Ideally, the project

team selection process would use weighted

pre-qualification criteria, past performance and

a process of intensive negotiation. For example,

a reputable architect would be awarded

increased weightings for certain criteria such as

experience, qualifications of personnel, quality

of service provided, quality management,

current workload, strategic alliances, and so on

(Wong et al., 2001). The architect with the

highest aggregate weighting would then be

selected and subsequently, a fee would be

negotiated along with an employment

specification and contract.

Contractors who have the capability of

undertaking the project or who have worked

with the project facilitator and/or the design

consultants would be selected in a similar

manner, though their input will not be required

until the concept and schematic stage had been

completed. The contractor may also be given

the opportunity to recommend to the client (at

this stage in the project) key service

subcontractors and suppliers who they had

formed a strategic alliance with. The client

should notify subcontractors and suppliers that

Building a cohesive project team

By applying and utilizing quality function

deployment (QFD) (in conjunction within

information and communication technologies

(ICTs), any existing cultural, behavioural and

organizational barriers between disciplines

could be eliminated. Integral to the successful

implementation of the proposed model is the

ability of team members to become

customer-focused early in the project. Here

QFD will enable team members to understand

customer requirements exactly. Early team

member assimilation and QFD

implementation, may also stimulate a high

degree of commitment and an increased level of

motivation among team members.

The QFD process begins by analyzing and

listening to customers to determine the

characteristics of the products. Through

detailed discussion during the design process

48

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

A seamless supply chain management model for construction

Peter E.D. Love, Zahir Irani and David J. Edwards

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

each customer's needs and preferences are

defined and broken down into categories called

customer attributes. Customer attribute

information forms the basis for a matrix called

the house of quality. By building a matrix of

customer requirements the multi-disciplinary

team can use customer feedback to make

design, engineering and production decisions.

The matrix assists the team to translate

customer attribute information into specific

operating goals. The important product

characteristics and goals for improvement are

jointly agreed on and detailed in the house of

quality matrix. This process encourages

different disciplines with disparate goals to work

collectively and results in a better

understanding of one another's goals:

ultimately the team becomes customer focused

(Karma et al., 2000).

For teamwork to flourish within a

multi-disciplinary environment, all members

need to pursue common goals. It is therefore

vital that the project facilitator formulates these

goals in conjunction with team members at the

project's outset. Once these principal goals have

been collectively agreed, the project team will

establish a group mission, a series of project

objectives, milestones and a number of critical

success factors and performance indicators.

But, perhaps more importantly the goals that

are established need to be realistic.

Consequently, progress toward them should be

seen to be a significant motivation factor for all

team members. Implicitly, project performance

is intricately linked with the team's

cohesiveness. Cohesiveness is the extent to

which individuals or groups are attracted to a

team and desire to remain in it (Levine and

Moreland, 1990). The degree of group

cohesiveness is a complex phenomenon that

results from combining the net attraction or

repulsion for each member (Kast and

Rosenzweig, 1985). As values, norms and

attitudes invariably differ, instances of

attraction or repulsion will occur. Hence, in

extreme circumstances a highly functional, or

dysfunctional, team may evolve.

If each individual and group aligns their goals

with that of the project organization (e.g. time,

cost, quality, client satisfaction, innovation),

then behaviour will most likely be functional

from an organizational perspective.

Nevertheless, each participating individual and

group will invariably have sub-goals that they

will pursue (e.g. marketing, turnover, survival,

training). These may clash with one another,

and may not be compatible with those of the

project. It is therefore important that the project

facilitator aligns these sub-goals with those of

the project so that a win-win scenario is

nurtured. The likelihood of the project team

becoming cohesive will be increased through

the use of a multi-disciplinary approach

Though excessive levels of team cohesiveness

may have dysfunctional consequences such as

tendencies to negatively stereotype outsiders,

team illusions of invulnerability, complacency,

and team isolation.

The nature of a project organization can have

an adverse affect on project effectiveness

because of inherent ambiguity in role and task

orientation experienced by individuals and

groups (Katz, 1982). Therefore, the proposed

model attempts to eliminate individual role

ambiguity through the use of a

multi-disciplinary ``entity'' team relationship.

Each team member is empowered with

responsibility and encouraged to be creative

and innovative. Team members are made aware

that they are solely accountable to the project

facilitator during the design process. This point

of accountability subsequently transfers to the

main contractor when the process of novation

has taken place. As the degree of cohesiveness

between members becomes explicit, role and

task orientation will evidently become

multi-functional.

Communication has been linked to team

effectiveness, the integration of work units

across organizational levels, characteristics of

effective supervision, job satisfaction, and

overall organizational effectiveness. In fact,

organizations are essentially complex

communication processes that create and

change events (Shockley-Zalaback, 1991).

Consequently, improved organizational

communication will play a significant part in

determining the effectiveness of the proposed

model in improving project performance. The

degree of communication effectiveness is

essentially a product of the project team's

ability to gel as a cohesive unit. The utilization

of ICTs within projects should enable team

members to have greater accessibility to one

49

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

another. This may enable a greater degree of

interaction between team members and thus

contribute to an effective communication

process in the project. ICTs have an important

role to play, as information can be stored more

efficiently and decision making enhanced.

Moreover, ICT can act as an interface between

functional disciplines, facilitating rapid

information exchange, and shared information.

