Академический Документы

Профессиональный Документы

Культура Документы

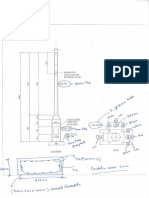

Mono Rail Connection

Загружено:

waquarshaiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Mono Rail Connection

Загружено:

waquarshaiАвторское право:

Доступные форматы

Profis Anchor 2.4.

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

1

ATS

23/11/2014

Specifier's comments:

1 Input data

Anchor type and diameter:

HVZ M16x105

Dynamic set or any suitable annular gap filling solution

Effective embedment depth:

hef = 105 mm, hnom = 125 mm

Material:

8.8

Evaluation Service Report:

ETA 03/0032

Issued I Valid:

4/6/2013 | 4/6/2018

Proof:

SOFA design method + fib (07/2011) - after ETAG testing

Stand-off installation:

eb = 0 mm (no stand-off); t = 16 mm

Anchor plate:

lx x ly x t = 400 mm x 400 mm x 16 mm; (Recommended plate thickness: not calculated)

Profile:

Advance UKB; (L x W x T x FT) = 303 mm x 165 mm x 10 mm x 10 mm

Base material:

cracked concrete, C25/30, fc = 25.00 N/mm2; h = 250 mm, Temp. short/long: 0/0 C

Reinforcement:

no reinforcement or reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

no longitudinal edge reinforcement

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.9

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

2

ATS

23/11/2014

2 Load case/Resulting anchor forces

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Anchor

Tension force

Shear force

Shear force x

1

17.700

0.300

0.000

2

17.700

0.300

0.000

3

18.500

0.300

0.000

4

18.500

0.300

0.000

max. concrete compressive strain:

- []

max. concrete compressive stress:

- [N/mm2]

resulting tension force in (x/y)=(0/3):

72.400 [kN]

resulting compression force in (x/y)=(0/0): 0.000 [kN]

Shear force y

0.300

0.300

0.300

0.300

Tension

3 Tension load SOFA (fib (07/2011), section 10.1)

Load [kN]

18.500

Steel Strength*

Pullout Strength*

Concrete Breakout Strength**

Utilization bN [%]

31

Status

OK

N/A

N/A

N/A

N/A

72.400

94.713

77

OK

N/A

N/A

N/A

N/A

Splitting failure**

* anchor having the highest loading

Capacity [kN]

60.000

**anchor group (anchors in tension)

3.1 Steel Strength

NRk,s [kN]

90.000

gM,s

1.500

NRd,s [kN]

60.000

NSd [kN]

18.500

3.2 Concrete Breakout Strength

Ac,N [mm2]

347475

A0c,N [mm2]

99225

yA,N

3.502

ccr,N [mm]

158

scr,N [mm]

315

ec1,N [mm]

0

yec1,N

1.000

ec2,N [mm]

3

yec2,N

0.979

ys,N

1.000

N0Rk,c [kN]

41.423

gM,c

1.500

NRd,c [kN]

94.713

NSd [kN]

72.400

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

yre,N

1.000

k1

7.700

Profis Anchor 2.4.9

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

3

ATS

23/11/2014

4 Shear load SOFA (fib (07/2011), section 10.2)

Load [kN]

0.300

Steel Strength (without lever arm)*

Steel failure (with lever arm)*

Capacity [kN]

40.800

Utilization bV [%]

1

Status

OK

N/A

N/A

N/A

N/A

Pryout Strength**

1.200

193.413

OK

Concrete edge failure in direction y+**

0.600

40.085

OK

* anchor having the highest loading

**anchor group (relevant anchors)

4.1 Steel Strength (without lever arm)

VRk,s [kN]

51.000

gM,s

1.250

VRd,s [kN]

40.800

VSd [kN]

0.300

Ac,N [mm2]

347475

A0c,N [mm2]

99225

yA,N

3.502

ccr,N [mm]

158

scr,N [mm]

