Академический Документы

Профессиональный Документы

Культура Документы

Layered Process Audit Form

Загружено:

Pawan SehrawatАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Layered Process Audit Form

Загружено:

Pawan SehrawatАвторское право:

Доступные форматы

Layered Audit Form

Production

Supervisor:______________________________

Time:____________________________________

DATE:___________________________________

Manager:

Time:

Date:

Audit Frequency: Supervisors daily, Management daily, Plant Manager monthly

Record line/product audited:

Supervisor

Item Audited

Audit Criteria

Audit

Result

Findings / Action Taken

Manager

Audit

Result

Key Area's

House Keeping Is floor clean? (including parts, tags

or other items)

Is the area organized?

Labeling

Is all non-conforming product tagged

and segregated from good product?

Is all obsolete stock off the dock?

Are all areas of the tags properly filled

out?

Are all containers properly labeled,

are moved tickets filled out?

Operator

Are work instruction posted at each

operation with training matrix?

Safety

Is all proper Personal Protective

Equipment being worn?

Are all containers stacked in a safe

and proper manner?

Quality

If there are quality alerts, are they

posted and signed off?

If applicable, are all steel coils

properly identified?

QSF 17.6 Rev. D 05/04/05

Findings/Action Taken

Layered Audit Form

Supervisor:______________________________

Time:____________________________________

DATE:___________________________________

Quality

Manager:

Time:

Date:

Audit Frequency: Supervisors daily, Management daily, Plant Manager monthly

Record line/product audited:

Supervisor

Item Audited

Audit Criteria

Audit

Result

Findings / Action Taken

Superintendent / Manager

Audit Result

Key Area's

House Keeping Is the floor clean? (including parts,

tags or other items)

Is the proper lighting available for

visual inspection?

Are there any light bulbs out?

Labeling

Operator

Safety

Quality

Is all non-conforming product tagged

and segregated from good product?

Is containment area clearly identified?

Are all areas of the tags properly filled

out?

Are there any pre-printed or old

part number labels in the area?

Are work instruction posted at each

operation with training matrix?

Is shift SAR sheet present and

in use?

Is all proper Personal Protective

Equipment being worn?

Are all the containers stacked in a

safe and proper manner?

Are all dimensional checks being

completed?

Are all GP12 requirements being

completed?

Are all dimensional checks within

customer tolerances?

Is there an action plan or corrective

action in place to deal with nonconformances?

Is there any missing information or

improper information on the boards?

Are all stage samples available at

the line?

Are all first off's signed, dated and

available at the line?

QSF 17.7 Rev. D 05/04/05

Findings/Action Taken

Layered Audit Form

Manager:

Supervisor:______________________________

Time:____________________________________

Shipping

Time:

DATE:___________________________________

Date:

Audit Frequency: Supervisors daily, Management daily, Plant Manager monthly

Record line/product audited:

Supervisor

Item Audited

Audit Criteria

Audit

Result

Findings / Action Taken

Manager

Audit Result

Key Area's

House Keeping Is floor clean? (including parts, tags

or other items)

Is the area organized?

Labeling

Is all non-conforming product tagged

and segregated from good product?

Is all obsolete stock off the dock?

Are all areas of the tags properly filled

out?

Are there any pre-printed or old

part number labels in the area?

Operator

Are work instruction posted at each

operation with training matrix?

Safety

Is all proper Personal Protective

Equipment being worn?

Are all containers stacked in a safe

and proper manner?

Quality

Is the dock auditor stamp present on

all shipping labels?

Is the dock auditor book available for

review?