Improving information flow throughout the

procurement process, especially during the

design process, should minimize variations and

rework. As variations and rework are

minimized, perhaps even eliminated, then a

greater degree of client satisfaction should be

attained.

Design development

The client would be encouraged to be actively

involved in the design process, as a committed

client can play a crucial role in assuming

responsibility for initiating, directing and

maintaining the momentum of a project (Ofori,

2000). During the design process the project

facilitator would essentially assume the role of a

pseudo-design manager. In doing so, a

design-planning scheme should be established

to determine the logical sequence for

information transfer among project team

members, thus avoiding any unnecessary

assumptions about the project that may occur.

In conjunction with QFD, tools such as the

analytical design planning technique (ADePT),

which utilise the design structure matrix

(Steward, 1981) can be used to identify missing

information, variations in the quality of

information exchange between participants and

thus can prevent costly design iterations (Austin

et al., 2000). Essentially, ADePT focuses on

efficient planning and management of design,

by scheduling design tasks on the basis of their

information requirements, thereby producing a

detailed programme of the optimised design

process. Prior to, and during, the

commencement of the detailed design and

documentation phase of the project, individual

project team members would be responsible for

the following:

.

the architect would present ideas on how

the client's requirements can be best met

aesthetically and functionally and provide

the detailed design documentation;

the engineers would design and develop the

structural and services capabilities required,

and in conjunction with the architect

provide detailed design documentation;

the QS would produce cost plans,

undertake life-cycle costing analysis and

cost checks as the design is developed

through its various stages;

the contractor and subcontractors

(including hydraulics, mechanical and

electrical subcontractors) would develop

and plan workable production strategies,

schedules, work methods using the last

planner concept (see below);

the key suppliers would propose material

and equipment alternatives; and

if a development project, then property and

marketing specialists organize tenant's or

potential purchasers.

Each member of the project team should be

encouraged to use computer aided

design/engineering (CAD/CAE) technologies

linked to electronic document management

systems (EDMS). By using linked CAD/E and

EDMS most facets of the product development

process can access the same design from

different disciplines by using a common

CAD/CAE database. Hence, the proposed

linked systems will support communication and

information transfer, exchange, retrieval, and

storage throughout the production process.

Noteworthy, there must be a convenient

platform on which different organisations

involved in procuring a project can work and

communicate simultaneously. For example, in

the case of architects and engineers, this

platform could be an advanced form of

CAD/CAE, which has solid and parametric

modelling capabilities. Increasing evidence

suggests that utilizing CAD/CAE can lead to

major reductions in rework and design time

(Karma et al., 2000).

Production process

Throughout the production process, the project

facilitator would assume an active coordination

role to ensure that the project runs smoothly

and specifically encourage the implementation

of lean production principles, which include the

reduction of activity cycle times and process

variability, and optimisation of resource flows.

50

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

example, an architect fails to provide approvals

for shop drawings; this can delay the fabrication

process, and the delivery of materials to site,

which may have an impact on the project's

critical path. As the available float disappears

from the schedule, increasing pressure is placed

on people involved within that specific chain to

minimise the delay's impact. This can further

exacerbate the situation and increase the

likelihood of errors being made as people work

harder to meet the program dates. Thus,

Ballard and Howell (1997) state that if the

traditional approach to planning worked

perfectly then did would always match should.

The ``last planner'' is responsible for the

operational planning of the production process

(Ballard, 1994). So, stabilising the work

environment begins by learning to make and

keep commitments to doing what should be

done, only to the extent it can be done. As the

foreman is typically the last planner in a project

they should select only those activities that can

and will be done rather than those activities that

should be done to compensate the project's

schedule (Howell et al., 1993).

Working closely with subcontractors will

enable the foreman to determine the resources

needed for what can be done (Ballard, 2000). If

what should be done is addressed instead, then

the site workforce may inherit the uncertainty

and variation of workflow that have not been

prevented. Resultantly, a high degree of

non-productive time and a de-motivated

workforce may transpire. The ``last planner

approach'' shields the site workforce from

up-steam variation and uncertainty and

therefore improves the ability to control

capability and variability of the workface.

The architect and engineering consultants

would be novated to the main contractor. In

other words, the architect and engineering

consultants' contract with the client is

discharged and substituted with a contract with

the contractor. The commencement of this

process varies depending on the client's

requirements. For example, design consultants

could be novated to the contractor when the

design is anywhere from 20 per cent to 80 per

cent complete (Love et al., 1998b). In doing so,

the main contractor would accept the risk and

assume single point responsibility for the

project. At this point it is proposed that a QS

would act in an advisory capacity to the client,

project facilitator and main contractor. It is

envisaged that the main contractor would offer

a guaranteed maximum price to complete the

project with any savings shared between

themselves, the client and possibly the

designers, key subcontractors and suppliers.

The key subcontractors and suppliers would be

invited to submit a competitive price to

undertake the work. In this case the QS would

act as the client's auditor, and would have

preliminary benchmarks for budgeting the

works. The main contractor would be

responsible for selecting the remaining

subcontractors and suppliers, although

preference would be given to those with whom

the main contractor had formed a strategic

alliance.