315

k4

2.000

ec1,V [mm]

0

yec1,N

1.000

ec2,V [mm]

0

yec2,N

1.000

ys,N

1.000

yre,N

1.000

N0Rk,c [kN]

41.423

gM,c,p

1.500

VRd,c1 [kN]

193.413

VSd [kN]

1.200

4.2 Pryout Strength

4.3 Concrete edge failure in direction y+

lf [mm]

105

dnom [mm]

18.0

kV

1.700

a

0.039

c1 [mm]

700

Ac,V [mm2]

587500

A0c,V [mm2]

2205000

yA,V

0.266

ys,V

1.000

yh,V

2.049

ya,V

1.000

ec,V [mm]

0

yec,V

1.000

V0Rk,c [kN]

220.230

n1

2

gM,c

1.500

VRd,c [kN]

40.085

VSd [kN]

0.600

b

0.039

yre,V

1.000

y90,V

2.000

Note: Resistance limit acc. to fib (07/2011) Eq. (10.2-7) is governing

5 Combined tension and shear loads SOFA (fib (07/2011), section 10.3)

steel

bN

0.308

bV

0.007

a

2.000

Utilization bN,V [%]

10

Status

OK

concrete

0.764

0.015

1.500

68

OK

bN + bV <= 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

13.704 [kN]

dN

0.167 [mm]

VSk

0.222 [kN]

dV

0.019 [mm]

dNV

0.168 [mm]

Long term loading:

NSk

13.704 [kN]

dN

0.557 [mm]

VSk

0.222 [kN]

dV

0.028 [mm]

dNV

0.558 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the anchor plate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.9

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

4

ATS

23/11/2014

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

The design method ETAG (filled holes) assumes that no hole clearance between the anchors and the fixture is present. This can

be

achieved by filling the gap with mortar of sufficient compressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

The design method fib (07/2011) assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by

filling the gap with mortar of sufficient sompressive strength (e.g. by using the Hilti Dynamic Set) or by other suitable means.

The compliance with current standards (e.g. EC3) is the responsibility of the user

Checking the transfer of loads into the base material is required in accordance with fib (07/2011)!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.4.9

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

5

ATS

23/11/2014

8 Installation data

Anchor plate, steel: Anchor type and diameter: HVZ M16x105

Profile: Advance UKB; 303 x 165 x 10 x 10 mm

Installation torque: 0.090 kNm

Hole diameter in the fixture: df = 18 mm

Hole diameter in the base material: 18 mm

Plate thickness (input): 16 mm

Hole depth in the base material: 125 mm

Recommended plate thickness: not calculated

Minimum thickness of the base material: 210 mm

Cleaning: Manual cleaning of the drilled hole according to instructions for use is required.

8.1 Required accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Manual blow-out pump

y

200

50

200

Setting

HVA square drive shafts

Dynamic set

Torque wrench

300

200

200

2

50

75

250

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

-125

125

-125

125

y

-150

-150

150

150

c-x

-

c+x

-

c-y

-

c+y

700

700

400

400

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

75

Profis Anchor 2.4.9

www.hilti.co.uk

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Page:

Project:

Sub-Project I Pos. No.:

Date:

6

ATS

23/11/2014

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- 20200311133916451Документ3 страницы20200311133916451waquarshaiОценок пока нет

- Retaining Wall (Type-1) Calculation-Rev01Документ10 страницRetaining Wall (Type-1) Calculation-Rev01waquarshaiОценок пока нет

- TDH 0500 SS RP 0107 - R1Документ3 страницыTDH 0500 SS RP 0107 - R1waquarshaiОценок пока нет

- X Direction 16Документ1 страницаX Direction 16waquarshaiОценок пока нет

- Foundation Design For 150 MM Area Longitudinal Bars (Along Y Direction)Документ2 страницыFoundation Design For 150 MM Area Longitudinal Bars (Along Y Direction)waquarshaiОценок пока нет

