Академический Документы

Профессиональный Документы

Культура Документы

741 Supplier Evalution

Загружено:

PrakashRaiАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

741 Supplier Evalution

Загружено:

PrakashRaiАвторское право:

Доступные форматы

SHARDA MOTOR INDUSTRIES LIMITED

TITLE:

PROCEDURE

SUPPLIER EVALUATION AND APPROVAL

DOCUMENT

QMP-741

SECTION

--

PAGE NO.

1 of 3

REVISION NO.

00

DATE

SIGNATURE

1.0

PURPOSE

To Document the process of Supplier Evaluation to ensure Product Quality.

2.0

3.0

SCOPE

2.1

Suppliers of Raw Materials, Consumables, Parts, Packing and preservation

materials.

2.2

Sub Contractors for job work like Tooling design & Fabrication, Plating,

Painting, Heat Treatment, Machining etc.

DEFINITIONS

Supplier

providers

SEF

ASL

4.0

- vendor / subcontractor of materials, parts or service

- Supplier Evaluation Form.

- Approved Supplier List

REFERENCES

QMP 561

Management Review Procedure

5.0

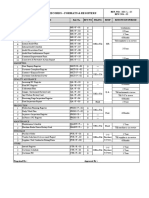

PROCEDURE

5.1

All Suppliers shall be evaluated and approved by CEO before any regular orders are

placed on them.

5.1.1 Evaluation shall be done on the SEF. The basis of Supplier Evaluation shall be one

or more of the following:

F.421 / 00

Having their Quality System certified to ISO 9000 : 2000 / QS 9000

On the Customers approved Sub Contractors List.

Manufacturers or Suppliers of proprietary items.

Regular Suppliers to reputed Customers.

Having Records of successful supplies to the Organisation for the last 6

months or more.

Reputed brands approved by the CEO.

SHARDA MOTOR INDUSTRIES LIMITED

TITLE:

PROCEDURE

SUPPLIER EVALUATION AND APPROVAL

DOCUMENT

QMP-741

SECTION

--

PAGE NO.

2 of 3

REVISION NO.

00

DATE

SIGNATURE

5.2

SUPPLIER QMS DEVELOPMENT:

5.2.1 The supplier Quality Management System shall be reviewed and audited by the

designated functions as per product requirements and remarks made on the SEF

referring to Review/Audit Reports.

5.2.2 Wherever required action plans shall be drawn jointly by the designated function and

supplier representative.

5.2.3 The action plan shall be closely monitored by the designated function and be a

subject of Management Review Meeting (QMP 561)

5.3

The suppliers approved by the CEO on the SEF shall be listed on the ASL.

5.4

CONTINUOUS EVALUATION.

5.4.1 Regular periodic monthly supplier evaluation shall be done by the designated

function on the basis of performance rating of all suppliers covering product Quality

and Delivery.

Rating = QO + QD x 0.7 + QR x 0.5 x 100

QS

Where QO = Quantity OK First Time.

QD = Quantity accepted under Deviation.

QR = Quantity after Rework / Repair or Segregation.

QS = Quantity scheduled for the Period.

5.4.2

All purchase orders / schedules and other necessary information shall be given to

the suppliers well in advance so that they are able to meet all delivery requirements.

5.4.2 Average Quarterly Rating shall be done and sent to the suppliers by the Designated

Function. The supplier is required to improve the rating if it is 80% or lower. Non

improvement of rating shall require the increase of one step in the inspection level as

per applicable Inspection Standard.

F.421 / 00

SHARDA MOTOR INDUSTRIES LIMITED

TITLE:

PROCEDURE

SUPPLIER EVALUATION AND APPROVAL

DOCUMENT

QMP-741

SECTION

--

PAGE NO.

3 of 3

REVISION NO.

00

DATE

SIGNATURE

5.4.3 Continuously failing rating may lead to dropping of supplier from the ASL by the

CEO.

6.0

DOCUMENTATION

F 741 Supplier Evaluation Form

F 742 Approved Supplier List

F 743 Supplier Performance Records

F.421 / 00

Вам также может понравиться

- Supplier Evalution & Control ProcedureДокумент4 страницыSupplier Evalution & Control ProcedurePrime Cap100% (1)

- Supplier Evaluation and Performance MonitoringДокумент5 страницSupplier Evaluation and Performance MonitoringAnonymous rXSeqXm100% (3)

- ISO Audit ProcedureДокумент3 страницыISO Audit Procedurekyunjae JetomoОценок пока нет

- SOP - Vendor Induction & Approval Procedure 062Документ1 страницаSOP - Vendor Induction & Approval Procedure 062ASIMОценок пока нет

- Supplier Quality Requirements (SQRДокумент8 страницSupplier Quality Requirements (SQRabedo danklawyОценок пока нет

