Академический Документы

Профессиональный Документы

Культура Документы

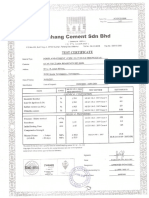

Cement Test

Загружено:

rat12345Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Cement Test

Загружено:

rat12345Авторское право:

Доступные форматы

CEMENT TESTING

Cement is tested to fulfil the following objectives:

1. Provide information relative to target cement properties;

2. Give chemical and physical test results on cement to permit comparison with Australian Standards and/or

previous test results for historical evaluation; and

3. Provide guidelines (eg concrete results) for field utilisation of products.

INTRODUCTION

Cement is usually tested on a composite sample basis.

This is particularly true for the high consumption types.

The test results are therefore an average of weekly

production. The test results for the lower consumption

cements (eg Types HE, LH, SR and SL) more

commonly represent the average of one production

batch (ie a silo). Samples are taken during the quality

control testing operations. A composite sample is

prepared from these, weighted according to the

production rates of the different production lines.

The testing of cement falls into two main areas:

1. Chemical tests; and

2. Physical tests.

It is the intention of this paper to provide a brief guide

to the evaluation and interpretation of the results of

chemical tests commonly carried out on cement, and to

give a brief description of the more common physical

tests carried out on cement. To many users of cement

its physical properties, particularly concrete strength,

slump, strength development and setting time are more

significant than its chemical composition.

Most of the tests commonly carried out on cement are

described in the following Australian Standards:

AS 2350 Methods of Testing Portland and Blended

Cements:

AS 2350.2 Chemical Composition of Portland

Cement;

AS 2350.3 Normal Consistency of Portland and

Blended Cements;

AS 2350.4 Setting Time of Portland and Blended

Cements;

AS 2350.5 Determination of Soundness of

Portland and Blended Cements;

AS 2350.8 Fineness Index of Portland Cement

by Air Permeability;

AS 2350.10 Calcium Oxide Content of Blended

Cement;

QCL Group Technical Note

Cement Testing

AS 2350.11 Compressive Strength of Portland

and Blended Cements; and

AS 1012 Methods of Testing Concrete.

CHEMICAL TESTS

Table 1 shows the chemical requirements of Portland

and blended cements in accordance with AS 3972

Portland and Blended Cements.

Some common

additional tests are also described.

Loss on Ignition (AS 2350.2)

This test determines the loss in weight of cement

when heated to approximately 1,000C. The loss in

weight occurs due to the liberation of absorbed

moisture and carbon dioxide. All cements exhibit a

loss on ignition (due to their gypsum content) so it

is the relative value of the loss and its variability

which should be noted. The accuracy of this test is

0.1%

Sulphuric Anhydride, SO3 (AS 2350.2)

This test measures the amount of sulphate present in

cement, which is indicative of the gypsum content.

Gypsum is added to cement primarily to control its

setting time. The accuracy of this test is 0.1%.

Magnesia, MgO (AS2350.2)

This test measures the amount of magnesium oxide

present in cement. It provides an estimate of the

potential quantity of periclase which when present

in substantial quantities can cause expansion of

cement related products. The accuracy of this test is

0.1%.

Page 1

August 95

QCL GROUP

Hypothetical Compound Composition

Alkalis are usually determined

photometric or XRF methods.

Compound

Abbreviation

Compound

Formula

Compound

Name

Mineral

Name

C4AF

C3A

4CaO.Al2O3.

