Академический Документы

Профессиональный Документы

Культура Документы

Water Treatment Poster Complete

Загружено:

dangerous0Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Water Treatment Poster Complete

Загружено:

dangerous0Авторское право:

Доступные форматы

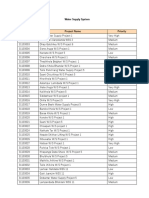

The mission of every water treatment professional is to provide a continuous

supply of drinking water that is free of contaminants that can cause disease

or be toxic to the consumer. The water must also be palatable that is,

free of unpleasant characteristics such as color, turbidity, taste and odor.

Water treatment professionals in the United States do an excellent job of

producing water that is safe and palatable. You can go virtually anywhere

in the United States and confidently drink water from the tap. Thats

because every municipal and private water treatment facility must meet

the stringent federal guidelines set forth in the Safe Drinking Water Act and

enforced by the United States Environmental

Protection Agency.

The methods used to treat water

depend on the characteristics of the

raw water. Surface water sources

(rivers, lakes, and reservoirs) generally

require more extensive treatment

than ground-water sources (well

water) because of greater exposure

to contamination. Most water treatment processes include a multi-step

approach to ensure that finished

water meets established standards.

1. Preliminary Treatment

Preliminary treatment or pretreatment is any physical, chemical or mechanical process used on water before

it undergoes the main treatment process. During preliminary treatment, screens can be used to remove rocks,

sticks, leaves and other debris; chemicals can be added to control the growth of algae; and presedimentation

can settle out sand, grit and gravel from raw water.

2. Coagulation, Flocculation and Clarification

To remove small particles that are made up of microbes, silt and other suspended material in the water, treatment

chemicals such as alum are added to the water and mixed rapidly in a large basin. The chemicals cause small

particles to clump together (coagulation). Gentle mixing brings the clumps together to form larger groups of

particles (floc). During flocculation, the heavy, dense floc slowly settles out of the water in large tanks.

Clarification occurs in a large basin where water is allowed to flow very slowly. Sludge, a residue of solids and

water, accumulates at the basins bottom and is pumped or scraped out for eventual disposal. Clarification is

sometimes called sedimentation.

4. Filtration

Turbidity is a physical characteristic that makes water appear

cloudy when suspended matter

is present. The filtration

process removes suspended

matter, which can consist of

floc, microorganisms (including

protozoan cysts such as Giardia

and Cyrptosporidium), algae,

silt, iron and manganese

precipitates from ground-water

sources, as well as precipitants

which remain after the softening process. These suspended

materials are filtered out when

water passes through beds of

granular material, usually composed of layers of sand, gravel,

coal, garnet, or related substances. (Measure turbidity

with a Hach turbidimeter.)

3. Softening and Stabilization

When water is too hard (i.e. contains

too much calcium, magnesium or other

minerals), it forms scale causing a

variety of problems in pipes. Hard water

can also result in laundering and washing

problems. Conversely, when too many of

these minerals are removed, water can

cause corrosion in pipes. That is why

drinking water plants attempt to maintain

a desirable balance between hardness and

softness. This is accomplished by adding

minerals to soft water and removing them

from hard water. (Measure hardness as

CaCO3 with a Hach titration procedure

based on the USEPA-approved method.)

5. Fluoridation & Disinfection

Finished water is

stored in holding

tanks and used

to meet the

changing water

demands of the

communities

they serve.

Lit. No. 1496

Printed in USA

K73.5 Hach Company. 1997

Fluoride (F-) is added to water to reduce tooth decay.

Fluoridation is an effective, economical process endorsed

by many public health groups worldwide. Fluoride is fed

into the water system as either a dry powder or in solution.

(A Hach fluoride test detects fluoride levels in the water.)

F-

During disinfection, disease-causing organisms are destroyed

or disabled. Chlorine (Cl2) is the most common disinfectant

used in the United States because it is practical, effective and

economical. Because chlorine dissipates rapidly, it is important that enough chlorine be added at the water treatment

plant to ensure disinfection continues while the water is flowing

through the distribution system.

