Академический Документы

Профессиональный Документы

Культура Документы

PWPS 013 PR

Загружено:

Renjith GopanОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PWPS 013 PR

Загружено:

Renjith GopanАвторское право:

Доступные форматы

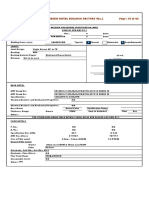

PROPOSED WELDING PROCEDURE SPECIFICATION FOR

Line Pipe - 8" x 15.9mm - Partial Repair

pWPS No.

Rev. No.

Date

12/23/2014

Page No

Rev. No.

Date

TBA

2 of 3

PQR No.

TBA

References

ISO 13847 , SHELL DEP 61.40.20.30 & ADCO AMENTMENT 30-99-00-0041-2

Techniques

Test Coupon

Process

Manual - SMAW

Material Grade

API 5L Gr X 65 QS PSL II

Joint Design

Single V Butt Weld

Dia & WT

8 " x 15.9 mm

Position

PF

Manufacturer

Shandong Molong Petroleium Machinery Company

Root Progression

NA

Heat Treatment

Quenched & Tempered

Other Passes

UpHill

Carbon

Equivalent

Highest Carbon Equivalent Pipe (TBC)

Range of variables covered

Material

API 5L Gr X 65 QS PSL II

Heat Treatment

Quenched & Tempered

Dia

8"

Manufacturer

Shandong Molong Petroleium Machinery Company

Wall Thk.

15.9 mm

Carbon Equivalent Highest Carbon Equivalent Pipe (TBC)

Filler Metal (SFA)

5.5

AWS Class

E 8018-C3H4R

Manufacturer Name

Bohler

Trade Name

Bohler Fox EV 60

Lot No

TBC

Filler Metal

Weld Pass

Process

Fill-1

Current

Volts

Range

Travel Speed

(mm/minutes)

140-180

25-32

100-150

DCEP

140-180

25-32

100-150

DCEP

140-180

25-32

100-150

E 8018-C3H4R

2.5

DCEP

80-100

25-32

90-120

TBA

E 8018-C3H4R

2.5

DCEP

80-100

25-32

90-120

TBA

E 8018-C3H4R

2.5

DCEP

80-100

22-24

90-120

Brand

Class

Dia (mm) Polarity

SMAW

TBA

E 8018-C3H4R

DCEP

Fill-2

SMAW

TBA

E 8018-C3H4R

Fill-3

SMAW

TBA

E 8018-C3H4R

Cap- 4

SMAW

TBA

Cap- 5

SMAW

Cap- 6

SMAW

Amps

Range

Shielding Gas

NA

Backing Gas

NA

Percent Composition

NA

Percent

Composition

NA

Flow Rate

NA

Flow Rate

NA

Signature

Name

Designation

Date

Heat Input

(KJ/mm)

To be

calculated

based on

actual PQR

run

parameters

PROPOSED WELDING PROCEDURE SPECIFICATION FOR

Line Pipe - 8" x 15.9mm - Partial Repair

Rev.

No.

Rev.

No.

pWPS No.

Date

12/23/2014

Page No

Date

TBA

2 of 3

PQR No.

TBA

References

ISO 13847 , SHELL DEP 61.40.20.30 & ADCO AMENTMENT 30-99-00-0041-2

Time lapse between completion of root pass and commencement of

NA

hot pass

Min. Number of passes to be deposited before to ambient cooling

weld interruption

No Interrution, Weld shall be completed in single cylce

Type of Clamp

NA

Point of clamp removal

NA

Point of Lowering on Support

NA

No.of welders

1 welder

Bevel End & Interpass Cleaning

Grinding & Brushing

Weld Finishing (Grinding & Brushing)

Derss up the start & stop points and remove slag, spatters etc

Type of Heating

Propane Torch

Type of Torch

Hand held type

No. of Torchs

Single

Method for measurement of preheat / interpass temp.

Infrared Digital Thermometer

Pre-heat Min. Temperature

100C

Inter Pass Temperature

Min.100 C & Max. 250 C

Post weld heat Treatment

Not Applicable

Joint Design & Typical Weld Layer - Single "V" Butt Weld

Notes

1 Adequate test coupons shall be made to avail required mech test specimens

2

Weld engraved bevel NDT (MT) shall be carried out.Repair Weld NDT RT shall be carried out.PQR coupons coupons

supplemented with UT weld scanning.

3 Pipe ends shall be de-magnetized if residual magnetism is more.

4

Control of welding consumables at site shall be as per approved QC Procedure for storage and handling of welding

consumables / Manufacturers instruction.