- 19 Purchasing ProcedureДокумент7 страниц19 Purchasing ProcedureSasi KssОценок пока нет

- Customer Complaint HandlingДокумент7 страницCustomer Complaint HandlingpapplionОценок пока нет

- Document change request form templateДокумент1 страницаDocument change request form templatesuresh kumarОценок пока нет

- Supplier Prequalification Form-NewДокумент4 страницыSupplier Prequalification Form-Newdanu100% (1)

- TEL - SOP Flow Chart - 1010 - Tool StoreДокумент1 страницаTEL - SOP Flow Chart - 1010 - Tool StoreMersal GopiОценок пока нет

- Procedure for Purchase SOPДокумент6 страницProcedure for Purchase SOPShakti ShuklaОценок пока нет

- Annual Supplier AuditДокумент13 страницAnnual Supplier Auditori wahyuni100% (1)

- Procedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical GuidelinesДокумент2 страницыProcedure For Qualification of Vendors For Raw Material and Packaging Materials - Pharmaceutical Guidelineskavya nainitaОценок пока нет

- Procedure - Outsourced ProcessesДокумент1 страницаProcedure - Outsourced Processesmgamal1080Оценок пока нет

- Non Conformance ProcedureДокумент3 страницыNon Conformance ProcedureBharamu Patil33% (3)

- SOP Corrective Action: SOP As Approved by The Program Signing AuthorityДокумент1 страницаSOP Corrective Action: SOP As Approved by The Program Signing Authoritysudar1477Оценок пока нет

- Process Effectiveness Assessment ReportДокумент2 страницыProcess Effectiveness Assessment Reportjohnoo7Оценок пока нет

- SOP - APS - PUR - 02 - Procedure For PurchaseДокумент6 страницSOP - APS - PUR - 02 - Procedure For PurchasePrakash PatelОценок пока нет

- Product Change Over ChecklistДокумент1 страницаProduct Change Over ChecklistSatee Manick100% (1)

- Customer Complaint HandlingДокумент3 страницыCustomer Complaint HandlingNageswara raoОценок пока нет

- 9001.2015 Quality Manual Ver. 3Документ3 страницы9001.2015 Quality Manual Ver. 3Vasu RajaОценок пока нет

- Customer Complaint FormДокумент1 страницаCustomer Complaint FormDharmesh Patel100% (1)

- Quality Assurance Supplier Survey Audit FormДокумент4 страницыQuality Assurance Supplier Survey Audit FormstevierayoОценок пока нет

- SOP For Handling of Rejected Raw MaterialДокумент6 страницSOP For Handling of Rejected Raw Materialanoushia alviОценок пока нет

- Department Quality & FS Objective (Revision2015) - SampleДокумент1 страницаDepartment Quality & FS Objective (Revision2015) - SampleRachel YapОценок пока нет

- Selecting and Approving SuppliersДокумент3 страницыSelecting and Approving SuppliersBharath50% (4)

- Mock Recall LogДокумент3 страницыMock Recall LogDerren Ivy Shine VeñigasОценок пока нет

- Fsms-Sop-14 - Procedure For Control of Non-Conforming ProductsДокумент5 страницFsms-Sop-14 - Procedure For Control of Non-Conforming ProductsSanthosh VelusamyОценок пока нет

- 123Документ30 страниц123Pinkoo QualityОценок пока нет

- CalibrationДокумент6 страницCalibrationListen TawandaОценок пока нет

- Evaluate Supplier Quality QuestionnaireДокумент6 страницEvaluate Supplier Quality Questionnairenithi_123100% (1)

- A Control of Nonconforming Material: Document Number Revision Title Rev DateДокумент3 страницыA Control of Nonconforming Material: Document Number Revision Title Rev DateImam MansyurОценок пока нет

- Blow Packaging India LTD: List of Approved SuppliersДокумент3 страницыBlow Packaging India LTD: List of Approved Suppliersvishvendan100% (1)

- ISO 13485:2016 Quality Systems Manual: Document No. QMD-001Документ11 страницISO 13485:2016 Quality Systems Manual: Document No. QMD-001Roslan.Affandi2351Оценок пока нет

- Name of Employee: Performance Evaluation FormДокумент5 страницName of Employee: Performance Evaluation FormShemu PlcОценок пока нет

- Process Performance MeasuresДокумент2 страницыProcess Performance MeasuresKarthi ThiyagarajanОценок пока нет

- Procedure Recall ProductДокумент3 страницыProcedure Recall ProductLinda Setya WatiОценок пока нет

- ISO SOP Procedure ControlДокумент4 страницыISO SOP Procedure ControlPINTU RAJОценок пока нет

- Sta-P08-02 Non Conforming ProductДокумент6 страницSta-P08-02 Non Conforming ProductAnonymous B7pghhОценок пока нет

