Академический Документы

Профессиональный Документы

Культура Документы

Circular Knitted Fabrics

Загружено:

rdsekar7633%(3)33% нашли этот документ полезным (3 голоса)

3K просмотров16 страницthe presentation is about how to construct a fabric with good feel and to acheieve correct weight, width and Feelings.

Авторское право

© Attribution Non-Commercial (BY-NC)

Доступные форматы

PPS, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документthe presentation is about how to construct a fabric with good feel and to acheieve correct weight, width and Feelings.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PPS, PDF, TXT или читайте онлайн в Scribd

33%(3)33% нашли этот документ полезным (3 голоса)

3K просмотров16 страницCircular Knitted Fabrics

Загружено:

rdsekar76the presentation is about how to construct a fabric with good feel and to acheieve correct weight, width and Feelings.

Авторское право:

Attribution Non-Commercial (BY-NC)

Доступные форматы

Скачайте в формате PPS, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 16

CIRCULAR KNITTED FABRICS

@ TEA-ERC 27-10-2009

Presentation by

CBC Fashions Asia Pvt Ltd.,

Tirupur – India

Any Errors in the

presentation write to

info@cbc.co.in

Types of Fabrics

Woven Fabrics Knitted Fabrics

- Warp/Weft - Loop formation

- Varieties are Poplin, - Varieties are Jersey,

Corduroy, Flannel, RIB, Interlock,

Denim, Drill, etc., Pique, Fleece, etc.,

- Looms - Knitting machines

- Flat Knit

- Circular Knit

Knitted Fabrics

Major Fabric Main Parameters

Structures • GSM

• Single Jersey • Width

• RIB

• Shrinkage

• Interlock

Any deviation in the

All our knitted fabrics

are 90% based on above parameters

these 3 Kinds only lead to heavy loss

Construction of

Circular Knitted Fabrics

• Our conventional method of fabric construction

is basically Trial and Error Method which is

time and cost consuming

• Using Starfish Predictions from Cotton

Technology International we can construct our

fabrics based on calculations

• Main aspect for fabric construction is the Fabric

Feeling or Tightness Factor (TF)

Fabrics Based on Feeling

• Tight Fabric – Problems – Streks, Needle Holes,

Holes, Colour shading, Slubs etc

• Loose Fabric – Problems – See thru, Shrinkage,

Spirality, Unstable, Deform etc

• Normal Fabric – Good, optimum performance,

proper fit, retains shape, stable, clean and

smooth surface etc.,

Tightness Factor

• How to differentiate the Tight fabric,

Loose Fabric and Normal fabric?

• Tightness Factor is the proper

measuring tool for the fabric feeling.

• TF = √Tex Count ÷ LL in cms for 1 loop

• Tex Count = 590.46/Ne Count

• Ex. Tex Count = 590.46/30’s = 19.682

• Ex. TF = √19.682 ÷ .29 = 15.29

TF value for Regular Fabrics

S.Jersey Rib 1 x 1Interlock2T Fleece

Normal 15.5 15.5 12.5 15 Face /

1.5 Loop

Innerwear 14.5 14.5 12.0

TF is inversely proportional to LL and so

Outerwea 16.5 16.5 13.5

if LL is more then TF=14 is Less which means the fabric is

rmore loose if LL is less then TF=18 is more which means the

fabric is more tight

Using Star Fish Predictions

• Based on the TF we need to construct our fabrics using

the Star Fish predictions

• Width GSM and Shrinkage is affected mainly due to Yarn

Count and LL.

• Diameter, Gauge, RPM, No of Needles, Feeders per Inch

are not much important factor for cost saving.

• If you exactly know Finishing GSM, Finishing Dia, Finishing

Shrinkage, Exact Yarn Count, Machine Gauge and

Machine Limitations, then the star fish predictions can

help you select the knitting Dia.

