Академический Документы

Профессиональный Документы

Культура Документы

Determination of Chloramphenicol in Bulk Drug and Pharmaceutical Dosage Forms by HPLC

Загружено:

IOSR Journal of PharmacyОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Determination of Chloramphenicol in Bulk Drug and Pharmaceutical Dosage Forms by HPLC

Загружено:

IOSR Journal of PharmacyАвторское право:

Доступные форматы

IOSR Journal Of Pharmacy

(e)-ISSN: 2250-3013, (p)-ISSN: 2319-4219

www.iosrphr.org Volume 4, Issue 12 (December 2014), PP. 60-70

Determination of Chloramphenicol in Bulk Drug and

Pharmaceutical Dosage Forms by HPLC

* P.Suguna, N.V.S.Naidu & B. Sathyanarayana

Department of Chemistry, S.V.University, Tirupati-517502, A.P., India.

ABSTRACT: A simple, economic, selective, precise, and accurate High Performance liquid Chromatographic

method for the analysis of Chloramphenicol in bulk drug and pharmaceutical formulations were developed and

validated in the present study. The mobile phase, employed in the present study, consists of a mixture of sodium

pentanesulfonate solution, acetonitrile, and glacial acetic acid in the proportion 85:15:1 respectively, the pH

of the solutions was maintained at 5.0 0.05 with sodium hydroxide solution . This was found to give a sharp

peak of Chloramphenicol at a retention time of 3.551 min. HPLC analysis of Chloramphenicol was carried out

at a wavelength of 272 nm with a flow rate of 2.0 ml/min. The linear regression analysis data for the calibration

curve showed a good linear relationship with a regression coefficient of 0.999 in the concentration range of 50

g ml-1to 150 g ml-1. The linear regression equation was y =38.493x-51.484. The developed method was

employed with a high degree of precision and accuracy for the analysis of Chloramphenicol. The developed

method was validated for accuracy, precision, robustness, detection and quantification limits as per the ICH

guidelines. The wide linearity range, accuracy, sensitivity, short retention time and composition of the mobile

phase indicated that this method is better for the quantification of Chloramphenicol.

KEYWORDS: Chloramphenicol. HPLC. Validation

I.

INTRODUCTION:

Several analytical methods have been reported for the determination of chloramphenicol in various

samples, such as shrimp,3,811 seafood, meat,7,1215 eggs,13 milk,4,13 honey,12,13,15 animal feeds,5

urine, serum1416 and pharmaceutical formulations1722 based on liquid chromatography (LC),5,12 liquid

chromatographymass

spectrometry

(LC-MS),3,711,14,15

gas chromatography (GC), gas

chromatographymass spectrometry (GC-MS),3,12,14 capillary zone electrophoresis,16,17 enzyme-linked

immunosorbent assay (ELISA),3,13 spectrophotometry,18,19 and chemiluminescence.2022 LC-MS is a

common method that is used to determine chloramphenicol, because of its high sensitivity and low

limit of detection. However, it needs expensive apparatus and reagents and is time-consuming. A

sensitive, rapid and cheap method for analysis is still needed. Electrochemical methods are widely used in

many applications because they are simple and involve no more reagents for derivatization and low cost.

Several methods have been developed for the determination of chloramphenicol using electrochemical

detection, such as voltammetry at electrochemically activated carbon fiber microelectrodes4 and capillaryzone electrophoresis with amperometric detection at a carbon disk electrode17 and a carbon fiber microdisk array electrode.16

Boron-doped diamond thin film (BDD) electrodes have many advantages for

electroanalytical applications, due to their unique characteristics,

which include a very low

23,24

background current,

a wide electrochemical potential window in aqueous solutions,25,26 a

long-term stability of response,2730 a slight adsorption of polar organic molecules28 and low

sensitivity to dissolved oxygen.31

Because of these attractive properties, BDD electrodes have been

successfully used for the determination of various compounds, such as tiopronin,30 acetaminophen,32 Dpenicillamine,33 captopril,34 lincomycin,35

sulfonamides,36

malachite green and leucomalachite

37

green.

Sensitive voltammetric determination of chloramphenicol by using single-wall carbon nanotube

gold nanoparticleionic liquid composite film modified glassy carbon electrodes was published by Fei Xiao, et

al 2007, Department of Chemistry, Wuhan University, Wuhan 430072, PR China . The empirical formula for

Chloramphenicol mesylate is C11H12Cl2N2O5 and the molecular weight is 323.13. It has the following structure.

60

Determination of Chloramphenicol in Bulk

Figure1.