Contractor and subcontractor interface

Poor planning and coordination on the

contractor's behalf can directly influence the

resource planning of subcontractors. So, the

project team, specifically the contractor and

subcontractor, need to ensure that any remedies

used to overcome project deviations cause

minimal disruption and delays. In deriving

effective remedies to reduce variability and

stabilise the flow of work activities, the

traditional approach to project planning needs

to be re-examined (Koskela, 2000). According

to Ballard and Howell (1997), the traditional

approach to project planning is effective for

informing people about what should be done, as

it is used to monitor and enforce conformance

of ``did'' to ``should''. This can work well until

something goes wrong and then a chain

reaction of unforseen events can unfold. For

Model validation: practitioners'

perspectives

The validation process sought expert opinions

on the validity of the model presented in

Figure 2 for improving the performance of the

projects. Semi-structured interviews were

undertaken with six industry practitioners who

had a combined total of 100 years industry

experience. These being a consultant project

manager, a project architect, a project QS, a

construction manager, mechanical and

51

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

pragmatic solution to resolving a complex

problem how to improve project

performance? The architect was opposed to the

model as it threatened the architect's traditional

role in the project delivery process. The idea of

being novated to a contractor was not

appealing, as it was suggested that the design of

a building would be compromised. Moreover,

the architect stated that quality control and

supervision of the project would be jeopardised

and that the shift in responsibility would inflate

the project's cost.

While the architect made some pertinent

observations, these issues have been given due

consideration in the model's development. For

example, the contractor would only be selected

for the project if they were quality assured.

What is more, audits in conjunction with a

proactive programme would ensure that quality

is built into the project and supervision

improved. Arguably, the project's initial cost

may be inflated, but it is suggested that this

additional cost would far outweigh the costs

associated with changes, rework and schedule

growth. Likewise, the idea of a novated

contractual strategy received a degree of

scepticism from the M&E consultant and

contractor. This was primarily because they

were not familiar with this approach, despite its

increasing popularity (Chan, 1994; Love et al.,

1998b). The contractor pointed out that there

were a number of disadvantages that could be

foreseen with this arrangement, which

included:

.

The demand for an experienced contractor

who is able to manage the design and

construction process. However, this point

can be addressed using a stringent

pre-qualification process.

.

The contractor assumes responsibility for

design omissions, errors and any other

problems that may have arisen during the

design. The inclusion of the contractor

during the design will enable them to

obtain a full understanding of how the

design has progressed. In addition, the

contractor can concentrate on developing

their construction programme and methods

prior to commencement on-site.

electrical (M&E) engineering consultant, and a

foreman for a mechanical subcontractor.

Unfortunately, several experienced clients were

unavailable to comment on the validity of the

proposed model.

Each interview was conducted on a

one-to-one basis so as to stimulate conversation

and break down any preconceived ``mental''

barriers and presuppositions that may have

existed between the interviewer and

interviewee. The interviewee was allowed to

talk freely without interruption or intervention.

Using this approach the interviewer acquired a

clearer picture of their perspective while

avoiding introducing any bias.

Validation of findings

Interviewees were generally open-minded and

enthusiastic about the proposed project SCM

model identified in Figure 2, especially the

notion of creating a multi-disciplinary team

during the project's formative phases. The use

of value management was identified as being

extremely important by the QS, though it was

pointed out that it was often difficult to

persuade clients to pay for this service. The

notion of identifying client's strategic needs,

then developing a brief was identified as being a

logical and systematic approach to take during

the design process. Although, the architect

would have resented the fact that a project

facilitator had an active role in developing the

client's brief. Challenging the traditional role of

the professional will always create a degree of

resentment, but it is something the industry

must do if the performance of projects is to be

improved.

The consultant project manager was familiar

with the QFD process and had used this

technique in previous projects. Other

interviewees were unaware of this technique

and how it could be used as part of the project

scoping strategy. The concept of QFD has only

recently begun to penetrate construction, so it

could be a while before it is regularly used in

projects (Love and Sohal, 2002). Every one of

the interviewees agreed that the model could

stimulate teamwork and a collective learning

environment, especially if the same team were

used on another project. With the exception of

the architect, all the other interviewees

considered the project SCM model to be a

The consultant project manager and QS

considered the idea of using a novated contract

52

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

as challenging and possibly rewarding way to

procure projects. It was suggested that the model

would certainly improve communication,

especially if ICTs were used in an integrated

manner. Considering the interviewees'

comments, it is suggested that the prosed model

is a valid approach that could potentially

improve project performance. However, before it

is effectively implemented in practice,

construction organizations must adopt a

customer-value focus founded on TQM so that

inter-organizational relations can be established

and a best practice culture nurtured.

Issues relating to the selection of project

team members if a public sector client were

to adopt the proposed SCM model.

Currently, public sector client's are subject

to public accountability so issues relating to

probity should be explored.

Clients' reactions to the model need to be

obtained as they ultimately pay for the delivery

of the product that is being procured. The

validation process was limited to the viewpoints

of six experienced industry practitioners, and

therefore it is acknowledged that the opinions

sought are not representative of the ``entire''

industry. Consequently, the proposed SCM

model needs to be exposed to a wider

population to gain feedback on its validity so it

can be refined and made suitable for

implementation within the project supply chain.

Implications for future research

The proposed SCM model has taken a

pragmatic approach to integrating design and

production processes in construction but

requires further development in several areas

before it can be applied in an industrial setting.

Areas requiring further research include:

.