• Gauge is selected based on the yarn count selected

Tex Count From Yarn

• Lea Method – Need Length in yards

and Weight in grams

• Count = 64.8/Lea Weight in grams

• 1 Lea = 120 yards

• 80 rotations in Wrap Reel = 120 yard

• 1 rotation in wrap reel = 1.5 yards

• 7 lea = 1 hanks = 840 yards

Tex Count From Fabric

• Tex Count = (Yarn Length in Inches ÷ Weight

in grams ) x 0.015

Or

• Tex Count = ( Yarn Length in cms ÷ Weight in

grams) x 0.0059

• Find out the LL from fabric is unraveling

• Then do find yarn count from the above

• Construct your fabrics

• No of 840 yards in 1 pound = Count

• 1 pound = 454 grams

• 1 yard = 0.914 mtrs

• 120 yards = 1 Lea

• 7 Leas = 7 x 120 yds = 840 yds = 1 hanks

• 454gms ÷ 7 Lea = 64.8 gms for 1 lea of 1’s

• 840 yds = 1 hanks = 1 pound or 454 gms

• 1 pound = 1 x 840 yds = 840 yds = 1’s

• 1 pound = 2 x 840 yds = 1680 yds = 2’s

• 1 pound = 10 x 840 yds = 8400 yds = 10’s

• 1 pound = 20 x 840 yds = 16800 yds = 20’s

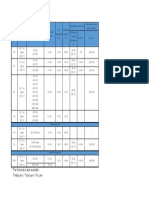

Single Jersey 150 gsm 30’s count 24gg

Knitting Quality Sample 1 Sample 2 Sample 3

Yarn Count, Ne30 28.5 28.5

Stitch Length mm2.68 2.84 2.852

Course Length in cm604.6 640.7 643.4

Tightness Factor Cgs16.56 16.03 15.96

Finishing

Course/cm20.08 18.88

Wales/CM14.97 14.27

Weight g/sq.mtr150.7 150.6 150.1

Width cm29.64 31.1 36

Yield m/Kg4.4 4.2

Length Shrinkage5 5 5

Width Shirnkage5 5 5

The star fish predictions are available

for

- Single Jersey

- 1 x 1 Rib

- 2 x 2 Rib

- Interlock

- 2t Fleece

- 2 Tuck Pique

- 1 Tuck Pique

Benetton 8110 2 x 2 Rib Live Example

• 2 x 2 Rib 220 gsm required

• Selected count 30’s so gauge 18

• LL = 27.5 cms for K.Dia = 26

• Actual count = 27.8Ne = Tex 21.23

• TF = 16.75

• Result GSM=240, width=16 Shrinkage = L -1% & W-5%

• LL can be raised to 29.5 to get lesser gsm with same count or try to get

exact count at 28.5 then the LL @ 28.5cms.

• Result awaited.

Quality Customer Service

• By doing the fabric construction in the

scientific way we can construct a good fabric,

with exact requirements regarding the gsm,

width and shrinkage, by this way we can save

a lot of time and money, which is ultimately

resulting in the customer satisfaction.

• Construct your fabric and take 1 mtr of fabric

and do 3 times washing and 3 times tumble

dry and review the resultant GSM and

Resultant Dia. Shrinkage is Nil.

More Information Contact

• Mr.Balakrishnan, Bala’s School of Knitting

• Fabric consultant - Tirupur

• +919443132940

• balas@realknit.com

• Take Experts Advice and Save Money

Вам также может понравиться

- Knitting Calculation WДокумент7 страницKnitting Calculation Wnavin19895230100% (4)

- 4.knit Fabric Specification Consumption Yarn Consumption PDFДокумент56 страниц4.knit Fabric Specification Consumption Yarn Consumption PDFRifatОценок пока нет

- Project On Knitted Fabric ParametreДокумент58 страницProject On Knitted Fabric ParametreMozzammal Hossain Shaown100% (3)

- Change of Fabric GSM With Yarn CountДокумент21 страницаChange of Fabric GSM With Yarn CountOptimisticPerson100% (2)

