Академический Документы

Профессиональный Документы

Культура Документы

Eigen Modes - PDF Timesaving-Torsiondesign-Ia PDF

Загружено:

George GeorgianОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Eigen Modes - PDF Timesaving-Torsiondesign-Ia PDF

Загружено:

George GeorgianАвторское право:

Доступные форматы

Eigen Modes.

pdf

Timesaving-TorsionDesign-IA.pdf

TIME SAVING DESIGN AID

Page 1 of 23

Torsion Design

The following example illustrates the design methods presented in the PCA book Simplified Design Reinforced Concrete Buildings of Moderate Size and Height third edition. Unless otherwise noted, all

referenced table, figure, and equation numbers are from that book.

Example Building

Below is a partial plan of a typical floor in a cast-in-place reinforced building. In this example, beam CD is

designed and detailed for the combined effects of flexure, shear, and torsion according to ACI 318-05.

Design Data

Materials

x Concrete: normal weight (150 pcf), fc = 4,000 psi

x Mild reinforcing steel: Grade 60 (fy = 60,000 psi)

Loads

x Dead load of joists = 77 psf

TIME SAVING DESIGN AID

Page 2 of 23

Torsion Design

x Superimposed dead load = 30 psf

x Live load = 50 psf

Additional data

x Typical bay size = 24 32 ft (5 bays in N-S direction, 3 bays in E-W direction)

x Typical story height = 12 ft

Factored Torsional Moment Tu

Since beam CD is part of an indeterminate framing system in which redistribution of internal forces can

occur following torsional cracking, the maximum factored torsional moment Tu at the critical section

located at a distance d from the face of the support can be determined from the following:

2

Acp

Tu = 4 fc'

pcp

This type of torsion is referred to as compatibility torsion, the magnitude of which is greater than the

factored torsional moment Tu, min below which torsional effects can be neglected, where

2

Acp

Tu,min = fc'

pcp

Since the beams and joists are cast monolithically, Acp and pcp for beam CD can include a portion of the

adjoining slab. The effective width be of the overhanging flange must conform to 13.2.4:

be = h hf = 20.5 4.5 = 16.0 in. (governs)

= 4hf = 4 4 .5 = 18.0 in.

Acp = (20.5 24 ) + (16.0 4.5) = 564.0 in.2

pcp = 2(20.5 +24 +16.0 ) = 121 in.

3

2

Acp

/ p cp = 2,629 in.

The torsional properties of the beam ignoring the overhanging flange are the following:

Acp = (20.5 24 ) = 492 in.2

pcp = 2(20.5 + 24 ) = 89 in.

3

2

Acp

/ p cp = 2,720 in.3 > 2,629 in.

Therefore, ignore flange per 11.6.1.1.

Tu = 0.75 4 4,000 2,720 = 516,084 in.-lbs = 43.0 ft-kips

It is assumed that the torsional loading on beam CD is uniformly distributed along the span.

TIME SAVING DESIGN AID

Page 3 of 23

Torsion Design

Shear Forces and Bending Moments in Beam CD

20 .5 24

w D =

150 + (77 + 30 ) (32 / 2 ) / 1,000 = 2.2 kips/ft

144

wL = 50 (32 / 2) / 1,000 = 0.8 kips/ft

wu = 1.2wD + 1.6w L = 3.9 kips/ft

This framing system satisfies the conditions for analysis by the coefficients of 8.3.3, as illustrated in

Figure 2-2. Thus, use Figures 2-3, 2-4, and 2-7 to determine the maximum positive moment, negative

moment, and shear force in an interior span:

2

22

3.9 24

2

l

w

12

= 119.8 ft-kips

Mu+ = u n =

16

16

Mu =

Vu =

wu l n2

16

= 119.8

= 174.3 ft-kips

11

11

wu ln

= 43.2 kips

2

Adequacy of Cross-sectional Dimensions

For solid sections:

2

Tp

Vu

+ u h

b d

1.7A2

w

oh

Vc + 8 fc'

b d

Using an average d = 20.5 2.5 = 18.0 in., the factored shear force at the critical section located at

a distance d from the face of the support is Vu = 37.4 kips. Also, the nominal shear strength provided by

the concrete is Vc = 2 fc' bw d .

Assuming a 1.5-in. clear cover to No. 4 closed stirrups:

Aoh = [20.5 (2 1.5) 0.5] [24 (2 1.5) 0.5] = 348.5 in.2

ph = 2 { [20.5 (2 1.5 ) 0.5] + [24 (2 1.5 ) 0.5] } = 75 in.

Therefore,

2

43 .0 12,000 75

37,400

+

1.7 348 .5 2

24 18

= 207 psi < 0.75 (2 + 8 ) 4,000 = 474 psi , OK.

Transverse Reinforcement Required for Torsion

Tu

At

=

s

2Ao fyv cot

TIME SAVING DESIGN AID

Page 4 of 23

Torsion Design

where Ao = 0.85 Ao h = 0.85 348.5 = 296.2 in.2

= 45

Therefore,

At

43.0 12,000

in.2 / in.

=

= 0.019

s

0.75 2 296.2 60,000 cot 45

leg

Transverse Reinforcement Required for Shear

Av Vu Vc 37,400 0.75 2 4000 24 18

37, 400 40,983

=

=

=

<0

s

fyv d

0.75 60,000 18

0.75 60,000 18

No transverse reinforcement for shear is required because Vu < Vc . However, since Vu > 0.5Vc ,

minimum area of transverse reinforcement shall be provided per ACI 11.5.6.1.

Total Required Transverse Reinforcement

For 4,000-psi concrete, minimum transverse reinforcement for shear and torsion

'

= 0.75 fc

bw

24

= 0.75 4,000

= 0.019 in.2/in.

fyv

60,000

= 50bw / fyv = 50 24 / 60,000 = 0.020 in.2/in. (governs)

Required transverse reinforcement

Av

A

in.2 / in.

+ 2 t = 0 + 2legs 0.019

= 0.038 in.2/in. > 0.020 in.2/in. OK.

leg

s

s

Maximum spacing of transverse reinforcement

= ph / 8 = 75 / 8 = 9.4 in. < 12.0 in.

= d / 2 = 18 / 2 = 9.0 in. (governs)

Assuming No. 4 closed stirrups (area per leg = 0.2 in.2), the required spacing s at the critical section =

0.2/0.019 = 10.5 in. < 9.0 in.

Provide No. 4 closed stirrups spaced at 9 in. on center at the critical section. In view of the shear and

torsion distribution along the span length, this same reinforcement and spacing can be provided from the

face of the support to a distance bt + d = 24 + 18 = 42 in. = 3.5 ft past the location where it is no longer

required.

Longitudinal Reinforcement Required for Torsion

A fyv

Al = t ph

s fyl

cot 2 = 0.019 75 60 cot 2 45 = 1.43 in.2

60

TIME SAVING DESIGN AID

Page 5 of 23

Torsion Design

Minimum longitudinal reinforcement:

Al ,min =

5 fc' Acp

fyl

A

t

s

fyv

ph

fyl

where At / s = 0.019 in.2/in. > 25bw / fyv = 25 24 / 60,000 = 0.010 in.2/in.

Al ,min =

5 4,000 492

60

2

2

0.019 75

= 1.17 in. < Al = 1.43in.

60,000

60

Use A l = 1.43 in.2

Longitudinal Reinforcement Required for Flexure

The required As is given in the table below, assuming rectangular section behavior and an average

d = 18 in.

Required Longitudinal Reinforcement for Flexure

Mu

As = Mu / 4d

(ft-kips)

(in.2)

Support

174.3

2.42

Midspan

119.8

1.66

Location

Total Required Longitudinal Reinforcement

The longitudinal reinforcement that is required for torsion will be combined with the longitudinal

reinforcement that is required for flexure.

The longitudinal torsional reinforcement must be distributed around the perimeter of the section with

a maximum spacing of 12 in. In order to have a uniform distribution of reinforcement around the

perimeter, assign approximately one-quarter of A l (= 0 .25 1 .43 = 0.36 in.2) to each face.

Use 1-No. 5 bar on each side (area = 0.31 in.2 0.36 in.2, bar diameter = 0.625 in. > 0.042 s = 0.38 in.).

This bar distribution satisfies the maximum spacing requirement, since the spacing (20.5 3 1)/2 =

8.25 in. < 12 in. Distribute the remaining steel required for torsion evenly between the top and bottom of

the section; thus, 0.5[1.43 (2 0.31)] = 0.41 in.2 will be added to the area of steel that is required for

flexure at both the top and bottom of the section.

x Face of support

Total top steel required = 2.42 + 0.41 = 2.83 in.2

For 4000-psi concrete, minimum As = 200bw d / fy = 1.44 in.2

Provide 3-No. 9 bars ( As = 3.00 in.2) at top of section. This satisfies both minimum and maximum spacing

requirements for bars in a single layer (see Tables 3-2 and 3-3).

