Академический Документы

Профессиональный Документы

Культура Документы

How To Deal With Grease, Sediment and Oil

Загружено:

aymanmkОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

How To Deal With Grease, Sediment and Oil

Загружено:

aymanmkАвторское право:

Доступные форматы

Uniclass

EPIC

CI/SfB

(52.4)

March 2014

grease,

sediment

and oil

GREASE CONVERTERS

A privately owned UK company with more

than fifty years experience in the industry,

Wade is established as a leading manufacturer

of quality drainage products.

Much of the success of the Company is

attributable to an ongoing commitment to

put technology to practical use, to generate

fresh ideas, and to guarantee quality

assured production.

Meeting demands of water and municipal

authorities, environmentalists, employers and

employees, Wade provides effective and easy

to use means of dealing with grease, oil

and sediment.

Actimatic Grease

Converter

Why use a Wade Actimatic Grease Converter?

Grease flushed down the drain can cause

blockages and unpleasant smells in work areas.

Blockages can lead to overflows and health

hazards, whilst drain clearing is an inconvenient

and costly operation.

A Wade Actimatic Grease Converter eliminates

such problems and is a Natural means of

Permanently converting grease to

bio-degradable products.

Use of an Actimatic Grease Converter is far

more acceptable than chemicals or detergents

which merely move grease downstream to

become a problem for someone else.

GREASE CONVERTERS

Degradation is a natural, slow process.

Wade Actimatic uses only natural organisms

to accelerate this process.

Some typical locations where Wade Grease Converters are installed.

How does it work?

The Actimatic Grease Converter works in

two stages:

Oil Rig, North Sea

Asda Store, Runcorn

A McDonalds Restaurant

Stock Exchange, London

1. Separation

effluent entering the converter passes over

a hydrafilter baffle* which causes grease to

form in globules which float to the surface.

2. Digestion

achieved by Wade Actimatic which

produces a colony of micro-organisms to

degrade wastes and convert to water

soluble, environmentally friendly products.

*Patent No. 13287055

Quality assurance

Certification of compliance with BS EN ISO 9001 underlines

our commitment to quality and service.

GREASE CONVERTERS

Types of installation

Floor standing

(Standard and low profile models)

Fully recessed in ground floor

(Standard invert models)

Fully recessed in ground floor

(Deep invert model)

Fully recessed in intermediate floor

(Hanger type)

Installation guidelines

Wade Actimatic Grease Converters are designed to be

installed in existing or new kitchens, at restaurants,

canteens, hotels, hospitals, etc., and also at

commercial or industrial premises where food is

cooked, prepared or processed. They are not suitable

for use with dedicated chicken rotisserie ovens unless

special housekeeping measures are taken, including

the introduction of water.

There is no optimum distance between the last fixture

and the converter; it is generally accepted that

pipework longer than 8 metres may allow grease to

solidify before it reaches the converter.

It is not recommended that waste disposal units

discharge into a Grease Converter, because frequent

cleaning out will be necessary.

Waste from vegetable peelers must be filtered before

discharging.

Certain cleaning agents (Chlorine, strong caustics,

bleach etc.) in concentrated form, have a detrimental

effect, and should not be discharged into a

Grease Converter.

Installations may require prior approval from the Local

Authority Environmental Health Department.

Wade Actimatic Grease Converters satisfy current

Building Regulations / Standards in the U.K., and meet

requirements of drainage systems designed in

accordance with BS EN 12056-1:2000.

Spigot adaptors for connecting to different types and

sizes of pipework are shown on page 8.

Note: Do not reduce the stated inlet or outlet size

otherwise blockages could occur.

GREASE CONVERTERS Stainless steel grade 304

How to select and size Grease Converters

To determine the optimum size of converter to be used, account must be taken of the volume of fixtures discharging

into the converter. Use the table below to calculate total volume by entering the quantity of each fixture, multiply by the

volume shown and enter as Total Vol.; finally, add up your answers.

Approx. size

(mm)

Type of fixture

Handwash sink

Domestic single sink

Domestic double sink

Commercial sink

Double commercial sink

Commercial potwash sink

Tilting kettle

Small dishwasher

Medium dishwasher

Large dishwasher

Other fixtures

Approx. vol.

(litres)

300 dia. x 180 deep

450 x 350 x 200

(450 x 350 x 200) x 2

600 x 450 x 300

(600 x 450 x 300) x 2

760 x 500 x 380

Total vol.

(litres)

Quantity

12

32

64

81

162

144

150

185

235

350

Outlet pipe 32 dia.

Outlet pipe 40 dia.

Outlet pipe 50 dia.

Total volume of fixtures (litres)

6000 Series

2" BSP vent pipe connection

(Vent to atmosphere if required)

6200 Series

B

F

A

A

C

150 Min.

C

200 min. 140

75

200

After selecting the appropriate TYPE of INSTALLATION, and calculating the TOTAL VOLUME of FIXTURES,

select the Spec.Code from the table below and add the required C dimension to nearest 10mm.

e.g. for Converter to serve fixtures with a total volume of 325 litres and having a C dimension of 400mm,

Specify: 6060XT C = 400mm. For details of materials, accessories and alternative covers, refer to page 8.