(Use a USEPA-approved Hach

2

method to measure chlorine

the water.)

Cl

ISO 9001 Certified

HACH COMPANY

Toll-free (USA only): 800-227-4224

Telephone: 970-669-3050

Fax: 970-669-2932

http://www.hach.com

Вам также может понравиться

- Mollier Chart WaterДокумент1 страницаMollier Chart Waterchouchou575% (8)

- German Dwa Rules and Standards: Standard DWA-A 117EДокумент6 страницGerman Dwa Rules and Standards: Standard DWA-A 117EMehmet Emre BastopcuОценок пока нет

- 10 States Standards - Recommended Standards For Wastewater FacilitiesДокумент116 страниц10 States Standards - Recommended Standards For Wastewater FacilitiesÁrpád VassОценок пока нет

- Irrigation Drawing ManualДокумент46 страницIrrigation Drawing Manualkalai vaani100% (2)

- Design of Wastewater Treatment PlantДокумент6 страницDesign of Wastewater Treatment PlantAkila100% (2)

- (N) Chapter 6 Open Drain MsmaДокумент57 страниц(N) Chapter 6 Open Drain MsmaIr Fik TОценок пока нет

- WATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 1b - IntroductionДокумент21 страницаWATER TREATMENT TECHNOLOGY (TAS 3010) LECTURE NOTES 1b - Introductionmamat88100% (1)

- Ion Exchange Vs Ultra Filtration SystemДокумент12 страницIon Exchange Vs Ultra Filtration SystemGauravОценок пока нет

- Sustainable Treatment and ReuseДокумент581 страницаSustainable Treatment and ReuseOlga Lucia Meza Barragan100% (1)

- Sewage Sludge Management in Egypt - Ghazy 2009Документ9 страницSewage Sludge Management in Egypt - Ghazy 2009Mohamed WahbyОценок пока нет

- 10 States Standards - Recommended Standards For Water WorksДокумент134 страницы10 States Standards - Recommended Standards For Water WorksMatt Harshbarger67% (3)

- Semester 1, 2019 Examination: School of Engineering & Applied TechnologyДокумент8 страницSemester 1, 2019 Examination: School of Engineering & Applied Technologyრაქსშ საჰაОценок пока нет

- Sanitaire Difussers AerationДокумент16 страницSanitaire Difussers Aerationxbelda5041Оценок пока нет

- WWTPДокумент47 страницWWTPHar Ley QuinnОценок пока нет

- Water Demand ManagementДокумент17 страницWater Demand ManagementShaira Mae VillolaОценок пока нет

- 0a11 Lecture Notes of Water Supply Engineering 2021-2022Документ131 страница0a11 Lecture Notes of Water Supply Engineering 2021-2022عبدالله ماجد عامر زغير-B-Оценок пока нет

- OM Extended Aeration PDFДокумент25 страницOM Extended Aeration PDFHendra SusantoОценок пока нет

- Ultra Pure WaterДокумент6 страницUltra Pure Watergauravgarg115Оценок пока нет

- Sewerage Design Manual 2013 India PDFДокумент976 страницSewerage Design Manual 2013 India PDFMd Muneer PashaОценок пока нет

- EE Notes FULLДокумент56 страницEE Notes FULLAnonymous Q4MsQAОценок пока нет

- Grey Water Treatment Using Different Design of Sand FilterДокумент8 страницGrey Water Treatment Using Different Design of Sand FilterHasnanurfajriahОценок пока нет

- FOG Interceptor Design and Operation (FOGIDO) Guidance ManualДокумент54 страницыFOG Interceptor Design and Operation (FOGIDO) Guidance ManualUmer Yousuf ChaudharyОценок пока нет

- Primary Wastewater TreatmentДокумент12 страницPrimary Wastewater TreatmentJAY4029364Оценок пока нет

- Water Treatment Facilities and Process: Group IiiДокумент24 страницыWater Treatment Facilities and Process: Group IiiJackie Beltran100% (1)

