Академический Документы

Профессиональный Документы

Культура Документы

Cs Woodpeckers Web

Загружено:

MarcosPauloGrilloАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cs Woodpeckers Web

Загружено:

MarcosPauloGrilloАвторское право:

Доступные форматы

Woodpeckers

COPING SLED

Assembly and Use

Instructions.

STEP 2. Installing the Top Plate Screws.

Assembly

(2) 112" Flat head screws.

(2) Thick, gold,

washers.

(2) Nuts with

star washer.

Insert two screws up through the bottom of the base. Slip on

one of the thick washers and thread on a nut. The star washer side of the nut needs to face the thick gold washer. Firmly

tighten each screw.

Made in USA.

STEP 1. Installing the Fence.

(5) 58" Flat head screws.

(5) Oval nuts.

STEP 3. Installing the Spacer Tubes.

(2) Registration pins.

(4) 212" Flat head screws.

(5) Oval nuts.

(4) Spacers tubes.

(1) 16" Fence.

Insert the screws up through the bottom of the base and

loosely start the oval nuts. Slide on the fence with the single

track side facing down.

Insert the two registration

pins behind the fence.

Align the fence flush with

the right edge of the base

and pull it back against the

pins. Firmly tighten the five

screws and Remove the

pins.

Loosely assemble each 212" screw, spacer tube and oval nut

into each of the four holes as shown. The screws are inserted

from the bottom. Do not tighten. Leave an approximate 18" gap

between the top of the tube and the bottom of the oval nut.

STEP 6. Installing the Clamp Beam.

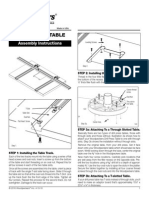

STEP 4. Installing the Top Plate.

(2) Star knobs.

(2) Large steel washers.

(2) Large nylon washers.

(1) Top Plate.

Position the top plate so the two spacer tubes and two screws

stick up through the slots. Notice that the top plate can only

be installed one way. Rotate it 180 if it won't drop on.

Once the top plate is in place, slip one large nylon washer and

then one large steel washer over each screw. Finally, install a

star knob on each screw.

STEP 5. Installing the Top Track.

(1) Clamp beam assy.

(2) Handle knobs.

(2) 1" Hex bolts.

First install one 114" hex bolt into the outside slot of each top

track. Then set the clamp beam in place so the bolts stick up

through the two holes.

Tighten the clamp beam in place with the two handle knobs.

Generally the clamp beam will be positioned over the center

of the work piece. For now, position it approximately 2" in

front of the fence.

STEP 7. Installing the Guide.

(2) 12" Top Tracks.

(2) Star knobs.

Each piece of top track gets attached with two screws. With

the single T-slot facing down, line up the oval nuts extending

up from the spacer tubes to slip into the T-slot. Slide the track

forward until both oval nuts are captured in the slot and the

back end is flush with the back edge of the base. Tighten both

screws from underneath and repeat the same procedure for

the second track.

(2) 1" Hex bolts. (2) Nylon washers.

(1) Guide.

Slip one 1" hex bolt into each end of the top track as shown.

The bolts need to be in the outside most T-slot. Set the guide

in place so that these two bolts protrude up through the slots.

Place one nylon washer onto each hex bolt and loosely install

the two star knobs.Position the guide so that the front and rear

edge are approximately aligned with the ends of the top track

and then tighten the knobs.

Using the Coping Sled

Star Knob

Star Knob

Star Knob

Guide

pa

"S

Ro

ut

"

er

Fe

nc

ce

Guide

Rou

ter F

enc

e

Spa

cer

Star Knob

Base

Adjusting the Guide.

Setting the guide only takes a minute, but is vital for proper

operation. First loosen the two star knobs which secure the

guide to the top track.

Next insert a " scrap wood spacer between the base and

the router fence. The spacer may need to be thicker if the

router bit would otherwise contact the base.

While holding the sled up against the spacer and the fence,

position the guide up against the fence as well and tighten the

two star knobs.

The guide should be the only part of the coping sled that runs

against the fence during use. It needs to be adjusted to keep

the base from contacting the router bit. At no time should the

base come in contact with the fence or the router bit. For larger

cutters, it may be necessary to use a wider spacer.

Installing Your Work Piece.

The coping sled is designed to provide the support and control

necessary to rout across the end grain of a board. This is a

necessary procedure for making raised panel doors as well as

tenon cuts. In most cases, the board will be less than 5" wide.

With this small amount of surface area, it would be nearly impossible to guide the end along the router fence to safely make

a profile cut without a sled.

The majority of force exerted on the board is torque. In other

words as the router bit is spinning in one direction, it is trying to

spin your board the opposite direction. Controlling this torque

is the function of the fence and top plate.

Using the top plate is simple, insert your board between the

sled fence and the top plate. Slide the top plate back against

the board and tighten the two knobs.

Now hold the guide against the router fence and slide the

board in until it bottoms out against it. And finally, position the

clamp beam over the center of the board and tighten both hold

down clamps.