- Centurion Power Cables (P) LTD.: 1.0 PurposeДокумент4 страницыCenturion Power Cables (P) LTD.: 1.0 PurposetriveshОценок пока нет

- List of Records - Formats & RegistersДокумент1 страницаList of Records - Formats & RegistersSuraj KadamОценок пока нет

- 1.procedure For Incoming Material. Customer Products (6 Files Merged)Документ16 страниц1.procedure For Incoming Material. Customer Products (6 Files Merged)Valentine GaneshОценок пока нет

- SOP-LoadingДокумент2 страницыSOP-LoadingWilliam BudiharsonoОценок пока нет

- Outsourced Processes Procedure Full Client Name Reg Caps Rev Rev NumberДокумент1 страницаOutsourced Processes Procedure Full Client Name Reg Caps Rev Rev Numberdellanadia putriОценок пока нет

- Control of Non ConformingДокумент5 страницControl of Non ConformingNaveenkumar R100% (1)

- Supplier Evaluation and Approval - Disapproval PGP2001AДокумент6 страницSupplier Evaluation and Approval - Disapproval PGP2001ASayed AbbasОценок пока нет

- Non-Conforming Product ProcedureДокумент3 страницыNon-Conforming Product ProcedureHamzah Abbass SibaiОценок пока нет

- List of Mandatory Records For ISO 9001Документ2 страницыList of Mandatory Records For ISO 9001NC Rigor Luis100% (2)

- Control of Monitoring and Measuring EquipmentДокумент3 страницыControl of Monitoring and Measuring EquipmentLinda Setya WatiОценок пока нет

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeДокумент1 страницаReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaОценок пока нет

- QP Nonconforming Product Sample 2014Документ2 страницыQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Control Nonconforming ProductsДокумент14 страницControl Nonconforming ProductsAli KayaОценок пока нет

- Form - Scar LogДокумент18 страницForm - Scar LogHarie BongkyОценок пока нет

- A6. Control of Nonconforming ProductДокумент6 страницA6. Control of Nonconforming ProductStanley MtamboОценок пока нет

- Draft Purchase ProceduresДокумент11 страницDraft Purchase Proceduresvishwanath cОценок пока нет

- 4list of DocumentsДокумент2 страницы4list of Documentsrishi gautam100% (1)

- Quality Manual 2020 V5.0Документ84 страницыQuality Manual 2020 V5.0KKSAT100% (1)

- Supplier Quality ManualДокумент29 страницSupplier Quality Manualppanambo100% (2)

- Vender Appoval SOP (PHARMA IND)Документ8 страницVender Appoval SOP (PHARMA IND)Prem Goel91% (23)

- Service & Maintenance of Jaguar & Land Rover CarsДокумент76 страницService & Maintenance of Jaguar & Land Rover CarsPrakashRaiОценок пока нет

- Presentation - IsO 14001Документ43 страницыPresentation - IsO 14001PrakashRaiОценок пока нет

- Innoregio Value AnalysisДокумент32 страницыInnoregio Value Analysisirinuca12Оценок пока нет

- 722 CSRДокумент1 страница722 CSRPrakashRaiОценок пока нет

- Process & Product Audit Check SheetДокумент6 страницProcess & Product Audit Check SheetPrakashRai100% (7)

- QFD Guide: Quality Function Deployment ProcessДокумент32 страницыQFD Guide: Quality Function Deployment ProcessPrakashRaiОценок пока нет

- Green Belt Project Documentation 182191KSP9300CДокумент45 страницGreen Belt Project Documentation 182191KSP9300CPrakashRai100% (1)

- Vendor RatingДокумент3 страницыVendor RatingPrakashRaiОценок пока нет

- Reducing Thickness Variation in Oil Cooler PartsДокумент49 страницReducing Thickness Variation in Oil Cooler PartsPrakashRai100% (1)

- 831 Control of NC ProductsДокумент2 страницы831 Control of NC ProductsPrakashRaiОценок пока нет

- Preparation and Audit of Process Sheet & Tool Sheet For in Vehicle Assembly ShopДокумент18 страницPreparation and Audit of Process Sheet & Tool Sheet For in Vehicle Assembly ShopPrakashRaiОценок пока нет

- InternshipДокумент45 страницInternshipPrakashRaiОценок пока нет

- Summry of Industrial ScenarioДокумент24 страницыSummry of Industrial ScenarioPrakashRaiОценок пока нет

- Automotive Maintenance and ServiceДокумент18 страницAutomotive Maintenance and ServicePrakashRaiОценок пока нет

- Analysis of Online Defects in Mass Production of AutomobileДокумент22 страницыAnalysis of Online Defects in Mass Production of AutomobilePrakashRaiОценок пока нет

- Automotive Transmission PDFДокумент148 страницAutomotive Transmission PDFssenthilguruОценок пока нет