- X Direction 16Документ1 страницаX Direction 16waquarshaiОценок пока нет

- CBSE Syllabus For KG Class PDFДокумент10 страницCBSE Syllabus For KG Class PDFwaquarshai80% (5)

- Lec17 Bearing CapacityДокумент57 страницLec17 Bearing CapacityMuhammad EhtshamОценок пока нет

- DESIGN CALCULATION For Scaffolding PlatformДокумент6 страницDESIGN CALCULATION For Scaffolding PlatformwaquarshaiОценок пока нет

- A.2. Punching Shear Check: (Plate Short Dimension) (Plate Long Dimension)Документ1 страницаA.2. Punching Shear Check: (Plate Short Dimension) (Plate Long Dimension)waquarshaiОценок пока нет

- Tower Crane 02Документ104 страницыTower Crane 02waquarshaiОценок пока нет

- 6 PDFДокумент1 страница6 PDFwaquarshaiОценок пока нет

- TQ.037-Al Sadd 3 SubstationДокумент1 страницаTQ.037-Al Sadd 3 SubstationwaquarshaiОценок пока нет

- Suspension Hook - 300 0Kg - Details: 350 THK RC SlabДокумент1 страницаSuspension Hook - 300 0Kg - Details: 350 THK RC SlabwaquarshaiОценок пока нет

- CBSE Syllabus For KG Class PDFДокумент10 страницCBSE Syllabus For KG Class PDFwaquarshai80% (5)

- RaftДокумент2 страницыRaftwaquarshaiОценок пока нет

- Arch SupportДокумент1 страницаArch SupportwaquarshaiОценок пока нет

- Chequered Plate Technical Details PDFДокумент2 страницыChequered Plate Technical Details PDFwaquarshaiОценок пока нет

- Deck 2Документ2 страницыDeck 2waquarshaiОценок пока нет

- 3 M Pole Details PDFДокумент1 страница3 M Pole Details PDFwaquarshaiОценок пока нет

- 3 M Pole DetailsДокумент1 страница3 M Pole DetailswaquarshaiОценок пока нет

- Analysis of Moment Resisting ConnectionsДокумент30 страницAnalysis of Moment Resisting ConnectionswaquarshaiОценок пока нет

- Schematic Design Drawings: SAFE V12.0.0Документ1 страницаSchematic Design Drawings: SAFE V12.0.0waquarshaiОценок пока нет

- Job No Sheet No Rev: Whole Structure Displacements 1000mm:1m 1 DEAD LOADДокумент6 страницJob No Sheet No Rev: Whole Structure Displacements 1000mm:1m 1 DEAD LOADwaquarshaiОценок пока нет

- BS5950 Load CasesДокумент46 страницBS5950 Load CasesthespecifierОценок пока нет

- Flat SlabДокумент1 страницаFlat SlabwaquarshaiОценок пока нет

- Steel Parapet 02-04-2014Документ119 страницSteel Parapet 02-04-2014waquarshaiОценок пока нет

- RAPIDSHOREДокумент44 страницыRAPIDSHOREwaquarshai100% (1)

- RAPIDSHOREДокумент44 страницыRAPIDSHOREwaquarshai100% (1)

- Wind LoadingДокумент34 страницыWind LoadingwaquarshaiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- Lerdge-Gcode List V3.0.5Документ108 страницLerdge-Gcode List V3.0.5osman perez vidalОценок пока нет

- Reflective Lesson Plan 4 Pythagorean TheoremДокумент9 страницReflective Lesson Plan 4 Pythagorean Theoremapi-339897912100% (1)

- Bacterial ClassificationДокумент2 страницыBacterial ClassificationAndrew JavierОценок пока нет

- Highwall Miner HWM 300Документ20 страницHighwall Miner HWM 300Amit100% (1)