5 Adequate weather protection shall be provided during welding.

5 Weaving width shall not exceed 3 times the diameter of electrode.

6 The maximum height of capping raised above the parent metal shall not be more than 1.6mm.

7 The following Mechanical Tests shall be carried out on welding procedure qualification test coupon;

a) Charpy V notch impact Test - 2sets.

b) Macro examination and vickers hardness test with macro photograph at 5X - 1 Nos. c) SSC & SOHIC - 4 Point bend - 12 Nos

Signature

Name

Designation

Date

Вам также может понравиться

- Class P6A6Документ24 страницыClass P6A6SalimОценок пока нет

- Proposed Welding Procedure Specification (PWPS) : REV:A3Документ1 страницаProposed Welding Procedure Specification (PWPS) : REV:A3Shanawas Abdul RazakОценок пока нет

- WPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmДокумент1 страницаWPQP 6gr Smaw API 5lx52 Od323mm 10mm 17.5mmufomski100% (1)

- Pipe Welding Traceability Record (Rev 01) As On 1st June 2018Документ1 913 страницPipe Welding Traceability Record (Rev 01) As On 1st June 2018gomathyselvi100% (1)

- RTCC Manual WPS Approval WE-WPS-001Документ7 страницRTCC Manual WPS Approval WE-WPS-001Akansha SharmaОценок пока нет

- Utoc Preliminary Wps Shell Project 270807 PDFДокумент55 страницUtoc Preliminary Wps Shell Project 270807 PDFErick HoganОценок пока нет

- Mechanical Test 1Документ21 страницаMechanical Test 1Manoranjan sharmaОценок пока нет

- Piping and Pipelines Network DesignДокумент3 страницыPiping and Pipelines Network DesignOmar EzzatОценок пока нет

- Surface Tension Transfer (STT) Pipe WeldingДокумент3 страницыSurface Tension Transfer (STT) Pipe WeldingahmedОценок пока нет

- 4d48f0f5e09b8 Plant Piping and Pipeline Systems 2010 Maurice For SiskaДокумент7 страниц4d48f0f5e09b8 Plant Piping and Pipeline Systems 2010 Maurice For Siskau04ajf3Оценок пока нет

- Procedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4Документ4 страницыProcedure Qualification Record (PQR) : FM-88 Issue - 02 Date: Jan 24,2017 Page 1 of 4tayyabОценок пока нет

- Wps Mma PipeДокумент2 страницыWps Mma PipeDimitris NikouОценок пока нет

- WPS NMB 001Документ6 страницWPS NMB 001mohamed nasserОценок пока нет

- WPS MS 01C Rev. 0Документ1 страницаWPS MS 01C Rev. 0alinor_tnОценок пока нет

- Curriculum Vitae: Total Experience 18.1 YearsДокумент7 страницCurriculum Vitae: Total Experience 18.1 Yearskbpatel123Оценок пока нет

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreДокумент3 страницыWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniОценок пока нет

- ITP Fuel Fillter (J-1001) Rev10+Документ9 страницITP Fuel Fillter (J-1001) Rev10+DjokoОценок пока нет

- Wps 1010 IfrДокумент28 страницWps 1010 IfrSyed Mahmud Habibur RahmanОценок пока нет

- Hot Tap Daily Welding Report 1Документ1 страницаHot Tap Daily Welding Report 1Jamal BakhtОценок пока нет

- PipingДокумент158 страницPipingmiteshmayurОценок пока нет

- Fabrication Procedure For Piping Pr-Skm-24a18012019164730Документ4 страницыFabrication Procedure For Piping Pr-Skm-24a18012019164730Danang Edi Prasetyo100% (1)

- WPS PQR-05Документ10 страницWPS PQR-05Ranjan KumarОценок пока нет

- WPS PQR Procedure PDFДокумент31 страницаWPS PQR Procedure PDFsudeesh kumarОценок пока нет

- Wps MainlineДокумент5 страницWps MainlineAlfian FebriansyahОценок пока нет

- Company Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsДокумент11 страницCompany Name Key Information Questions Answers File Reference Test Conducted On Reviews & ApprovalsMAT-LIONОценок пока нет

- Limak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Документ2 страницыLimak/Sawaed Welding Procedure Specification (WPS) SWCC: (QW-402) (QW-407)Alam MD SazidОценок пока нет

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Документ1 страницаWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaОценок пока нет

- WPS 2014-002 006 - 6G PipeДокумент3 страницыWPS 2014-002 006 - 6G PipejeswinОценок пока нет

- Welder ID Card BRE KarahaДокумент5 страницWelder ID Card BRE KarahaHerruSetiawan100% (1)

- WPQ Template (Asme Ix) No LogoДокумент4 страницыWPQ Template (Asme Ix) No LogorcpretoriusОценок пока нет