The legal issues surrounding the allocation

of risk and responsibility specifically design

liability. According to Gaafar and Perry

(1999) the extent of liability is not

necessarily dependent on who does what,

but rather who accepts liability? So in this

instance further research is needed to

explore the ramifications of adopting a

novation contractual strategy proposed in

the project SCM model.

.

The design and development of a

benchmarking framework, in particular

metrics, for evaluating the interface

between project life-cycle phases.

.

Exploring how architects and engineers

can utilize QFD in an integrated

and systematic way. As noted above,

the technique is not currently being

used by practitioners to assist them during

the design process (Love and Sohal,

2002), hence, the palpable benefits of

QFD need to be explored more

definitively. Several researchers have

provided demonstrable evidence that

QFD is effective in construction (e.g.

Mohamed, 1995; Karma, 1999;

Abdul-Rahman et al., 1999), yet it

remains an enigma as to why it has not

been embraced more widely.

Conclusion

Supply chain management is an emerging

concept in the construction industry. In this

paper, a holistic SCM is proposed that can be

used to procure construction projects. The

proposed model is not radically different from

some of the forms of design and construct

procurement systems that are currently being

used within the industry. The main difference

lays in the emphasis that is placed on

inter-organizational collaboration, cooperation

and learning. In essence therefore, the new

approach proposed represents a move towards

assimilating a symbiotic project team entity. It

signifies a definite positive move away from the

traditional fragmented project team where

professionals within it aspire to disparate goals

and objectives. If such a model were to be

implemented, it would have to be client-driven,

that is, by either public or experienced private

clients and initially managed by the project

facilitator who would act as a catalyst for the

novation process. Therefore, it is necessary they

are educated about the potential time and cost

savings that could be acquired through

implementing the project SCM model. If a

significant reduction cost savings can be

achieved, clients may well invest these savings

into other facilities and thus use the same

project team to deliver their future projects.

53

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Peter E.D. Love, Zahir Irani and David J. Edwards

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Once experienced clients have acquired the

benefits of the proposed model, then small and

occasional clients may follow suit.

Consequently, this may significantly improve

the performance and productivity of the

construction industry, its services to

construction clients and its contribution to

gross domestic product.

Solutions, Construction Industry Development Agency

and Masters Builders Australia, Sydney.

CIDA (1995), Measuring Up or Muddling Through: Best

Practice in the Australian Non-Residential

Construction Industry, Construction Industry

Development Agency and Masters Builders Australia,

Sydney.

Cooper, M.C. and Ellram, L.M. (1993), ``Characteristics of

supply chain management and the implications for

purchasing and logistics strategy'', International

Journal of Logistics Management, Vol. 4 No. 2,

pp. 13-24

Construct 21 Steering Committee (1999), Construct 21,

Ministry of Manpower and Ministry of National

Development, Singapore.

Dainty, A., Briscoe, G.H. and Millet, S. (2001), ``New

perspectives on construction supply chain integration'',

Supply Chain Management: An International Journal,

Vol. 6 No. 4, pp. 163-73.

DIST (1998), Building for Growth: A Draft Strategy for the

Building and Construction Industry, Department of

Industry, Science and Tourism, Commonwealth of

Australia Publication, February, Canberra.

DISR (1999), Building for Growth: An Action Agenda for the

Building and Construction Industries, a report for

Government by the National Building and

Construction Committee, The Department of Industry,

Science and Tourism, Canberra.

Dubios, A. and Gadde, L-E. (2000), ``Supply strategy and

network effects purchasing behaviour in the

construction industry'', European Journal of Purchasing

and Supply Management, Vol. 6 No. 3-4, pp. 207-15.

Egan, J. Sir (1998), Rethinking Construction, Construction

Task Force report, Department of the Environment,

Transport and the Regions, London.

Gaafar, H.K. and Perry, J.G. (1999), ``Limitation of design

liability for contractors'', International Journal of

Project Management, Vol. 17 No. 5, pp. 301-8.

Graham, J.H. (1996), ``Machiavellian project managers:

do they perform better?'', International Journal of

Project Management, Vol. 14 No. 2, pp. 64-7.

Green, S. (1996), ``A metaphorical analysis of client

organisations and the briefing process'', Construction

Management and Economics, Vol. 14 No. 1,

pp. 155-64.

Grove, J.B. (1998), Consultant's Report on Review of

General Conditions of Contract for Construction Works

for the Government of the Hong Kong Special

Administrative Region, available at:

www.constructionweblinks.com/Resources/

Industry_Reports__ Newsletters/Nov_6_ 2000/

grove_report.htm

Haugen, T.J. (1999), ``The building process: challenges in a

changing environment'', Proceedings of the Nordic

Seminar on Construction Economics and Organisation,

12-13 April, Goteborg, pp. 29-32.

Holt, G.D., Proverbs, D. and Love, P.E.D. (2000), ``Survey

findings on UK construction procurement: is it

achieving lowest cost, or value?'', Asia Pacific Building

and Construction Management Journal, Vol. 5 No. 2,

pp. 13-20.

References

Abdul-Rahman, H., Kwan, C.L. and Woods, P.C. (1999),

``Quality function deployment in construction design:

application in low-cost housing design'', International

Journal of Quality & Reliability Management, Vol. 16

No. 6, pp. 591-605.

Agapiou, A., Flanagan, R., Norman, G. and Notman, D.