Max. total vol. of

fixtures in litres

Spec.

code

In/Outlet

BSP inches

A

mm

B

mm

C

mm

D

mm

E

mm

160

160

290

290

6020LR

6022LR

6032LR

6035LR

4

2

2

4

775

775

988

988

482

482

669

669

150

150

150

150

180

180

180

180

330

330

330

330

Floor standing

Standard invert

210

410

625

6030

6060

6080

4

4

4

594

775

988

382

482

669

150

150

150

368

432

419

Fully recessed

ground floor

Deep invert

210

410

625

6030XT

6060XT

6080XT

4

4

4

594

775

988

382

482

669

Fully recessed

ground floor

1250

2100

6215

6225

6

6

1516 953

1869 1142

Fully recessed

intermediate floor

Hanger type

210

410

625

6030H

6060H

6080H

4

4

4

594

775

988

Floor standing

Low profile

382

482

669

To be specified on order

Type of

installation

F

mm

G Req. slab Load

mm opening class

l

518

582

569

368

432

419

737

940

482

482

775

775

368

432

419

625 x 445

805 x 545

1020 x 730

A15

A15

A15

A15

A15

A15

A15

A15

A15

A15

D400

D400

A15

A15

A15

For the hanger types listed, the dimension from finished floor level to the underside of the hanger frame

(normally slab level) is adjustable on site from 35mm minimum to 75mm maximum.

N.B. In practice fixtures do not all discharge at the full rate simultaneously. This has been allowed for and the table enables the

correct grease converter to be selected. In abnormally high or dump situations contact our Technical Services Department.

GREASE CONVERTERS

Wade Actimatic Powder

and Liquid

Wade Actimatic is a bacterial product specifically

formulated to deal with kitchen effluent. It is available in

powder or liquid form.

Actimatic Powder is a free flowing, buff coloured, granular

powder; Actimatic Liquid is a green coloured, watersoluble liquid which is suitable for manual and automatic

dosing. For technical information refer to back cover.

To function efficiently grease converters must be dosed

regularly with Wade Actimatic. Daily dosing is

recommended, but where this is impracticable, dosing

twice weekly is an acceptable minimum.

When a converter is first put into service, and whenever

it is cleaned out, a culture must be established or

re-established within the converter per the Initial Dosing

Procedure.

The best time for dosing is just before closing down

for the night; this is because the micro-biological

activity is more effective when there is least flow

through the converter.

Details of automatic dosing are given on page 7.

Initial dosing procedure

(1 3 days after kitchen commences

operation)

Actimatic Powder

Day 1 (a) Mix 8 level scoops (280 gm)

with 2.25 litres (4 pints) of

lukewarm water (30C);

stir to form a slurry.

(b) Remove the dosing

plug from the

converter and pour

in the slurry.

(c) Wipe up any spillage and

replace the dosing plug.

(d) Wait at least 4 hours before allowing any

discharge into the converter this waiting

time enables the micro-organisms to grow

and reproduce in an ideal environment.

Day 2

Repeat as for Day 1.

Day 3

Commence daily dosing.

Actimatic Liquid

Day 1

Remove the dosing plug from the converter

and pour in TWICE the amount

shown in the Dosage Rate Guide.

Day 2-7 Repeat as for Day 1

Day 8

Commence daily dosing.

Daily dosing procedure

Actimatic Powder

(a) Mix the amount of powder shown in the

Dosage Rate Guide with a little lukewarm

water (30C).

(b) Remove the dosing plug from

the converter and pour in

the solution.

(c) Wipe up any spillage and

replace the dosing plug.

Actimatic Liquid

Remove the dosing plug

and pour in the amount

shown in the Dosage

Rate Guide.

Remote dosing

As an alternative to using the dosing plug facility,

Actimatic may be poured into a sink which empties

into the converter, and flushed with lukewarm

(not hot) water.

Dosage rate

The amount of Actimatic needed depends on the

converter model and the type and number of meals

prepared. If there is a build-up of grease, increase the

dosage, if there is little indication of grease, reduce the

dosage. Actimatic is highly concentrated; overdosing is

wasteful but not harmful.

Daily dosage rate guide (with monthly equivalents)

Converter

Model No.

6020LR

6022LR

6030

6032LR

6035LR

6060

6080

6215

6225

POWDER

Daily

Monthly

level scoop

Kg

1

1

1

1

1

1

1.5

1.5

1.5

1.5

1.5

1.5

2

2

2

2

2

2

LIQUID

Daily

Monthly

capfuls

litres

3

1

3

1

3

1

4

1

4

1

4

1

5

2

6

2

6

2

Note: If dosing twice weekly instead of

daily, use three times the rate shown.

To Specify / Order:

Spec. Code: AL1 Actimatic Liquid

Spec. Code: AP1 Actimatic Powder

Discount applies to standing orders.

(1 ltr.)

(1 kg)

GREASE CONVERTERS

Automatic dosing system

Control box

A mains powered dispenser unit is available for use

with Actimatic Liquid. The unit automatically doses the

Converter with diluted Actimatic Liquid once daily at a

time selected by the user.

