Академический Документы

Профессиональный Документы

Культура Документы

SYN069

Загружено:

Seby EusebiuАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SYN069

Загружено:

Seby EusebiuАвторское право:

Доступные форматы

Proceedings of the 4th International Conference on Nanostructures (ICNS4)

12-14 March, 2012, Kish Island, I.R. Iran

Characterization of Carbon Nanotubes Decorated with -Zink Ferrite (ZnFe2O4) Nanoparticles

by Citrate-gel method

M. Zolfaghari*, R. Sepahvand ,H. Zolfaghari

Department of Physics, Faculty of Science, Lorestan University, Khoramabad

*omid0652@yahoo.com

Abstract

A magnetic nanocomposite of multiwalls carbon nanotube (MWCNT), decorated with ZnFe2O4 nanoparticles, was

synthesized successfully by citrate sol-gel method. The structural, morphological and magnetic properties of the

nanocomposite were characterized by XRD, FT-IR, TEM and vibrating sample magnetometer (VSM). The results from

these techniques showed that CNTs and ZnFe2O4 were coexisted in the nanocomposite and the ZnFe2O4nanoparticles

were successfully attached on the surface of CNTs. Also the magnetization curve of the decorated CNTs at room

temperature showed that the saturated magnetization (Ms), remanence (Mr) and coercivity (Hc) values are 132/49

emu/g, 12/37 emu/g and 48/35, respectively.

Keywords: MWCNTs, Zink Ferrite; nanocomposite; Citrate-gel

Introduction

Composites, formed by two or more distinct materials,

have desirable combinations of properties that are not

found in the individual component [1]. Carbon nanotubes

[2, 3] are attracting much interest due to their potential

applications as high-performance nanoscale materials [4,

5] and electronic devices [6, 7]. More specifically, metalfilled carbon nanotubes may also have a variety of

industrial applications [8]. Different methods of synthesis

have been attempted and various materials encapsulated

have been tested [9]. The spinel ferrite of nanoparticles

and composition MFe2O4 (M = Co, Ni, Mn, Mg, Fe or

Zn) exhibit interesting magnetic, magetoresisitive, and

magneto-optical properties that are potentially useful for

a broad range of applications [10-12]. The most widely

used technique for the production of CNTs is the direct

current (DC) arc-discharge, because it can yield ructurally

excellent high quality CNTs. This process produces

carbon soot on the cathode surface containing nanotubes

[13], nanoparticles [14], fullerenes [15], nanocapsules

[16], nanowires [17], nanorods [18], and nanofibers [19].

Experimental

MWCNTs (formed by CVD process) were provided

by Sun Nano Company (China) and the purity was

claimed to be 95% by the producer. The outer diameters

of CNTs were 10 to 20 nm. Fe(NO3)3,Zn(NO3)2 and

C6H8O7 were purchased from Merck.

MWCNTs were first opened according to the

procedure reported in literature. Briefly, MWCNTs was

milled and dispersed in a 3/1 mixture of H2SO4/ HNO3 by

an ultrasonic shaker. The mixture was refluxed for 10h at

120C. Then it was cooled, filtered and washed by

distilled water adjusted at pH 5. Finally, the oxidized

carbon nanotubes (o-MWCNTs) were dried at 120 C for

6 h before use. An insitu chemical citrate-gel method was

developed to obtain the ZnFe2O4/MWCNTs precursor. A

proper amount of o-MWCNTs was first added to a

solution of citric acid (C6H8O7.H2O) and ultrasonicated in

distilled water for 10 min. Afterward, this suspension was

mixed with an aqueous solution of Zn(NO3)2.6H2O and

Fe(NO3)3.9H2O, in which the Zn:Fe molar ratio was

maintained at 1:2. In order to reach the PH of the solution

to 9, ammonia solution was drop wisely added to the

mixture with vigorous stirring. The mixture was also

stirred at 30 C for 48 h and dried in an oven at 80 C for

24 h, followed by calcination at temperature 700 C for

2h in an Argon atmosphere. Also we synthesized

magnesium ferrite (ZnFe2O4) nanoparticles by citrate-gel

method. To synthesize nanoparticle, Fe(NO3)3 and

Zn(NO3)2.6H2O mixed solution was added to citric acid

dissolved in distilled water. The solution was stirred and

then was concentrated until a viscous liquid was obtained.