- Project On Knitted Fabric ParametreДокумент47 страницProject On Knitted Fabric Parametresaifsabid82% (22)

- MSC Presentation Apparel Consumption & CostingДокумент44 страницыMSC Presentation Apparel Consumption & Costingsaaqib100% (1)

- Calculate Nominal Production of A Fleece-Knitting Machine Per HourДокумент3 страницыCalculate Nominal Production of A Fleece-Knitting Machine Per HourkhurshidОценок пока нет

- Knitting CalculationsДокумент11 страницKnitting CalculationsArul Deepak50% (2)

- KnittingДокумент15 страницKnittingReyad Billah100% (1)

- Process Flow Chart of Knitting: A. Stitch LengthДокумент9 страницProcess Flow Chart of Knitting: A. Stitch LengthAushru HasanОценок пока нет

- Textile CalculationДокумент6 страницTextile CalculationKhandaker Sakib FarhadОценок пока нет

- What Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsДокумент1 страницаWhat Is Deference Between Feeder Stripe Knit Fabric With Engeenering Stripe Knit FabricsMoktar Hossain0% (1)

- Efficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionДокумент4 страницыEfficiency Losses Calculation and Identify Causes of Losses of Circular Knitting Machine During Knit Fabric ProductionElias KhalilОценок пока нет

- ..Knitting Defects and Remedies..: Made By: Raisa GuptaДокумент39 страниц..Knitting Defects and Remedies..: Made By: Raisa Guptalovelife_gupta83% (6)

- Fully FashionДокумент30 страницFully FashiondewОценок пока нет

- How To Find Yarn Count From GSM - Textile Learner PDFДокумент1 страницаHow To Find Yarn Count From GSM - Textile Learner PDFKM NAZRUL IslamОценок пока нет

- Fabric CostingДокумент3 страницыFabric CostingAsif Newton100% (1)

- Presentation ShrinkageДокумент27 страницPresentation Shrinkagemhrscribd014Оценок пока нет

- Knitting CalculationДокумент2 страницыKnitting Calculationmontasirahmed100% (1)

- Relation Betwwen Yarn Count and Fabric GSM and About Accessories and Trimmings of BangladeshДокумент32 страницыRelation Betwwen Yarn Count and Fabric GSM and About Accessories and Trimmings of BangladeshAkanda Rasel100% (10)

- Costing of Knit Garments PDFДокумент5 страницCosting of Knit Garments PDFNurlan0% (1)

- Fabric Consumption For Knit Garments Knit Fabric Consumptio CalculationДокумент2 страницыFabric Consumption For Knit Garments Knit Fabric Consumptio CalculationFaisal Ibn Haque100% (3)

- Yarn WindingДокумент22 страницыYarn WindingPRAKASH B. MALAKANE0% (1)

- Knitted Fabric Analysis CalculationДокумент5 страницKnitted Fabric Analysis Calculationmbstutextile75% (4)

- Fabric CostingДокумент5 страницFabric CostingAsif NewtonОценок пока нет

- Weaving Commission CalculationsДокумент1 страницаWeaving Commission Calculationsraj_85Оценок пока нет

- Knitting Basics: Glossary of Knitting TermsДокумент21 страницаKnitting Basics: Glossary of Knitting TermsrizvifarabiОценок пока нет

- SpiralityДокумент9 страницSpiralitySenthil KumarОценок пока нет

- Yarn Count Used According To Grey GSM - Textile CalculationДокумент3 страницыYarn Count Used According To Grey GSM - Textile CalculationSZОценок пока нет

- Circular Knitted Cotton Fabrics: Yarn Count and Respective Finished GSM (Reactive Dyeing)Документ1 страницаCircular Knitted Cotton Fabrics: Yarn Count and Respective Finished GSM (Reactive Dyeing)Kushagradhi DebnathОценок пока нет

- Formula For Fabric Weight CalcualtionДокумент2 страницыFormula For Fabric Weight Calcualtionmichahkg100% (1)