QSF 17.5 Rev. C 02/08/05

Findings/Action Taken

Вам также может понравиться

- Traceability Audit ChecklistДокумент12 страницTraceability Audit ChecklistFirmino Simplicio0% (1)

- Appendix 25 VDA 6 3 Process AuditДокумент12 страницAppendix 25 VDA 6 3 Process AuditSeda De Drasnia100% (1)

- Manufacturing Process Audit ScorecardДокумент1 страницаManufacturing Process Audit ScorecardSachin Kumbhar100% (1)

- Daimler-Chrysler LPA Training at SRAFДокумент27 страницDaimler-Chrysler LPA Training at SRAFMarcela Gonçalves100% (3)

- LPA Checklist Excel Table v6Документ3 страницыLPA Checklist Excel Table v6Je UrdanetaОценок пока нет

- IATF 16949:2016 Audit Guide and Checklist 2nd EditionОт EverandIATF 16949:2016 Audit Guide and Checklist 2nd EditionРейтинг: 4.5 из 5 звезд4.5/5 (10)

- VDA 6.3 Audit Report (English)Документ4 страницыVDA 6.3 Audit Report (English)bruno_inácio80% (5)

- Annexure-1 Customer Specific Requirement MatrixДокумент5 страницAnnexure-1 Customer Specific Requirement MatrixSunil Shrivastava50% (2)

- Control Plan 1st Edition - AnalysisДокумент9 страницControl Plan 1st Edition - AnalysisYassin Serhani100% (1)

- Process-Audit-VDA-6.3 ChecklistДокумент10 страницProcess-Audit-VDA-6.3 ChecklistRambir Kaushik50% (2)

- IATF 16949-2016 Audit ChecklistДокумент129 страницIATF 16949-2016 Audit ChecklistRajeshLSОценок пока нет

- Layered Audit System VerificationДокумент13 страницLayered Audit System VerificationcpsinasОценок пока нет

- VDA Volume 4 8D-MethodДокумент23 страницыVDA Volume 4 8D-MethodJuan Egara100% (8)

- Control Plan for Manufacturing Sway BarsДокумент3 страницыControl Plan for Manufacturing Sway BarsSaravana Bharathy Reddy100% (2)

- Internal Audit ChecklistДокумент37 страницInternal Audit ChecklistSumeet Rathee100% (5)

- PRODUCT AUDIT CHECKLIST (WO Schedule)Документ7 страницPRODUCT AUDIT CHECKLIST (WO Schedule)Ranjeet Dongre100% (1)

- Vda 63 Potenzialanalyse Version r3 EnglДокумент18 страницVda 63 Potenzialanalyse Version r3 EnglSudhagarОценок пока нет

- Cqi - 9Документ63 страницыCqi - 9karina medi100% (2)

- VDA Special CharacteristicsДокумент45 страницVDA Special Characteristicsrenato fabbri100% (11)

- VDA 6.3 QuestionДокумент2 страницыVDA 6.3 QuestionRamavallabhan83% (6)

- IATF 16949 2016 Mandatory ProcedureДокумент1 страницаIATF 16949 2016 Mandatory Procedureshivendrakumar100% (3)

- MSA Reference Manual 4th EditionДокумент241 страницаMSA Reference Manual 4th Editionarnaljos100% (6)

- APQP Check ListДокумент17 страницAPQP Check ListmdjeckelОценок пока нет

- VDA6.3 GuideДокумент207 страницVDA6.3 GuideVanessa Alves Moreira90% (10)

- Apqp PpapДокумент50 страницApqp PpapEvandro Ribeiro50% (2)

- VDA 6.3 Process Audit OverviewДокумент18 страницVDA 6.3 Process Audit OverviewdavidОценок пока нет

- Sop-Special Characteristics IdentificationДокумент3 страницыSop-Special Characteristics IdentificationSaravana kumar NagarajanОценок пока нет

- LPA - Layer Process Audit GuidelinesДокумент23 страницыLPA - Layer Process Audit GuidelinesR J100% (2)

- IATF 16949-2016 Intro and Clauses PDFДокумент274 страницыIATF 16949-2016 Intro and Clauses PDFneetuyadav2250% (2)

- VDA 6.3 Based Supplier AssessmentДокумент11 страницVDA 6.3 Based Supplier AssessmentGrecu Dragos100% (1)