The liquid was dried in an oven at 120 C and calcined at

temperature 700 C for 2h in an Argon atmosphere.

The XRD of the synthesized composites were

obtained by an X-ray powder diffractometer (XRD,

D8ADVANCE, Bruker, Germany) with Cu K radiation

(= 1. 5406 ) and a Ni-filter. IR spectra were recorded

on an FT-IR, Nicolet 320. The morphologies of the

samples were observed through transmission electron

microscopy (TEM, Philips CH 200, LaB6 Cathode160

kv). Magnetic properties of the samples were measured

by vibrating sample magnetometers (VSM) with a

maximal applied field of 10 kOe.

Results and Discussion

The FT-IR spectrum of the pristine, opened MWCNTs,

the

ZnFe2O4/MWCNTs

nanocomposites

and

ZnFe2O4nanoparticles in the range of 4000-400 cm-1 are

shown in (Fig. 1) and (Fig. 2) respectively. As it can be

seen, the IR spectra of the pristine CNTs (Fig. 1a) show

217

Proceedings of the 4th International Conference on Nanostructures (ICNS4)

12-14 March, 2012, Kish Island, I.R. Iran

no obvious absorbance bands due to the symmetrical

structure of carbon nanotube. Treatment of the carbon

nanotubes with acid in order to open their tips causes the

formation of functional groups on their surface. In the IR

spectra of the opened MWCNTs (Fig. 1b) and the

ZnFe2O4/MWCNTs nanocomposites (Fig. 2b) the

absorbance band at 3600-3100 is assigned to the O-H

bond of the carboxyl functional groups created on their

surface. Absorbance bands around at 1700, 1620 and

1500 cm-1 could be attributed to the stretching

frequencies of the C=O and C=C bonds, respectively.

The absorption bands around 1100 cm-1 could be

attributed to the stretching vibration of CCC group. In

addition (Fig. 2a, b) show two persistent absorption bands

corresponding to the vibration of tetrahedral and

octahedral complexes at 567 and 435 cm-1, respectively,

which are indicative of formation of spinel ferrite

structure. As is seen from (Fig. 2), the normal mode of

vibration of tetrahedral cluster (567 cm-1) is higher than

that of octahedral cluster (435 cm-1).

CNTs and can be indexed to the (002), (101) and (004)

reflection of CNTs, respectively. In (Fig. 4) and (Fig. 5)

well-resolved diffraction peaks revealed the good

crystallinity of the ZnFe2O4specimens, located at 2 of

30.15, 35.51, 37.14, 43.10, 53.49,56.88, 62.54 and

73.86,respectively.These

diffraction

peaks

corresponding to planes (111), (311), (400), (422), (333),

(440) and (620) provide a clear evidence for the

formation of spinel structure of the ferrite.The grain size

of ZnFe2O4/MWCNTs at 700 C are obtained using

Scherrers formula as 28/72 nm respectively.

Figure 1. FT-IR spectra of (a) Pristine MWCNTs (b)

opened MWCNs.

Figure 4. XRD pattern of the ZnFe2O4nanoparticles

calcined in Ar at 700 C/2h.

Figure 3. XRD pattern of the opened MWCNT.

Figure 5. XRD patterns of the ZnFe2O4/MWCNTs

nanocomposites calcined in Ar at 700 C/2h .

Figure

2.

FT-IR

spectrum

of

(a)

the

ZnFe2O4nanoparticles calcined in Ar at 700 C/2h. (b)

The ZnFe2O4/MWCNTs nanocomposites calcined in Ar

at 700 C/2h .

(Fig. 3) shows the XRD pattern of the opened

MWCNTs.

(Fig.

4)

show

XRD

of

the

ZnFe2O4nanoparticles calcined in Ar at 700 C/2h, show

ZnFe2O4/MWCNTs nanocomposites calcined in Ar at

700C/2h. The XRD peaks correspond with the reported

values of ZnFe2O4 (PDF card: 360398), CNTs (PDF

card: 01-0640) and ZnO (PDF card: 08-0415). The

diffraction peaks at 2= 25.8, 43.08 and 53.8 in (Fig.

3) and (Fig. 5) are the typical Bragg peak of pristine

218

(Fig. 6) shows the TEM images of (a) the pristine, (b)

opened,(c)decorated

MWCNTs

and

(d)

ZnFe2O4nanoparticles, respectively. In (Fig. 6c) the

ZnFe2O4 nanoparticles can be seen clearly on the surface

of the MWCNTs.