Fe2O3

3CaO.Al2O3

C2S

2CaO.SiO2

"Ferrite"

phase

"Aluminate"

phase

Belite

C3S

3CaO.SiO2

Tetracalciumalumino ferrite

Tricalcium

aluminate

Dicalcium

silicate

Tricalcium

silicate

Alite

The hypothetical compound composition of a

cement is calculated from its chemical analysis

using the following formulae, which are contained

in AS 2350.2:

% C4 AF = 3. 04 % Fe2O3

% C3A = 2. 65 % Al2O3 1. 69 % Fe2O3

% C 3 A = 4. 07 % CaO 7. 60 % SiO 2

6. 72 % Al 2 O 3 1. 43 % Fe 2 O 3

2. 85 % SO 3

% C 2S = 2. 87 % SiO 2 0. 754 % C 3S ( Calculated )

The mineralogy of a cement determines its

performance, that is, strength development, setting

action and durability.

Chemical analysis is normally done by XRF (x-ray

fluorescence).

The reporting accuracy of the

calculated hypothetical compound composition is:

1% for C4AF

0.5% for C3A

1% for C2S

1% for C3S

Free Lime

This test determines the quantity of uncombined

lime (CaO) present in a cement which can be a

measure of sintering efficiency and/or premature

hydration of the cement. However, the test as such

cannot differentiate between free calcium oxide and

calcium oxide present as calcium hydroxide which

is a cement hydration product.

Alkali (Na2O/K20)

Some types of aggregates contain reactive silicates.

These aggregates when used in concrete can

potentially react with any alkali present, causing

deterioration of the concrete.

QCL Group Technical Note

Cement Testing

by

flame-

The Na2O equivalent = %Na20 = 0.658 %K2O.

Calcium Oxide Content of Blended Cement

(AS 2350.10)

This test determines the amount of calcium oxide

(CaO) in blended cement which dissolves in acid,

and may be used to estimate the proportion of

supplementary cementitious material (eg fly ash)

present when the calcium oxide content of the

supplementary cementitious material used is known.

PHYSICAL TESTS

Table 1 also shows the physical requirements of

Portland and blended cements in accordance with

AS 3972.

Normal Consistency (AS 2350.3)

The plasticity or consistency of cement is measured

by the amount of water required to produce a

cement paste of specified workability, as determined

by a penetration plunger (see Figure 3, AS 2350.3).

This property influences setting time and

compressive strength in cement pastes and mortar,

and is itself influenced by the cement's mineralogy

and its fineness.

The amount of water required to produce a paste of

normal consistency is essentially found by trial and

error. An operator estimates the required amount of

water (percentage by weight of cement), from

previous test results.

Following the mixing procedure specified, the

paste's resistance to penetration by a plunger of

fixed weight and size is measured within a fixed

time.

The procedure is repeated using different water

contents until the specified penetration is achieved.

The test is a precursor to other tests on cement such

as setting time, soundness and false set.

The reporting accuracy of this test is 0.1%.

Fineness Index (AS 2350.8)

Fineness of cement is expressed as the total surface

area in square metres of all the cement particles in

one kilogram of cement. The higher the fineness

index, the finer the cement will be.

Page 2

August 95

QCL GROUP

Fineness index is determined using an air

permeability method. A bed of cement is prepared

in a special permeability cell which is connected to

a manometer.

The time taken for a fixed volume of air to be drawn

through this bed of cement is measured, and the

fineness index, in m2/kg, is calculated from this

time.

The apparatus is calibrated with a standard cement

of known fineness.

A cement's fineness influences its hydration rate

and therefore strength development and setting

behaviour.

The reported accuracy of this test is 5m2/kg.

Concrete (AS 1012)

Concrete testing aims to evaluate the performance

of a cement in constant slump concrete. When

evaluating the test results, the following parameters

are worthy of note:

1. The absolute compressive strength achieved at

each age;

2. The relationship between the strength values

obtained and historical trends;

3. The relative strengths at different ages and

variations from the historical trend; and

4. The relationship between water demand and

slump, and variation from the historical trend.

Compressive Strength of Portland & Blended

Cement (AS 2350.11) - ISO/CEN Mortar Prism

Test For Cement Strength

Soundness (AS 2350.5)

The soundness (volume stability) of a cement may

be estimated by the Le Chatelier test which uses a

neat cement paste of normal consistency placed in a

special mould. This is cured underwater for 24

hours and then placed in boiling water for six hours.