- Clauses & PhrasesДокумент2 страницыClauses & PhrasesmrskumarОценок пока нет

- MKT4419 Final ReportДокумент28 страницMKT4419 Final ReportGlenn HengОценок пока нет

- Speciifactions and Cross Reference Bosch Spark PlugДокумент3 страницыSpeciifactions and Cross Reference Bosch Spark Plugcarlos puerto100% (1)

- Anchor Lliberty Mpa ManДокумент8 страницAnchor Lliberty Mpa ManIgnacio Barriga NúñezОценок пока нет

- VB For PowerpointДокумент5 страницVB For PowerpointSfm FuadОценок пока нет

- 235practice Exam 2 AnswerДокумент9 страниц235practice Exam 2 Answernbobs7Оценок пока нет

- Irjet V4i10201 PDFДокумент8 страницIrjet V4i10201 PDFBesmir IsmailiОценок пока нет

- DF1740N PLCC Modem Catalog: DescriptionДокумент3 страницыDF1740N PLCC Modem Catalog: DescriptionmanishОценок пока нет

- Dcs 2019 Questions PaperДокумент14 страницDcs 2019 Questions PaperDASHARATH VISHAWAKARMAОценок пока нет

- Class and ObjectsДокумент15 страницClass and ObjectsIwan SaputraОценок пока нет

- Question Report - 11Документ17 страницQuestion Report - 11Suryakant AgrawalОценок пока нет

- Time-Domain Analysis of The Linear SystemsДокумент32 страницыTime-Domain Analysis of The Linear SystemskamalОценок пока нет

- Mcknight - Proposed Mastering Eq PDFДокумент3 страницыMcknight - Proposed Mastering Eq PDFIordan Dan FfnОценок пока нет

- Module 1Документ45 страницModule 1Leigh Kyster BenlotОценок пока нет

- Comba ODV-065R15E18J-GДокумент1 страницаComba ODV-065R15E18J-GGaga ChubinidzeОценок пока нет

- Training - Manual - Diagnostic - and - Troublesh CPC 202GДокумент186 страницTraining - Manual - Diagnostic - and - Troublesh CPC 202GGA AnnerОценок пока нет

- R134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFДокумент16 страницR134a HXWC Series Water Cooled Screw Flooded Chillers Cooling Capacity 200 To 740 Tons 703 To 2603 KW Products That Perform PDFmohamad chaudhariОценок пока нет

- CHE504 - Lab Report On Gas Absorption L8 PDFДокумент23 страницыCHE504 - Lab Report On Gas Absorption L8 PDFRakesh KumarОценок пока нет

- Heat and Thermodynamics According To KPK Textbook & Sindh TextbookДокумент15 страницHeat and Thermodynamics According To KPK Textbook & Sindh Textbookswatmiandam44Оценок пока нет

- Microstation Tutorial 01Документ85 страницMicrostation Tutorial 01Anonymous 82KmGf6Оценок пока нет

- Mechanics of Solids by Crandall, Dahl, Lardner, 2nd ChapterДокумент118 страницMechanics of Solids by Crandall, Dahl, Lardner, 2nd Chapterpurijatin100% (2)

- JLN550 InstalДокумент54 страницыJLN550 InstalCostas PeppasОценок пока нет

- Ee 494 AДокумент43 страницыEe 494 AGopinath B L NaiduОценок пока нет

- UACE BIO PAPER TWO SET 3 2023-JusanДокумент3 страницыUACE BIO PAPER TWO SET 3 2023-JusanCampbell OGENRWOTОценок пока нет

- Full Download Test Bank For Information Technology Project Management 9th Edition Kathy Schwalbe PDF Full ChapterДокумент36 страницFull Download Test Bank For Information Technology Project Management 9th Edition Kathy Schwalbe PDF Full Chapterpannageimban.81c15100% (16)

- Coding Bobol ExcelДокумент4 страницыCoding Bobol ExcelMuhammad IsmunandarsyahОценок пока нет