- LANL Sustainable Design Guide PDFДокумент264 страницыLANL Sustainable Design Guide PDFThanh Nguyen NgocОценок пока нет

- Sika Solutions For Waste Water Treatment Plants LowДокумент48 страницSika Solutions For Waste Water Treatment Plants LowFranky KenОценок пока нет

- Lessons in Water Treatment and DistributionДокумент202 страницыLessons in Water Treatment and DistributionChristian D. Orbe100% (1)

- Working of Water Treatment PlantДокумент19 страницWorking of Water Treatment PlantJunaid Danish100% (1)

- Chapter 17 - MathematicsДокумент13 страницChapter 17 - MathematicsLivingston JosephОценок пока нет

- C08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFДокумент123 страницыC08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFAbdelilah KadriОценок пока нет

- SAB2513 Hydraulic Chapter 7Документ37 страницSAB2513 Hydraulic Chapter 7Tuan JalaiОценок пока нет

- Wastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsДокумент34 страницыWastewater Treatment Methods Physical Unit Operations Chemical Unit Operations Biological Unit OperationsNumanОценок пока нет

- Proposed Design of Wastewater Treatment Facility in Southern Luzon State University Main CampusДокумент18 страницProposed Design of Wastewater Treatment Facility in Southern Luzon State University Main CampusAce Mikko Bernardo JubeleaОценок пока нет

- CONTENTSДокумент60 страницCONTENTSsalmanОценок пока нет

- Decentralized Wastewater Treatment Highlights BrochureДокумент20 страницDecentralized Wastewater Treatment Highlights BrochureSulaiman Mohsin AbdulAzizОценок пока нет

- Assignment QuestionsДокумент5 страницAssignment QuestionsKinson Prabu100% (2)

- Combined & Separate Sewer SystemsДокумент9 страницCombined & Separate Sewer SystemsKhairylle JuanОценок пока нет

- History of Water Quality Modeling in Distribution Systems: Walter M. GraymanДокумент9 страницHistory of Water Quality Modeling in Distribution Systems: Walter M. GraymanJeison Ariel Giler MuentesОценок пока нет

- Problems of Drinking Water in Rural AreaДокумент14 страницProblems of Drinking Water in Rural AreaRoumyadeep ChakrabortyОценок пока нет

- Groundwater Quality Evaluation in Thal Doab of Indus Basin of PakistanДокумент12 страницGroundwater Quality Evaluation in Thal Doab of Indus Basin of PakistanIJMER100% (1)

- BE FeeguideДокумент18 страницBE FeeguideIrzam Hardiansyah100% (1)

- Package Type STPДокумент4 страницыPackage Type STPjeykumar.BalannairОценок пока нет

- Storage Tank BrauerДокумент31 страницаStorage Tank BrauerhbsheenОценок пока нет

- Water Resources and EngineeringДокумент26 страницWater Resources and EngineeringMayann BacerraОценок пока нет

- Drainage SystemДокумент56 страницDrainage SystemGita PitalokaОценок пока нет

- WRD Ot Activated Sludge Process 445196 7Документ162 страницыWRD Ot Activated Sludge Process 445196 7anpuselvi125Оценок пока нет

- MA - LFP Submersible MixerДокумент12 страницMA - LFP Submersible MixerSid Esterico SestosoОценок пока нет

- Softening: Water TreatmentДокумент20 страницSoftening: Water Treatmentpkgarg_iitkgpОценок пока нет

- Waste Water EngineeringДокумент14 страницWaste Water EngineeringMuhammad MubasharОценок пока нет

- Industrial Waste Water Treatment Auxiliary System Post Maintenance ChecksДокумент11 страницIndustrial Waste Water Treatment Auxiliary System Post Maintenance ChecksAbeer arifОценок пока нет

- Introduction To Water Pollution PDH Source LLCДокумент46 страницIntroduction To Water Pollution PDH Source LLCAmit Kumar MondolОценок пока нет