The change in distance between the two arms of the

mould is measured before and after immersion in

the boiling water. The difference is the cement

paste's expansion. This apparatus is shown in

Figures 1 and 2 of AS 2350.5.

AS 3972 permits a maximum soundness of 5 mm.

The reporting accuracy is 1 mm.

Setting Time (AS 2350.4)

This test measures the setting time of cement in the

form of a paste of normal consistency. The paste is

confined in a mould identical to that used for

measurement of normal consistency and setting

time is determined by use of a penetration needle.

The setting of a cement is reported at two stages.

The initial set occurs when the penetration needle

fails to penetrate the cement paste, to within 1 mm

of the bottom of the mould. Hard set occurs when

the needle fails to penetrate 0.5 mm into the surface.

Temperature, humidity, fineness and mineralogy all

influence cement setting time.

The reporting accuracy of this test is 15 min.

QCL Group Technical Note

Cement Testing

Compressive strength is one of the most important

attributes which define the quality and performance

of

a cement. The internationally recognised

ISO/CEN test for mortar compressive strength has a

number of features which are of great value:

1. It provides a measure of the intrinsic strength of

the cement, in a manner which is independent of

extraneous variables such as ambient curing

conditions, water content, and aggregate quality

and quantity;

2. It provides a reliable means of evaluating

relative compressive strength against historical

trends; and

3. All other variables being equal, there is a high

correlation between ISO/CEN test data and

concrete strength performance. In other words,

ISO/CEN data can be used to make predictions

about concrete performance.

The test involves mixing defined proportions of

cement and a special sand (of standard grading) at a

fixed water content. The grading of the sand is such

that the mixture prepared is intentionally a microconcrete, rather than a simple sand-cement mortar.

In detail, the test procedure is carried out in four

phases:

1. Mixing of the mortar (in a standard mixer)

using a standard pre-weighed and pre-packaged,

graded sand, currently obtained from Germany.

The water/cement ratio is set at 0.5.

Page 3

August 95

QCL GROUP

2. Compacting this mortar mix into special

ISO/CEN prism moulds, using a vibrating table

at a fixed frequency.

Residue + 45 m - Fly Ash Blended Cement

(AS 2350.9)

The fineness test used for Portland cements cannot

be used for fly ash blended cement, because of

limitations of the test procedure.

3. Curing of the mortar prisms under standard

conditions, until testing age - normally 3, 7 and

28 days.

A wet sieve residue on a 45m screen is therefore

used to give an indication of the fineness of fly ash

blended cements.

4. Compression testing of the mortar prism.

The test data from the compression test are required

to meet minimum standards set down in AS 3972.

This value indicates the percentage material by

weight retained on a 45 micron mesh following a

specific washing and drying procedure.

Table 1: Properties and characteristics for Portland and blended cements (AS 3972)

Type of cement

Property

General purpose

Type GP

Type GB

Special purpose

Type HE

Type LH

Type SR

Type SL

Chemical tests

SO3 content (AS 2350.2) maximum (%)

C3A content (AS 2350.2) maximum (%)

Heat of hydration (AS 2350.7) maximum (J/g)

at 7 days

at 28 days

3.5

-

3.5

-

3.5

-

3.5

-

3.0

5.0

3.5

-

280

320

Physical tests

Setting time (AS 2350.4)

minimum (min)

maximum (h)

Soundness (AS 2350.5) maximum (mm)

Compressive strength (AS 2350.11) min (MPa)

at 3 days

at 7 days

at 28 days

Shrinkage (AS 2350.13) maximum microstrain

at 28 days

QCL Group Technical Note

Cement Testing

45

10

5

45

10

5

45

10

5

45

10

5

45

10

5

45

10

5

25

40

15

30

20

30

-

10

30

20

30

20

30

750

Page 4

August 95

Вам также может понравиться

- As 2350.2-2006 Methods of Testing Portland Blended and Masonry Cements Chemical CompositionДокумент2 страницыAs 2350.2-2006 Methods of Testing Portland Blended and Masonry Cements Chemical CompositionSAI Global - APACОценок пока нет