- IATF Process Audit Check Sheet FormatДокумент14 страницIATF Process Audit Check Sheet Formatukavathekar71% (7)

- Control Plan Audit FormДокумент2 страницыControl Plan Audit Formdpcastilla50% (2)

- PFMEA Audit ChecklistДокумент2 страницыPFMEA Audit Checklistadnans100% (3)

- MSIL Audit Cheklist 16Документ22 страницыMSIL Audit Cheklist 16Pravin Balasaheb GunjalОценок пока нет

- VDA 6.3audit GuidelinesДокумент25 страницVDA 6.3audit Guidelinesavinash_k007100% (4)

- VDA 6.3 Training MaterialДокумент128 страницVDA 6.3 Training MaterialSachin Ramdurg100% (7)

- IATF 16949 Documentation Toolkit GuideДокумент4 страницыIATF 16949 Documentation Toolkit GuideOscar Solis MartirОценок пока нет

- IATF 16949 Documentation Toolkit GuideДокумент4 страницыIATF 16949 Documentation Toolkit GuideRahul SharmaОценок пока нет

- Trigger matrix appendix changesДокумент1 страницаTrigger matrix appendix changesJuan José Viñas Méndez0% (1)

- Gap Analysis (Vda Vs TS)Документ4 страницыGap Analysis (Vda Vs TS)Saipul Iza100% (2)

- VDA 6.3 Standard Questionnaire enДокумент19 страницVDA 6.3 Standard Questionnaire enFlorida Elena MitroiОценок пока нет

- Cqi 8 Layered Process Audits GuidelineДокумент2 страницыCqi 8 Layered Process Audits GuidelinePraveen Malavae33% (3)

- Msa4 Vda5 EaДокумент6 страницMsa4 Vda5 EaAderitoef100% (1)

- ISO 9001 Quality Procedure Context of the OrganizationДокумент1 страницаISO 9001 Quality Procedure Context of the OrganizationKarim HakimОценок пока нет

- Updated - VDA 6 5 Module Training For Product Auditors PDFДокумент2 страницыUpdated - VDA 6 5 Module Training For Product Auditors PDFAnikesh KumarОценок пока нет

- Supplier Quality Management A Complete Guide - 2020 EditionОт EverandSupplier Quality Management A Complete Guide - 2020 EditionОценок пока нет

- Excel Tool Potential Analyse VDA 6.3 2010 enДокумент9 страницExcel Tool Potential Analyse VDA 6.3 2010 enJohn Oo100% (1)

- IATF 16949 2016 Gap Tool InstructionsДокумент11 страницIATF 16949 2016 Gap Tool InstructionsJosé María Moreno63% (8)

- Company Name: Engineering Location: Customer Name: Model Year / PlatformДокумент45 страницCompany Name: Engineering Location: Customer Name: Model Year / Platformsuresh kumar0% (1)

- VDA FMEA TemplateДокумент53 страницыVDA FMEA Templatewatna0% (2)

- QD83 - Global Supplier Quality Directive - Edition 2018Документ66 страницQD83 - Global Supplier Quality Directive - Edition 2018mirosek100% (1)

- QAF12 Process Audit Rev 09Документ4 страницыQAF12 Process Audit Rev 09ukavathekarОценок пока нет

- Production Part Approval Process A Complete Guide - 2019 EditionОт EverandProduction Part Approval Process A Complete Guide - 2019 EditionОценок пока нет

- Supplier Assessment ChecklistДокумент2 страницыSupplier Assessment ChecklistCOLONEL ZIKRIA100% (1)

- Progressive AuditДокумент40 страницProgressive AuditMaye MtzОценок пока нет

- BulletinДокумент18 страницBulletinPawan SehrawatОценок пока нет

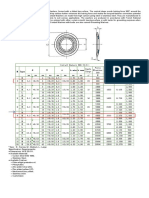

- Conical Contact Washers NFE 25-511Документ1 страницаConical Contact Washers NFE 25-511Pawan SehrawatОценок пока нет