These should only be moderately tight. Excessive force is not

needed and could lead to warping of the base plate.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Toyota R150 R151Документ4 страницыToyota R150 R151Christian Rhadames Barkley Chavez100% (1)

- Lever-Action Rifle Model 1873Документ34 страницыLever-Action Rifle Model 1873Gabriel Palacios100% (7)

- Circle.: Midterm TestДокумент4 страницыCircle.: Midterm TestThu Hiền Thái100% (1)

- A ParadorДокумент7 страницA ParadorMarcosPauloGrillo100% (1)

- ArtofWoodworking 40 ProjectsДокумент440 страницArtofWoodworking 40 ProjectsMarcosPauloGrilloОценок пока нет

- Flip Shop Stop ManualДокумент1 страницаFlip Shop Stop ManualMarcosPauloGrilloОценок пока нет

- Uni Lift InstructionsДокумент2 страницыUni Lift InstructionsMarcosPauloGrilloОценок пока нет

- TSLSДокумент12 страницTSLSMarcosPauloGrilloОценок пока нет

- Dp3 Drill Press Fence InstructionsДокумент1 страницаDp3 Drill Press Fence InstructionsMarcosPauloGrilloОценок пока нет

- Flip Shop Stop ManualДокумент1 страницаFlip Shop Stop ManualMarcosPauloGrilloОценок пока нет

- Woodpecker Plungelift™ Installation Instructions: Step 1Документ2 страницыWoodpecker Plungelift™ Installation Instructions: Step 1MarcosPauloGrilloОценок пока нет

- DP Table Instructions Woodpeckers 2010Документ3 страницыDP Table Instructions Woodpeckers 2010MarcosPauloGrilloОценок пока нет

- TupiaДокумент12 страницTupiaMarcosPauloGrilloОценок пока нет

- Ac2304 Producer Statement Design ps1Документ2 страницыAc2304 Producer Statement Design ps1Prateek ChandraОценок пока нет

- Codementum - TestДокумент11 страницCodementum - Testluan kОценок пока нет

- Lakdawala Cyrus The Colle Move by Move (051-100)Документ50 страницLakdawala Cyrus The Colle Move by Move (051-100)Carla NatoliОценок пока нет

- Bravo-A Service Manual Vol2Документ622 страницыBravo-A Service Manual Vol2Vlad ManeaОценок пока нет

- PoopДокумент4 страницыPoopchloeingle23Оценок пока нет

- Como Desmontar o Painel Do AzeraДокумент8 страницComo Desmontar o Painel Do AzeraRicardo MeloОценок пока нет

- Delchev Alexander - The Modern Reti An Anti-Slav Repertoire 2012-OCR ChessStars 214pДокумент214 страницDelchev Alexander - The Modern Reti An Anti-Slav Repertoire 2012-OCR ChessStars 214pVicalo Alonso100% (1)

- Homeric Hymn To Delian ApolloДокумент8 страницHomeric Hymn To Delian ApolloSharnОценок пока нет

- Complementarytraining Net Strength Training Planning The Training Block Part 3Документ7 страницComplementarytraining Net Strength Training Planning The Training Block Part 3Nacho MoreiraОценок пока нет

- Full Body Workout 30 MinuteДокумент8 страницFull Body Workout 30 MinuteFelicia Angelini TaroreОценок пока нет

- Pilates For ScoliosisДокумент13 страницPilates For ScoliosisIoan-Alexandru CodarceaОценок пока нет

- VSD Character Sheet FinalДокумент3 страницыVSD Character Sheet FinalSimon TrucmucheОценок пока нет

- Sailing Hydrofoil: Typical Configurations Foiling ClassesДокумент5 страницSailing Hydrofoil: Typical Configurations Foiling ClassesbogdanОценок пока нет

- Game SoundsДокумент12 страницGame SoundsdanchristianoОценок пока нет

- Quests in Lineage 2 ClassicДокумент22 страницыQuests in Lineage 2 ClassicMisscreant EveОценок пока нет

- David GogginsДокумент2 страницыDavid GogginsKaotiix0% (1)

- Balay OPSIДокумент2 страницыBalay OPSIGrignionОценок пока нет

- 1.5.2 Hookes Law Set 1 MsДокумент7 страниц1.5.2 Hookes Law Set 1 MsKoser IrshadОценок пока нет

- My Favorite Things - Barney Wiki - FandomДокумент5 страницMy Favorite Things - Barney Wiki - FandomchefchadsmithОценок пока нет

- TUCSON (LM) 2011 G 2.0 DOHC 4 Wheel Drive (4WD) SystemДокумент13 страницTUCSON (LM) 2011 G 2.0 DOHC 4 Wheel Drive (4WD) SystemLuis LopzОценок пока нет

- Cannondale Enduro Tour #1 - DaboДокумент6 страницCannondale Enduro Tour #1 - DaboSebastianBeilmannОценок пока нет

- Gaelic-Lesson Year 8Документ5 страницGaelic-Lesson Year 8api-334831608Оценок пока нет

- Big Waaagh Magic CardsДокумент2 страницыBig Waaagh Magic Cardsjdwratcliffe8552Оценок пока нет

- Lastexception 63846760522Документ2 страницыLastexception 63846760522cardosoribeiroyОценок пока нет

- Top Beginner Guitar Songs by Artist - Learn Guitar - Fender Play 1 PDFДокумент54 страницыTop Beginner Guitar Songs by Artist - Learn Guitar - Fender Play 1 PDFAndy BeckОценок пока нет

- SDLG - LG958 Brochure Single PagesДокумент2 страницыSDLG - LG958 Brochure Single PagesMuraliОценок пока нет

- Ball Two Pieces Steel A105 / A216 WCB, 2000 - 1500 PSIG: Pressure Temperature RatingsДокумент2 страницыBall Two Pieces Steel A105 / A216 WCB, 2000 - 1500 PSIG: Pressure Temperature RatingsAlicia MartinezОценок пока нет

- Bailer 4Документ1 страницаBailer 4samanОценок пока нет