Академический Документы

Профессиональный Документы

Культура Документы

Roc l8 Atlas Copco

Загружено:

jacc009Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Roc l8 Atlas Copco

Загружено:

jacc009Авторское право:

Доступные форматы

Atlas Copco Surface drill rigs

ROC L825 and L830

Technical specification

The total drilling solution for large-scale mining and quarry production

Productivity and flexibility beyond conventional mining and quarry drill rigs

Improves ore to waste ratio through double benching and pre-splitting

In pit grade control with reverse circulation sampling

ROC L8 series is intended for open pit mining including selective mining, in pit grade controlwith reverse flushing, rock de-pressurerisation and quarrying. The main components are:

Opertors cabin, ROPS and FOPS approved with rubber

vibration dampers

Hydraulic cylinder operated feed system mounted inside

an aluminium profile feed beam

Toe hole drilling capability, option

Hydraulic operated rotary head

Break out table

Built for use with 4, 5 and 6 down-the-hole hammers

Reverse circulation capability, option

Caterpillar turbo charged diesel engines

Atlas Copco high pressure screw compressors

Single boom system

Heavy duty track frames with triple grouser pads and

cleaning holes, hydraulic track oscillation and two speed

traction

Hole range

Recommended hole range

ROC L825

COP 44, COP 54GE, COP 64 Gold

110-178 mm

4 5/16-7

ROC L830

COP 44, COP 54GE, COP 64 Gold

110-203 mm

4 5/16-8

Hydraulic tube handling system for max hole depth, with 5 m (16,4) tubes

ROC L825 and L830

89-114 mm (3 1/2- 4 1/2) drill tubes

45 m

148

ROC L8 and L8

127-140 mm (5- 5 /2) drill tubes

25 m

82

25

30

Hydraulic tube handling system for max hole depth, with 6 m (20) tubes and a 7.5 m starter tube

ROC L825 and L830

89-114 mm (3 1/2- 4 1/2) drill tubes

55.5 m

182

ROC L8 and L8

127-140 mm (5- 5 /2) drill tubes

31.5 m

103

ROC L825 SF and ROC L830 SF

5,4 m

18

ROC L8 LF and ROC L8 LF

7,5 m

25

25

30

Single pass drilling, max hole depth

25

30

Specifications

ROC L825 and L830

Engine

Compressor

ROC L825

Caterpillar turbo charged, diesel engine, CAT C13, Tier III/stage 3

Power rating at 1800 rpm.................... 328 kW 440 HP

ROC L830

Caterpillar turbo charged, diesel engine, CAT C15, Tier III/stage 3

Power rating at 1800 rpm.................... 402 kW 539 HP

Carrier

Tramming speed, max......................... 3.5 km/h 2.2 mph

Traction force, max.............................. 166 kN

37 310 lbf

Track oscillation.................................. 10

Ground clearance................................. 405 mm 16

Hydraulic system

Hydraulic oil cooler

Max ambient temperature.................... 50C.

122F

Pumps

Axial piston pump (1)..........................248 l/min 50 US gal/min

Gear pump (2) ....................................117 l/min 32 US gal/min

Gear pump (3) ....................................63 l/min 16.6 US gal/min

Gear pump (4) ....................................39 l/min 10.3 US gal/min

Gear pump (5) ....................................37 l/min 9.8 US gal/min

Gear pump (6)......................................37 l/min 9.8 US gal/min

Return and drainage filters (2 x 3 filters)

Filtration rate.......................................20 m absolute

Aluminium feed

Hydraulic cylinder feed with hose guide and double drill tube

support with break-out table and movable lower guide/dust hood

Feed rate, max..................................... 0.9 m/s 177 ft/min

Feed force, max................................... 40 kN

8 992 lbf

Tractive pull, max................................ 50 kN

11 240 lbf

Long Feed (LF)

Feed extension..................................... 1 150 mm 3 9

Travel length........................................ 7 540 mm 25

Short Feed (SF)

Feed extension..................................... 1 900 mm 6 3

Travel length........................................ 5 400 mm 17 7

Electrical system

Voltage................................................. 24 V

Batteries............................................... 2 x 12 V, 185 Ah

Alternator............................................. 28 V, 95 Ah

Work lights, front................................. 4 x 70 W

Work lights, rear.................................. 2 x 70 W

Warning lamp and reverse buzzer

Work lights, feed.................................. 2 x 70 W

Dust collector DCT 320F including pre-separator

Filter area.............................................32 m2

Number of filter elements....................32 pcs

Suction capacity at 500 mm wg...........1270 l/s

Suction hose diam................................203 mm

Cleaning air pressure, max..................8 bar

Cleaning air consumption....................2-4 l/pulse

.............................................................