TIME SAVING DESIGN AID

Page 6 of 23

Torsion Design

x Midspan

Total bottom steel required = 1.66 + 0.41 = 2.07 in.2

Provide 3-No. 8 bars ( As = 2.37 in.2) at bottom of section. This satisfies both minimum and maximum

spacing requirements for bars in a single layer (see Tables 3-2 and 3-3).

It can be shown that the section is tensioned-controlled.

Reinforcement Details

According to the provisions for structural integrity in 7.13, at least one-sixth of the tension

reinforcement required for negative moment at the support, but not less than 2 bars, and one-quarter of

the positive moment reinforcement at midspan, but not less than 2 bars, must be continuous and tied

with closed stirrups having not less than 135-deg hooks around the continuous top bars. Thus, at least 2

of the 3-No. 9 top bars must be made continuous or spliced with a Class A splice or a mechanical or

welded splice satisfying 12.14.3 at midspan, and at least 2 of the 3-No. 8 bottom bars must be made

continuous or spliced with a Class A splice or a mechanical or welded splice satisfying 12.14.3 over the

supports. No. 4 closed stirrups spaced at 9 in. on center can also be used wherever torsion and shear

reinforcement is not required.

One of the 3-No. 9 bars at the top of the section can be theoretically cutoff at the location where the

factored bending moment is equal to the design moment strength of the section based on a total area of

steel equal to the area of 2-No. 9 bars ( As = 2.00 in.2) minus the area of steel that is required for

torsion (0.41 in.2). Thus, with As = 2.00 0.41 = 1.59 in.2, Mn = 125 ft-kips. The distance x from the

face of the support to where the factored bending moment Mu = 125 ft-kips is obtained by summing

moments about the section at this location:

3.9 2

x 43.2x + 174.3 = 125

2

Solution of this equation gives x = 1.2 ft. The 1-No. 9 bar must extend a distance d = 18 in. or 12 db =

12 1 .128 = 13.5 in. beyond the distance x. Thus, from the face of the support, the total bar length must

be at least equal to 1.2 + (18/12) = 2.7 ft. Also, the bars must extend a full development length l d beyond

the face of the support. The development length for the No. 9 bar can be determined as follows:

ld

3 fy

=

40

fc'

db

c +K

tr

db

where = reinforcement location factor = 1.3

= coating factor = 1.0

= reinforcement size factor = 1.0

= lightweight aggregate concrete factor = 1.0

TIME SAVING DESIGN AID

Page 7 of 23

Torsion Design

1.128

2 + 0.5 + 1.5 = 2.6 in. (governs )

c = spacing or cover dimension =

24 2(1.5 + 0.5 ) 1.128

= 4.7in.

22

Ktr = transverse reinforcement index

= 0 (conservative)

c + Ktr 2.6 + 0

=

= 2.3 < 2.5

db

1.128

Therefore,

3 60,000 1.3 1.0 1.0 1.0

1.128 = 45.4 in. = 3.8 ft > 2.7 ft

2.3

l d =

40 4,000

Thus, the total required length of the 1-No. 9 bar must extend at least 3.8 ft beyond the face of the

support.

The positive reinforcing bar cutoff location is determined in a similar manner. Assuming that 1 of the 3No. 8 bars will be terminated, the positive moment strength with an area of steel As equal to (2 0.79)

0.41 = 1.17 in.2 is Mn = 93 ft-kips. The distance from the centerline of the span to the location where

the factored moment Mu = 93 ft-kips is 3.7 ft. Thus, the bar length on each side of the span centerline

must be at least equal to 3.7 + (18/12) = 5.2 ft, which is greater than the development length l d = 2.4 ft

(conservatively assuming Ktr = 0).

The following figure shows the reinforcement details for beam CD.

For comparison, output form pcaBeam program is also included on the following pages.

TIME SAVING DESIGN AID

Torsion Design

Page 8 of 23

TIME SAVING DESIGN AID

Page 9 of 23

Torsion Design

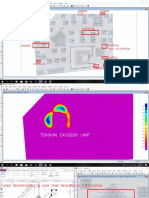

pcaBeam v2.00. Licensed to: PCA. License ID: 12345-1234567-4-2D2DE-2C8D0

File: C:\Data\Time Saving Design Aid\Torsion example.slb

Project: Torsion Example

Frame: Exterior

Engineer: DAF

TIME SAVING DESIGN AID

Page 10 of 23

Torsion Design

CASE: EQ

CASE: Wind

800

800

800

800

1712

1712

1712

1712

35.83

35.83

35.83

35.83

800

CASE: Live

1712

35.83

CASE: Dead

512.5

512.5

512.5

512.5

512.5

CASE: SELF

pcaBeam v2.00. Licensed to: PCA. License ID: 12345-1234567-4-2D2DE-2C8D0

File: C:\Data\Time Saving Design Aid\Torsion example.slb

Project: Torsion Example

Frame: Exterior

Engineer: DAF

TIME SAVING DESIGN AID

Page 11 of 23

Torsion Design

601.94

Torsion Diagram - k-ft

700.0

601.94

-601.94

-700.0

50.0 45.99

601.94

-601.94

-601.94

47.98

601.94

-601.94

-601.94

49.43

47.88

Shear Diagram - kip

48.09

601.94

LEGEND:

Envelope

Moment Diagram - k-ft

-47.88

-49.43

-50.0

-250.0

-160.62

-204.87-196.15

107.14

-47.98

-193.56-194.23

99.63

-194.23-193.56

100.39

-196.15-204.87

99.63

250.0

pcaBeam v2.00. Licensed to: PCA. License ID: 12345-1234567-4-2D2DE-2C8D0

File: C:\Data\Time Saving Design Aid\Torsion example.slb

Project: Torsion Example

Frame: Exterior

-45.99

-48.09

Engineer: DAF

-160.62

107.14

TIME SAVING DESIGN AID

Page 12 of 23

Torsion Design

Beam Shear and Torsion Capacity: Stirrup Intensity - in^2/in

0.05

0.039

1.5

0.039

1.5

0.039

1.5

0.039

1.5

0.039

0.039

0.039

1.5

1.5

0.039

1.5

1.5

0.039

1.5

0.039

1.5

LEGEND:

Demand - (Av+2At)/s

Demand - At/s

Demand - Av/s

Demand - Al

Provided - (Av+2At)/s

Provided - Al

Support Centerline

Face of Support

Critical Section

7.0

Beam Shear and Torsion Capacit y: Longitudinal Bar Area - in^2

pcaBeam v2.00. Licensed to: PCA. License ID: 12345-1234567-4-2D2DE-2C8D0

File: C:\Data\Time Saving Design Aid\Torsion example.slb

Project: Torsion Example

Frame: Exterior

Engineer: DAF

TIME SAVING DESIGN AID

Page 13 of 23

Torsion Design

32-#4@8.4

32-#4@8.4

32-#4@8.4

32-#4@8.4

32-#4@8.4

Transverse Reinforcement

pcaBeam v2.00. Licensed to: PCA. License ID: 12345-1234567-4-2D2DE-2C8D0

File: C:\Data\Time Saving Design Aid\Torsion example.slb

Project: Torsion Example

Frame: Exterior

Engineer: DAF

Frame: Exterior

pcaBeam v2.00. Licensed to: PCA. License ID: 12345-1234567-4-2D2DE-2C8D0

File: C:\Data\Time Saving Design Aid\Torsion example.slb

Project: Torsion Example

Engineer: DAF

2-#8(288.0)c

1-#8(36.0)

2-#8(288.0)c

1-#8(36.0)

2-#8(288.0)c

1-#8(36.0)

2-#8(288.0)c

1-#8(36.0)

2-#8(288.0)c

1-#8(36.0)

2-#9(70.8)

1-#9(34.5)

1-#9(42.9)

2-#9(85.7)

2-#9(85.7)

1-#9(41.4)

1-#9(40.9)

2-#9(85.7)

2-#9(85.7)

1-#9(41.0)

1-#9(41.0)

2-#9(85.7)

2-#9(85.7)

1-#9(40.9)

1-#9(41.4)

2-#9(85.7)

2-#9(85.7)

1-#9(42.9)

1-#9(34.5)

2-#9(70.8)