(1998), ``The changing role of builders' merchants in

the construction supply chain'', Construction

Management and Economics, Vol. 16, pp. 351-61.

Akintoye, A., McIntosh, G. and Fitzgerald, E. (2000), ``A

survey of supply chain collaboration and management

in the UK construction industry'', European Journal of

Purchasing and Supply Management, Vol. 6 No. 3-4,

pp. 159-68.

APCC (1997), Construct Australia: Building a Better

Construction Industry in Australia, The Australian

Procurement and Construction Council Inc., Deakin

West.

Austin, S., Baldwin, A., Li, B. and Waskett, P. (2000),

``Analytical design planning technique (ADePT): a

dependency structure matrix tool to schedule the

building design process'', Construction Management

and Economics, Vol. 18 No. 2, pp. 173-82.

Ballard, G. (1994), The Last Planner, Northern Californian

Construction Institute, Monterey, CA.

Ballard, G. (2000), Phase Scheduling. White Paper #7, Lean

Construction Institute, 27 April, available at:

www.leanconstruction.org

Ballard, G. and Howell, G. (1997), ``Shielding production: an

essential step in production control'', ASCE

Construction Engineering and Management, Vol. 124

No. 1, pp. 11-17.

Banwell, H. (1964), The Placing and Management of

Contracts for Building and Civil Engineering Works

(The Banwell Report), HMSO, London.

Barker, R., Hong-Minh, S. and Naim, M.M. (2000), ``The

terrain scanning methodology: assessing and

improving construction supply chains'', European

Journal of Purchasing and Supply Management, Vol. 6

No. 3-4, pp. 179-93.

Chan, A.P.C. (1994), ``Evaluation of novation contract'',

Proceedings of the National Construction

Management Conference, University of New South

Wales, Sydney, 17-18 February, pp. 383-96.

CIDA (1994), Transforming Construction: The Total Project

Approach Managing Change-Achieving Integrated

54

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

A seamless supply chain management model for construction

Peter E.D. Love, Zahir Irani and David J. Edwards

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Howell, G., Laufer, A. and Ballard, G. (1993), ``Interaction

between sub-cycles: one key to improved methods'',

ASCE Journal of Construction, Engineering and

Management, Vol. 119 No. 4, pp. 714-28.

Hoxley, M. (2001), ``Purchasing UK public sector property

and construction professional services: competition v.

quality'', European Journal of Purchasing and Supply

Management, Vol. 7 No. 2, pp. 133-9.

Johnston, P. (1995), ``Supply chain management: past, the

present and the future'', The Manufacturing Engineer,

pp. 213-17.

Karma, J.M. (1999), ``Client requirements processing for

concurrent life-cycle design and construction'',

unpublished PhD thesis, University of Teeside,

Middlesbrough.

Karma, J.M., Anumba, C.J. and Evbuomwan, N.F.O. (2000),

``Developments in the implementation of concurrent

engineering in construction'', Computer-Integrated

Design and Construction, Vol. 2 No. 1, pp. 68-78.

Kast, F.E. and Rosenzweig, J.E. (1985), Organisation and

Management: A Systems and Contingency Approach,

4th ed., McGraw-Hill, New York, NY, pp. 279-389.

Katz, K. (1982), ``The effects of group longevity on project

communication and performance'', Administrative

Science Quarterly, Vol. 27, pp. 81-104.

Khalfan, M.M.A, Anumba, C.J., Siemieniuch, C.E. and

Sinclair, M.A. (2001), ``Readiness assessment of the

construction supply chain for concurrent engineering'',

European Journal of Purchasing and Supply

Management, Vol. 7 No. 2, pp. 141-53.

Kommerskollegium (1996), Byggesktorn Spelregler for

okad Konkurrens (Building Sector Rules for

Increased Competition), Stockholm.

Koskela, L. (2000), An Exploration Towards a Production

Theory and its Application to Construction, VTT

Technical Research Centre of Finland, Espoo.

Kranz, S. (1996), ``What is it?'', Purchasing Today, October,

p. 4.

KTM (1996), Laatu Rakentamisen Menestrystekijaksi

(Quality as a Success Factor in Construction), KTM

Tyoryhma ja Toimikuntaraportteja, Helsinki.

Lamming, R. (1996), ``Squaring the lean supply with supply

chain management'', International Journal of

Operations & Production Management, Vol. 16 No. 2,

pp. 183-96.

Latham, M. (1994), Constructing the Team: Joint Review of

Procurement and Contractual Arrangements in the UK

Construction Industry, Department of the

Environment, London.

Levine, J.M. and Moreland, R.L. (1990), ``Progress in small

group research'', Annual Review of Psychology,

Vol. 41, pp. 585-634.

Li, H., Cheng, E.W.L. and Love, P.E.D. (2000), ``Partnering

research in construction'', Engineering Construction

and Architectural Management, Vol. 7 No. 1,

pp. 76-92.

Li, H., Cheng, E.W.L., Love, P.E.D. and Irani, Z. (2001),

``Cooperative benchmarking: a tool for partnering

excellence in construction'', International Journal of

Project Management, Vol. 19 No. 3, pp. 171-9.

Love, P.E.D. (2000), ``Construction supply chains'', European

Journal of Purchasing and Supply Management, Vol. 6

No. 3-4, pp. 145-7.