- Why Are Solids Are Floating On My Secondary Clarifier - Biological Waste TreatmДокумент6 страницWhy Are Solids Are Floating On My Secondary Clarifier - Biological Waste TreatmIsaac FernándezОценок пока нет

- Air Stripping TowerДокумент5 страницAir Stripping Towerchristian_ignacioОценок пока нет

- Final DPR For Tallah TankДокумент75 страницFinal DPR For Tallah TankSandeepan ChowdhuryОценок пока нет

- Telemetry For Water NetworksДокумент12 страницTelemetry For Water NetworkssusmitamandaliОценок пока нет

- EutrophicationДокумент49 страницEutrophicationBhe Bhe RanОценок пока нет

- Pool Circulation PDF Document Aqua Middle East FZCДокумент18 страницPool Circulation PDF Document Aqua Middle East FZCAdolfsmith69Оценок пока нет

- Al-Jasser, A.O. 2007 - Chlorine Decay in Drinking-Water Transmission and Distribution Systems Pipe Service Age EffectДокумент10 страницAl-Jasser, A.O. 2007 - Chlorine Decay in Drinking-Water Transmission and Distribution Systems Pipe Service Age EffectRebeca RochaОценок пока нет

- Biosolids Treatment and ManagementДокумент466 страницBiosolids Treatment and ManagementDien Dang VanОценок пока нет

- En 8491 Water Supply EngineeringДокумент36 страницEn 8491 Water Supply EngineeringsanthiamuthaОценок пока нет

- Introduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationДокумент33 страницыIntroduction To Activated Sludge Study Guide: Wisconsin Department of Natural Resources Wastewater Operator CertificationAgus WitonoОценок пока нет

- K-1 Soil and Water ConservationДокумент30 страницK-1 Soil and Water ConservationJaluPrayogaОценок пока нет

- Water Treatment ProcessesДокумент47 страницWater Treatment ProcessesTyler MontoyaОценок пока нет

- 13 - nbc-17-277 - Visible and Subvisible Particles Guide WorkshopДокумент42 страницы13 - nbc-17-277 - Visible and Subvisible Particles Guide Workshopdangerous0Оценок пока нет

- Particulate Matter: USP Requirements and Particle IdentificationДокумент53 страницыParticulate Matter: USP Requirements and Particle Identificationdangerous0Оценок пока нет

- Particle Determination: Guidance For Parenteral Products: United State PharmacopeiaДокумент36 страницParticle Determination: Guidance For Parenteral Products: United State Pharmacopeiadangerous0Оценок пока нет

- Waters LCMSWaters LCMS TroubleshootingДокумент82 страницыWaters LCMSWaters LCMS Troubleshootingdangerous0Оценок пока нет

- Page 1 of 9 HPLC Troubleshooting: 4. Problems With The ChromatogramДокумент9 страницPage 1 of 9 HPLC Troubleshooting: 4. Problems With The Chromatogramdangerous0100% (1)

- LC-MS-I (Intro)Документ29 страницLC-MS-I (Intro)dangerous0Оценок пока нет

- Performance, Productivity and Value - Combined: API 3200 Lc/Ms/Ms SystemДокумент5 страницPerformance, Productivity and Value - Combined: API 3200 Lc/Ms/Ms Systemdangerous0Оценок пока нет

- Mass Spectrometry Fundamental LC-MSДокумент24 страницыMass Spectrometry Fundamental LC-MSdangerous067% (3)

- LC/MS/MS System: Triple Quadrupole Power and Performance. On Your BenchtopДокумент6 страницLC/MS/MS System: Triple Quadrupole Power and Performance. On Your Benchtopdangerous0Оценок пока нет

- 221-03 ++Документ7 страниц221-03 ++dangerous0Оценок пока нет

- McCabe Thiele MethodДокумент7 страницMcCabe Thiele Methoddangerous0Оценок пока нет

- DistillationДокумент8 страницDistillationdangerous0100% (2)

- McCabe Thiele MethodДокумент7 страницMcCabe Thiele Methoddangerous0Оценок пока нет