- Automotive Service and Maintenance in Mercedes Benz: Swapnil Ravi Sharma A23262 13027Документ14 страницAutomotive Service and Maintenance in Mercedes Benz: Swapnil Ravi Sharma A23262 13027PrakashRaiОценок пока нет

- Study On FixtureДокумент24 страницыStudy On FixturePrakashRaiОценок пока нет

- Supplier Quality Assurance in Auto SectorДокумент27 страницSupplier Quality Assurance in Auto SectorPrakashRaiОценок пока нет

- M&E PlanДокумент13 страницM&E PlanVitalise AdongoОценок пока нет

- Child Custody Evaluations and Need For StandardsДокумент12 страницChild Custody Evaluations and Need For StandardsRaghu72Оценок пока нет

- NCM 102 Midterm NotesДокумент444 страницыNCM 102 Midterm NotesJude Marie Claire DequiñaОценок пока нет

- BUSINESS & FUNCTIONAL LEVEL STRATEGIESДокумент26 страницBUSINESS & FUNCTIONAL LEVEL STRATEGIESsejal AgarwalОценок пока нет

- Cochrane Handbook For Systematic Reviews of InterventionsДокумент8 страницCochrane Handbook For Systematic Reviews of InterventionsvinkaauriaОценок пока нет

- Coun 569 Dev Foun in Coun Syllabus 10 9 13Документ9 страницCoun 569 Dev Foun in Coun Syllabus 10 9 13api-307653540Оценок пока нет

- PCW DILG DBM NEDA JMC No. 2013-01-0Документ74 страницыPCW DILG DBM NEDA JMC No. 2013-01-0florianjunior0% (1)

- Business Policy and Strategic ManagementДокумент11 страницBusiness Policy and Strategic Managementanjankumar88% (16)

- E Learning Essentials 508Документ28 страницE Learning Essentials 508api-559575515Оценок пока нет

- Advanced Design Culture - BookДокумент168 страницAdvanced Design Culture - Bookivan.tolicОценок пока нет

- ReSource 4.3.6 Mining Route GVERKДокумент19 страницReSource 4.3.6 Mining Route GVERKFana BurzoОценок пока нет

- COVID Test AuditДокумент133 страницыCOVID Test AuditChris BerinatoОценок пока нет

- Environmental Psychology Exam 4 Study Guide (Questions Only)Документ3 страницыEnvironmental Psychology Exam 4 Study Guide (Questions Only)Generic_PersonaОценок пока нет

- AssessmentДокумент6 страницAssessmentElson ValenciaОценок пока нет

- MKIS & MR Techniques for Marketing DecisionsДокумент13 страницMKIS & MR Techniques for Marketing DecisionsSahilesh PathakОценок пока нет

- QuestionnaireДокумент48 страницQuestionnaireگلوبل کنسلٹنٹسОценок пока нет

- IB AQ 8A - June2020Документ17 страницIB AQ 8A - June2020lingedzaninОценок пока нет

- Grophel L. Mesa EDUC 214 (Midterm Exam)Документ5 страницGrophel L. Mesa EDUC 214 (Midterm Exam)Grophel MesaОценок пока нет

- Perspective PlanДокумент70 страницPerspective PlanMunah KausarОценок пока нет

- BPSM Unit-4: Strategic Analysis, Objectives and ImplementationДокумент5 страницBPSM Unit-4: Strategic Analysis, Objectives and Implementationsarita sahooОценок пока нет

- Revised Assessment Tool SBMДокумент20 страницRevised Assessment Tool SBMRichard Alboro50% (2)

- Agricultural Extension OverviewДокумент67 страницAgricultural Extension OverviewAlvin Watin100% (1)

- PDCAДокумент3 страницыPDCARicardo Damasceno Moreira FilhoОценок пока нет

- Gad 1Документ98 страницGad 1LalaLanibaОценок пока нет

- Cadets Views On Undergoing Maritime Education andДокумент10 страницCadets Views On Undergoing Maritime Education andErcan YüksekyıldızОценок пока нет

- RussiaMikeScholey ESPДокумент14 страницRussiaMikeScholey ESPsayyed.rashidОценок пока нет

- iTEP Academic Plus Vs TOEFL IBT Comparison Chart PDFДокумент1 страницаiTEP Academic Plus Vs TOEFL IBT Comparison Chart PDFAbera MamoОценок пока нет

- Topic 4 Roles of Curr WorkerДокумент8 страницTopic 4 Roles of Curr Workerruffmyza100% (5)

- Guidance For Post Covid Restart of Operations Cbta Training SolutionsДокумент75 страницGuidance For Post Covid Restart of Operations Cbta Training SolutionskyawОценок пока нет

- The Relationship Between ISO 9000 and Business PerformanceДокумент15 страницThe Relationship Between ISO 9000 and Business PerformanceJamile L GérsonОценок пока нет