TIME SAVING DESIGN AID

Page 14 of 23

Torsion Design

Flexural Reinforcement

TIME SAVING DESIGN AID

Page 15 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

ooooooo

oooooooo

oo

oo

oo

oo

oooooooo

ooooooo

oo

oo

oo

OOOOO

OO

OO

OO

OO

OO

OO

OOOOO

OO

OO

OO

OO

OO

OO

OOOOO

oooooo

oooooooo

oo

oo

oo

oo

oo

oo

oo

oo

oooooooo

oooooo

OOOOOO

OO

OO

OO

OOOOO

OO

OO

OO

OOOOOO

OOOOO

OO

OO

OO

OO

OO

OO

OOOOOOO

OO

OO

OO

OO

OO

OO

OO

OO

ooooo

ooooooo

oo

oo

oo

oo

ooooooo

ooooooo

oo

oo

oo

oo

oo

oo

05-03-2007, 09:33:38 AM

Page 1

ooooo

ooooo

OO

OO

OOO

OOO

OO O

O OO

OO O O OO

OO

O

OO

OO

OO

OO

OO

OO

OO

OO

OO

=============================================================================

pcaBeam v2.00 (TM)

A Computer Program for Analysis, Design, and Investigation of

Reinforced Concrete Beams and One-way Slab Systems

=============================================================================

Copyright 1992-2006, Portland Cement Association

All rights reserved

Licensee stated above acknowledges that Portland Cement Association

(PCA) is not and cannot be responsible for either the accuracy or

adequacy of the material supplied as input for processing

by the

pcaBeam computer program. Furthermore, PCA neither makes any warranty

expressed nor implied with respect to the correctness of the output

prepared by the pcaBeam

program. Although PCA has endeavored to

produce pcaBeam error free the program is not and cannot be certified

infallible. The final and only responsibility for analysis, design and

engineering documents is the licensees. Accordingly, PCA disclaims all

responsibility in contract, negligence or other tort for any analysis,

design or engineering documents prepared in connection with the use of

the pcaBeam program.

=============================================================================================

[1] INPUT ECHO

=============================================================================================

General Information:

====================

File name: C:\Data\Time Saving Design Aid\Torsion example.slb

Project: Torsion Example

Frame: Exterior

Engineer: DAF

Code: ACI 318-02

Reinforcement Database: ASTM A615

Mode: Design

Number of supports = 6

Floor System: One-Way/Beam

Live load pattern ratio = 100%

Deflections are based on cracked section properties.

In negative moment regions, Ig and Mcr DO NOT include flange/slab contribution (if available)

Long-term deflections are calculated for load duration of 60 months.

0% of live load is sustained.

Compression reinforcement calculations NOT selected.

Moment redistribution NOT selected.

Effective flange width calculations selected.

Rigid beam-column joint NOT selected.

Torsion analysis and design selected.

Stirrups in flanges (if available) NOT selected.

Compatibility torsion selected.

Material Properties:

====================

Slabs|Beams

-----------wc

=

150

f'c

=

4

Ec

=

3834.3

fr

=

0.47434

fy

fyv

Es

=

=

=

Columns

-----------150

4

3834.3

0.47434

lb/ft3

ksi

ksi

ksi

60 ksi, Bars are not epoxy-coated

60 ksi

29000 ksi

TIME SAVING DESIGN AID

Page 16 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

05-03-2007, 09:33:38 AM

Page 2

Reinforcement Database:

===============

Units: Db (in), Ab (in^2), Wb (lb/ft)

Size

Db

Ab

Wb

Size

Db

Ab

Wb

---- -------- -------- ----------- -------- -------- -------#3

0.38

0.11

0.38

#4

0.50

0.20

0.67

#5

0.63

0.31

1.04

#6

0.75

0.44

1.50

#7

0.88

0.60

2.04

#8

1.00

0.79

2.67

#9

1.13

1.00

3.40

#10

1.27

1.27

4.30

#11

1.41

1.56

5.31

#14

1.69

2.25

7.65

#18

2.26

4.00

13.60

Span Data:

==========

Slabs: L1, wL, wR (ft); t, bEff, Hmin (in)

Span Loc

L1

t

wL

wR

bEff

Hmin

---- ---- -------- -------- -------- -------- -------- -------1 Int

24.000

0.00

1.000

1.000

24.00

0.00

2 Int

24.000

0.00

1.000

1.000

24.00

0.00

3 Int

24.000

0.00

1.000

1.000

24.00

0.00

4 Int

24.000

0.00

1.000

1.000

24.00

0.00

5 Int

24.000

0.00

1.000

1.000

24.00

0.00

Ribs and Longitudinal Beams: b, h, Sp (in)

__________Ribs____________

_______Beams_____

Span

b

h

Sp

b

h

---- -------- -------- --------------- -------1

0.00

0.00

0.00

24.00

20.50

2

0.00

0.00

0.00

24.00

20.50

3

0.00

0.00

0.00

24.00

20.50

4

0.00

0.00

0.00

24.00

20.50

5

0.00

0.00

0.00

24.00

20.50

__Span__

Hmin

-------15.57

13.71

13.71

13.71

15.57

Support Data:

=============

Columns: c1a, c2a, c1b, c2b (in); Ha, Hb (ft)

Supp

c1a

c2a

Ha

c1b

c2b

Hb

---- -------- -------- --------------- -------- -------1

22.00

22.00

12.000

22.00

22.00

12.000

2

22.00

22.00

12.000

22.00

22.00

12.000

3

22.00

22.00

12.000

22.00

22.00

12.000

4

22.00

22.00

12.000

22.00

22.00

12.000

5

22.00

22.00

12.000

22.00

22.00

12.000

6

22.00

22.00

12.000

22.00

22.00

12.000

Red%

---100

100

100

100

100

100

Boundary Conditions: Kz (kip/in); Kry (kip-in/rad)

Supp

Spring Kz

Spring Kry Far End A Far End B

---- ------------ ------------ --------- --------1

0

0

Fixed

Fixed

2

0

0

Fixed

Fixed

3

0

0

Fixed

Fixed

4

0

0

Fixed

Fixed

5

0

0

Fixed

Fixed

6

0

0

Fixed

Fixed

Load Data:

==========

Load Cases and Combinations:

Case

SELF

Dead

Live

Type

DEAD

DEAD

LIVE

U1

1.400

1.400

0.000

U2

1.200

1.200

1.600

U3

1.200

1.200

1.600

U4

1.200

1.200

1.600

U5

1.200

1.200

1.000

U6

1.200

1.200

1.000

U7

0.900

0.900

0.000

U8

0.900

0.900

0.000

U9

1.200

1.200

1.000

U10

1.200

1.200

1.000

U11

0.900

0.900

0.000

U12

0.900

0.900

0.000

Span

Span

---Line

1

2

3

4

5

1

2

3

4

5

Wind

LATERAL

0.000

0.000

0.800

-0.800

1.600

-1.600

1.600

-1.600

0.000

0.000

0.000

0.000

EQ

LATERAL

0.000

0.000

0.000

0.000

0.000

0.000

0.000

0.000

1.000

-1.000

1.000

-1.000

Loads:

Case

Wa

La

Wb

Lb

-------- ------------ ------------ ------------ -----------Loads - Wa | Wb (lb/ft), La | Lb (ft):

Dead

1712

0

1712

24

Dead

1712

0

1712

24

Dead

1712

0

1712

24

Dead

1712

0

1712

24

Dead

1712

0

1712

24

Live

800

0

800

24

Live

800

0

800

24

Live

800

0

800

24

Live

800

0

800

24

Live

800

0

800

24

TIME SAVING DESIGN AID

Page 17 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

Line

1

2

3

4

5

05-03-2007, 09:33:38 AM

Page 3

Torque - Wa | Wb (k-ft/ft), La | Lb (ft):

Dead

35.83

0

35.83

Dead

35.83

0

35.83

Dead

35.83

0

35.83

Dead

35.83

0

35.83

Dead

35.83

0

35.83

Support Loads:

24

24

24

24

24

--- NONE ---

Support Displacements:

--- NONE ---

Lateral Load Effects - M (k-ft):

Span Case

Mleft

Mright

---- -------- ------------ -----------1 EQ

0

0

2 EQ

0

0

3 EQ

0

0

4 EQ

0

0

5 EQ

0

0

6 EQ

0

0

1 Wind

0

0

2 Wind

0

0

3 Wind

0

0

4 Wind

0

0

5 Wind

0

0

Reinforcement Criteria:

=======================

_____Top bars___ ___Bottom bars__ ____Stirrups____

Min

Max

Min

Max

Min

Max

------- ------- ------- ------- ------- ------Slabs and Ribs:

Bar Size

#5

#8

#5

#8

Bar spacing

1.00

18.00

1.00

18.00 in

Reinf ratio

0.14

5.00

0.14

5.00 %

Cover

1.50

1.50

in

Top bars have 12 in of concrete below them.