ROC L825

Atlas Copco XRX 10, two stage screw type compressor

Working pressure, max........................ 25 bar

363 psi

FAD, at normal working pressure........ 405 l/s

858 cfm

ROC L830

Atlas Copco XRX 10, two stage screw type compressor

Working pressure, max........................ 30 bar

435 psi

FAD, at normal working pressure........ 470 l/s

995 cfm

344 ft2

2 690 cfm

8

116 psi

0,06-0,12

cf/pulse

Volumes

Hydraulic oil tank................................ 380 l

100 US gal

Hydraulic system, total........................ 470 l

124 US gal

Compressor oil..................................... 63 l

12 US gal

Diesel engine oil.................................. 30/42 l 8 US gal

Diesel engine, cooling water............... 68 l

18 US gal

Diesel engine, fuel tank....................... 760/1050 l 201/277 US gal

Traction gear........................................ 3 l

0.8 US gal

Lubrication tank (HECL).................... 20 l

5.3 US gal

Safety cabin

ROPS and FOPS approved with rubber vibration dampers

2 x wipers with washer

Clear laminated glass (front and roof windows)

Clear toughened glass (side and rear windows)

Fully adjustable operators seat

Adjustable foot rest

Cabin light

Rig inclination indicator

Rear view mirror

Fire extinguisher, 6 kg (13 lbs) dry chemical type ABE class

III type

Outlet socket, 24 V

Prepared for radio/speakers for CD radio or DVD radio

Electric combined engine/inclination/hole depth instrument

Air conditioner

Refrigerant...........................................R134a

Cooling capacity..................................5,5 kW

Fan suction capacity............................125 l/s

265 cfm

Rotary head

Rotary head

Connection thread

Max rpm

DHR 48H 45

API 2 3/8 REG, box

DHR 48H 56

API 3 1/2 REG, box

DHR 48H 68

DHR 48H RC

Max torque, drilling

Max torque, breaking

Suitable for DTH-hammer

Nm

Ibf

Nm

Ibf

137

1839

1356

1916

1413

COP 44 (COP 54)

107

2353

1735

2452

1809

COP 54, COP 64

API 3 /2 REG, box

68

3677

2712

3831

2818

COP 64

Metzke long pin, male

68

3677

2712

3831

2818

RC hammers

Down-the-hole hammer (to be ordered separately)

Hole range

Top sub thread

Weight

Length excl thread

Down-the-hole

hammer

mm

in

Type and size

kg

Ibf

mm

in

COP 44

110-130

4 5/16 - 5 1/8

API 2 3/8 REG pin

38

84

958

37,72

COP 54 GE

134-152

5-6

1119

44,1

156-178

6 1/8 - 7

165-203

6 1/2 - 8

1163

45,78

COP 64 Gold

API 2 7/8 REG pin

66

145

API 3 REG pin

76 HD

167 HD

API 3 REG pin

96

212

109 HD

241 HD

HD = Heavy duty

Transport dimensions

ROC L825 and L830

Feed dumped LF

Hight and lenght

Long Feed (LF) dumped

Height (H1)

3 500 mm

11 6

Length (L1)

11 700 mm

38 5

Height (H2)

3 350 mm

11

Length (L2)

10 700 mm

35 1

H1

Short Feed (SF) dumped

L1

Feed dumped SF

H2

L2

Dimensions and weight

Feed height (H)

Long feed (LF)

Weight

11 700 mm

Standard unit excluding all options and drill steel

385

Option Short Feed

Short Feed (SF)

9 390 mm

31

Long feed (LF)

22 600 kg

49 800 lb

Short Feed (SF)

22 200 kg

48 950 lb

2500

Side view

330

3030

3550

5450

Selection of optional equipment

Carrier

Hydraulic support leg

Service hand lights inside

canopy

Protection hand rails on top of

canopy

Halogen work light pointing to

feed support, transport position

Xenon work lights, 2 pcs on top

of canopy pointing forward and

2 pcs on top of canopy pointing

to the rear

Combined warning sound and

warning light, beacon type

Reverse camera

Automatic fire extinguisher,

P21M, type Ansul, manually

activated

Automatic fire extinguisher,

P21EAM, type Ansul, automatically activated

Tropical ambient kit for 55

ambient temperature

Electric pump for filling hydrau-

lic oil

Electric fuel filling pump

Fast fuel filling system

Cold weather kit +5 C to -25

C, including diesel engine heater

Cold weather kit -25 C and

below, including diesel engine

heater and ether start

ProCom satellite based drill rig

monitoring system (only in combination with a written service

agreement)