- PWPS Fillet WeldДокумент2 страницыPWPS Fillet WeldUgonnaОценок пока нет

- Welding Variable Calculator AS1554.1Документ2 страницыWelding Variable Calculator AS1554.1Alin TomozeiОценок пока нет

- API Welding Procedure Specification PDFДокумент3 страницыAPI Welding Procedure Specification PDFBob LeeОценок пока нет

- Welding Procedure Qualification Record: Shipyard LogoДокумент4 страницыWelding Procedure Qualification Record: Shipyard LogoGökhan TEZCAN100% (1)

- TopCoreBelco 101 FCДокумент9 страницTopCoreBelco 101 FCCesar ArellanoОценок пока нет

- 2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDДокумент9 страниц2.QC Inspection Test Report With Procedure For MS Tank With FRP Lining - APPROVEDSripathi SeetharamanОценок пока нет

- QA-R-04 - Visual Inspection ReportДокумент1 страницаQA-R-04 - Visual Inspection ReportvinothОценок пока нет

- 17-020-Ms-002 Welding For Fuel Gas r2Документ53 страницы17-020-Ms-002 Welding For Fuel Gas r2Alaa M. GhazalahОценок пока нет

- WPS ListДокумент2 страницыWPS ListAdeel OmerОценок пока нет

- STD 1104 - Welding of Pipelines and Related FacilitiesДокумент38 страницSTD 1104 - Welding of Pipelines and Related FacilitiesGishnu SunilОценок пока нет

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQДокумент4 страницы163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Calified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Документ11 страницCalified Welding Procedures List Aplicable For ASD TUG 2810 YN513513Costin RotaruОценок пока нет

- Asme WPS Demo PWHT PDFДокумент3 страницыAsme WPS Demo PWHT PDFGanesh rohitОценок пока нет

- QW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)Документ1 страницаQW 484-Record of Welder Qualification Tests: (See Asme BPV Code Section Ix)rohitbhat2345Оценок пока нет

- WPS - 017Документ12 страницWPS - 017MAT-LIONОценок пока нет

- Al Jalhami Cont. & Trad. Co.: Qa/QcДокумент2 страницыAl Jalhami Cont. & Trad. Co.: Qa/QcRichard PeriyanayagamОценок пока нет

- WPS PQR PDFДокумент23 страницыWPS PQR PDFtomj9104Оценок пока нет

- 12.6 Welding Procedures List (Li-002)Документ31 страница12.6 Welding Procedures List (Li-002)Ana GameroОценок пока нет

- Welding Procedure Specification (WPS) : N.A N.AДокумент1 страницаWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiОценок пока нет

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- WPS Asme IxДокумент4 страницыWPS Asme Ixjcarlosherrerac7100% (1)

- Form Wps JBL09-2011Документ2 страницыForm Wps JBL09-2011fawad aliОценок пока нет

- CV - Fabio Madeira en - 082018Документ3 страницыCV - Fabio Madeira en - 082018inspetorfabiomadeiraОценок пока нет

- Company Name Key Information Questions Answers File Reference Reviews & ApprovalsДокумент7 страницCompany Name Key Information Questions Answers File Reference Reviews & ApprovalsMAT-LIONОценок пока нет

- N0200003 - NEW-F201-0 - Inspection & Test PlanДокумент3 страницыN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliОценок пока нет

- Welding Procedure Welding Procedure Specification SpecificationДокумент2 страницыWelding Procedure Welding Procedure Specification SpecificationHamid MansouriОценок пока нет

- 57 PQRДокумент13 страниц57 PQRAbdul Tri Hamdani HamdaniОценок пока нет

- Welding Presentation by NoreastДокумент78 страницWelding Presentation by Noreastravi00098Оценок пока нет

- Hot-Rolled Coils For The Manufacture of Large-Diameter PipesДокумент2 страницыHot-Rolled Coils For The Manufacture of Large-Diameter PipesismailinesОценок пока нет

- Volume3A MechДокумент321 страницаVolume3A MechAdeel JamilОценок пока нет

- TOPSOE KBR Damage Mechanisms Causes and PreventionДокумент121 страницаTOPSOE KBR Damage Mechanisms Causes and Preventionjonnie myersОценок пока нет

- P No QaДокумент11 страницP No QadhasdjОценок пока нет

- CH 3Документ3 страницыCH 3Viraaj SinghОценок пока нет

- Bolt Depot - Bolt Grade Markings and Strength ChartДокумент2 страницыBolt Depot - Bolt Grade Markings and Strength ChartKiara Ticangan Argel100% (1)