- GB700-88 Carbon Structural SteelsДокумент7 страницGB700-88 Carbon Structural SteelsyuОценок пока нет

- SCC Guideline MixDesign May 2008 ISBN 87 7756 769 2Документ22 страницыSCC Guideline MixDesign May 2008 ISBN 87 7756 769 2Hafidh Mulyadi Hst100% (1)

- Fire Proof PlasterДокумент1 страницаFire Proof PlasterMuhammad Sarmad SonyalОценок пока нет

- Common Defects in PlasterДокумент2 страницыCommon Defects in PlasterHatta RizqОценок пока нет

- Maufacturing of Dry Lean ConcreteДокумент1 страницаMaufacturing of Dry Lean ConcreteairpavsetОценок пока нет

- GGBSДокумент20 страницGGBSratnakarОценок пока нет

- Concrete Mix Plant Bis 4925.2004Документ14 страницConcrete Mix Plant Bis 4925.2004DilipKumarDaddalaОценок пока нет

- Disclosure To Promote The Right To InformationДокумент18 страницDisclosure To Promote The Right To Informationsudhir5441Оценок пока нет

- BS 12-1989Документ8 страницBS 12-1989U Thaung MyintОценок пока нет

- 2143R 88Документ17 страниц2143R 88DIDIER ANGEL LOPEZ RINCONОценок пока нет

- Shotcrete Boiled Water AbsorptionДокумент6 страницShotcrete Boiled Water AbsorptiondjajadjajaОценок пока нет

- Standard Test Method Organic Impurities in Fine Aggregates For Concrete'Документ2 страницыStandard Test Method Organic Impurities in Fine Aggregates For Concrete'ayan3176Оценок пока нет

- Introduction of Cement: When Was Cement Begin?Документ11 страницIntroduction of Cement: When Was Cement Begin?مايف سعدونОценок пока нет

- en 197 1 2011 SR PDFДокумент1 страницаen 197 1 2011 SR PDFUdari LiyanageОценок пока нет

- Excel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness ModulusДокумент6 страницExcel Sheet For Sieve Analysis of Aggregate and To Calculate Fineness Modulusmersed123Оценок пока нет

- NDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiДокумент12 страницNDT On Concrete Pull Off Test: by Subhodeep Neogi Sai Prakash VaddiManish Mittal100% (1)

- Ytl Cement - Kursb 1Документ1 страницаYtl Cement - Kursb 1الهادي الياس100% (1)

- Astm.c330.1999 Concreto LeveДокумент6 страницAstm.c330.1999 Concreto LevepcpontesОценок пока нет

- DMRB All Parts Jan 2012Документ492 страницыDMRB All Parts Jan 2012vijaya guniputiОценок пока нет

- SCC ConcreteДокумент27 страницSCC ConcreteAbsiye Aden0% (1)

- C156 PDFДокумент5 страницC156 PDFMateriales FicОценок пока нет

- C1582C1582M-Aditivos Inhibidores de CorrosionДокумент10 страницC1582C1582M-Aditivos Inhibidores de CorrosionAnthony López HuamanОценок пока нет

- Technical Report TR 5 Conc Mix DesignДокумент18 страницTechnical Report TR 5 Conc Mix DesignSunil ReddyОценок пока нет

- ASTM C28C28M (2015) Standard Specification For Gypsum PlastersДокумент5 страницASTM C28C28M (2015) Standard Specification For Gypsum PlastersKatherine CarabaliОценок пока нет