GO

The system, once set, requires only monthly attention

to replenish the liquid supply, and is suitable for use in

most new and existing drainage systems. A warning

light and an audible alarm indicates low level of liquid.

16:34

Pump

To pipe run

Outlet tube

8mm dia. Nylon

Control box

Low level sensor

Storage drum

Inlet tube

8mm dia. Nylon

Storage drum

Grease Converter

Automatic dosing system installation notes

Construction

Control box should be wall mounted.

Control box enclosure suitable for wall mounting; made of flame

retardant polystyrene with removable cover, sealed to IP56. Size

180mm x 110mm x 90mm deep.

Electrical 220240V, (Fuse rating 3 amp internally protected by

1.6 amp fuse). 5060Hz single phase supply must be continuous

and connected to control box via an isolator by a QUALIFIED

ELECTRICIAN.

Plumbing ensure control box and storage drum are in final

operating positions.

Inlet connect nylon tube to pump by pushing tube into INLET

fitting. Feed other end of tube through hole in cap of storage drum

until it reaches the bottom of drum (tube may be cut to length

if desired).

Outlet connect nylon tube to pump by pushing tube into OUTLET

fitting. For connection to pipework up to 50mm dia., use quick fit

adjustable pipe connector supplied. If connecting to pipework above

50mm dia., drill and tap a 1/8" BSP hole in a suitable pipe run leading

to the grease converter. This hole MUST be located after the last trap

in the run and in the top of the pipe if the run is horizontal.

Screw and seal the supplied 1/8" BSP fitting into the tapped hole.

Connect free end of tube by pushing into fitting. (Tube may be cut to

length if desired).

Audible alarm may be easily disabled if not required.

Timer programming

Dosing time must be set by following the instructions supplied.

Optimum start time is 2 hours after kitchen closes.

Start-up operation

1. Read Health and Safety notes printed on the 1 litre jerrycan

containing Actimatic Liquid.

2. Fill storage drum with water to level indicated on drum label.

3. Add 1 litre of Actimatic Liquid. Larger grease converters require an

additional amount refer to drum label.

4. Replace cap on drum and ensure that tube reaches the bottom of

the drum.

Fixings stainless steel grade 304 minimum.

Pump peristaltic type delivering 110 ml of liquid per minute.

Storage Drum 10 ltr. capacity made of high density polythene;

with screw cap and carrying handle; octagonal, 229mm across

corners x 381mm high.

Switches push-button, sealed to IP56.

Timer programmable by user; Mains On and Low Liquid Level

indicators; rechargeable back-up battery (maintains the timer

programme, it will not run the pump).

Tubing 8mm dia. clear nylon or equivalent.

Maintenance

1. 30 days after start-up and every 30 days thereafter, re-fill storage

drum with water and Actimatic Liquid.

2. Every 30 days check fittings and tubes for leaks.

3. Every 6 months check pump tubing for signs of wear.

To Specify / Order:

Automatic Dosing Unit

Spec. Code: ADU

Spec. Code: AL1

Actimatic Liquid (1ltr.)

Options: Wall mounting bracket for storage drum made of

grade 304 stainless steel with large radiussed corners to facilitate

cleaning add suffix MB to Spec. Code.

GREASE CONVERTERS

Accessories

Covers are treadplate (anti-slip) stainless

steel grade 304

Covers For alternative covers, add suffix to

Spec.Code as follows:

Heavy Duty (class D400) HD

Recessed (min.C dimension = 170) REC

For use with sheet floor covering

(min.C dimension = 180) SVF

Maintenance

Commissioning period maintenance

During the first few weeks of dosing operation, regular

inspection of the internal condition of the Converter

should be made to gauge the performance of the

dosage amount. If a thickening of the contents is

noted, with a distinct caking effect across the surface,

or an offensive, pungent odour is emitted, then

gradually increase the suggested dosage rate to

compensate. If the contents appear to remain in a

minimal semi-liquid state with little or no odour, this

indicates successful degradation of the grease.

Grease Converter performance

The Converter is working if there is:

(a) Consistency similar to thick soup.

(b) Little or no odour.

(c) No dry deposit building up on its sides.

(d) No caked deposit floating on surface.

(e) No grease build-up in downstream drain line.

T103

T104

T105

T106

T1702

T1704

T303

T401

T402

T501

T502

BS 416 / DIN 19522

BS 416 / DIN 19522

BS 437

BS 437

Plastic

Plastic

Plastic

Clay

(Densleve)

Clay

(Supersleve)

100

150

100

150

54

110

160

100

150

100

150

90

90

90

90

60

126

166

170

105

130

130

}

}

For best performance

1. Follow the Initial and Daily Dosing Procedures.

2. Do not discharge very hot water into the Converter

immediately before or immediately after dosing.

3. Do not discharge chlorine, strong caustics,

concentrated disinfectants, bleach or sanitisers into

the Converter.

4. Do not deliberately discharge cooking oil or grease

into the Converter.

5. Remember that food scraps and solid particles will

settle on the bottom of the Converter and will need

to be removed periodically. Do not discharge waste

disposal units into the Converter.

6. Follow maintenance procedures.

7. Contact Wade Technical Services Department if you

need advice; a free call out service is provided in

mainland UK for regular users of Actimatic.