Safety cabin

Clear laminated glass (front and

roof windows)

Tinted toughened glass (side and

rear windows)

Sun shade kit

Cab heating

Electric heated operators seat

Radio/CD or Radio/DVD

Reverse camera with cab

mounted monitor. May also be

used for monitoring DVD

Feed

Toe hole drilling kit (ROC L825

and ROC L830 short feed)

Service winch with jib boom

mounted on the feed

Wide feed foot

Break out table pressure regulating kit

Hole measuring systems

Adding aiming unit function to

standard instrument

Adding aiming unit-, and laser

receiver function to standard

instrument

GPS compass

Lube oil, lube system and

water mist system

Central lubrication system, type

Lincoln

Thread lubrication, spray system

Artic hydraulic oil, VG 32

Tropical hydraulic oil, VG 68

Biological hydraulic oil, VG 46

Water mist system, preplumbed

for local mounted water tank

Water mist system with water

pump and 400 l water tank

Water mist system, pressurized

and with a 200 l water tank

Water mist system, insulated for

artic conditions, with water

pump and 400 l water tank

Delivered equipment, not

mounted

First 50 hours service kit for

compressor

Tool kit for rotary head with

fixed spindle sub

Tool kit for rotary head with

floating spindle sub

25

2140

Vertical reach (mm)

30

2140

Horizontal reach (mm) with long feed

2440

Horizontal reach (mm) with short feed

A

B

Long Feed

582

2 277

Short Feed

1 040

2 659

Vertical reach (mm)

30

Feed swing angles long feed

2440

4230

30

Toe-hole drilling reach for short feed

Feed swing angles

32

95

Feed with Toe-hole drilling kit for short feed

Copright 2007 Atlas Copco Rock Drills AB, rebro, Sweden. Any unauthorized use copying contents or any part there of is prohibited. This applies in particular to trademarks, model denominations, partnumbers and drawings.

Illustrations and photos in this brochure may show equipment with optional extras. Specifications and equipment subjects to change without notice. Consult your Atlas Copco sales company for specific information.

13

9851 2517 01e

Printed in Sweden 0709

Coverage areas

ROC L825 and L830

17

25

Вам также может понравиться

- SmartROC T40 Tech SpecДокумент4 страницыSmartROC T40 Tech SpecibilgeОценок пока нет

- Boomer 282.PDF PerforaoДокумент4 страницыBoomer 282.PDF Perforaoperfo 49r67% (3)

- Spec MT431B 9851 2356 01 K - tcm835-1540889Документ4 страницыSpec MT431B 9851 2356 01 K - tcm835-1540889Ariel Gallardo GalazОценок пока нет

- 07 ST1030 Steering System With Emergency SteeringДокумент20 страниц07 ST1030 Steering System With Emergency Steeringmarcelo ortiz100% (1)

- AC Explorac 220 RC SpecificationДокумент94 страницыAC Explorac 220 RC Specificationவிமல் அந்தோணி83% (6)

- 9852 1920 01g User Manual Scooptram RRCДокумент66 страниц9852 1920 01g User Manual Scooptram RRCraymundoОценок пока нет

- Simba L6CДокумент4 страницыSimba L6CsasidharreddyОценок пока нет

- 6200 Operators Manual 10218 - EnglishДокумент123 страницы6200 Operators Manual 10218 - EnglishMauro PérezОценок пока нет

- Diagrama and Drawings - PDF S1D EPIROCДокумент85 страницDiagrama and Drawings - PDF S1D EPIROCAngel Saravia Padua100% (1)

- Epiroc Drill StringsДокумент16 страницEpiroc Drill StringsCarlos Regaliza100% (1)

- DTH Drill StringsДокумент16 страницDTH Drill StringsCarlos RegalizaОценок пока нет

- Scooptram ST1030: Atlas Copco Underground LoadersДокумент4 страницыScooptram ST1030: Atlas Copco Underground LoadersHernán100% (1)

- FlexiRoc T35 EpirocДокумент5 страницFlexiRoc T35 EpirocDaniel Páez100% (2)

- 9852 1319 44 COP 44 Instructions and Part ListДокумент72 страницы9852 1319 44 COP 44 Instructions and Part ListCesar GutierrezОценок пока нет