The HPLC method describe here is simple, sensitive, and reproducible for Chloramphenicol

determination in formulations with low background interference. An attempt has been made to develop and

validate to ensure their accuracy, precision and other analytical method validation parameters as mentioned in

various gradients. One method reported for the HPLC determination for developed based on the use of a C-18

column with a suitable mobile phase, without the use of any internal standard. For pharmaceutical formulation

the proposed method is suitable for their analysis with virtually no interference of the usual additives present in

pharmaceutical formulations.

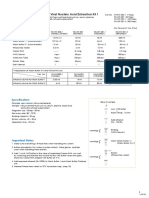

Experimental Instrumentation

HPLC Analytical column Nucleosil C-18, 100mm x 4.6mm x 5m Column

Table 1.1: Chromatographic conditions of Chloramphenicol

Analytical Methodology

1. Preparation of Mobile phase

2.1 g of Sodium pentanesulfonate was weighed accurately and transferred into one liter volumentric

flask and dissolved in doubly distilled water and made up to the 1000ml with the water. For isocratic system, a

solution of mixture of sodium pentanesulfonate solution, acetonitrile, and glacial acetic acid in the proportion

85:15:1 respectively was prepared and filtered through 0.2 m Nylon membrane filter paper and degased prior

to use.

2. Chromatographic conditions

Separation was performed on Nucleosil - C18, 100mm x 4.6mm x 5m Column. Methanol was used as

a diluent and mobile phase consists of mixture of Sodium pentanesulfonate solution, acetonitrile, and glacial

acetic acid in the proportion 85:15:1 respectively. Injection volume of 20 l was used. Mobile phase was filtered

before use through 0.5 m Nylon membrane filter paper and degassed with helium purge for 20 min. The

components of the mobile phase were pumped from solvent reservoir to the column at flow rate 2 ml/min and

wavelength was set to 272 nm. The column temperature was set at 25 oC.

3. Preparation of Chloramphenicol Standard Solution: (pure sample)

About 100mg of Chloramphenicol working standard was weighed accurately and transferred into

100 ml volumetric flask and 10 ml of diluents was added and sonicated to dissolve. The solution in the flask

was made up to the mark with diluents.Dilute to volume with diluent. i.e. 1000 g/ml (Stock solution A)

From the above stock solution A 10 ml of the solution was pipette out into 100 ml volumetric flask

and the volume was made up to the mark with methanol to obtained the final concentration of 100 g/ml (Stock

solution B) From the stock solution B ranging from 5-15 ml were transferred into a series of 10 ml volumetric

flasks to provide final concentration range of 50-150 g/ml and each flask was made up to the mark with

diluent.

61

Determination of Chloramphenicol in Bulk

4. Preparation of Test Solutions :( Formulation)

Twenty tablets containing Chloramphenicol were weighed and finely powered. An

accurately weighed portion of the powder equivalent to 100 mg of Chloramphenicol was transferred into a 100

ml volumetric flask. About 10 ml of diluent was added and shaken for 20 minutes by manually and further

sonicated for 30 minutes and diluted up to the mark with diluent. This solution was centrifuged at 8000 rpm for

10 minutes and decanted the supernatant solution into another test tube (. i.e. 1000 g/ml) and transferred 10 ml

of supernatant solution into another 100 ml volumetric flask and made up the volume with diluent (100 g/ml).

Further transfer 5-15 ml of solution was transferred into another 10 ml volumetric flask and made up the

volume with diluent. The solution was filtered through 0.45 m Nylon membrane filter paper. (50-150 g/ml)

5. Assay procedure:

The column was equilibrated for at least 30 minutes with mobile phase flowing through the system

with a flow rate of 1.0 ml/min. Detector was set at a wavelength of 251 nm. Five sets of the Drug solutions were

prepared in diluent containing Chloramphenicol at a concentration range of 50 - 150 g/ml. Then 20 l of each

standard and sample solution were injected for five times separately. The retention time for Chloramphenicol

was found to be 3.551 min (Fig -3.15). The peak areas of the drug concentrations were calculated.

6. System Suitability Solution:

Chloramphenicol standard working solution was used as system suitability solution.

7. Procedure:

Equal volumes of blank and five replicate injections of system suitability solution (Chloramphenicol

standard working solution) were separately injected into C-18 column. Then two injections of test solution

were injected and chromatograms were recorded. Any peak due to blank in the test solution was

disregarded. % RSD of five replicate injections of system suitability solution (Chloramphenicol standard

working solution) was calculated. Tailing factor and theoretical plates of the peak in the chromatogram

obtained with 5th injection of system suitability solution (Chloramphenicol standard working solution)were

checked.