Anti-slip

removable

main cover

(Sealed)

Dosing plug

(Sealed)

Outlet

(Threaded

BSP)

Deep seal

trap

Q

Annually

Check joints and seal

Whenever tank is cleaned out the Initial Dosing procedure must be

repeated. Sediment build-up can be reduced if strainers are fitted to

sinks to prevent solids entering the Converter.

Rodding

access

(Sealed)

Anti-siphon

tube

Inlet

(Threaded

BSP)

Remove main cover

Quarterly

Check for sediment build-up. If build-up

has occurred tank should be cleaned

Clean out tank completely

Pipework

Main cover

seal

Remove and clean Hydrafilter baffle

Remove and clean Hydrafilter baffle

Spec.

code

Frequency

Remove main cover

Check contents for caking

Hydrafilter

baffle

Routine maintenance

Operation

Threaded pipework adaptors to connect

converter to pipework

Units with C

dim.up to 750mm

Materials

Seal expanded closed cell neoprene.

Other parts stainless steel grade 304.

For grade 316 stainless steel, add suffix M to Spec.

Code; a plain cover is supplied with grade 316

versions, if anti-slip cover is required add suffix MAS

(anti-slip cover is grade 304).

Note: 6200 series models have covers with no dosing

plug or rodding access.

SEDIMENT INTERCEPTORS Stainless steel grade 304

Sediment Interceptors

Sediment Interceptors are used to help

prevent blockages where solids such as

food scraps, hair, plaster, sediment etc.

are discharged into drain lines.

Sealed removable

cover

Bucket lifting

handle

How does it work?

Solid material is captured in a collector

a bucket or, for fine particles, a filter bag

which needs to be lifted out of the

interceptor for emptying at an

appropriate frequency.

Features

l suitable for floor standing or

semi-recessed installations

l 2" BSP female inlet and outlet may

be connected to pipework by

means of proprietary connectors

390 x 390

105

125

Fastener

2" BSP inlet

2" BSP outlet

430

Sediment bucket

or filter bag

Material

Stainless steel grade 304, satin finish

Seal expanded closed cell neoprene.

Options

For polished finish, add suffix P to

Spec. Code.

Spec.

code

Flow rate

l/sec.

Solids

collector

5740

0.4

Bucket stainless steel

(1.75mm dia. hole size)

5750

0.4

Bag polyester

(100 micron hole size)

Routine maintenance

Operation

Frequency

Remove main cover

Remove and clean collector

Drain and clean tank

Annually

Check joints and seal

Note: Minimum clearance above cover of 450mm is

required for removal of bucket/bag

OIL INTERCEPTORS Stainless steel grade 304

Oil Interceptors

Oil Interceptors are installed in drain lines to help prevent

the pollution of rivers, streams, drainage systems and

water treatment plants.

Units are used where spillages of oil or diesel could occur

such as garages, transport workshops, diesel re-fuelling

and storage areas, and where vehicles or plant are washed

down or steam cleaned.

Oil Interceptors are not suitable for petrol and volatile liquids.

Features

l suitable for floor standing or recessed installations.

l vent and draw-off connections are provided on

both sides of the Interceptor for ease of

installation and use.

l draw-off points located inside the Interceptor are

adjustable by the user (see drawing and notes on

page 11).

l loading class: D400.

l recessed covers can be made to special order.

l threaded inlet and outlet are for connection to

pipework by means of a spigot adaptor, shown

on page 8.

How does it work?

The Wade trapped Oil Interceptor works in three stages.

1. Separation

Effluent entering the Interceptor passes through a filter

bucket which retains solid material; oil, being lighter

than water, floats to the surface, pending draw-off.

2. Removal of oil

By automatic or manual means, oil flows through an

adjustable draw-off point to a sump or a similar storage

container awaiting disposal.

3. Removal of solids

The bucket which retains solid material needs to be

lifted out of the Interceptor for emptying at an

appropriate frequency.

Materials

Seal expanded closed cell neoprene.

Other parts stainless steel grade 304.

For grade 316 stainless steel, add suffix M to Spec.

Code; a plain cover is supplied with grade 316

versions, if anti-slip cover is required add suffix MAS

(anti-slip cover is grade 304).

A x B

2" BSP vent

connections

(Both Sides)

100

Anti-slip, sealed

removable cover

250

Rodding access

(Sealed)

100

C

Outlet

(Threaded BSP)

160

Inlet

(Threaded BSP)

D

Deep seal trap

Sediment bucket

2" BSP adjustable

draw off (Both sides)

200

To Specify / Order

Select the appropriate code from the table and add the required C dimension, e.g. for oil interceptor to accept a

flow 3.5 l/sec. and having a C dimension of 250mm. Specify 6360, C dimension = 250mm.

Spec.

code

6330

6360

6380

Flow rate

l/sec.

1.9

3.8

5.7

Inlet / Outlet

size BSP

4"

4"

4"

A

594

775

988

B

382

482

669

C

To be

Specified

on order *

D

368

432

419

Note:

*Minimum C dimension available is 150mm, larger dimensions should be specified in increments of 10mm.

Larger sizes of oil interceptors are available, please contact our Technical Services Department for details.