- Yarn Selection Chart Jun-2011Документ7 страницYarn Selection Chart Jun-2011montasirahmed83% (6)

- Woven Shirt Garments CostingДокумент6 страницWoven Shirt Garments CostingMd. Al-Amin AhmedОценок пока нет

- Knitting DepertmentДокумент24 страницыKnitting DepertmentLabiz Saroni ZidaОценок пока нет

- Textile Calculation Different Formula of Textile CalculationДокумент9 страницTextile Calculation Different Formula of Textile CalculationJaved AyubОценок пока нет

- Study On TEXtile FinishingДокумент8 страницStudy On TEXtile FinishingZAyed0% (1)

- Knit Fabric DefectsДокумент14 страницKnit Fabric DefectsArjun YadavОценок пока нет

- Knit Fabric FaultДокумент9 страницKnit Fabric FaultLucas HillОценок пока нет

- Operation BullatinДокумент4 страницыOperation BullatinraiyanduОценок пока нет

- Knit CalculationДокумент2 страницыKnit CalculationSelçuk AslantaşОценок пока нет

- Textil Testing Manual-Gihan RanganaДокумент16 страницTextil Testing Manual-Gihan RanganaGihan RanganaОценок пока нет

- Single Jersey and Rib FabricДокумент5 страницSingle Jersey and Rib FabricVasant Kothari100% (11)

- Sadia Alam, Lecturer (FDT), Chittagong BGMEA Institute of Fashion & TechnologyДокумент23 страницыSadia Alam, Lecturer (FDT), Chittagong BGMEA Institute of Fashion & TechnologyJubayer Uddin100% (1)

- Apparel Costing Unit - II NДокумент49 страницApparel Costing Unit - II NAnonymous BstqCP5aОценок пока нет

- Knitting 3Документ6 страницKnitting 3Sanaullah MuradОценок пока нет

- Consumption and ChartДокумент8 страницConsumption and Chartmohsin alamОценок пока нет

- Consumption Costing 2Документ10 страницConsumption Costing 2Al Arafat RummanОценок пока нет

- Winding Efficiency and CalculationДокумент16 страницWinding Efficiency and CalculationTanzila NusratОценок пока нет

- How Do Calculate The Fabric & Yarn Consumption of A Yarn Dyed T-Shirt?Документ9 страницHow Do Calculate The Fabric & Yarn Consumption of A Yarn Dyed T-Shirt?light lightОценок пока нет

- Textile InternshipДокумент62 страницыTextile InternshipNeetek SahayОценок пока нет

- Knitting Technology: A Comprehensive Handbook and Practical GuideОт EverandKnitting Technology: A Comprehensive Handbook and Practical GuideРейтинг: 3.5 из 5 звезд3.5/5 (3)

- Carr and Latham's Technology of Clothing ManufactureОт EverandCarr and Latham's Technology of Clothing ManufactureDavid J. TylerРейтинг: 4 из 5 звезд4/5 (1)

- The Jacquard Machine Analyzed and Explained: With an appendix on the preparation of jacquard cards, and practical hints to learners of jacquard designingОт EverandThe Jacquard Machine Analyzed and Explained: With an appendix on the preparation of jacquard cards, and practical hints to learners of jacquard designingОценок пока нет

- Manual Merchandising (New)Документ396 страницManual Merchandising (New)Muhammad Mubeen Iqbal PuriОценок пока нет

- Bed Linen: Profile No.: 05 NIC Code: 13924Документ8 страницBed Linen: Profile No.: 05 NIC Code: 13924amrish raiОценок пока нет

- Compression Compression FatigueДокумент11 страницCompression Compression FatigueFederico LamonОценок пока нет

- Knitting CaluculationsДокумент4 страницыKnitting CaluculationsChamal Jayasinghe100% (1)

- CV CalculationДокумент7 страницCV CalculationNirbhay Sharma71% (7)