- As 3583.1-1998 Methods of Test For Supplementary Cementitious Materials For Use With Portland and Blended CemДокумент2 страницыAs 3583.1-1998 Methods of Test For Supplementary Cementitious Materials For Use With Portland and Blended CemSAI Global - APACОценок пока нет

- Energy TestДокумент19 страницEnergy TestDataОценок пока нет

- Standards and Update For Concrete Block Paving and Paving Flags in The United KingdomДокумент6 страницStandards and Update For Concrete Block Paving and Paving Flags in The United KingdomΓιάννης ΜούσιαςОценок пока нет

- WD-40 Multi-Use Product: Technical Data SheetДокумент3 страницыWD-40 Multi-Use Product: Technical Data SheetKatsukiDaito100% (1)

- Uniformity Test of ConcreteДокумент3 страницыUniformity Test of Concreterajam1997100% (1)

- Guide For The Use of Polymers in Concrete: ACI 548.1R-97Документ29 страницGuide For The Use of Polymers in Concrete: ACI 548.1R-97Control de calidad Antamina100% (1)

- GFRCДокумент11 страницGFRCMhmd AbdoОценок пока нет

- Hemanth PPT NewДокумент59 страницHemanth PPT NewhemrajbmsОценок пока нет

- Method Statement Floor and Speciality JointsДокумент10 страницMethod Statement Floor and Speciality JointsJamsheed Ap KadangodОценок пока нет

- Setting Time of ConcreteДокумент2 страницыSetting Time of ConcretevempadareddyОценок пока нет

- Determination of Water-Cement Ratio of HardenedДокумент6 страницDetermination of Water-Cement Ratio of HardenedMárcio AlvesОценок пока нет

- Kurva: Gradasi PasirДокумент13 страницKurva: Gradasi PasirFaisalОценок пока нет

- BS EN 933-2 - Nominal Size of Apetures PDFДокумент8 страницBS EN 933-2 - Nominal Size of Apetures PDFCraig LongОценок пока нет

- No Fines ConcreteДокумент5 страницNo Fines ConcretedannyОценок пока нет

- CSA3000EДокумент2 страницыCSA3000EMinОценок пока нет

- Experimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Документ6 страницExperimental Study On Concrete Using Copper Slag As Replacement Material of Fine Aggregate 2165 784X.1000156Siddhesh Kamat Mhamai100% (2)

- As 2758.0-2009 Aggregates and Rock For Engineering Purposes Definitions and ClassificationДокумент7 страницAs 2758.0-2009 Aggregates and Rock For Engineering Purposes Definitions and ClassificationSAI Global - APACОценок пока нет

- Silica Fume 5 PDFДокумент14 страницSilica Fume 5 PDFNour KottiОценок пока нет

- Bond Strength of Mortar To Masonry Units: Standard Test Method ForДокумент8 страницBond Strength of Mortar To Masonry Units: Standard Test Method Foranon_694321072100% (1)

- Acid-Soluble Chloride in Mortar and Concrete: Standard Test Method ForДокумент4 страницыAcid-Soluble Chloride in Mortar and Concrete: Standard Test Method Foralexjos1Оценок пока нет

- C1872 − 18ε2Документ7 страницC1872 − 18ε2Hamed HamidpourОценок пока нет

- Testing of Cement: Free Powerpoint Templates Free Powerpoint TemplatesДокумент23 страницыTesting of Cement: Free Powerpoint Templates Free Powerpoint TemplatesVivekChaudharyОценок пока нет

- Shrinkage of ConcreteДокумент3 страницыShrinkage of Concretegmgoutam550Оценок пока нет

- CommercialComplete NFPA 285 BrochureДокумент8 страницCommercialComplete NFPA 285 BrochureMehmet OzdenОценок пока нет

- Design and Application of Self Compacting ConcreteДокумент38 страницDesign and Application of Self Compacting ConcreteAby AnjaliseОценок пока нет

- Silica FumeДокумент24 страницыSilica FumeRatna Sai0% (1)