10

OIL INTERCEPTORS

Installation

Notes:

1. 2" BSP Vent and drawoff connections are

provided on both sides of

the interceptor for ease

of installation.

2. All connection points not

used must be sealed.

3. Ensure location of

interceptor enables easy

access to draw-off valve

and cover.

OUTLET

Interceptor vents. Ensure

pipework is extended so that

one vent finishes 250mm.

above the other.

Draw-off valve (not supplied).

Required only if manual

operation is desired.

INLET

To receiving container. For

automatic operation use

storage tank. For manual

operation any suitable

container may be used.

Settings of adjustable draw-off

Adjustable draw-off

Adjustable draw-off

Normal water

operating line

Normal water

operating line

3mm

6mm

Static water line

To receiving

container

Static water line

To receiving

container

Setting A

Setting B

Ensures that only oil is taken from interceptor

Normally used in automatic installations with drawn-off oil collecting in

storage tank. This setting will retain a layer of oil in the interceptor.

Ensures that ALL oil is removed from interceptor

Normally used with manual draw-off installations. This setting will

allow water to enter the draw-off line.

Checking operation

If during normal working conditions water is found to be entering the

draw-off line, the following action should be taken;

For manual and automatic operations:

Adjust draw-off upward by 3mm. Check operation, repeat if required.

Checking operation

If during normal working conditions oil is found to be remaining in

interceptor, the following action should be taken;

Manual installations: Draw-off oil more frequently and/or lower

draw-off by 3mm. Check operation and repeat if required.

Automatic installations: Lower adjustable draw-off by 3mm.

Check operation, repeat if required.

Maintenance

Commissioning period maintenance

Manual draw-off

During the first 4 weeks of operation, regular inspection of the internal

condition of the interceptor should be made to determine how often

the oil needs to be drained off and the sediment bucket emptied.

Automatic draw-off

During the first 4 weeks of operation check the oil storage tank for

build-up, and the sediment bucket to determine how often it needs to

be emptied.

Anti-slip

main cover

Sediment

bucket

Rodding

access

Routine Maintenance

Operation

Frequency

MANUAL Remove main cover

Drain off oil

Remove and clean sediment bucket

As indicated by

inspection during

commissioning

period.

AUTOMATIC Remove main cover

Remove and clean sediment bucket

Vent

connections

Outlet

Inlet

Adjustable

draw-off

BOTH TYPES Remove main cover

Remove and clean sediment bucket

Drain and clean tank completely

Check joints and seal

Main cover

seal

Annually

Baffle

plates

Trap

11

GREASE CONVERTERS SEDIMENT INTERCEPTORS OIL INTERCEPTORS

Wade Actimatic supplementary information

Wade Actimatic is a mixture of micro-organisms, free enzymes,

inorganic salts, buffers and non-ionic surfactants.

In 1989 Wade became the first manufacturer of grease converters to

be awarded an Agrment Certificate.

Six strains of micro-organism are selected because of their ability to

produce the enzymes required to break down the range of waste

materials produced by the catering industry. The micro-organism

population comprises a range of bacilli, micrococcus and

streptomycete cultures.

For the Grease Converter, an innovative product, there is no

applicable British or European product standard. BS EN 1825 applies

to products that require the physical removal of grease; the scope of

the standard states The standard does not cover the use of biological

means (bacteria and enzymes).

Four main types of enzymes are produced by the micro-organisms

which operate in Wade Actimatic:

Lipases

Amylases

Proteases

Cellulase

to break down fats and grease

to break down starch

to break down protein

to break down cellulose

Enzymes serve to accelerate the establishment of the micro-biological

culture; they have a limited life and will eventually be used up. Any

dead micro-organisms will themselves be broken down and digested

by other bacteria.

The micro-organisms in Actimatic Powder are naturally occurring and

are not genetically engineered or genetically modified; they belong to

Class1 as defined in the EU Council Directive 90/679/EEC of 26th

November, 1990 and as amended by EU Council Directive 93/88/EEC

of 12th October, 1993.

Actimatic Powder and its intermediates are tested using procedures

recommended by the USDA and AOAC to ensure that they are free of

Salmonella.

Environmental impact. The term BOD, biological oxygen demand, is

often used in association with biological breakdown. BOD is a

measure of the amount of organic matter in water and waste; it is the

amount of oxygen in a given volume of water, consumed by microorganisms during the degradation of organic matter over a five day

period. High BOD causes concern since the loss of soluble oxygen in

the water can create anaerobic conditions, which give rise to the

production of foul odours arising from the formation of sulphides

(particularly H2S ) and methane; these conditions inhibit the

degradation of fats and grease.

Wade Actimatic will not increase the BOD of the discharge from a

correctly sized grease converter, nor the BOD loading of the final

effluent plant.

Independent product assessment:

Other products

Wade manufactures a wide range of products for use in and near all

kinds of buildings, worldwide: Floor gullies, access covers, channel

and grating, roof outlets, water points. Full details, including CAD files

are accessible on our website

Service

Product information and technical advice are available from the Wade

Technical Services Department at Halstead, Essex, from Wade

Technical Consultants located throughout the UK and from selected

distributors throughout the world.