Figure 6. TEM images of (a) the pristine MWCNTs, (b)

MWCNTs after acid treatment,(c)the ZnFe2O4/MWCNTs

Proceedings of the 4th International Conference on Nanostructures (ICNS4)

12-14 March, 2012, Kish Island, I.R. Iran

nanocomposites calcined in Ar at 700 C/2h and (d) )

ZnFe2O4nanoparticles.

The magnetic properties of the ZnFe2O4 nanoparticles

and decorated MWCNTs were measured in magnetic

fields of 10 kOe at room temperature. The hysteresis

loop of the decorated MWCNTs is presented in (Fig. 7).

The values of the saturation magnetization (MS),

retentivity

(MR)

and

coercivity

(HC)

of

ZnFe2O4/MWCNTs, obtained from the VSM data, were

obtained as 48/35, 12/37 emu/g, and 132/49Oe,

respectively. In Fig. 8, the Hysteresis loops were

compared for the ZnFe2O4nanoparticles and decorated

MWCNTs. Also, the values of MS, HC and MR of

specimens obtained from the VSM data were compared in

(Table 1). The increment in all values of magnetic

parameters is due to the method and the existence of

MWCNTs which it is coused to be synthesized the grand

size of ZnFe2O4nanoparticles. Due to the large sized

nanoparticles. As, shown in the inset of (Fig. 7), the

coercive force (HC) of the magnetic nanocomposites is

only 132/49 Oe, which can reflect a typical characteristic

of superparamagnetic materials. With this unique

property, it can be used as a promising vehicle for

magnetic field-directed drug delivery systems.

Figure 7. Hysteresis loop of the ZnFe2O4/MWCNTs

nanocomposites calcined in Ar at calcined in Ar at 700

C/2h.

Figure 8. Hysteresis loops of (a ZnFe2O4nanoparticeles

and (b) the ZnFe2O4/MWCNTs nanocomposites calcined

in Ar at

700 C/2h

Table 1. Comparison of the Magnetic properties of

ZnFe2O4nanoparticeles

and

ZnFe2O4/MWCNTs

nanocomposites calcined in Ar at 700 C/2h.

Specimen

MS(mueg-1)

HC(Oe)

MR(mueg-1)

ZnFe2O4

50/34

11/41

1/4

ZnFe2O4/MWCNTs

132/49

48/35

12/37

Conclusions

The synthesised superparamagnetic ZnFe2O4/MWCNTs

/MWCNTs nanocomposites can be used in the fabrication

of magnetic, heterogeneous catalysis, magnetic

technologies, and in biotechnology as promising vehicle

for magnetic field-directed drug delivery systems.

References

[1] P.M. Ajayan, J.M. Tour, Nature 447 (2007) 1066.

[2] S. Iijima: Nature 354, 56 (1991)

[3] C.H. Klang, M.S. de Vries, G. Gorman, R. Savoy, J.

Vazquez. R. Beyers:

Nature 363, 605 (1993)

[4] T.W. Ebbesen: Phys. Today 49, 26 (1996)

[5] M.M.J. Treacy, T.W. Ebbesen, J.M. Gibson: Nature

381, 678 (1996)

[6] W.A. de Heer, A. Chatelain, D. Ugarte: Science 270,

1179 (1996)

[7] R.F. Service: Science 271, 1232 (1996)

[8] M. Freemantle: Chem. Eng. News 74, 62 (1996)

[9 J. Sloan, J. Cook, M.L.H. Green, J.L. Hutchison, R.

Tenne: J. Mater.

Chem. 7, 1089 (1997)

[10] Bao N.Z., Shen L.M., Wang Y., Padhan P. and

Gupta A., 12374-12375 (2007).

[11] Song Q., Ding Y., Wang Z.L. and Zhang Z.J., 46334638 (2007).

[12] Yan A., Liu X.H., Yi R., . Shi R.R, Zhang N. and

Qiu G.Z., 8558-8563 (2008).

[13] Rakov EG.

2000;69:3552.

[14] Setlur AA, Dai JY, Lauerhaas JM, Chang RPH.

;36:7213.

[15] Lange H, Huczko A, Byszewski P, Mizera E,

Shinohara H.

289:17480.

[16] Saito Y1995;33:97988.

[17] Dai JY, Lauerhaas JM, Setlur AA, Chang

RPH.;258:54753.