- BricksДокумент15 страницBricksKeysang WangmoОценок пока нет

- Is549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysДокумент4 страницыIs549 Evaluation of Alkali Silica Reactivity (Asr) Mortar Bar Testing (Astm c1260 and c1567) at 14 Days and 28 DaysSandro MendesОценок пока нет

- Lecture 10-Hot & Cold Weather ConcretingДокумент13 страницLecture 10-Hot & Cold Weather ConcretingSyed Azmat Ali ShahОценок пока нет

- As 2350.14-2006 Methods of Testing Portland Blended and Masonry Cements Length Change of Cement Mortars ExposДокумент2 страницыAs 2350.14-2006 Methods of Testing Portland Blended and Masonry Cements Length Change of Cement Mortars ExposSAI Global - APAC100% (1)

- Effect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsДокумент8 страницEffect of y Ash and Silica Fume On Compressive Strength of Self-Compacting Concrete Under Different Curing ConditionsgeostaterОценок пока нет

- Artigo - Control Tests For ConcreteДокумент24 страницыArtigo - Control Tests For ConcreteRonald Rolim de Moura100% (1)

- FDOT BB978 RPTДокумент14 страницFDOT BB978 RPTirfanquadriОценок пока нет

- Standard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteДокумент4 страницыStandard Test Method For Density and Void Content of Freshly Mixed Pervious ConcreteManaswini VadlamaniОценок пока нет

- M 302 DesДокумент9 страницM 302 DesJuan Daniel Rojas PalmaОценок пока нет

- ParvatiДокумент1 страницаParvatirat12345Оценок пока нет

- KuntiДокумент1 страницаKuntirat12345Оценок пока нет

- Sa Bhogakāya: Celestial ManifestationsДокумент3 страницыSa Bhogakāya: Celestial Manifestationsrat12345Оценок пока нет

- Bhutan: Druk Yul Druk Gyal Khap)Документ5 страницBhutan: Druk Yul Druk Gyal Khap)rat12345Оценок пока нет

- Democratic Socialist Republic of Sri LankaДокумент5 страницDemocratic Socialist Republic of Sri Lankarat12345Оценок пока нет

- ArjunДокумент1 страницаArjunrat12345Оценок пока нет

- RavanaДокумент3 страницыRavanarat12345Оценок пока нет

- Pakistan: Islamic Republic of PakistanДокумент10 страницPakistan: Islamic Republic of Pakistanrat12345Оценок пока нет

- HoliДокумент5 страницHolirat12345Оценок пока нет

- Buying Guide For Voltage StabilizersДокумент8 страницBuying Guide For Voltage Stabilizersrat12345Оценок пока нет

- KilnДокумент7 страницKilnrat12345Оценок пока нет

- 06Документ8 страниц06rat12345Оценок пока нет

- Republic of IndiaДокумент5 страницRepublic of Indiarat12345100% (1)

- LemonДокумент7 страницLemonrat12345Оценок пока нет

- Published Date: 9 Jul 2018 Publication: The Economic Times Edition: New Delhi Page No: 9 Circulation: 126805Документ13 страницPublished Date: 9 Jul 2018 Publication: The Economic Times Edition: New Delhi Page No: 9 Circulation: 126805rat12345Оценок пока нет

- Published Date: 16 Jul 2018 Publication: The Economic Times Edition: New Delhi Page No: 7 Circulation: 126805Документ25 страницPublished Date: 16 Jul 2018 Publication: The Economic Times Edition: New Delhi Page No: 7 Circulation: 126805rat12345Оценок пока нет

- 1490 Highlights of The Week 9th July - 15th July 2018 PDFДокумент13 страниц1490 Highlights of The Week 9th July - 15th July 2018 PDFrat12345Оценок пока нет

- Largest Collection of Food Technology Ebooks - Free Download - Discover Food TechДокумент14 страницLargest Collection of Food Technology Ebooks - Free Download - Discover Food Techrat12345100% (1)