- Aquazinc Water Based Zinc Flake Coating by Dip Spin ProcessДокумент3 страницыAquazinc Water Based Zinc Flake Coating by Dip Spin Processkdhakane9460Оценок пока нет

- Thermal Expansion CalculatorДокумент2 страницыThermal Expansion CalculatorPriyanathan ThayalanОценок пока нет

- Prosthetic Dentistry 1916Документ1 248 страницProsthetic Dentistry 1916lotusfrog100% (1)

- G-277 Cancamo CrosbyДокумент1 страницаG-277 Cancamo CrosbyDavid Borja HuarachiОценок пока нет

- Borates in Wire Drawing: Technical BulletinДокумент4 страницыBorates in Wire Drawing: Technical BulletinNguyen Thanh TrungОценок пока нет

- Howrah (Wire Drawing and Galvanising) Cluster: S.No. Name of Unit Address Contact Person Contact NoДокумент2 страницыHowrah (Wire Drawing and Galvanising) Cluster: S.No. Name of Unit Address Contact Person Contact NoVishal Kumar ShawОценок пока нет

- Normazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesДокумент5 страницNormazione 52861: Cold Rolled Steels Cold Worked Strips and PlatesRizwanAliОценок пока нет

- Environmentally Safe VCI/MCI TechnologiesДокумент8 страницEnvironmentally Safe VCI/MCI TechnologiesOscarОценок пока нет

- Test: Test Method(s) : Corrosion:: Tests)Документ4 страницыTest: Test Method(s) : Corrosion:: Tests)Sheik Mohamed AliОценок пока нет

- A666-15 Standard Specification For Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat BarДокумент8 страницA666-15 Standard Specification For Annealed or Cold-Worked Austenitic Stainless Steel Sheet, Strip, Plate, and Flat Bartjt4779100% (2)

- Die Casting PDFДокумент16 страницDie Casting PDFGokul PrabuОценок пока нет

- Rusting WorksheetДокумент2 страницыRusting WorksheetSelwah Hj AkipОценок пока нет

- Pilani Campus: Practice, EDD, BITS PilaniДокумент3 страницыPilani Campus: Practice, EDD, BITS PilaniRitik GuptaОценок пока нет

- Do You Supply Similar Materials?: SAE J404 Grade 4130Документ3 страницыDo You Supply Similar Materials?: SAE J404 Grade 4130ALEX MURPHYОценок пока нет

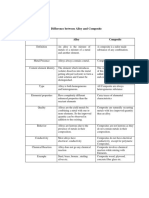

- Difference Between Alloy and Composite Word FinalДокумент2 страницыDifference Between Alloy and Composite Word FinalMehedi HasanОценок пока нет

- Aws Wps PQR FormДокумент2 страницыAws Wps PQR FormHamid MansouriОценок пока нет

- Sapa Thermal ManagementДокумент8 страницSapa Thermal Managementwww.profilalouminio.comОценок пока нет

- Fig. 4 Fig. 4 Fig. 3 Fig. 4: 3.2.2. Analysis of Microscopic Appearance of Fatigue FractureДокумент7 страницFig. 4 Fig. 4 Fig. 3 Fig. 4: 3.2.2. Analysis of Microscopic Appearance of Fatigue FractureLuis HiguerasОценок пока нет

- ACE Battery Knives ENДокумент4 страницыACE Battery Knives ENr0ll3rОценок пока нет

- General Requirements For Wire Rods and Coarse Round Wire, Alloy Steel (Metric)Документ9 страницGeneral Requirements For Wire Rods and Coarse Round Wire, Alloy Steel (Metric)Paulo GalvãoОценок пока нет

- Carbon Alloy Steel Stainless SteelДокумент4 страницыCarbon Alloy Steel Stainless Steelaswar_mhОценок пока нет

- Böhler CM 5-Ig: TIG Rod, High-Alloyed, Creep ResistantДокумент1 страницаBöhler CM 5-Ig: TIG Rod, High-Alloyed, Creep Resistantwesley59Оценок пока нет

- B 654 - B 654M - 03 - Qjy1nc9cnju0ts1sruqДокумент7 страницB 654 - B 654M - 03 - Qjy1nc9cnju0ts1sruqZahid AnwerОценок пока нет

- Polyethylene: Assembly Name: Water Pump FixtureДокумент1 страницаPolyethylene: Assembly Name: Water Pump FixtureRAJAОценок пока нет

- Temper Embrittlement - J and X FactorДокумент2 страницыTemper Embrittlement - J and X Factorgovimano100% (2)

- A582A582M-12e1 Standard Specification For Free-Machining Stainless Steel BarsДокумент4 страницыA582A582M-12e1 Standard Specification For Free-Machining Stainless Steel Barstjt4779Оценок пока нет