Love, P.E.D. (2002a), ``Influence of project type and

procurement method on rework costs in building

construction projects'', ASCE Journal of Construction,

Engineering and Management, Vol. 128 No. 1,

pp. 18-29.

Love, P.E.D. (2002b), ``Determinants of rework in Australian

construction projects'', unpublished PhD thesis, Faculty

of Business and Economics, Monash University,

Melbourne.

Love, P.E.D. and Sohal, A.S. (2002), ``Influence of

organisational learning practices on rework costs in

projects'', Proceedings of the Eighth International

Conference on ISO 9000 & TQM (Change

Management), Centre for Management Quality

Research (CMQR) at RMIT University, RMIT Storey

Hall, Melbourne, 13-15 April.

Love, P.E.D., Gunasekaran, A. and Li, H. (1998a), ``Putting an

engine into re-engineering: toward a process based

organisation'', International Journal of Operations &

Production Management, Vol. 18 No. 9, pp. 937-49.

Love, P.E.D., Li, H. and Mandal, P. (1999), ``Rework: a

symptom of dysfunctional supply chain'', European

Journal of Purchasing and Supply Management, Vol. 5

No. 1, pp. 1-11.

Love, P.E.D., Skitmore, R.M. and Earl, G. (1998b), ``Selecting

a suitable procurement method for a building project'',

Construction Management and Economics, Vol. 16

No. 2, pp. 221-33.

Love, P.E.D., Irani, Z., Cheng, E.W.L. and Li, H. (2002), ``A

model for supporting inter-organisational relations in

the supply chain'', Engineering, Construction and

Architectural Management, Vol. 9 No. 1, pp. 2-15.

Love, P.E.D., Li, H., Irni, Z. and Faniran, O. (2000), ``Total

quality management and the learning organization: a

dialogue for change in construction'', Construction

Management and Economics, Vol. 18 No. 3,

pp. 321-32.

Mohamed, S. (1995), ``Improving construction through QFD'',

Proceedings of the First Pacific Rim Symposium on

Quality Deployment, 12th-14 February, Macquarie

University, Sydney, Australia, pp. 233-8.

Nesan, J-L. and Holt, G.D. (1999), Empowerment in

Construction: The Way Forward for Performance

Improvement, Research Studies Press, Taunton.

Ofori, G. (2000), ``Greening the construction supply chain in

Singapore'', European Journal of Purchasing and

Supply Management, Vol. 6 No. 3-4, pp. 195-206.

Pearson, A. (1999), ``Chain reaction'', Building, 12 March,

pp. 54-5.

Shockley-Zalaback, P. (1991), Fundamentals of

Organisational Communication, Longman, New York,

NY, pp. 7-8.

Silen, T. (1997), Kansallista Laatustrategiaa Koskeva Selvitys

(Investigation Concerning a National Quality Strategy),

Kauppa ja Tellisuusministerion Tutimuksia ja

Raportteja 15, Helsinki.

55

A seamless supply chain management model for construction

Supply Chain Management: An International Journal

Volume 9 . Number 1 . 2004 . 43-56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

Peter E.D. Love, Zahir Irani and David J. Edwards

Simon Report (1944), Report of the Management and

Planning of Contracts (The Simon Report), HMSO,

London.

Smith, J. and Jackson, N. (2000), ``Strategic needs analysis:

its role in brief development'', Facilities, Vol. 18

No. 13-14, pp. 502-12.

Steward, D.V. (1981), ``The design structure system: a

method for managing the design of complex systems'',

IEEE Transactions on Engineering Management, Vol. 1

No. 3, pp. 71-4.

Tang, H. (2001), Report of the Construction Industry Review

Committee, Hong Kong, available at: www.wb.gov.hk/

report.htm

Vollman, T., Cordon, C. and Raabe, H. (1998), Supply Chain

Management: Mastering Management, Pitman,

London.

Vrijhoef, L. and Koskela, L. (2000), ``The four roles of supply

chain management in construction'', European Journal

of Purchasing and Supply Chain Management, Vol. 6

No. 3-4, pp. 169-78.

Walker, D.H.T., Hampson, K. and Peters, R. (2002), ``Project

alliancing v. project partnering: a case study of the

Australian National Museum project'', Supply Chain

Management: An International Journal, Vol. 7 No. 2,

pp. 83-91.

Wong, A. and Fung, P. (1998), ``Total quality management in

the construction industry in Hong Kong. A supply

chain management perspective'', Total Quality

Management, Vol. 10 No. 2, pp. 199-208.

Wong, A. and Kanji, G.K. (1998), ``Quality culture in the

construction industry'', Total Quality Management,

Vol. 9 No. 4-5, pp. 133-40.

Wong, C.H., Holt, G.D. and Harris, P.T. (2001),

``Pre-qualification criteria a survey of UK

construction practitioners' opinions'', Journal of

Construction Research, Vol. 2 No. 1, pp. 41-56.

Further reading

Ballard, G. (1997), ``Lean construction and EPC performance

improvement'', in Alarcon, L. (Ed.), Lean Construction,

Balkema, Lisse, pp. 79-91.

Gyles, R. (1992), Royal Commission into Productivity in the

Building Industry in New South Wales, Vol. 1-10,

Sydney.