- Food ProcessingДокумент1 страницаFood Processingrat12345Оценок пока нет

- Cement Tech BooksДокумент7 страницCement Tech Booksrat12345Оценок пока нет

- Petroleum Coke Utilization For Cement Kiln FiringДокумент8 страницPetroleum Coke Utilization For Cement Kiln FiringSyeed SofieОценок пока нет

- Protect Your Family From A Life of CompromisesДокумент28 страницProtect Your Family From A Life of Compromisesrat12345Оценок пока нет

- Disclosure To Promote The Right To InformationДокумент9 страницDisclosure To Promote The Right To Informationrat12345Оценок пока нет

- Hot Air Generator Cost SheetДокумент4 страницыHot Air Generator Cost Sheetrat12345Оценок пока нет

- HFBFB 121sd1 FG 2 S 2 Fgs 22 S 2 SG 121 Sad 55 D 6 F 11 Ds 1 11Документ1 страницаHFBFB 121sd1 FG 2 S 2 Fgs 22 S 2 SG 121 Sad 55 D 6 F 11 Ds 1 11rat12345Оценок пока нет

- AnticyclonesДокумент5 страницAnticyclonescicileanaОценок пока нет

- Pe 03 - Course ModuleДокумент42 страницыPe 03 - Course ModuleMARIEL ASIОценок пока нет

- Mcdonald 2016Документ10 страницMcdonald 2016Andrika SaputraОценок пока нет

- Read While Being Blind.. Braille's Alphabet: Be Aware and Active !Документ3 страницыRead While Being Blind.. Braille's Alphabet: Be Aware and Active !bitermanОценок пока нет

- Monergism Vs SynsergismДокумент11 страницMonergism Vs SynsergismPam AgtotoОценок пока нет

- Assessment of Students' Oral Communication in English ClassДокумент10 страницAssessment of Students' Oral Communication in English ClassKeebeek S ArbasОценок пока нет

- Costbenefit Analysis 2015Документ459 страницCostbenefit Analysis 2015TRÂM NGUYỄN THỊ BÍCHОценок пока нет

- Shostack ModSec08 Experiences Threat Modeling at MicrosoftДокумент11 страницShostack ModSec08 Experiences Threat Modeling at MicrosoftwolfenicОценок пока нет

- Tribal Banditry in Ottoman Ayntab (1690-1730)Документ191 страницаTribal Banditry in Ottoman Ayntab (1690-1730)Mahir DemirОценок пока нет

- Review1 ScheduleДокумент3 страницыReview1 Schedulejayasuryam.ae18Оценок пока нет

- Computing of Test Statistic On Population MeanДокумент36 страницComputing of Test Statistic On Population MeanKristoffer RañolaОценок пока нет

- Ib History Command Term PostersДокумент6 страницIb History Command Term Postersapi-263601302100% (4)

- Organizational ConflictДокумент22 страницыOrganizational ConflictTannya AlexandraОценок пока нет

- Law of EvidenceДокумент14 страницLaw of EvidenceIsha ChavanОценок пока нет

- All You Need To Know About Egg YolkДокумент7 страницAll You Need To Know About Egg YolkGolden Era BookwormОценок пока нет

- Assignment#10 Global Strategy and The Multinational CorporationДокумент1 страницаAssignment#10 Global Strategy and The Multinational CorporationAnjaneth A. VillegasОценок пока нет

- 74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicДокумент8 страниц74HC00D 74HC00D 74HC00D 74HC00D: CMOS Digital Integrated Circuits Silicon MonolithicAssistec TecОценок пока нет

- Outdoor Air Pollution: Sources, Health Effects and SolutionsДокумент20 страницOutdoor Air Pollution: Sources, Health Effects and SolutionsCamelia RadulescuОценок пока нет