Beams:

Bar Size

#9

#9

#8

#8

Bar spacing

1.00

18.00

1.00

18.00

Reinf ratio

0.14

5.00

0.14

5.00

Cover

2.00

2.00

Side cover

1.50

1.50

Layer dist.

1.00

1.00

No. of legs

Top bars have 12 in of concrete below them.

%

in

in

in

#4

6.00

#4

18.00 in

=============================================================================================

[2] DESIGN RESULTS

=============================================================================================

Top Reinforcement:

==================

Units: Width (ft), Mmax (k-ft), Xmax (ft), As (in^2), Sp (in)

Span Zone

Width

Mmax

Xmax

AsMin

AsMax

SpReq

AsReq

Bars

---- ------ -------- ------------ -------- -------- -------- -------- -------- ------1 Left

2.00

120.12

0.917

1.435

7.775

9.308

1.537

3-#9

Middle

2.00

0.00

12.000

0.000

7.775

0.000

0.000

--Right

2.00

161.22

23.083

1.435

7.775

9.308

2.087

3-#9

*5

2 Left

Middle

Right

2.00

2.00

2.00

153.72

0.00

151.32

0.917

12.000

23.083

1.435

0.000

1.435

7.775

7.775

7.775

9.308

0.000

9.308

1.985

0.000

1.953

3-#9

--3-#9

*5

3 Left

Middle

Right

2.00

2.00

2.00

151.90

0.00

151.90

0.917

12.000

23.083

1.435

0.000

1.435

7.775

7.775

7.775

9.308

0.000

9.308

1.961

0.000

1.961

3-#9

--3-#9

*5

4 Left

Middle

Right

2.00

2.00

2.00

151.32

0.00

153.72

0.917

12.000

23.083

1.435

0.000

1.435

7.775

7.775

7.775

9.308

0.000

9.308

1.953

0.000

1.985

3-#9

--3-#9

*5

5 Left

2.00

161.22

0.917

1.435

7.775

Middle

2.00

0.00

12.000

0.000

7.775

Right

2.00

120.11

23.083

1.435

7.775

NOTES:

*5 - Number of bars governed by maximum allowable spacing.

9.308

0.000

9.308

2.087

0.000

1.537

3-#9

--3-#9

Top Bar Details:

================

Units: Length (ft)

_____________Left______________

Span

Bars Length

Bars Length

---- ------- ------- ------- ------1

2-#9

5.90

1-#9

2.88

___Continuous__

Bars Length

------- ---------

_____________Right_____________

Bars Length

Bars Length

------- ------- ------- ------2-#9

7.14

1-#9

3.58

*5

*5

*5

*5

TIME SAVING DESIGN AID

Page 18 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

05-03-2007, 09:33:38 AM

Page 4

2-#9

7.14

1-#9

3.45

---

2-#9

7.14

1-#9

3.41

2-#9

7.14

1-#9

3.42

---

2-#9

7.14

1-#9

3.42

2-#9

7.14

1-#9

3.41

---

2-#9

7.14

1-#9

3.45

2-#9

7.14

1-#9

3.58

---

2-#9

5.90

1-#9

2.88

Bottom Reinforcement:

=====================

Units: Width (ft), Mmax (k-ft), Xmax (ft), As (in^2), Sp (in)

Span

Width

Mmax

Xmax

AsMin

AsMax

SpReq

AsReq

Bars

---- -------- ------------ -------- -------- -------- -------- -------- ------1

2.00

107.14

11.626

1.440

7.803

9.354

1.361

3-#8

*5

2.00

99.63

12.125

1.440

7.803

9.354

1.263

3-#8

*5

2.00

100.39

11.875

1.440

7.803

9.354

1.272

3-#8

*5

2.00

99.63

11.875

1.440

7.803

9.354

1.263

3-#8

*5

5

2.00

107.14

12.374

1.440

7.803

9.354

NOTES:

*5 - Number of bars governed by maximum allowable spacing.

1.361

3-#8

*5

Bottom Bar Details:

===================

Units: Start (ft), Length (ft)

_______Long Bars_______ ______Short Bars_______

Span

Bars

Start Length

Bars

Start Length

---- ------- ------- ------- ------- ------- ------1

2-#8

0.00

24.00

1-#8

10.13

3.00

2

2-#8

0.00

24.00

1-#8

10.62

3.00

2-#8

0.00

24.00

1-#8

10.37

3.00

2-#8

0.00

24.00

1-#8

10.37

3.00

2-#8

0.00

24.00

1-#8

10.87

3.00

Flexural Capacity:

==================

Units: x (ft), As (in^2), PhiMn (k-ft)

Span

x AsTop AsBot

PhiMnPhiMn+

---- --------- ----- ----- ------------ -----------1

0.000 3.00 1.58

-227.25

123.85

0.917 3.00 1.58

-227.25

123.85

0.918 3.00 1.58

-227.25

123.85

2.877 2.00 1.58

-154.81

123.85

3.939 2.00 1.58

-154.81

123.85

5.898 0.00 1.58

0.00

123.85

8.675 0.00 1.58

0.00

123.85

10.125 0.00 1.58

0.00

123.85

11.487 0.00 2.37

0.00

182.68

11.766 0.00 2.37

0.00

182.68

12.000 0.00 2.23

0.00

172.71

13.127 0.00 1.58

0.00

123.85

15.325 0.00 1.58

0.00

123.85

16.856 0.00 1.58

0.00

123.85

19.517 2.00 1.58

-154.81

123.85

20.422 2.00 1.58

-154.81

123.85

23.082 3.00 1.58

-227.25

123.85

23.083 3.00 1.58

-227.25

123.85

24.000 3.00 1.58

-227.25

123.85

2

0.000

0.917

0.918

3.449

4.612

7.144

8.675

10.624

11.887

12.000

12.362

13.626

15.325

16.856

19.347

20.592

23.082

23.083

24.000

3.00

3.00

3.00

2.00

2.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

2.00

2.00

3.00

3.00

3.00

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

2.37

2.37

2.37

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

-227.25

-227.25

-227.25

-154.81

-154.81

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-154.81

-154.81

-227.25

-227.25

-227.25

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

182.68

182.68

182.68

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

TIME SAVING DESIGN AID

Page 19 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

3

0.000

0.917

0.918

3.418

4.643

7.144

8.675

10.374

11.648

12.000

12.103

13.376

15.325

16.856

19.357

20.582

23.082

23.083

24.000

3.00

3.00

3.00

2.00

2.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

2.00

2.00

3.00

3.00

3.00

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

2.37

2.37

2.37

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

-227.25

-227.25

-227.25

-154.81

-154.81

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-154.81

-154.81

-227.25

-227.25

-227.25

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

182.68

182.68

182.68

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

0.000

0.917

0.918

3.408

4.653

7.144

8.675

10.374

11.638

12.000

12.113

13.376

15.325

16.856

19.388

20.551

23.082

23.083

24.000

3.00

3.00

3.00

2.00

2.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

2.00

2.00

3.00

3.00

3.00

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

2.37

2.37

2.37

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

-227.25

-227.25

-227.25

-154.81

-154.81

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-154.81

-154.81

-227.25

-227.25

-227.25

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

182.68

182.68

182.68

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

0.000

0.917

0.918

3.578

4.483

7.144

8.675

10.873

12.000

12.234

12.513

13.875

15.325

18.102

20.061

21.123

23.082

23.083

24.000

3.00

3.00

3.00

2.00

2.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

2.00

2.00

3.00

3.00

3.00

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

2.23

2.37

2.37

1.58

1.58

1.58

1.58

1.58

1.58

1.58

1.58

-227.25

-227.25

-227.25

-154.81

-154.81

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

-154.81

-154.81

-227.25

-227.25

-227.25

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

172.71

182.68

182.68

123.85

123.85

123.85

123.85

123.85

123.85

123.85

123.85

05-03-2007, 09:33:38 AM

Page 5

Longitudinal Beam Shear And Torsion Reinforcement Required:

===========================================================

Section properties:

Units: d, pcp, pch (in), Acp, Ach, Ao (in^2)

PhiVc (kip), PhiTcr (k-ft), PhiSvt (ksi)

Span

d

pcp

ph

Acp

Aoh

Ao

PhiVc

PhiTcr

PhiSvt

---- -------- -------- -------- ---------- ---------- ---------- -------- -------- -------1