- 3-Gama de Productos - Simbas (Документ31 страница3-Gama de Productos - Simbas (dan roy wouters sarabiaОценок пока нет

- COP 1838HD+ VerF Maintenance InstructionsДокумент50 страницCOP 1838HD+ VerF Maintenance Instructionshaimay118Оценок пока нет

- Mr-hl500 Data SheetДокумент1 страницаMr-hl500 Data SheetAlmaОценок пока нет

- Christensen 140: Surface Core Drilling RigДокумент12 страницChristensen 140: Surface Core Drilling RigAriel100% (2)

- Boomer 282 - Technical Specification (Canopy) v2Документ4 страницыBoomer 282 - Technical Specification (Canopy) v2Daniela Devlahovich BecerraОценок пока нет

- RCS-ECS-DCS V1 Atlas CopcoДокумент11 страницRCS-ECS-DCS V1 Atlas Copconechuza100% (4)

- Pit Viper 351Документ6 страницPit Viper 351Sebastian Robles100% (2)

- Pit Viper 235 High Resolution US Tcm1241-3515574Документ4 страницыPit Viper 235 High Resolution US Tcm1241-3515574Mackarena Isabel Santander Alegre100% (1)

- Power Extractors For Rock DrillsДокумент2 страницыPower Extractors For Rock DrillsMax RojasОценок пока нет

- Smartroc d65 Tier 4 Final PDFДокумент220 страницSmartroc d65 Tier 4 Final PDFnenad100% (2)

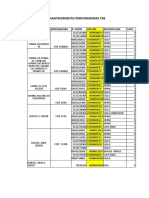

- Mantenimiento Perforadoras T38: Equipo Perforadora #Parte Cod JRC Descripccion CantДокумент1 страницаMantenimiento Perforadoras T38: Equipo Perforadora #Parte Cod JRC Descripccion CantPaulAldoОценок пока нет

- COP 1638 PresentationДокумент52 страницыCOP 1638 PresentationDavis Paredes100% (3)

- DM30Документ6 страницDM30Marco BacianОценок пока нет

- Sandvik RD927L (Underground Drills) TS2-356 - 01Документ2 страницыSandvik RD927L (Underground Drills) TS2-356 - 01rolandОценок пока нет

- Shanks Adapters Rock DrillДокумент18 страницShanks Adapters Rock DrillBelmondo Giulio50% (2)

- ECM 660IV: Atlas Copco Surface Drill RigДокумент2 страницыECM 660IV: Atlas Copco Surface Drill RigWilson wayer100% (1)

- Scooptram&Minetruck 9851 2450 01eДокумент36 страницScooptram&Minetruck 9851 2450 01elidoОценок пока нет

- Sandvik TH550 TechspecДокумент3 страницыSandvik TH550 TechspecDaniel LopezОценок пока нет

- Roc L8Документ2 страницыRoc L8Sara Contreras AОценок пока нет

- Specification Cop 1838 MeДокумент2 страницыSpecification Cop 1838 MeVeljko Lapcevic50% (4)

- ST14 V1.2 OverviewДокумент20 страницST14 V1.2 OverviewDugao Aya-os100% (2)

- Bolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec SДокумент10 страницBolting Unit: Docmine Drill Steel Sup - 200X200 Plates 8999361000-001 Boltec Scristian nahuelcuraОценок пока нет

- Minetruck MT436B 9851 2249 01N tcm835 1540890 PDFДокумент4 страницыMinetruck MT436B 9851 2249 01N tcm835 1540890 PDFbenjamin100% (1)

- DD210-V 9604sb PDFДокумент4 страницыDD210-V 9604sb PDFBrandon MoralesОценок пока нет

- Jumbo Perfuracao - Atlas Copco - Boomer L3C, XL3C, WL3C (Intervalos de Manutencao) (En)Документ50 страницJumbo Perfuracao - Atlas Copco - Boomer L3C, XL3C, WL3C (Intervalos de Manutencao) (En)Augusto Oliveira100% (3)

- Atlas Copco Diamec 232 Atlas Copco Diamec U6 PHCДокумент12 страницAtlas Copco Diamec 232 Atlas Copco Diamec U6 PHCÂngela de Carvalho50% (2)

- 9853 6819 20h Spare Parts Catalog COP 1838HD+Version FДокумент105 страниц9853 6819 20h Spare Parts Catalog COP 1838HD+Version FARMANDO ROJO80% (5)