- Machines, Parts and Accessories CatalogДокумент74 страницыMachines, Parts and Accessories CatalogPawan SehrawatОценок пока нет

- Fundamentals of GD&T With The Background of GD&TДокумент50 страницFundamentals of GD&T With The Background of GD&TRajasekaran VtОценок пока нет

- GN1 - Good Practice A4 DONEДокумент10 страницGN1 - Good Practice A4 DONEchris655Оценок пока нет

- GDT Spring 2010tДокумент278 страницGDT Spring 2010tYanaki HristovОценок пока нет

- Jenny Gas Fired Steam Cleaner: Solving Individual Cleaning Problems WorldwideДокумент2 страницыJenny Gas Fired Steam Cleaner: Solving Individual Cleaning Problems WorldwidePawan SehrawatОценок пока нет

- Psychromoist User GuideДокумент10 страницPsychromoist User GuidePawan SehrawatОценок пока нет

- Selecting Air Filters for Indoor Air QualityДокумент11 страницSelecting Air Filters for Indoor Air QualityPawan SehrawatОценок пока нет

- Steam Jenny ElectricДокумент2 страницыSteam Jenny ElectricPawan SehrawatОценок пока нет

- Engineering & Design: Geometric Dimensioning: SectionДокумент34 страницыEngineering & Design: Geometric Dimensioning: SectionVinaya Almane DattathreyaОценок пока нет

- Steam Jenny ManualДокумент48 страницSteam Jenny ManualPawan SehrawatОценок пока нет

- SOP - Reliability AssessmentДокумент12 страницSOP - Reliability AssessmentPawan Sehrawat0% (2)

- Introduction to Geometric Dimensioning and TolerancingДокумент8 страницIntroduction to Geometric Dimensioning and TolerancingPawan SehrawatОценок пока нет

- R134a PropertiesДокумент2 страницыR134a PropertiesPawan SehrawatОценок пока нет

- Standard Tightening TorqueДокумент1 страницаStandard Tightening TorquebalramkinageОценок пока нет

- Laboratory Quality StandardsДокумент74 страницыLaboratory Quality StandardsPawan Sehrawat100% (2)

- R134a Properties at - 6.7 Deg PDFДокумент2 страницыR134a Properties at - 6.7 Deg PDFPawan SehrawatОценок пока нет

- Natural ConvectionДокумент7 страницNatural ConvectionPeterОценок пока нет

- Natural ConvectionДокумент7 страницNatural ConvectionPeterОценок пока нет

- Kcn463hag BXXXДокумент4 страницыKcn463hag BXXXPawan SehrawatОценок пока нет

- LPA MistakesДокумент1 страницаLPA MistakesPawan SehrawatОценок пока нет

- How To Dry A Refrigeration System?Документ5 страницHow To Dry A Refrigeration System?Pawan SehrawatОценок пока нет

- Understanding LPA SystemДокумент1 страницаUnderstanding LPA SystemPawan SehrawatОценок пока нет

- Pareto Diagram PDFДокумент39 страницPareto Diagram PDFPawan SehrawatОценок пока нет

- Type 2 Switchgear CombinationДокумент15 страницType 2 Switchgear CombinationPawan SehrawatОценок пока нет

- LPA SystemДокумент6 страницLPA SystemPawan SehrawatОценок пока нет

- Importance of Moisture Free Refrigeration SystemДокумент5 страницImportance of Moisture Free Refrigeration SystemPawan SehrawatОценок пока нет

- General Safety Rules in HINDIДокумент3 страницыGeneral Safety Rules in HINDIPawan Sehrawat67% (6)

- The Investment Function in Banking and Financial-Services ManagementДокумент18 страницThe Investment Function in Banking and Financial-Services ManagementHaris FadžanОценок пока нет

- BDW94CДокумент7 страницBDW94CWalter FabianОценок пока нет

- Advanced Accounting Part 2 Dayag 2015 Chapter 12Документ17 страницAdvanced Accounting Part 2 Dayag 2015 Chapter 12crispyy turon100% (1)