- 2009 Cuyahoga River Environmental Monitoring ReportДокумент23 страницы2009 Cuyahoga River Environmental Monitoring ReportNortheast Ohio Regional Sewer DistrictОценок пока нет

- Namanve Drainage ReportДокумент27 страницNamanve Drainage Reportsoleb50% (2)

- Seepage Drainage and Flow Nets 3rd Edition Cedergren 1989 Harry R. CedergrenДокумент242 страницыSeepage Drainage and Flow Nets 3rd Edition Cedergren 1989 Harry R. CedergrenMario GalvánОценок пока нет

- ProposalДокумент8 страницProposalXenia Mae FloresОценок пока нет

- Ramsar Factsheets 1-4 enДокумент8 страницRamsar Factsheets 1-4 enPuneetОценок пока нет

- Cairo University: Faculty of EngineeringДокумент2 страницыCairo University: Faculty of Engineeringayman_awadallahОценок пока нет

- Floods in BangladeshДокумент8 страницFloods in BangladeshGopal Saha KoushikОценок пока нет

- Groundwater Monitoring in Amran Basin 2008-2010Документ24 страницыGroundwater Monitoring in Amran Basin 2008-2010FadhlОценок пока нет

- Iso 5667 11 2009 en PDFДокумент11 страницIso 5667 11 2009 en PDFRahile İyidikerОценок пока нет

- Examine The Costs and Benefits For Different StakeholdersДокумент2 страницыExamine The Costs and Benefits For Different StakeholdersElle OОценок пока нет

- JurnalДокумент7 страницJurnalJaya SinagaОценок пока нет

- National Water Quality Standards For Malaysia Parameter Unit ClassДокумент6 страницNational Water Quality Standards For Malaysia Parameter Unit ClassmaizansofiaОценок пока нет

- Water Management in CropsДокумент30 страницWater Management in CropsAarnan Buena FelizardoОценок пока нет

- Walawe Basin Short ProfileДокумент2 страницыWalawe Basin Short ProfileharshanaОценок пока нет

- Annex1 Hydraulic Calculation of The Sewer NetworkДокумент17 страницAnnex1 Hydraulic Calculation of The Sewer NetworkmuthunayakeОценок пока нет

- Annex-II Prioritize Project List PDFДокумент12 страницAnnex-II Prioritize Project List PDFpunk luitelОценок пока нет

- UF Membranes For RO Desalination Pretreatment: Peter H. Wolf, Steve Siverns, Sandro MontiДокумент8 страницUF Membranes For RO Desalination Pretreatment: Peter H. Wolf, Steve Siverns, Sandro MontiDaniela Zapata AlarcónОценок пока нет

- Davao City Water Source: University of Southeastern Phillipines Bo. Obrero, Davao CityДокумент15 страницDavao City Water Source: University of Southeastern Phillipines Bo. Obrero, Davao CityJC AsisОценок пока нет

- Presentation CWC Kerala FloodДокумент35 страницPresentation CWC Kerala FloodRahul SinghОценок пока нет

- Angat DamДокумент8 страницAngat DamChristine RiveraОценок пока нет

- Folio ScienceДокумент12 страницFolio ScienceAwang Muhammad Hamiduddin100% (1)

- Inventory of Dams in MassachusettsДокумент29 страницInventory of Dams in MassachusettsThe Boston GlobeОценок пока нет

- Rainwater Harvesting in Urban BuildingsДокумент8 страницRainwater Harvesting in Urban BuildingsTilahun TegegneОценок пока нет

- Department of Civil Engineering: Project MembersДокумент20 страницDepartment of Civil Engineering: Project MembersKanhaiya BhagatОценок пока нет

- 2SBR REACTOR - 550CMD-MAHA POLICE - XLSXДокумент5 страниц2SBR REACTOR - 550CMD-MAHA POLICE - XLSXHemant KaleОценок пока нет

- Basic Sanitation Training ManualДокумент46 страницBasic Sanitation Training ManualHelder MbidiОценок пока нет