- Vendor Information Sheet - LFPR-F-002b Rev. 04Документ6 страницVendor Information Sheet - LFPR-F-002b Rev. 04Chelsea EsparagozaОценок пока нет

- Psychological Contract Rousseau PDFДокумент9 страницPsychological Contract Rousseau PDFSandy KhanОценок пока нет

- Making Effective Powerpoint Presentations: October 2014Документ18 страницMaking Effective Powerpoint Presentations: October 2014Mariam TchkoidzeОценок пока нет

- Article An Incident and Injury Free Culture Changing The Face of Project Operations Terra117 2Документ6 страницArticle An Incident and Injury Free Culture Changing The Face of Project Operations Terra117 2nguyenthanhtuan_ecoОценок пока нет

- Sindi and Wahab in 18th CenturyДокумент9 страницSindi and Wahab in 18th CenturyMujahid Asaadullah AbdullahОценок пока нет

- ISBN Safe Work Method Statements 2022 03Документ8 страницISBN Safe Work Method Statements 2022 03Tamo Kim ChowОценок пока нет

- Lesson PlanДокумент2 страницыLesson Plannicole rigonОценок пока нет

- Prelim Examination MaternalДокумент23 страницыPrelim Examination MaternalAaron ConstantinoОценок пока нет

- Module 1: Overview of Applied Behaviour Analysis (ABA)Документ37 страницModule 1: Overview of Applied Behaviour Analysis (ABA)PriyaОценок пока нет

- 18 June 2020 12:03: New Section 1 Page 1Документ4 страницы18 June 2020 12:03: New Section 1 Page 1KarthikNayakaОценок пока нет

- Grade 7 ExamДокумент3 страницыGrade 7 ExamMikko GomezОценок пока нет

- Product CatalogsДокумент12 страницProduct Catalogscab666Оценок пока нет

- To Engineer Is Human: The Role of Failure in Successful DesignОт EverandTo Engineer Is Human: The Role of Failure in Successful DesignРейтинг: 4 из 5 звезд4/5 (138)

- Sodium Bicarbonate: Nature's Unique First Aid RemedyОт EverandSodium Bicarbonate: Nature's Unique First Aid RemedyРейтинг: 5 из 5 звезд5/5 (21)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)От EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda Cans (Father's Day Gift for Science and Engineering Curious Dads)Оценок пока нет

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeОт EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeРейтинг: 4.5 из 5 звезд4.5/5 (59)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansОт EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansРейтинг: 4.5 из 5 звезд4.5/5 (21)

- Guidelines for Chemical Process Quantitative Risk AnalysisОт EverandGuidelines for Chemical Process Quantitative Risk AnalysisРейтинг: 5 из 5 звезд5/5 (1)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetОт EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetРейтинг: 4.5 из 5 звезд4.5/5 (10)

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyОт EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyРейтинг: 4.5 из 5 звезд4.5/5 (5)

- Process Plant Equipment: Operation, Control, and ReliabilityОт EverandProcess Plant Equipment: Operation, Control, and ReliabilityРейтинг: 5 из 5 звезд5/5 (1)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОт EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersОценок пока нет

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОт EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsОценок пока нет

- Lees' Process Safety Essentials: Hazard Identification, Assessment and ControlОт EverandLees' Process Safety Essentials: Hazard Identification, Assessment and ControlРейтинг: 4 из 5 звезд4/5 (4)

- Geotechnical Engineering Calculations and Rules of ThumbОт EverandGeotechnical Engineering Calculations and Rules of ThumbРейтинг: 4 из 5 звезд4/5 (17)

- An Applied Guide to Water and Effluent Treatment Plant DesignОт EverandAn Applied Guide to Water and Effluent Treatment Plant DesignРейтинг: 5 из 5 звезд5/5 (4)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОт EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsОценок пока нет

- Skyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownОт EverandSkyway: The True Story of Tampa Bay's Signature Bridge and the Man Who Brought It DownОценок пока нет