- L-5 - Regulatory Framework For BanksДокумент21 страницаL-5 - Regulatory Framework For BanksVinay SudaniОценок пока нет

- Environmental Assessment Template Group MembersДокумент4 страницыEnvironmental Assessment Template Group MembersPaula NguyenОценок пока нет

- Guide to Labuan International Financial CentreДокумент5 страницGuide to Labuan International Financial CentreFaizah RazakОценок пока нет

- Engagements To Review Financial Statements PSRE 2400Документ13 страницEngagements To Review Financial Statements PSRE 2400ChristineThereseBrazulaОценок пока нет

- Financing Methods For Import of Capital Goods in IndiaДокумент13 страницFinancing Methods For Import of Capital Goods in IndiaAneesha KasimОценок пока нет

- E-Business Tax Application SetupДокумент25 страницE-Business Tax Application Setuprasemahe4100% (1)

- Annual Training Calendar 2011-2012Документ10 страницAnnual Training Calendar 2011-2012krovvidiprasadaraoОценок пока нет

- Supply Chain-Case Study of DellДокумент3 страницыSupply Chain-Case Study of DellSafijo Alphons100% (1)

- India Is The Second Largest Employment Generator After AgricultureДокумент2 страницыIndia Is The Second Largest Employment Generator After AgriculturevikashprabhuОценок пока нет

- Chapter 4 Transportation and Assignment ModelsДокумент88 страницChapter 4 Transportation and Assignment ModelsSyaz Amri100% (1)

- Registration FormДокумент2 страницыRegistration Formapi-300796688Оценок пока нет

- Presentation On Attrition Rate of DeloitteДокумент13 страницPresentation On Attrition Rate of DeloitteRohit GuptaОценок пока нет

- Louis Vuitton in IndiaДокумент16 страницLouis Vuitton in IndiaFez Research LaboratoryОценок пока нет

- Hygeia International: I. Title of The CaseДокумент7 страницHygeia International: I. Title of The CaseDan GabonОценок пока нет

- Keegan gm7 STPPT 01Документ20 страницKeegan gm7 STPPT 01Dirco JulioОценок пока нет

- Irf 3205 HexfetДокумент12 страницIrf 3205 Hexfetconti51Оценок пока нет

- Afghan Rose Project - Some More DetailsДокумент4 страницыAfghan Rose Project - Some More DetailsShrinkhala JainОценок пока нет

- Product MarketingДокумент2 страницыProduct MarketingAmirul AzwanОценок пока нет

- A Report On Integrated Marketing Communication Plan For Dove Baby Care Products in IndiaДокумент14 страницA Report On Integrated Marketing Communication Plan For Dove Baby Care Products in IndiaSukanya Bhattacharjee80% (5)

- Case of HyfluxДокумент6 страницCase of HyfluxMai NganОценок пока нет

- Chiffon Camisole and Tap Pants PDFДокумент34 страницыChiffon Camisole and Tap Pants PDFpiano lov100% (3)

- Bill of Lading: Cable: CSHKAC Telex: 87986 CSHKAHX Port-to-Port or Combined TransportДокумент1 страницаBill of Lading: Cable: CSHKAC Telex: 87986 CSHKAHX Port-to-Port or Combined TransportMoineeОценок пока нет

- Aptitude GoodДокумент139 страницAptitude GoodrupeshkumarinfoОценок пока нет

- CompleteДокумент2 страницыCompleteappledeja7829Оценок пока нет

- LC Financial Report & Google Drive Link: Aiesec Delhi IitДокумент6 страницLC Financial Report & Google Drive Link: Aiesec Delhi IitCIM_DelhiIITОценок пока нет

- c19b - Cash Flow To Equity - ModelДокумент6 страницc19b - Cash Flow To Equity - ModelaluiscgОценок пока нет

- Cash Inflow and OutflowДокумент6 страницCash Inflow and OutflowMubeenОценок пока нет