[18] Han W, Redlich P, Ernst F, Ruhle M. Synthesis of

GaNcarbon

composite nanotubes and GaN nanorods by arc discharge

in

nitrogen atmosphere. Appl Phys Lett 2000;76:6524.

[19] Huang H, Kajiura H, Murakami Y, Ata M. Metal

41:579625.

219

Вам также может понравиться

- FlowChart SymbolsДокумент5 страницFlowChart SymbolskalubandihariОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- DДокумент47 страницDSusheel RajОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- E 18 DaylightДокумент19 страницE 18 Daylightkaunghtet san1212Оценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- LM 723Документ17 страницLM 723Maty AgaccioОценок пока нет

- Elec 3404 Lab Note 2011Документ15 страницElec 3404 Lab Note 2011Mrinal MitraОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Application of Trans-Guard™ EXT and OS FusesДокумент14 страницApplication of Trans-Guard™ EXT and OS FusesroquceОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Begiinner's Guide For Raspberry Pi PicoДокумент148 страницBegiinner's Guide For Raspberry Pi Picoshohimi harunОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Module Code and Title: Programme: Credit: Module Tutor: General ObjectivesДокумент5 страницModule Code and Title: Programme: Credit: Module Tutor: General ObjectivesAmrith SubidiОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Update ITRPV 2019 PresentationДокумент17 страницUpdate ITRPV 2019 PresentationSanjeev MahadevanОценок пока нет

- Isolation Frequency Response: Headphone Measurements: Urbanears PlattanДокумент1 страницаIsolation Frequency Response: Headphone Measurements: Urbanears PlattankristoceaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Signal TransmissionДокумент25 страницSignal TransmissionKumbati SupertiksОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Power Supply Test PlanДокумент2 страницыPower Supply Test PlanStephen GomezОценок пока нет

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- RET and TMA ProcessДокумент3 страницыRET and TMA ProcessVikas KhantwalОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- PC1800 6Документ18 страницPC1800 6Mohsen KhabirОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Arteche CT Tripping Relays Catalog PDFДокумент28 страницArteche CT Tripping Relays Catalog PDFtamky SubstationОценок пока нет

- Data SheetДокумент2 страницыData SheetIsrael GavilanesОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

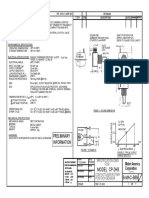

- Preliminary Information: B-MAC-B69 Model Cp-2HbДокумент1 страницаPreliminary Information: B-MAC-B69 Model Cp-2HbCykhong KhongОценок пока нет

- 5 DC GridsДокумент75 страниц5 DC GridsNamiraОценок пока нет

- 8051 Trainer Kit User and Technical Reference ManualДокумент87 страниц8051 Trainer Kit User and Technical Reference ManualpavanОценок пока нет

- Kenwood Models.: Kenwood Mc30-Mc35 MicrophoneДокумент9 страницKenwood Models.: Kenwood Mc30-Mc35 MicrophoneRigoberto Martinez LopezОценок пока нет

- Dell Inspiron-17-N7010 Setup Guide En-UsДокумент94 страницыDell Inspiron-17-N7010 Setup Guide En-UsWalter Luna FrancoОценок пока нет

- Ghép nối qua cổng-ghép nối kênh 1. Ghép nối bộ nhớДокумент139 страницGhép nối qua cổng-ghép nối kênh 1. Ghép nối bộ nhớBùi Việt ĐứcОценок пока нет

- Pine Labs Q2 ManualДокумент10 страницPine Labs Q2 ManualAli WarsiОценок пока нет

- Project ReportДокумент50 страницProject ReportHassaan ChОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Electrical BtechДокумент27 страницElectrical BtechNikhil AnandОценок пока нет

- Mechanical-Biomimetics 2019 W6Документ70 страницMechanical-Biomimetics 2019 W6Josi Ayu WulandariОценок пока нет

- Question BankДокумент3 страницыQuestion BankDivyaОценок пока нет

- Catalogo EndressДокумент76 страницCatalogo EndressDaniel MuratallaОценок пока нет

- snc2d Chemistry Quiz Review - TeacherДокумент3 страницыsnc2d Chemistry Quiz Review - Teacherapi-263850753Оценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- ARL-300 EU-Type Examination CertificateДокумент1 страницаARL-300 EU-Type Examination CertificateSamir Ben RomdhaneОценок пока нет