Академический Документы

Профессиональный Документы

Культура Документы

Customer Story Tank Cleaning PPI00148EN

Загружено:

buddhansamratАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Customer Story Tank Cleaning PPI00148EN

Загружено:

buddhansamratАвторское право:

Доступные форматы

Improve your plants production efficiency

Alfa Laval automated tank cleaning systems for the ethanol industry

New operating concept

Alfa Laval tank cleaning technology enables ethanol

producers to make radical changes to their cleaning

procedures. The rapid, automated cleaning procedures now

available mean that the time needed for cleaning between

batches is shorter. This leads to increased production

efficiency and lower costs.

Installing Alfa Laval rotary jet heads in tanks and other

equipment also makes it possible to ensure a highly efficient,

continuous production flow. This both reduces costs and

maintains a high level of production at all times.

Rapid, automated cleaning of your fermenters

All the process systems and tanks used in the ethanol

production industry need regular cleaning to prevent

contamination during the fermentation process. In particular,

cleaning of the fermenters after each batch with or without

the use of biocide is part of the normal cleaning procedure.

For this application, the spray ball technology currently

available has proven ineffective because the spray ball

does not provide any impact effect on the surface of the

fermenters. This means that effective cleaning then takes

much longer.

Main benefits for ethanol producers

By installing Alfa Laval rotary jet heads inside the fermenters,

it is now possible to carry out such tank cleaning both rapidly

and automatically. This specialist equipment provides 360

indexed impact cleaning that is defined over a preset time

period.

Such a rapid, fully automated cleaning method virtually

eliminates downtime and other production disruptions due to

tank cleaning. These new cleaning procedures also reduce

the quantities of water and biocide used.

Finally, efficient cleaning of the fermenters increases

fermentation performance and saves money on antibiotics.

Rapid cleaning, resulting in less downtime

Reduced biocide consumption

Reduced water consumption

Less use of antibiotics, avoiding savage yeast

Reduced manpower requirements

Reduced environmental impact

Moderate investment/rapid return

Optimizing installation

TRAX and installation example

Installation specifications

To ensure correct installation, Alfa Laval technicians provide

drawings with optimized positioning of the machine, with

details of location, piping and pressure/flow requirements,

based on the customers specific tank dimensions.

Process design

The unique Alfa Laval design includes process parameters

and computerized TRAX simulation. This advanced

software provides an analysis of cleaning shadows and

generates customized patterns for the vessel concerned.

Wetting

intensity

[l/m]

2.5

3.0

3.7

4.4

5.4

6.5

7.9

9.6

12

14

17

21

25

Operational procedures

Our extensive experience in this field means that Alfa Laval is

able to suggest the best possible operating procedures for

this kind of tank cleaning equipment.

Free on-site trial

Before installing your new tank cleaning system, let Alfa Laval

provide you with a trial model that you can try out for yourself

entirely free of charge.

Ethanol tank ID = 6000 mm (19.6 ft), H = 9000 mm (29.5 ft)

Time = 14.7 min Water used = 5152 l (1361 US gal.)

Alfa Laval tank cleaning machines in operation.

PPI00148EN 0705

How to contact Alfa Laval

Up-to-date contact details for all

countries are available on our

website at www.alfalaval.com.

Alfa Laval reserves the right to change specifications without prior notification.

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Engineering QuotesДокумент10 страницEngineering QuotesGendakenОценок пока нет

- GuidewireClaimCenter Performance TestPlanДокумент18 страницGuidewireClaimCenter Performance TestPlanshanthan117Оценок пока нет

- SiddharVaithiyam PDFДокумент15 страницSiddharVaithiyam PDFClarence Irudaya SamyОценок пока нет

- NASA ERAST Program Develops High-Altitude UAVsДокумент17 страницNASA ERAST Program Develops High-Altitude UAVsEgz AguilarОценок пока нет

- Construction Companies in IndiaДокумент11 страницConstruction Companies in Indiashobhit.goel33% (3)

- Cs15 Gas Tank Cleaning Degassing 1997Документ12 страницCs15 Gas Tank Cleaning Degassing 1997kirandevi1981100% (2)

- Iaido HandbookДокумент14 страницIaido Handbookprakharmishra90250% (2)

- Plant Cost EstimationДокумент49 страницPlant Cost EstimationAlpianto100% (1)

- Strategic Supply Chain Management and LogisticsДокумент16 страницStrategic Supply Chain Management and LogisticsNalaka Manawadu67% (3)

- Why and Wherefores of Power System BlackoutsДокумент6 страницWhy and Wherefores of Power System BlackoutsmentongОценок пока нет

- The Siddha Pharmacopoeia of IndiaДокумент224 страницыThe Siddha Pharmacopoeia of Indiaponsooriya100% (5)

- Biological ControlДокумент24 страницыBiological ControlbuddhansamratОценок пока нет

- IjcbsДокумент11 страницIjcbsbuddhansamratОценок пока нет

- Former JNU Professor Kapil Kapoor BioДокумент2 страницыFormer JNU Professor Kapil Kapoor BiobuddhansamratОценок пока нет

- Organic - Insect Pest Management For Organic CropsДокумент5 страницOrganic - Insect Pest Management For Organic CropsCharlesОценок пока нет

- ZNKR Iaido 2009Документ27 страницZNKR Iaido 2009pacmanguaiОценок пока нет

- World Development and Outlook 1820-2030: Its Implications for Energy UseДокумент8 страницWorld Development and Outlook 1820-2030: Its Implications for Energy UseCindy BerrymanОценок пока нет

- BAPASI 2015 Chennai Book Fair Stall Allocation LayoutДокумент16 страницBAPASI 2015 Chennai Book Fair Stall Allocation Layoutengage4u2020Оценок пока нет