Warranty

The Company warrants its products to be free from defects in material

and workmanship for a period of 12 months from the date of delivery.

The Companys obligation under this warranty is limited, at its option,

to the repair or replacement, free of charge, or refund of the net

invoiced price of any part found to be defective, and which, in the

Companys opinion, has not been subject to undue wear and tear,

accident, alteration, abuse or misuse. Consequential damages are

expressly disclaimed.

Technical advice from Wade International Ltd., whether verbal, in

writing or by way of trials, is given in good faith but without warranty.

The application, use and installation of the Companys products are

beyond the control of the Company and the purchaser is solely

responsible for ensuring that goods are fit for any particular purpose.

In line with the Companys policy of continual research and

development, product specifications and availability are subject to

change or withdrawal without prior notice.

Dimensions

In line with general practice all dimensions shown are nominal.

All the ingredients of Wade Actimatic are bio-degradable and will have

no adverse effect on the downstream biological clean-up operation.

Load rating class

Grease is converted permanently into soluble products which will not

re-deposit further down the drainage system.

This catalogue shows the load rating class for covers based

on BS EN 124.

Wade Actimatic, when properly used, is not harmful to people, wildlife

or the environment.

PERFORMANCE BY DESIGN

Wade International Ltd.

Third Avenue . HALSTEAD

Essex . CO9 2SX . UK

TELEPHONE: +44 (0)1787 475151 . FACSIMILE: +44 (0)1787 475579

e-mail: tech@wade.eu . web site: www.wade.eu

7412

QUALITY BY TRADITION

Вам также может понравиться

- Humidity Control Design Guid - ASHRAEДокумент23 страницыHumidity Control Design Guid - ASHRAEaymanmk100% (4)

- Modeling, Control, and Optimization of Natural Gas Processing PlantsОт EverandModeling, Control, and Optimization of Natural Gas Processing PlantsРейтинг: 5 из 5 звезд5/5 (1)

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003От EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Рейтинг: 5 из 5 звезд5/5 (1)

- Grease Trap SizingДокумент9 страницGrease Trap SizingEngFaisal Alrai100% (2)

- Reineveld CentrifugeДокумент12 страницReineveld CentrifugeI. Murali KrishnaОценок пока нет

- Palm Oil RefiningДокумент10 страницPalm Oil Refiningharrison_sОценок пока нет

- .. PDF SugarДокумент34 страницы.. PDF SugarSnehal Badwaik100% (1)

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisОт EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisРейтинг: 5 из 5 звезд5/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualОт EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualОценок пока нет

- ASHRAE Symposis Degrading Delta-T-TaylorДокумент13 страницASHRAE Symposis Degrading Delta-T-TaylormondsbaОценок пока нет

- Biology BIOL 1003 CH 1-3 QuizДокумент14 страницBiology BIOL 1003 CH 1-3 QuizYummyWords100% (1)

- MID13284 1 ParticulateДокумент14 страницMID13284 1 ParticulatechichavlajaОценок пока нет

- Spray Dryer ExperimentДокумент17 страницSpray Dryer Experimentthurgah100% (1)

- 01 Operator Manual - StirLIN-2 - J0847 - ENДокумент54 страницы01 Operator Manual - StirLIN-2 - J0847 - ENA TurkiОценок пока нет

- Nes 155 Part 2Документ66 страницNes 155 Part 2Cinthia KhanОценок пока нет

- Grease ConvertorsДокумент12 страницGrease ConvertorsRoyce AgabasОценок пока нет

- Sludge Treatment: Efficient Solutions For Wastewater Treatment PlantsДокумент10 страницSludge Treatment: Efficient Solutions For Wastewater Treatment PlantsLaurentiu ApostolОценок пока нет

- Biodiesel Filtration OptionsДокумент0 страницBiodiesel Filtration OptionsMei HermansyahОценок пока нет

- Tech PDFДокумент3 страницыTech PDFAwais JalaliОценок пока нет

- Duracable CatalogДокумент68 страницDuracable CatalogCleaner MagazineОценок пока нет

- Granulation Collette MixerДокумент16 страницGranulation Collette Mixerattaullahjohar040Оценок пока нет

- Solutex Solvent Recycling Range 2023Документ7 страницSolutex Solvent Recycling Range 2023091961Оценок пока нет

- Recirculating Biotower: High Performance CompactДокумент4 страницыRecirculating Biotower: High Performance CompactfatamorgganaОценок пока нет

- Kodak, Single-Use Chemistry Kit, ProcessДокумент8 страницKodak, Single-Use Chemistry Kit, ProcessErden Sizgek100% (2)

- DEMA Dispensing CatalogДокумент28 страницDEMA Dispensing CatalogmagdafzОценок пока нет

- Process TechnologyДокумент31 страницаProcess TechnologyEugene MicarandayoОценок пока нет

- Washer GTWN3000MWS ManualДокумент24 страницыWasher GTWN3000MWS ManualTravisОценок пока нет

- Dishwasher ThesisДокумент5 страницDishwasher Thesismistyharrismurfreesboro100% (2)