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

2

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

3

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

4

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

5

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

Required transverse reinforcement:

Units: Start, End, Xu (ft), Vu (kip), Tu (k-ft), vf (ksi)

Av/s, Av/s, A(v+2t)/s (in^2/in)

Span

Start

End

Vu

Tu

vf

Xu Case/Patt

Av/s

At/s A(v+2t)/s

---- -------- -------- -------- -------- -------- -------- --------- -------- -------- --------1

2.411

5.151

28.29

43.00

0.199

2.41

U1/All

0.0000

0.0194

0.0387 *4

5.151

7.891

19.76

43.00

0.193

5.15

U1/All

0.0000

0.0194

0.0387 *4

7.891

10.630

11.23

43.00

0.189

7.89

U1/All

0.0000

0.0194

0.0387 *4

10.630

13.370

5.84

43.00

0.188

13.37

U1/All

0.0000

0.0194

0.0387 *4 *5

13.370

16.109

14.37

43.00

0.190

16.11

U1/All

0.0000

0.0194

0.0387 *4

16.109

18.849

22.90

43.00

0.195

18.85

U1/All

0.0000

0.0194

0.0387 *4

18.849

21.589

31.43

43.00

0.201

21.59

U1/All

0.0000

0.0194

0.0387 *4

2

2.411

5.151

29.98

43.00

0.200

2.41

U1/All

0.0000

0.0194

0.0387 *4

TIME SAVING DESIGN AID

Page 20 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

05-03-2007, 09:33:38 AM

Page 6

5.151

7.891

10.630

13.370

16.109

18.849

7.891

10.630

13.370

16.109

18.849

21.589

21.45

12.92

4.39

12.68

21.21

29.74

43.00

43.00

43.00

43.00

43.00

43.00

0.194

0.190

0.188

0.190

0.194

0.200

5.15

7.89

10.63

16.11

18.85

21.59

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0194

0.0194

0.0194

0.0194

0.0194

0.0194

0.0387

0.0387

0.0387

0.0387

0.0387

0.0387

*4

*4

*4 *5

*4

*4

*4

2.411

5.151

7.891

10.630

13.370

16.109

18.849

5.151

7.891

10.630

13.370

16.109

18.849

21.589

29.86

21.33

12.80

4.27

12.80

21.33

29.86

43.00

43.00

43.00

43.00

43.00

43.00

43.00

0.200

0.194

0.190

0.188

0.190

0.194

0.200

2.41

5.15

7.89

10.63

16.11

18.85

21.59

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0194

0.0194

0.0194

0.0194

0.0194

0.0194

0.0194

0.0387

0.0387

0.0387

0.0387

0.0387

0.0387

0.0387

*4

*4

*4

*4 *5

*4

*4

*4

2.411

5.151

7.891

10.630

13.370

16.109

18.849

5.151

7.891

10.630

13.370

16.109

18.849

21.589

29.74

21.21

12.68

4.39

12.92

21.45

29.98

43.00

43.00

43.00

43.00

43.00

43.00

43.00

0.200

0.194

0.190

0.188

0.190

0.194

0.200

2.41

5.15

7.89

13.37

16.11

18.85

21.59

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0194

0.0194

0.0194

0.0194

0.0194

0.0194

0.0194

0.0387

0.0387

0.0387

0.0387

0.0387

0.0387

0.0387

*4

*4

*4

*4 *5

*4

*4

*4

2.411

5.151

7.891

10.630

13.370

16.109

18.849

5.151

7.891

10.630

13.370

16.109

18.849

21.589

31.43

22.90

14.37

5.84

11.23

19.76

28.29

43.00

43.00

43.00

43.00

43.00

43.00

43.00

0.201

0.195

0.190

0.188

0.189

0.193

0.199

2.41

5.15

7.89

10.63

16.11

18.85

21.59

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0000

0.0194

0.0194

0.0194

0.0194

0.0194

0.0194

0.0194

0.0387

0.0387

0.0387

0.0387

0.0387

0.0387

0.0387

*4

*4

*4

*4 *5

*4

*4

*4

NOTES:

*4 - Design torsional moment reduced to PhiTcr due to compatibility torsion.

*5 - Minimum transverse (stirrup) reinforcement required.

Required longitudinal reinforcement:

Units: Start, End, Xu (ft), Tu (k-ft), Al (in^2)

Span

Start

End

Tu

Xu Case/Patt

Al

---- -------- -------- -------- -------- --------- -------1

2.411

5.151

43.00

2.41

U1/All

1.452 *4

5.151

7.891

43.00

5.15

U1/All

1.452 *4

7.891

10.630

43.00

7.89

U1/All

1.452 *4

10.630

13.370

18.74

11.63

U1/All

1.843 *4 *5

13.370

16.109

43.00

13.37

U1/All

1.452 *4

16.109

18.849

43.00

16.11

U1/All

1.452 *4

18.849

21.589

43.00

18.85

U1/All

1.452 *4

2

2.411

5.151

7.891

10.630

13.370

16.109

18.849

5.151

7.891

10.630

13.370

16.109

18.849

21.589

43.00

43.00

43.00

18.74

43.00

43.00

43.00

2.41

5.15

7.89

11.63

13.37

16.11

18.85

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

1.452

1.452

1.452

1.843

1.452

1.452

1.452

*4

*4

*4

*4 *5

*4

*4

*4

2.411

5.151

7.891

10.630

13.370

16.109

18.849

5.151

7.891

10.630

13.370

16.109

18.849

21.589

43.00

43.00

43.00

18.74

43.00

43.00

43.00

2.41

5.15

7.89

11.63

13.37

16.11

18.85

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

1.452

1.452

1.452

1.843

1.452

1.452

1.452

*4

*4

*4

*4 *5

*4

*4

*4

2.411

5.151

7.891

10.630

13.370

16.109

18.849

5.151

7.891

10.630

13.370

16.109

18.849

21.589

43.00

43.00

43.00

18.74

43.00

43.00

43.00

2.41

5.15

7.89

11.63

13.37

16.11

18.85

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

1.452

1.452

1.452

1.843

1.452

1.452

1.452

*4

*4

*4

*4 *5

*4

*4

*4

2.411

5.151

7.891

10.630

13.370

16.109

18.849

5.151

7.891

10.630

13.370

16.109

18.849

21.589

43.00

43.00

43.00

18.74

43.00

43.00

43.00

2.41

5.15

7.89

11.63

13.37

16.11

18.85

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

U1/All

1.452

1.452

1.452

1.843

1.452

1.452

1.452

*4

*4

*4

*4 *5

*4

*4

*4

NOTES:

*4 - Design torsional moment reduced to PhiTcr due to compatibility torsion.

*5 - Minimum longitudinal reinforcement required.

Longitudinal Beam Shear Reinforcement Details:

==============================================

Units: spacing & distance (in).

Span Size Stirrups (2 legs each unless otherwise noted)

---- ---- --------------------------------------------1

#4 32 @ 8.4

TIME SAVING DESIGN AID

Page 21 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

2

3

4

5

#4

#4

#4

#4

32

32

32

32

@

@

@

@

05-03-2007, 09:33:38 AM

Page 7

8.4

8.4

8.4

8.4

Longitudinal Torsional Reinforcement Details:

==============================================

Units: Start (ft), Length (ft)

_______Long Bars_______ ______Short Bars_______

Span

Bars

Start Length

Bars

Start Length

---- ------- ------- ------- ------- ------- ------1

--8-#8

0.00

13.00

--8-#8

11.00

13.00

2

--8-#8

0.00

13.00

--8-#8

11.00

13.00

3

--8-#8

0.00

13.00

--8-#8

11.00

13.00

4

--8-#8

0.00

13.00

--8-#8

11.00

13.00

5

--8-#8

0.00

13.00

--8-#8

11.00

13.00

Beam Shear And Torsion Capacity:

================================

Section properties:

Units: d, pcp, pch (in), Acp, Ach, Ao (in^2)

PhiVc (kip), PhiTcr (k-ft), PhiSvt (ksi)

Span

d

pcp

ph

Acp

Aoh

Ao

PhiVc

PhiTcr

PhiSvt

---- -------- -------- -------- ---------- ---------- ---------- -------- -------- -------1

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

2

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

3

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

4

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

5

17.94

89.00

75.00

492.000

348.500

296.225

40.84

43.00

0.474

Beam shear and torsion transverse reinforcement capacity in terms of provided and required area:

Units: Start, End, Xu (ft), Sp (in), A(v+2t)/s (in^2/in)

Vu (kip), Tu (k-ft), vf (ksi)