O'Brien, W.J. (1999), ``Construction supply chain

management: a vision for advanced co-ordination,

costing and control'', Proceedings of the

Berkeley-Stanford Construction Engineering and

Management Workshop: Defining a Research Agenda

for AEC Process/Product Development in 2000 and

Beyond, 26-28 August, University of California,

Berkeley, CA.

56

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

This article has been cited by:

1. Lon L. olde Scholtenhuis, Andr G. Dore. 2014. High reliability organizing at the boundary of the CM domain. Construction

Management and Economics 32, 658-664. [CrossRef]

2. Jonathan Gosling, Denis R. Towill, Mohamed M. Naim, Andrew R. J. Dainty. 2014. Principles for the design and operation of

engineer-to-order supply chains in the construction sector. Production Planning & Control 1-16. [CrossRef]

3. Nenad u-Babi, Danijel Rebolj, Matja Nekrep-Perc, Peter Podbreznik. 2014. Supply-chain transparency within industrialized

construction projects. Computers in Industry 65:2, 345-353. [CrossRef]

4. Stuart Tennant, Scott Fernie. 2014. Theory to practice: A typology of supply chain management in construction. International

Journal of Construction Management 14:1, 72-87. [CrossRef]

5. Mohd Nasrun Mohd Nawi, Santhisegaran Nadarajan, Mohd Faizal Omar, Mohd Azian Zaidi, Mohd Fadzil Mat Yasin, M.A.

Othuman Mydin, A.I. Che Ani. 2014. Towards Integrated Team Practice: A Case of Malaysian Industrialised Building System

(IBS) Construction Projects. E3S Web of Conferences 3, 01014. [CrossRef]

6. Mohd Nasrun Mohd Nawi, Nazim Baluch, Ahmad Yusni Bahauddin, M.A. Othuman Mydin, N.A. Agus Salim. 2014. Impact

of Fragmentation Issue in Construction Industry: An Overview. MATEC Web of Conferences 15, 01009. [CrossRef]

7. Mohd Nasrun Mohd Nawi, Santhisegaran Nadarajan, Mohd Faizal Omar, Mohd Azian Zaidi, Mohd Fadzil Mat Yasin, M.A.

Othuman Mydin, N.A. Agus Salim. 2014. Towards Integrated Team Practice: A Case of Malaysian Industrialised Building System

(IBS) Construction Projects. MATEC Web of Conferences 15, 01025. [CrossRef]

8. Liu Bo, Shen Ju-Qin, Tan Fei ., Wang Da-Wei ., Tang Liang ., Xu Zi-Lin .. 2013. Study on the Influence Factor System of

Engineering Project Schedule in Construction Supply Chain Model. Journal of Applied Sciences 13:19, 4057-4061. [CrossRef]

9. Prof. Mohammed Arif, Prof. Matt Syal, John Muhumuza Kakitahi, Anne Landin, Henry M. Alinaitwe. 2013. An exploratory

study of rework causality in Uganda. Construction Innovation 13:3, 266-280. [Abstract] [Full Text] [PDF]

10. Linda D. Peters, Andrew D. Pressey, Markus Vanharanta, Wesley J. Johnston. 2013. Constructivism and critical realism as

alternative approaches to the study of business networks: Convergences and divergences in theory and in research practice.

Industrial Marketing Management 42:3, 336-346. [CrossRef]

11. Lena Elisabeth Bygballe, Hkan Hkansson, Marianne Jahre. 2013. A critical discussion of models for conceptualizing the

economic logic of construction. Construction Management and Economics 31:2, 104-118. [CrossRef]

12. Stuart Tennant, Scott Fernie. 2013. Organizational learning in construction supply chains. Engineering, Construction and

Architectural Management 20:1, 83-98. [Abstract] [Full Text] [PDF]

13. Davide Aloini, Riccardo Dulmin, Valeria Mininno, Simone Ponticelli. 2012. Supply chain management: a review of

implementation risks in the construction industry. Business Process Management Journal 18:5, 735-761. [Abstract] [Full Text]

[PDF]

14. Patrick X. W. Zou, Paul Couani. 2012. Managing risks in green building supply chain. Architectural Engineering and Design

Management 8:2, 143-158. [CrossRef]

15. Hong Long Chen. 2012. Empirical behavioral analysis of project contractors' supplychain payment terms. Supply Chain

Management: An International Journal 17:3, 277-289. [Abstract] [Full Text] [PDF]

16. Stuart Tennant, Scott Fernie. 2012. The commercial currency of construction framework agreements. Building Research &

Information 40:2, 209-220. [CrossRef]

17. Xianhai Meng. 2012. The effect of relationship management on project performance in construction. International Journal of

Project Management 30:2, 188-198. [CrossRef]

18. Gary D. Holt, David J. Edwards. 2012. Innovation or business survival?. Construction Innovation 12:1, 99-122. [Abstract] [Full

Text] [PDF]

19. O. Kwon, G.P. Im, K.C. Lee. 2011. An agent-based web service approach for supply chain collaboration. Scientia Iranica 18:6,

1545-1552. [CrossRef]

20. Des Doran, Mihalis Giannakis. 2011. An examination of a modular supply chain: a construction sector perspective. Supply Chain

Management: An International Journal 16:4, 260-270. [Abstract] [Full Text] [PDF]

21. Gunjan Soni, Rambabu Kodali. 2011. A critical analysis of supply chain management content in empirical research. Business Process