- STP 125 KLDДокумент9 страницSTP 125 KLDAbhay SisodiaОценок пока нет

- Depliant - RECYCLING - New - ENG 2Документ8 страницDepliant - RECYCLING - New - ENG 2Ste Baccouche Negoce SbnОценок пока нет

- Hydraulic Flushing Rolls RoyseДокумент4 страницыHydraulic Flushing Rolls RoysemsmldxbОценок пока нет

- Welch AMC 2010 - 11 FINAL Email 032712 - SubДокумент60 страницWelch AMC 2010 - 11 FINAL Email 032712 - SubJose PerozoОценок пока нет

- FLOTTWEG Technologie Separateur EN-FRДокумент32 страницыFLOTTWEG Technologie Separateur EN-FRdrevetphОценок пока нет

- Key Notes - Grease Trap - 4Документ8 страницKey Notes - Grease Trap - 4rufuslaiОценок пока нет

- 1Документ6 страниц1Kumar NОценок пока нет

- Maquina de Biodiesel A Partir de Aceite CaseraДокумент2 страницыMaquina de Biodiesel A Partir de Aceite CaseraAndres Echeverri CastroОценок пока нет

- Edible Oil and Biodiesel Refining - Biodiesel Expansion - Biodiesel ReactorsДокумент11 страницEdible Oil and Biodiesel Refining - Biodiesel Expansion - Biodiesel ReactorsJohn Maguire100% (1)

- Jay R Smith Grease InterceptorsДокумент6 страницJay R Smith Grease InterceptorsonspsnonsОценок пока нет

- Haus Palm Oil Eng Brosur 260214-rДокумент12 страницHaus Palm Oil Eng Brosur 260214-rSupatmono NAIОценок пока нет

- Residential and Commercial High StrengthДокумент36 страницResidential and Commercial High StrengthNiong DavidОценок пока нет

- Cat Hydo Advanced 10WДокумент4 страницыCat Hydo Advanced 10Waliosk8799Оценок пока нет

- Internship Report (LIN)Документ18 страницInternship Report (LIN)aditya patelОценок пока нет

- Gravfil BrochureДокумент16 страницGravfil BrochureIDAОценок пока нет

- Products DatabaseДокумент104 страницыProducts DatabaseAlexОценок пока нет

- System Saver Operating InstructionsДокумент5 страницSystem Saver Operating InstructionsFrancisco Javier López BarrancoОценок пока нет

- K Pack Systems Pvt. LTD.: Www. Kpack - inДокумент20 страницK Pack Systems Pvt. LTD.: Www. Kpack - inBắp BắpОценок пока нет

- GP Degreaser: Vecom MarineДокумент2 страницыGP Degreaser: Vecom MarineHernan GirautОценок пока нет

- Gefico Maritime SectorДокумент28 страницGefico Maritime SectorAugustine Dharmaraj100% (1)

- Sandwiching Performance, Like No OtherДокумент8 страницSandwiching Performance, Like No OtherNeuro ToxinОценок пока нет

- Krauss-Maffei Pusher Centrifuge SZ EДокумент16 страницKrauss-Maffei Pusher Centrifuge SZ ECesar MonteОценок пока нет

- Food Waste Decomposers: Das Waste Recycle System PuneДокумент11 страницFood Waste Decomposers: Das Waste Recycle System PuneAslam SayedОценок пока нет

- Paradip Etp O&m Sop-FinalДокумент39 страницParadip Etp O&m Sop-FinalDhal Engineering Company SalesОценок пока нет

- 8 Horn Big DipperДокумент31 страница8 Horn Big DipperHüseyinGörenОценок пока нет

- De Oiler WEMCOДокумент6 страницDe Oiler WEMCONicolas RehОценок пока нет

- инструкция-для-кофемашин-servomat-vending machinesteigler-cino-xs-speed-mixнемДокумент52 страницыинструкция-для-кофемашин-servomat-vending machinesteigler-cino-xs-speed-mixнемiliesml0% (1)

- PETRECO BILECTRIC Dehydrators - DesaltersДокумент2 страницыPETRECO BILECTRIC Dehydrators - DesaltersRoyster Cabral100% (1)

- Brewing: Improve Your ProcessДокумент4 страницыBrewing: Improve Your Processprakash1010Оценок пока нет

- Flottweg Centrifuges: For Biodiesel ProductionДокумент8 страницFlottweg Centrifuges: For Biodiesel Productionpachis3Оценок пока нет

- Residential - Community - CommercialДокумент6 страницResidential - Community - CommercialGary McKayОценок пока нет

- How Reverse Osmosis Works: A Look at Industrial ROОт EverandHow Reverse Osmosis Works: A Look at Industrial ROРейтинг: 2.5 из 5 звезд2.5/5 (2)

- Adiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringОт EverandAdiabatic Fixed-Bed Reactors: Practical Guides in Chemical EngineeringОценок пока нет

- Run Your Diesel Vehicle on Biofuels: A Do-It-Yourself Manual: A Do-It-Yourself ManualОт EverandRun Your Diesel Vehicle on Biofuels: A Do-It-Yourself Manual: A Do-It-Yourself ManualРейтинг: 5 из 5 звезд5/5 (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowОт EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowРейтинг: 4 из 5 звезд4/5 (1)