___________________Provided__________________ _______________________Required________________________

Span

Start

End A(v+2t)

Sp A(v+2t)/s

Xu

Vu

Tu Case/Patt

vf A(v+2t)/s

---- -------- -------- -------- -------- --------- -------- -------- -------- --------- -------- --------1

0.000

1.167

-------------0.00

45.40

43.00

U2/All

0.22

0.0444

1.167

11.875

0.400

8.39

0.0477

2.41

28.29

43.00

U1/All

0.20

0.0387

11.875

12.125

0.400

8.39

0.0477

12.12

1.96

6.25

U1/All

0.03

0.0000

12.125

22.833

0.400

8.39

0.0477

21.59

31.43

43.00

U1/All

0.20

0.0387

22.833

24.000

-------------24.00

49.38

43.00

U2/All

0.22

0.0493

*4

*4 *5

*2

*4 *5

*4

0.000

1.167

11.875

12.125

22.833

1.167

11.875

12.125

22.833

24.000

----0.400

0.400

0.400

-----

----8.39

8.39

8.39

-----

-----0.0477

0.0477

0.0477

------

0.00

2.41

11.88

21.59

24.00

47.55

29.98

0.51

29.74

47.24

43.00

43.00

6.25

43.00

43.00

U2/All

U1/All

U1/All

U1/All

U2/All

0.22

0.20

0.03

0.20

0.22

0.0470

0.0387

0.0000

0.0387

0.0466

*4

*4 *5

*2

*4 *5

*4

0.000

1.167

11.875

12.125

22.833

1.167

11.875

12.125

22.833

24.000

----0.400

0.400

0.400

-----

----8.39

8.39

8.39

-----

-----0.0477

0.0477

0.0477

------

0.00

2.41

11.88

21.59

24.00

47.39

29.86

0.39

29.86

47.39

43.00

43.00

6.25

43.00

43.00

U2/All

U1/All

U1/All

U1/All

U2/All

0.22

0.20

0.03

0.20

0.22

0.0468

0.0387

0.0000

0.0387

0.0468

*4

*4 *5

*2

*4 *5

*4

0.000

1.167

11.875

12.125

22.833

1.167

11.875

12.125

22.833

24.000

----0.400

0.400

0.400

-----

----8.39

8.39

8.39

-----

-----0.0477

0.0477

0.0477

------

0.00

2.41

12.12

21.59

24.00

47.24

29.74

0.51

29.98

47.55

43.00

43.00

6.25

43.00

43.00

U2/All

U1/All

U1/All

U1/All

U2/All

0.22

0.20

0.03

0.20

0.22

0.0466

0.0387

0.0000

0.0387

0.0470

*4

*4 *5

*2

*4 *5

*4

0.000

1.167

11.875

12.125

22.833

1.167

11.875

12.125

22.833

24.000

----0.400

0.400

0.400

-----

----8.39

8.39

8.39

-----

-----0.0477

0.0477

0.0477

------

0.00

2.41

11.88

21.59

24.00

49.38

31.43

1.96

28.29

45.40

43.00

43.00

6.25

43.00

43.00

U2/All

U1/All

U1/All

U1/All

U2/All

0.22

0.20

0.03

0.20

0.22

0.0493

0.0387

0.0000

0.0387

0.0444

*4

*4 *5

*2

*4 *5

*4

NOTES:

*2 - Torsion ignored (Tu < PhiTcr/4).

*4 - Design torsional moment reduced to PhiTcr due to compatibility torsion.

*5 - Minimum transverse (stirrup) reinforcement required.

Beam torsion longitudinal reinforcement capacity in terms of provided and required area:

Units: Start, End, Xu (ft), Al (in^2), Tu (kip)

_________Provided_________ _____________Required_______________

Span

Start

End

Al

Xu

Tu Case/Patt

Al

---- -------- -------- -------- -------- -------- --------- -------1

0.000

1.167

----0.00

43.00

U2/All

1.452 *4

1.167

11.875

6.320

11.63

18.74

U1/All

1.843 *4 *5

11.875

12.125

----11.88

6.25

U1/All

0.000 *2

12.125

22.833

6.320

12.37

18.74

U1/All

1.843 *4 *5

22.833

24.000

----22.83

43.00

U2/All

1.452 *4

2

0.000

1.167

-----

0.00

43.00

U2/All

1.452 *4

TIME SAVING DESIGN AID

Page 22 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

05-03-2007, 09:33:38 AM

Page 8

1.167

11.875

12.125

22.833

11.875

12.125

22.833

24.000

6.320

----6.320

-----

11.63

11.88

12.37

22.83

18.74

6.25

18.74

43.00

U1/All

U1/All

U1/All

U2/All

1.843

0.000

1.843

1.452

*4 *5

*2

*4 *5

*4

0.000

1.167

11.875

12.125

22.833

1.167

11.875

12.125

22.833

24.000

----6.320

----6.320

-----

0.00

11.63

11.88

12.37

22.83

43.00

18.74

6.25

18.74

43.00

U2/All

U1/All

U1/All

U1/All

U2/All

1.452

1.843

0.000

1.843

1.452

*4

*4 *5

*2

*4 *5

*4

0.000

1.167

11.875

12.125

22.833

1.167

11.875

12.125

22.833

24.000

----6.320

----6.320

-----

0.00

11.63

11.88

12.37

22.83

43.00

18.74

6.25

18.74

43.00

U2/All

U1/All

U1/All

U1/All

U2/All

1.452

1.843

0.000

1.843

1.452

*4

*4 *5

*2

*4 *5

*4

0.000

1.167

11.875

12.125

22.833

1.167

11.875

12.125

22.833

24.000

----6.320

----6.320

-----

0.00

11.63

11.88

12.37

22.83

43.00

18.74

6.25

18.74

43.00

U2/All

U1/All

U1/All

U1/All

U2/All

1.452

1.843

0.000

1.843

1.452

*4

*4 *5

*2

*4 *5

*4

NOTES:

*2 - Torsion ignored (Tu < PhiTcr/4).

*4 - Design torsional moment reduced to PhiTcr due to compatibility torsion.

*5 - Minimum longitudinal reinforcement required.

Slab Shear Capacity:

====================

Units: b, d (in), Xu (ft), PhiVc, Vu(kip)

Span

b

d

Vratio

PhiVc

Vu

Xu

---- -------- -------- -------- ------------ ------------ -----------1 --- Not checked --2 --- Not checked --3 --- Not checked --4 --- Not checked --5 --- Not checked --Deflections:

============

Section properties

-----------------Units: Ig, Icr, Ie (in^4), Mcr, Mmax (k-ft)

________________Load Level_______________

________Ie,avg_________

_________Dead_______ ______Dead+Live_____

Span

Dead

Dead+Live Zone

Ig

Icr

Mcr

Mmax

Ie

Mmax

Ie

---- ----------- ----------- ------ ----------- ----------- -------- -------- ----------- -------- ----------1

15725

10689 Middle

17230

3996

66.45

58.89

17230

80.07

11560

Right

17230

4797

66.45 -115.00

7195 -156.35

5751

2

14389

11863 Left

17230

4797

66.45 -108.21

7675 -147.13

5942

Middle

17230

3996

66.45

52.98

17230

72.03

14386

Right

17230

4797

66.45 -106.15

7846 -144.33

6010

3

14401

11683 Left

17230

4797

66.45 -106.71

7798 -145.09

5991

Middle

17230

3996

66.45

53.43

17230

72.65

14122

Right

17230

4797

66.45 -106.71

7798 -145.09

5991

4

14389

11863 Left

17230

4797

66.45 -106.15

7846 -144.33

6010

Middle

17230

3996

66.45

52.98

17230

72.03

14386

Right

17230

4797

66.45 -108.21

7675 -147.13

5942

5

15725

10689 Left

17230

4797

66.45 -115.00

7195 -156.35

5751

Middle

17230

3996

66.45

58.89

17230

80.07

11560

Maximum Instantaneous Deflections

--------------------------------Units: D (in)

Span

Ddead

Dlive

Dtotal

---- -------- -------- -------1

0.064

0.050

0.114

2

0.057

0.033

0.090

3

0.058

0.035

0.092

4

0.057

0.033

0.090

5

0.064

0.050

0.114

Maximum Long-term Deflections

----------------------------Time dependant factor for sustained loads = 2.000

Units: D (in)