- Operacion Roc D65 A DistanciaДокумент26 страницOperacion Roc D65 A DistanciaEnzo Piero Saez Gallardo100% (2)

- ) ) CT20 Parts - Pedido Stock Crítico 15-04-11 - Rudyñ-Ñ-ÑДокумент23 страницы) ) CT20 Parts - Pedido Stock Crítico 15-04-11 - Rudyñ-Ñ-Ñjhon ramosОценок пока нет

- 13.atlas Copco ROCKET BOOMER E1-E2 SerijaДокумент8 страниц13.atlas Copco ROCKET BOOMER E1-E2 Serijaadamajaks1985Оценок пока нет

- Electrical Instrument PDFДокумент6 страницElectrical Instrument PDFLonghuynh LêОценок пока нет

- Roc L8 (25) & Roc L8Документ4 страницыRoc L8 (25) & Roc L8Washington Huallpa100% (1)

- Rock DrillДокумент72 страницыRock Drilljosue100% (3)

- Spec ST3.5 9851 2254 01 G - tcm836-1532853Документ4 страницыSpec ST3.5 9851 2254 01 G - tcm836-1532853IoannisVourdounisОценок пока нет

- Specification Jumbo Drill Sandvik DD311D-40Документ4 страницыSpecification Jumbo Drill Sandvik DD311D-40Nathania Boas E SОценок пока нет

- Atlas Copco BOLTEC MD DIAGRAMS AND DRAWI PDFДокумент113 страницAtlas Copco BOLTEC MD DIAGRAMS AND DRAWI PDFGuillermo Velasquez AmasОценок пока нет

- Smartroc T35 and T40: Atlas Copco Surface Drill RigsДокумент4 страницыSmartroc T35 and T40: Atlas Copco Surface Drill RigsalmirОценок пока нет

- t45 Atlas CopcoДокумент4 страницыt45 Atlas CopcoEVCYОценок пока нет

- Roc L6Документ4 страницыRoc L6parikshit purohit100% (1)

- Powerroc D55: Atlas Copco Surface Drill RigsДокумент4 страницыPowerroc D55: Atlas Copco Surface Drill RigsalmirОценок пока нет

- Technical Specification Boomer E1 C - 9851 3137 01 - tcm835-3515820Документ4 страницыTechnical Specification Boomer E1 C - 9851 3137 01 - tcm835-3515820VVyldher UghoОценок пока нет

- 3406C 275 KW Prime Low BSFC - Larne1Документ6 страниц3406C 275 KW Prime Low BSFC - Larne1kichiОценок пока нет

- Boomer L2 D PDFДокумент4 страницыBoomer L2 D PDFAndres CampusanoОценок пока нет

- Simba L6 CДокумент4 страницыSimba L6 CKoko ElrОценок пока нет

- 3344 f2440Документ4 страницы3344 f2440Darwin AjomadoОценок пока нет

- Brochure Atlas Copco D65 PDFДокумент4 страницыBrochure Atlas Copco D65 PDFAldair Hugo Achahui HuarachaОценок пока нет

- Enfoques - Amenaza de Arsénico en BangladeshДокумент3 страницыEnfoques - Amenaza de Arsénico en Bangladeshjacc009Оценок пока нет

- Hot Work Fabrics Just Got SaferДокумент24 страницыHot Work Fabrics Just Got Saferjacc009Оценок пока нет

- Petzl Sport Catalog 2014 enДокумент94 страницыPetzl Sport Catalog 2014 enjacc009Оценок пока нет

- Beryllium Properties and Uses: Centers For Disease Control and PreventionДокумент30 страницBeryllium Properties and Uses: Centers For Disease Control and Preventionjacc009Оценок пока нет

- OSHA Fatal Fact 57Документ2 страницыOSHA Fatal Fact 57jacc009Оценок пока нет

- Conte945071G2 JHA 40137Документ1 страницаConte945071G2 JHA 40137jacc009Оценок пока нет

- Specific Types of Ladders: Wood Ladders Must Not Be Coated With AnyДокумент1 страницаSpecific Types of Ladders: Wood Ladders Must Not Be Coated With Anyjacc009Оценок пока нет

- Fatal Facts 72Документ2 страницыFatal Facts 72jacc0090% (1)

- Field Method Identification of Soil TextureДокумент2 страницыField Method Identification of Soil Texturejacc009Оценок пока нет

- Accident Summary No 48Документ2 страницыAccident Summary No 48jacc009Оценок пока нет