- Ussr, Riw, 1998Документ27 страницUssr, Riw, 1998buddhansamratОценок пока нет

- Brazil 500Документ13 страницBrazil 500buddhansamratОценок пока нет

- Economic EpochsДокумент15 страницEconomic EpochsbuddhansamratОценок пока нет

- Background Note On "Historical Statistics" in (March 2010)Документ5 страницBackground Note On "Historical Statistics" in (March 2010)Edwin Lopez RiveraОценок пока нет

- China Economic Performance Long RunДокумент1 страницаChina Economic Performance Long RunbuddhansamratОценок пока нет

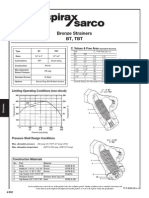

- Bronze Strainers BT, TBT: C Values & Free AreaДокумент2 страницыBronze Strainers BT, TBT: C Values & Free AreabuddhansamratОценок пока нет

- Double Safety PHEs for TransformersДокумент3 страницыDouble Safety PHEs for TransformersbuddhansamratОценок пока нет

- Thermo-Dynamic Liquid Drain Trap TDA52: Typical ApplicationsДокумент2 страницыThermo-Dynamic Liquid Drain Trap TDA52: Typical ApplicationsbuddhansamratОценок пока нет

- MahabharataДокумент13 страницMahabharatajohn145Оценок пока нет

- Fluke and Scopemeter Test Tools: Sample ScreensДокумент1 страницаFluke and Scopemeter Test Tools: Sample ScreensbuddhansamratОценок пока нет

- Thermodynamic Steam TrapsДокумент12 страницThermodynamic Steam TrapsbuddhansamratОценок пока нет

- Project Report On JaankariДокумент37 страницProject Report On JaankariMayank YuvarajОценок пока нет

- Guide To U.S. Cargo Insurance: DisclaimerДокумент13 страницGuide To U.S. Cargo Insurance: DisclaimerrajasekharboОценок пока нет

- Iumi Reforms To York-Antwerp Rules Presentation To Aimu 20 January 2004 1. 2. Costs of G.AДокумент4 страницыIumi Reforms To York-Antwerp Rules Presentation To Aimu 20 January 2004 1. 2. Costs of G.ArajasekharboОценок пока нет

- Project Report On JaankariДокумент37 страницProject Report On JaankariMayank YuvarajОценок пока нет

- Profibus GlossárioДокумент92 страницыProfibus GlossárioREGGNOMUSОценок пока нет

- Buch Cover On The RoadДокумент1 страницаBuch Cover On The RoadbuddhansamratОценок пока нет

- Finkelstein SteveДокумент27 страницFinkelstein StevebuddhansamratОценок пока нет

- Pietro PolaДокумент13 страницPietro PolarajasekharboОценок пока нет

- 5SL43407RC Datasheet enДокумент5 страниц5SL43407RC Datasheet enDiana Martinez SifuentesОценок пока нет

- Desizing of CottonДокумент16 страницDesizing of CottonDeepali RastogiОценок пока нет

- TI Oxydur PTB 206 - en PDFДокумент5 страницTI Oxydur PTB 206 - en PDFgonzalogvargas01100% (1)

- Data Collector 2.03.00Документ20 страницData Collector 2.03.00vyaskingОценок пока нет

- Internship Report-1Документ64 страницыInternship Report-1VIJAY SPОценок пока нет

- Chapter 4.1 Basic Call Procedure (ED01 - 53 - EN)Документ53 страницыChapter 4.1 Basic Call Procedure (ED01 - 53 - EN)quaderbtech06Оценок пока нет

- 2019 Zeta Zwheel Catalogs PDFДокумент30 страниц2019 Zeta Zwheel Catalogs PDFSales One - Plusgrow - IndiaОценок пока нет

- EPMA Introduction To Powder MetallurgyДокумент36 страницEPMA Introduction To Powder MetallurgyPranjal SinghОценок пока нет

- Electrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caДокумент9 страницElectrostatic and Electromagnetic Forces: Electronic Address: Tim - Henley@mail - Utoronto.caTimothy Murray HenleyОценок пока нет

- Nitobond EP 0608Документ2 страницыNitobond EP 0608James PittsОценок пока нет

- Mycom Nims ProptimaДокумент4 страницыMycom Nims ProptimasamnemriОценок пока нет

- You Yangs RP Visitor GuideДокумент2 страницыYou Yangs RP Visitor GuideSomaОценок пока нет

- E380b PDFДокумент12 страницE380b PDFanaОценок пока нет

- American English File Starter Ichecker - File 3Документ3 страницыAmerican English File Starter Ichecker - File 3Daniel AugustoОценок пока нет

- The Magnaflux Advantage (Whole Catalog)Документ51 страницаThe Magnaflux Advantage (Whole Catalog)Andy StkОценок пока нет

- R5310105-Structural Analysis - IIДокумент4 страницыR5310105-Structural Analysis - IIsivabharathamurthyОценок пока нет

- Structural Theory Eval Exam by SorianoДокумент6 страницStructural Theory Eval Exam by SorianoBenjie MorenoОценок пока нет

- Canusa GTS - 3LPEДокумент2 страницыCanusa GTS - 3LPEarifin rizalОценок пока нет

- Deterministic Inventory Control FormulasДокумент6 страницDeterministic Inventory Control FormulasvivekОценок пока нет

- Zw3d2022 Lite Vs Cadbro 2022Документ4 страницыZw3d2022 Lite Vs Cadbro 2022Carlos LimaОценок пока нет

- PX 9 enДокумент532 страницыPX 9 enjjccmmaaОценок пока нет

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesДокумент1 страницаChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimОценок пока нет