Span

Dsust Lambda

Dcs

Dcs+lu

Dcs+l

Dtotal

---- -------- ------ -------- -------- -------- -------1

0.064 2.000

0.128

0.178

0.178

0.242

2

0.057 2.000

0.114

0.147

0.147

0.204

3

0.058 2.000

0.115

0.150

0.150

0.208

4

0.057 2.000

0.114

0.147

0.147

0.204

5

0.064 2.000

0.128

0.178

0.178

0.242

Material Takeoff:

=================

Reinforcement in the Direction of Analysis

------------------------------------------

TIME SAVING DESIGN AID

Page 23 of 23

Torsion Design

pcaBeam v2.00 Portland Cement Association

Licensed to: PCA, License ID: 12345-1234567-4-2D2DE-2C8D0

C:\Data\Time Saving Design Aid\Torsion example.slb

Top Bars:

Bottom Bars:

Torsion Bars:

Stirrups:

Total Steel:

Concrete:

582.6

680.9

2776.7

2057.4

6097.6

410.0

lb

lb

lb

lb

lb

ft^3

<=>

<=>

<=>

<=>

<=>

<=>

4.85

5.67

23.14

17.15

50.81

3.42

lb/ft

lb/ft

lb/ft

lb/ft

lb/ft

ft^3/ft

<=>

<=>

<=>

<=>

<=>

<=>

2.427

2.837

11.569

8.573

25.407

1.708

05-03-2007, 09:33:38 AM

Page 9

lb/ft^2

lb/ft^2

lb/ft^2

lb/ft^2

lb/ft^2

ft^3/ft^2

Вам также может понравиться

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОт EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionОценок пока нет

- Tall Buildings Chap 3 AДокумент7 страницTall Buildings Chap 3 ATharangi MunaweeraОценок пока нет

- Chapter 3 Shear ExamplesДокумент30 страницChapter 3 Shear ExamplesRefisa JiruОценок пока нет

- RC Practice Set 2 2016 SolutionsДокумент5 страницRC Practice Set 2 2016 SolutionsSayed YusufОценок пока нет

- CE 434 Single Plate Shear Connection Design ExampleДокумент6 страницCE 434 Single Plate Shear Connection Design ExampleSimasero CeroОценок пока нет

- Member resistance under combined bi-axial bending and axial compressionДокумент12 страницMember resistance under combined bi-axial bending and axial compressionrd radenОценок пока нет

- Ultimate Strength Design (Doubly)Документ17 страницUltimate Strength Design (Doubly)C.j. CaparasОценок пока нет

- Designing Trapezoidal Footings for Unequal Column LoadsДокумент11 страницDesigning Trapezoidal Footings for Unequal Column LoadsJosh EdilreyОценок пока нет

- Structural Analysis II Notes Rev1Документ106 страницStructural Analysis II Notes Rev1Chris Jansen Van Rensburg100% (1)

- Slab Thickness (One Way)Документ1 страницаSlab Thickness (One Way)Jr BongabongОценок пока нет

- C 9 - Long ColumnsДокумент29 страницC 9 - Long ColumnsRekanОценок пока нет

- (Problem) Soft Storey Check in Etabs - Printable VersionДокумент2 страницы(Problem) Soft Storey Check in Etabs - Printable VersionkilmasterОценок пока нет

- Concrete Slab Design - Aci 318Документ4 страницыConcrete Slab Design - Aci 318Kutty MansoorОценок пока нет

- Lecture 5 09-29-2021 - Development, Anchorage & Splicing of ReinforcementДокумент99 страницLecture 5 09-29-2021 - Development, Anchorage & Splicing of ReinforcementMoh Sal100% (1)

- Time Period Calculation in ETABS As Per IS 1893 Part 1Документ2 страницыTime Period Calculation in ETABS As Per IS 1893 Part 1NAYAN RANPURA100% (1)

- 29 - Portal Method of Approximate AnalysisДокумент4 страницы29 - Portal Method of Approximate AnalysisMUTHUKKUMARAMОценок пока нет

- Lateral Force On Non Building StructureДокумент18 страницLateral Force On Non Building Structurefebby016Оценок пока нет

- Two-Way Concrete Slab Analysis and DesignДокумент81 страницаTwo-Way Concrete Slab Analysis and DesignBizimenyera Zenza TheonesteОценок пока нет

- How to fix STAAD.Pro warnings and errorsДокумент5 страницHow to fix STAAD.Pro warnings and errorsMohdDanishОценок пока нет

- Spandrel Flexural Design: Technical NoteДокумент11 страницSpandrel Flexural Design: Technical Notetomxxx34Оценок пока нет

- Chapter 07 PDFДокумент16 страницChapter 07 PDFMohd Aizat NasirОценок пока нет

- Deep Beams and Special Structural ElementsДокумент14 страницDeep Beams and Special Structural Elementsomar100% (1)

- CE429 - U07 - Day5 - Diaphragm - Design - ExampleДокумент14 страницCE429 - U07 - Day5 - Diaphragm - Design - Examplenick gomezОценок пока нет

- Asian Journal of Civil Engineering-Pushover Analysis of Reinforced Concrete FrameДокумент9 страницAsian Journal of Civil Engineering-Pushover Analysis of Reinforced Concrete FrameFady W. IskanderОценок пока нет

- Design of Doubly Reinforced BeamДокумент7 страницDesign of Doubly Reinforced BeamAmrutha SivaramanОценок пока нет

- Coefficient Method for Two Way Slab DesignДокумент8 страницCoefficient Method for Two Way Slab DesignMichael Vincent Estrada ObeñaОценок пока нет

- STAAD - Foundation Users Manual PDFДокумент487 страницSTAAD - Foundation Users Manual PDFTravis PaulОценок пока нет

- Strut and tie modeling, yield line analysis, and plastic analysis of concrete and steel structuresДокумент9 страницStrut and tie modeling, yield line analysis, and plastic analysis of concrete and steel structuresmalumius100% (2)

- Long Term Deflection in Concrete BeamsДокумент6 страницLong Term Deflection in Concrete BeamsRenganayagi BalajiОценок пока нет

- Lec9 Strength Design Methoddoubly Reinforced Beams 160214192041 PDFДокумент8 страницLec9 Strength Design Methoddoubly Reinforced Beams 160214192041 PDFဒုကၡ သစၥာОценок пока нет

- Ce 208Документ58 страницCe 208julesОценок пока нет

- HallДокумент30 страницHallMuhammad Faheem100% (1)

- Long Term DeflectionДокумент59 страницLong Term DeflectionWanda BeasleyОценок пока нет

- Concrete Lectures Slab.2 Direct Design Method - PPT ExamplesДокумент58 страницConcrete Lectures Slab.2 Direct Design Method - PPT ExamplesUmer WaheedОценок пока нет

- Reinforced Concrete Slab DesignДокумент29 страницReinforced Concrete Slab DesignMapanguriSitoeОценок пока нет

- Accelerated Brideg Construction in Washington StateДокумент16 страницAccelerated Brideg Construction in Washington StatesyedabdulhannanОценок пока нет

- Durable Precast Bleachers and Grandstands for Spans Up to 28 FeetДокумент5 страницDurable Precast Bleachers and Grandstands for Spans Up to 28 FeetMardeOpamenОценок пока нет

- Analysis and Design of Building Structures Aci 318R-11 With Seismic Considerations Ibc 2012 PDFДокумент338 страницAnalysis and Design of Building Structures Aci 318R-11 With Seismic Considerations Ibc 2012 PDFDavid Garcia100% (1)

- Earthquake Load Calculation (Base Shear Method) : Rigid FrameДокумент4 страницыEarthquake Load Calculation (Base Shear Method) : Rigid FrameJohn Rheynor MayoОценок пока нет

- Designing Beams for Shear ResistanceДокумент7 страницDesigning Beams for Shear ResistancestarykltОценок пока нет

- Fig. 8.5.2a-Typical Stirrup Shapes For Girders and Beams. Fig. 8.5.2b-Typical Stirrup Shape For Joists, in Addition To Fig. 8.5.2aДокумент4 страницыFig. 8.5.2a-Typical Stirrup Shapes For Girders and Beams. Fig. 8.5.2b-Typical Stirrup Shape For Joists, in Addition To Fig. 8.5.2aAdolfo OrellanaОценок пока нет

- Full Hand Calculation, Analysis and Design of Multi Story Building IIДокумент2 страницыFull Hand Calculation, Analysis and Design of Multi Story Building IIMuhammed Sarwar Hussin RosunОценок пока нет

- Composite - Design ProjectДокумент6 страницComposite - Design ProjectSomen DasОценок пока нет

- Analysis and Design of One Way SlabsДокумент9 страницAnalysis and Design of One Way Slabsسيف جمال مدين عبداللهОценок пока нет