- Stenter Machine Operator CurriculumДокумент5 страницStenter Machine Operator CurriculumMohon KhanОценок пока нет

- Develop and Compare New Software Based On Lord Equations To Calculate Fineness and Maturity Parameters by Using Hvi Instrument 2165 8064.1000178Документ4 страницыDevelop and Compare New Software Based On Lord Equations To Calculate Fineness and Maturity Parameters by Using Hvi Instrument 2165 8064.1000178niloy mominОценок пока нет

- The Influence of Cotton Fiber Properties On The Effectiveness of Lint Cleaning in GinningДокумент63 страницыThe Influence of Cotton Fiber Properties On The Effectiveness of Lint Cleaning in Ginningcan ergenekonОценок пока нет

- Dual Core YarnДокумент55 страницDual Core YarnTuan Nguyen MinhОценок пока нет

- Aircraft Fabric Covering and Finishing ModДокумент142 страницыAircraft Fabric Covering and Finishing ModEjigayehu Lemma75% (4)

- Organic Cotton Yarn QualityДокумент87 страницOrganic Cotton Yarn QualityMuhammad Qamar TusiefОценок пока нет

- 1424 - Cotton CanvasДокумент11 страниц1424 - Cotton CanvasKaushik SenguptaОценок пока нет

- Determining The Number of Constrictions "M" of Non-Woven Geotextiles As A Complementary Filtration PropertyДокумент5 страницDetermining The Number of Constrictions "M" of Non-Woven Geotextiles As A Complementary Filtration PropertymithileshОценок пока нет

- The Drapables: Our Textile Materials Made From Carbon, Glass, and Aramid FibersДокумент20 страницThe Drapables: Our Textile Materials Made From Carbon, Glass, and Aramid FibersVörös LajosОценок пока нет

- Advanced Nonwoven - Part 4Документ47 страницAdvanced Nonwoven - Part 4vamshi SiddharthОценок пока нет

- FibreДокумент4 страницыFibreAkash YadavОценок пока нет

- Annex 1, Part 2 - Schedule of Malaysia - 2bДокумент195 страницAnnex 1, Part 2 - Schedule of Malaysia - 2bJessie KhongОценок пока нет

- Card Clothing: Getting Fibers Into ShapeДокумент24 страницыCard Clothing: Getting Fibers Into ShapeKhosroОценок пока нет

- Spinning Maths-1Документ12 страницSpinning Maths-1tsukuyomi03Оценок пока нет

- Apparel Industry ReportДокумент60 страницApparel Industry ReportSachin Vaidya100% (1)

- Is 9755 2003Документ12 страницIs 9755 2003Deepak BhanjiОценок пока нет

- Mid Presentaion FYP-01Документ39 страницMid Presentaion FYP-01LARAIB JARWARОценок пока нет

- Certificate of AnalysisДокумент2 страницыCertificate of AnalysisShailesh ShahОценок пока нет

- Stiffning of CottonДокумент31 страницаStiffning of CottonPARIKSHIT RAJОценок пока нет

- Shirt Fabric Selection - Shirt Fabric Guide - Bombay Shirt CompanyДокумент3 страницыShirt Fabric Selection - Shirt Fabric Guide - Bombay Shirt CompanySaurabhОценок пока нет

- Test Parameters - Services - Textiles Committee (Ministry of Textiles, Government of India)Документ14 страницTest Parameters - Services - Textiles Committee (Ministry of Textiles, Government of India)RobinOberoyОценок пока нет

- Optimization Using Concept of Simulated AnnealingДокумент18 страницOptimization Using Concept of Simulated AnnealingSimran KerniОценок пока нет

- Summary of Solvron YarnДокумент1 страницаSummary of Solvron YarnShahan AkhtarОценок пока нет

- Testing by Ghosh PDFДокумент37 страницTesting by Ghosh PDFRajendrakumarОценок пока нет

- Knitted Fabric Analysis CalculationДокумент5 страницKnitted Fabric Analysis Calculationmbstutextile75% (4)