- Lathe MachineДокумент9 страницLathe MachineSteven Josh bernalОценок пока нет

- Seamless Copper Tube, Bright Annealed: Standard Specification ForДокумент6 страницSeamless Copper Tube, Bright Annealed: Standard Specification ForMostafa NabilОценок пока нет

- Einhell Catalogue RED PowerTools enДокумент84 страницыEinhell Catalogue RED PowerTools enYury Lorenz0% (1)

- HEMM Drill05Документ8 страницHEMM Drill05miningnova2Оценок пока нет

- Catalog BredentДокумент520 страницCatalog Bredentee100% (1)

- UNIT-5 Thermal Energy Based Processes: ExamplesДокумент8 страницUNIT-5 Thermal Energy Based Processes: ExamplesRamanvlrОценок пока нет

- 2006-2007 Varel FixedCutterBitsCatalogДокумент24 страницы2006-2007 Varel FixedCutterBitsCatalogAndrzej KonopkaОценок пока нет

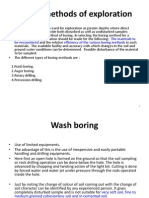

- Boring Methods of Exploration 1Документ12 страницBoring Methods of Exploration 1Amal AgharkarОценок пока нет

- Tools For Glass FinishingДокумент12 страницTools For Glass FinishingSarinОценок пока нет

- Investigation of Crane Toppling Incident: Career Episode-2Документ6 страницInvestigation of Crane Toppling Incident: Career Episode-2Thasleem ReyasОценок пока нет

- Manual - 5d Jig - V5Документ12 страницManual - 5d Jig - V5Michael PОценок пока нет

- DIY Suppliers ListДокумент39 страницDIY Suppliers Listchuck_schürch100% (6)

- Geothermal Drilling Basics Part One - Overburden DrillingДокумент2 страницыGeothermal Drilling Basics Part One - Overburden Drillingrigkits1Оценок пока нет

- Dd421 Specification Sheet EnglishДокумент4 страницыDd421 Specification Sheet Englisheduama0% (1)

- AquaTec - BR - ENДокумент20 страницAquaTec - BR - ENNashrul HakimОценок пока нет

- Method Statement - Soil Nailing ON SHEET PILESДокумент4 страницыMethod Statement - Soil Nailing ON SHEET PILESharold bindadanОценок пока нет

- Drill String ComponentsДокумент56 страницDrill String ComponentsEbenezer Amoah-Kyei50% (4)

- Fabrication of Automatic Pneumatic Clamping IgnovДокумент7 страницFabrication of Automatic Pneumatic Clamping IgnovChockalingam AthilingamОценок пока нет

- 1032329Документ6 страниц1032329Ahmed GharbiОценок пока нет

- Instructions For Childers Guns Fire Control Group Drill JigДокумент15 страницInstructions For Childers Guns Fire Control Group Drill JigFrank MeekerОценок пока нет

- Flexiroc D65: Surface Drill Rig For Quarrying and MiningДокумент5 страницFlexiroc D65: Surface Drill Rig For Quarrying and MiningCarlos FlorinОценок пока нет

- Brown 1989Документ10 страницBrown 1989PisethSaoОценок пока нет

- G & M Codes For CNC Programming: Department of Mechanical EngineeringДокумент1 страницаG & M Codes For CNC Programming: Department of Mechanical Engineeringmech_nricemОценок пока нет

- 360 Degree Flexible Drilling MachineДокумент28 страниц360 Degree Flexible Drilling MachineDHINESH IT100% (1)

- Fish PlateДокумент18 страницFish PlateAbhishek ShuklaОценок пока нет

- Basic Woodworking TextДокумент76 страницBasic Woodworking Textstaticfactory9281100% (3)

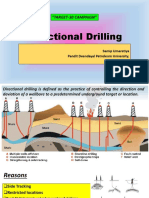

- Directional DrillingДокумент29 страницDirectional DrillingAkashShuklaОценок пока нет

- WOCD-0306-02 Rotary Drilling With Casing - A Field Proven Method of Reducing Wellbore Construction CostДокумент7 страницWOCD-0306-02 Rotary Drilling With Casing - A Field Proven Method of Reducing Wellbore Construction CostMile SikiricaОценок пока нет

- Build Your Own Flamethrower Step-By-Step Manual: Parts ListДокумент9 страницBuild Your Own Flamethrower Step-By-Step Manual: Parts Listchevy-usa-175% (4)

- SAMPLE MastercamX7 Nesting TutorialДокумент26 страницSAMPLE MastercamX7 Nesting TutorialTerapong NakthanomОценок пока нет