- Operator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowОт EverandOperator’S Guide to Centrifugal Pumps: What Every Reliability-Minded Operator Needs to KnowРейтинг: 2 из 5 звезд2/5 (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualОт EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualРейтинг: 2.5 из 5 звезд2.5/5 (2)

- Astm d1785 1986Документ11 страницAstm d1785 1986aymanmkОценок пока нет

- Unlock-UAE FIRE AND LIFE SAFETY CODE OF PRACTICE - WITHOUT LINKS PDFДокумент738 страницUnlock-UAE FIRE AND LIFE SAFETY CODE OF PRACTICE - WITHOUT LINKS PDFmuhammadfaisal32717Оценок пока нет

- Hunter GP100 08-2003 PDFДокумент1 страницаHunter GP100 08-2003 PDFaymanmkОценок пока нет

- NEMA Enclosure Types 11-05-2Документ9 страницNEMA Enclosure Types 11-05-2Duron SaavedraОценок пока нет

- Waterchar IwasteДокумент8 страницWaterchar IwasteCharisma CabanogОценок пока нет

- Fit Out GuidelinesДокумент46 страницFit Out GuidelinesAiswarya SreekumarОценок пока нет

- Mobilgear 630 MSDS 영문Документ6 страницMobilgear 630 MSDS 영문thisbaboОценок пока нет

- BY Manali.G Suharsh.LДокумент37 страницBY Manali.G Suharsh.LRohit SinglaОценок пока нет

- Masterseal BДокумент7 страницMasterseal Bapi-283891975Оценок пока нет

- Murrel Farming PDFДокумент10 страницMurrel Farming PDFshridhanОценок пока нет

- Chemistry Jan2012 Unit-4 QPДокумент24 страницыChemistry Jan2012 Unit-4 QPAkila RahmanОценок пока нет

- Solar Panel Cleaning Bot Vikas Janu Institute of Engineering and Technology, JK Lakshmipat University, Jaipur 302026, IndiaДокумент1 страницаSolar Panel Cleaning Bot Vikas Janu Institute of Engineering and Technology, JK Lakshmipat University, Jaipur 302026, IndiaVikas ChoudharyОценок пока нет

- Washer-Disinfectors For Hospitals and Central Sterilisation DepartmentsДокумент72 страницыWasher-Disinfectors For Hospitals and Central Sterilisation DepartmentsRizky ZulfadlanОценок пока нет

- Maynilad Water Services v. Secretary of Denr GR 202897, 206823, 207969 August 6, 2019Документ8 страницMaynilad Water Services v. Secretary of Denr GR 202897, 206823, 207969 August 6, 2019Carlos James100% (1)

- The Earth Provides Enough To Satisfy Every Person's Need But Not Every Person's Greed"Документ50 страницThe Earth Provides Enough To Satisfy Every Person's Need But Not Every Person's Greed"Darshan M MОценок пока нет

- Socio Economic Study in KoraputДокумент19 страницSocio Economic Study in KoraputSahooОценок пока нет

- Water CUT:: Hussein Abdul-Kareem Abdul-NabiДокумент22 страницыWater CUT:: Hussein Abdul-Kareem Abdul-Nabiحسين رامي كريم A 12Оценок пока нет

- Petrotest S - CL - 13-0670Документ3 страницыPetrotest S - CL - 13-0670Wahid MiaОценок пока нет

- 1-Measuring Enthalpy Change of NeutralisationДокумент2 страницы1-Measuring Enthalpy Change of NeutralisationNkemzi Elias NzetengenleОценок пока нет

- Wg11 CementДокумент154 страницыWg11 CementAbhinav ShrivastavaОценок пока нет

- Bridge FoundationДокумент24 страницыBridge FoundationR MathewОценок пока нет

- Water Diversion ManualДокумент4 страницыWater Diversion ManualPaulОценок пока нет

- Case Brief - Osmeña vs. CapiliДокумент5 страницCase Brief - Osmeña vs. CapiliEra gasperОценок пока нет

- Site Context Analysis Guide: AB316 Interior Architecture Design 3 July-November 2019Документ21 страницаSite Context Analysis Guide: AB316 Interior Architecture Design 3 July-November 2019Han Leong TanОценок пока нет

- Australian Police Survival GuideДокумент88 страницAustralian Police Survival GuideRodrigo P AvorОценок пока нет

- Roadside Tree Planting Manual: June.2020Документ36 страницRoadside Tree Planting Manual: June.2020prabhakar beeravelliОценок пока нет

- Sewerage and Drainage System For Murree City (PC-II)Документ13 страницSewerage and Drainage System For Murree City (PC-II)ShamsUlislamОценок пока нет

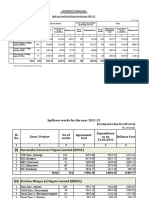

- Spill-Over and Fresh Works For The Year 2021-22: Rs. in CroresДокумент4 страницыSpill-Over and Fresh Works For The Year 2021-22: Rs. in Croreshoney honeyОценок пока нет

- De Thi Luyen Vao Chuyen 10 - 01Документ8 страницDe Thi Luyen Vao Chuyen 10 - 01Bích HiệpОценок пока нет