Management Journal 17:2, 238-266. [Abstract] [Full Text] [PDF]

Downloaded by SP JAIN INSTITUTE OF MANAGEMENT AND RESEARCH At 08:41 28 August 2014 (PT)

22. Rodney McAdam, ShirleyAnn Hazlett, Sean Johnston. 2011. Establishing ex ante public construction supply chain guidelines

in the public procurement of schools' estate. International Journal of Public Sector Management 24:3, 250-273. [Abstract] [Full

Text] [PDF]

23. Florence Crespin-Mazet, Philippe Portier. 2010. The reluctance of construction purchasers towards project partnering. Journal

of Purchasing and Supply Management 16:4, 230-238. [CrossRef]

24. Anders Segerstedt, Thomas Olofsson, Lars Bankvall, Lena E. Bygballe, Anna Dubois, Marianne Jahre. 2010. Interdependence

in supply chains and projects in construction. Supply Chain Management: An International Journal 15:5, 385-393. [Abstract]

[Full Text] [PDF]

25. Ivan K.W. Lai, Frankie K.S. Lam. 2010. Perception of various performance criteria by stakeholders in the construction sector in

Hong Kong. Construction Management and Economics 28:4, 377-391. [CrossRef]

26. Vanita Ahuja, Jay Yang, Ravi Shankar. 2009. Benefits of collaborative ICT adoption for building project management. Construction

Innovation 9:3, 323-340. [Abstract] [Full Text] [PDF]

27. Heng Li, Hongling Guo, Miroslaw J. Skibniewski, Martin Skitmore. 2008. Using the IKEA model and virtual prototyping

technology to improve construction process management. Construction Management and Economics 26:9, 991-1000. [CrossRef]

28. I. Adetunji, A. D. F. Price, P. Fleming. 2008. Achieving sustainability in the construction supply chain. Proceedings of the ICE

- Engineering Sustainability 161:3, 161-172. [CrossRef]

29. James Sommerville. 2007. Defects and rework in new build: an analysis of the phenomenon and drivers. Structural Survey 25:5,

391-407. [Abstract] [Full Text] [PDF]

30. Nina Modig. 2007. The division of responsibility for project supply. Journal of Purchasing and Supply Management 13:2, 87-97.

[CrossRef]

31. Chandika Diran Wickramatillake, S.C. Lenny Koh, A. Gunasekaran, Subramanium Arunachalam. 2007. Measuring performance

within the supply chain of a large scale project. Supply Chain Management: An International Journal 12:1, 52-59. [Abstract]

[Full Text] [PDF]

32. Khalid Karim, Marton Marosszeky, Steven Davis. 2006. Managing subcontractor supply chain for quality in construction.

Engineering, Construction and Architectural Management 13:1, 27-42. [Abstract] [Full Text] [PDF]

33. Xiaolong Xue, Xiaodong Li, Qiping Shen, Yaowu Wang. 2005. An agent-based framework for supply chain coordination in

construction. Automation in Construction 14:3, 413-430. [CrossRef]

Вам также может понравиться

- Din 8743 PDFДокумент35 страницDin 8743 PDFSanjeev Reddy Kasula100% (2)

- Organisation Structure To Support Concurrent Engineering in ConstructionДокумент11 страницOrganisation Structure To Support Concurrent Engineering in ConstructionAhmed Adel MoemenОценок пока нет

- The Maverick Case ChallengeДокумент4 страницыThe Maverick Case ChallengefaskdkjdbkjОценок пока нет

- Norsok R-003, Safe Use of Lifting EquipmentДокумент58 страницNorsok R-003, Safe Use of Lifting EquipmentPatranОценок пока нет

- Azure Devops Vs GitlabДокумент8 страницAzure Devops Vs GitlabdebajyotiguhaОценок пока нет

- International Journal of Quality & Reliability Management: Article InformationДокумент24 страницыInternational Journal of Quality & Reliability Management: Article InformationasyrafmuhddОценок пока нет

- Lean Management in The Context of Construction Supply ChainsДокумент16 страницLean Management in The Context of Construction Supply Chainsmimarpolat23Оценок пока нет

- Improving Construction Supply Chain An CollaborationДокумент12 страницImproving Construction Supply Chain An CollaborationCitizen Kwadwo AnsongОценок пока нет

- Supply Chain Management Research PaperДокумент23 страницыSupply Chain Management Research PapersahilkaushikОценок пока нет

- Sustainable Construction Literature ReviewДокумент5 страницSustainable Construction Literature Reviewafdtorpqk100% (1)

- Construction Project ProcurementДокумент19 страницConstruction Project ProcurementRupeshKumarОценок пока нет

- Critical Review of Procurement Method Research in Construction JournalsДокумент8 страницCritical Review of Procurement Method Research in Construction JournalsArunkumar TalantiОценок пока нет

- 2006 3.content.07613Документ21 страница2006 3.content.07613Trang NgoОценок пока нет

- Identifying Barriers in Lean Implementation in The Construction IndustryДокумент12 страницIdentifying Barriers in Lean Implementation in The Construction Industryr4kinОценок пока нет

- 5430 Key Antecedents Practices Supply Chain Management Adoption Project ContextsДокумент16 страниц5430 Key Antecedents Practices Supply Chain Management Adoption Project ContextsfedorОценок пока нет