- Panel Zone Rigid ETABS-SAP2000Документ4 страницыPanel Zone Rigid ETABS-SAP2000Carlos Manuel CorregidorОценок пока нет

- A184 PDFДокумент3 страницыA184 PDFluisОценок пока нет

- Composite Columns Design GuideДокумент66 страницComposite Columns Design Guideabdelrahman emadОценок пока нет

- Unit-IV-Shear Reinforcement and Bond by Limit State MethodДокумент50 страницUnit-IV-Shear Reinforcement and Bond by Limit State MethodAshish KaleОценок пока нет

- Advantages and DisadvantagesДокумент14 страницAdvantages and Disadvantagespaul machariaОценок пока нет

- One Way SlabДокумент5 страницOne Way SlabShoaib Mohammad Quraishi100% (2)

- Concrete Slab Analysis by Coefficient Method PDFДокумент7 страницConcrete Slab Analysis by Coefficient Method PDFJones EdombingoОценок пока нет

- 2.3 Section Properties of Built-Up Steel Sections PDFДокумент5 страниц2.3 Section Properties of Built-Up Steel Sections PDFkhx2Оценок пока нет

- Pratt Roof Truss DesignДокумент6 страницPratt Roof Truss DesignARSEОценок пока нет

- Design of Continuous Beams PDFДокумент4 страницыDesign of Continuous Beams PDFBlend DlerОценок пока нет

- Design of Reinfonced Concrete Slab by Eng:Kusundwa 0757-537605Документ53 страницыDesign of Reinfonced Concrete Slab by Eng:Kusundwa 0757-537605GoodluckОценок пока нет

- Analytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Документ15 страницAnalytical Behavior of Concrete-Encased CFST Columns Under Cyclic Lateral Loading, 2016 (Wei-Wu Qian)Phan Đào Hoàng Hiệp100% (1)

- Beam Columns: Analysis and Design for Combined Bending and Axial LoadДокумент56 страницBeam Columns: Analysis and Design for Combined Bending and Axial LoadSana'a AamirОценок пока нет

- Isolated Footing Design ProblemДокумент5 страницIsolated Footing Design ProblemthabisОценок пока нет

- MBR- DUBAI HILLS ESTATE DEVELOPMENT LANDSCAPING COST PROPOSALДокумент1 страницаMBR- DUBAI HILLS ESTATE DEVELOPMENT LANDSCAPING COST PROPOSALlayaljamal2Оценок пока нет

- General Details RoofingДокумент1 страницаGeneral Details RoofingGeorge GeorgianОценок пока нет

- PC 7r1Документ6 страницPC 7r1George GeorgianОценок пока нет

- T2Документ1 страницаT2George GeorgianОценок пока нет

- SДокумент1 страницаSGeorge GeorgianОценок пока нет

- 3Документ4 страницы3George GeorgianОценок пока нет

- 2Документ1 страница2George GeorgianОценок пока нет

- DetailДокумент1 страницаDetailGeorge GeorgianОценок пока нет

- Torsional Amplification Factor - Ax-For Response Spectrum Analysis (RSA)Документ3 страницыTorsional Amplification Factor - Ax-For Response Spectrum Analysis (RSA)George GeorgianОценок пока нет

- Seismic Design Manual (SEAOC) Vol 1 - Code Application ExamplesДокумент171 страницаSeismic Design Manual (SEAOC) Vol 1 - Code Application Examplesmgrubisic60% (5)

- Nitoproof 600Документ4 страницыNitoproof 600sandeepuaeОценок пока нет

- T1Документ1 страницаT1George GeorgianОценок пока нет

- Water TanksДокумент1 страницаWater TanksGeorge GeorgianОценок пока нет

- B 2Документ1 страницаB 2George GeorgianОценок пока нет

- B4Документ1 страницаB4George GeorgianОценок пока нет

- 0.85m (-0.55mm FROM ROAD: Missed Road Base Layer 25Cm As Per The Soil ReportДокумент1 страница0.85m (-0.55mm FROM ROAD: Missed Road Base Layer 25Cm As Per The Soil ReportGeorge GeorgianОценок пока нет

- B3Документ1 страницаB3George GeorgianОценок пока нет

- BДокумент1 страницаBGeorge GeorgianОценок пока нет

- Sub-Grade Is Less Than Required in Soil Report 26,250 kn/m3..!!Документ1 страницаSub-Grade Is Less Than Required in Soil Report 26,250 kn/m3..!!George GeorgianОценок пока нет

- Safe Out PutДокумент9 страницSafe Out PutGeorge GeorgianОценок пока нет

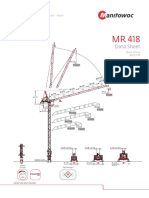

- Tower CraneДокумент1 страницаTower CraneGeorge GeorgianОценок пока нет

- Foundation Level - 1M From Road LVL Is Less Than Required in Soil Report - 1.5M As Minimum!!Документ15 страницFoundation Level - 1M From Road LVL Is Less Than Required in Soil Report - 1.5M As Minimum!!George GeorgianОценок пока нет

- Tower Crane Found.Документ1 страницаTower Crane Found.George GeorgianОценок пока нет

- TensionДокумент1 страницаTensionGeorge GeorgianОценок пока нет

- Thick PlateДокумент1 страницаThick PlateGeorge GeorgianОценок пока нет

- Moduls of Rapture..Документ1 страницаModuls of Rapture..George GeorgianОценок пока нет

- Thermal LoadsДокумент1 страницаThermal LoadsGeorge GeorgianОценок пока нет

- Miss Matching Model 1.48M, Drawings 1.15M, (More Pressure On Raft in Actual)Документ1 страницаMiss Matching Model 1.48M, Drawings 1.15M, (More Pressure On Raft in Actual)George GeorgianОценок пока нет

- Raft LevelДокумент1 страницаRaft LevelGeorge GeorgianОценок пока нет

- PunchingДокумент1 страницаPunchingGeorge GeorgianОценок пока нет

- Operation and Maintenance Manual: COD.: MUM0129 REV. 01Документ28 страницOperation and Maintenance Manual: COD.: MUM0129 REV. 01Laura Camila ManriqueОценок пока нет

- Gigabyte Sandy Bridge Overclocking GuideДокумент27 страницGigabyte Sandy Bridge Overclocking GuideGIGABYTE UK100% (2)

- Work Method Statement For Roof Sheeting WorksДокумент8 страницWork Method Statement For Roof Sheeting WorksRepl microsoft, Pune100% (1)

- Web Based Attendance Management SystemДокумент19 страницWeb Based Attendance Management SystemAnonymous zenL7LОценок пока нет

- Choose bellows size and flange styleДокумент3 страницыChoose bellows size and flange styleKrishna ChettyОценок пока нет

- Trawler SampleДокумент80 страницTrawler SampleChet Stephens100% (2)

- Senior Finance Accounting Manager in Memphis TN Resume Frank FreeseДокумент2 страницыSenior Finance Accounting Manager in Memphis TN Resume Frank FreeseFrankFreeseОценок пока нет

- Locking and Unlocking of Automobile Engine Using RFID1Документ19 страницLocking and Unlocking of Automobile Engine Using RFID1Ravi AkkiОценок пока нет

- Software Engineering FundamentalsДокумент20 страницSoftware Engineering FundamentalsNâ MííОценок пока нет

- Emergency Replacement Parts for Grove RT 760E CraneДокумент1 страницаEmergency Replacement Parts for Grove RT 760E CraneraulОценок пока нет

- 12V 8AH Deep Cycle Battery SpecsДокумент2 страницы12V 8AH Deep Cycle Battery SpecsAdrianHomescuОценок пока нет

- Inter Op Publisher User GuideДокумент322 страницыInter Op Publisher User GuideQiuniu0% (1)

- AC CIRCUIT Power AnalysisДокумент48 страницAC CIRCUIT Power AnalysisFerrer Francia Nel SabasОценок пока нет

- IEEE Práctica Recomendada Según La IEEE para Modelos de Sistemas de Excitación Parte 7Документ4 страницыIEEE Práctica Recomendada Según La IEEE para Modelos de Sistemas de Excitación Parte 7Emmanuel ZamoranoОценок пока нет

- AlbafixwffДокумент7 страницAlbafixwffjawadbasit0% (1)

- BP Solar Bp275Документ2 страницыBP Solar Bp275NandoMoralesОценок пока нет

- Acceptance Criteria Boiler (API 573)Документ1 страницаAcceptance Criteria Boiler (API 573)Nur Achmad BusairiОценок пока нет

- Final PPT BpoДокумент21 страницаFinal PPT BpoPradeepОценок пока нет