Figure-2: Chromatogram of Chloramphenicol

62

Determination of Chloramphenicol in Bulk

Figure -3: Linearity of Chloramphenicol standard

Table -1.2: Performance calculations, detection characteristics precision and acuracy of the proposed

method for Chloramphenicol

Parameter

HPLC Method

Wavelength (nm)

272

Retention time (t) min

3.551

Linearity range (g ml-1)

40-120

LOD

1.4039

LOQ

4.6798

Regression equation (y=bc+a)

Slope (b)

38.493

Intercept (a)

51.484

Standard deviation (SD)

18.0145

Correlation coefficient(r2)

0.9995

Relative Standard deviation (%RSD)

0.5753

Intermediate Precision (%RSD)

0.34

Range of errors

Confidence limits with 0.05 level

15.7901

Confidence limits with 0.01 level

20.7517

RSD of 5 independent determinations

63

Determination of Chloramphenicol in Bulk

Table 1.3: System suitability - Selectivity

Sr. No.

Area of Chloramphenicol

3303.16

3318.64

Mean

3310.90

Standard Deviation ()

10.95

(%) Relative Standard Deviation

0.33

Tailing factor

Theoretical plates

1.12

4214

Table -1.4: System suitability - Linearity of standard

Sr. No.

Area of Chloramphenicol

3045.54

3030.64

2965.65

2946.30

3065.97

Mean

3010.82

Standard Deviation ()

52.06

(%) Relative Standard Deviation

1.73

Tailing factor

Theoretical plates

1.09

4025

Table -1.5: Results of linearity of standard

Linearity Level

Sample Concentration (in g ml-1)

Average Area (n = 2)

Level 1

40

1604.40

Level 2

60

2326.62

Level 3

80

3130.05

Level 4

100

3953.47

Level 5

120

4640.34

Correlation Coefficient

0.999

Table -1.6: Results of linearity of sample

Linearity Level

Sample Concentration (in g ml-1 )

Average Area (n = 2)

Level 1

40

1699.97

Level 2

60

2457.98

Level 3

80

3115.05

Level 4

100

3942.70

Level 5

120

4648.41

64

Correlation Coefficient

0.999

Determination of Chloramphenicol in Bulk

Table -1.7: Results of Linearity of standard in presence of placebo

Linearity

Level

Sample Concentration

(in g ml-1)

Level-1

Level-2

Level-3

Level-4

Level-5

40

60

80

100

120

Placebo added to

the standard

solution

( g)

137.2

137.2

137.2

137.2

137.2

Average Area

(n=1)

Correlation

Coefficient

1268.38

2082.58

2676.42

3657.2

4104.67

0.999

Table 1.8: System precision

Sr. No.

Area of

Chloramphenicol

3237.79

3266.92

3236.73

3246.17

3240.59

3245.22

3243.92

3274.16

3281.76

10

3218.77

Mean

3249.20

Tailing factor

Theoretical

plates

Standard

Deviation ()

(%) Relative Standard

Deviation

19.25

1.16

4036

0.59

Table 1.9: Results of method precision

Test Solution

% Assay of Chloramphenicol

100.84

100.02

100.84

99.24

100.09

100.67

Mean

100.28

Standard Deviation ()

0.63

(%) Relative Standard Deviation

0.63

65

Determination of Chloramphenicol in Bulk

Table -1.10: Results of intermediate precision

Test Solution

% Assay of Chloramphenicol

100.50

100.64

99.96

100.62

100.93

100.26

Mean

100.49

Standard Deviation ()

0.34

(%) Relative Standard Deviation

0.34

Table -1.11: Results of twelve test solutions of Chloramphenicol in Ocupol-D Eye/Ear Drops

(Six of method precision & six of intermediate precision)

Analysis performed during method precision study

By Analyst 1 on system 1 and on column 1 on day 1

% Assay of Chloramphenicol

Same column

1

100.84

100.02

100.84

99.24

100.09

100.67

Analysis performed during intermediate precision study

By Analyst 2 on system 2 and on column 2 on day 2

Column sr. no.

015337030136 01

Test Solution

% Assay of Chloramphenicol

100.50

100.64

99.96

10

100.62

11

100.93

12

100.26

Mean of twelve samples

100.38

Standard Deviation ()

0.49

(%) Relative Standard Deviation

0.49

66

Determination of Chloramphenicol in Bulk

Table-1.12(A): Determination of accuracy of Chloramphenicol

Level of % Recovery

Amount of CPC in

formulation (mg)

50%

100%

150%

Total amount

found (mg)

% Recovery

99.92

Amount of

Standard CPC

added (mg)

100

199.84

99.91

99.87

100

199.74

99.86

99.95

100

199.90

99.94

99.96

150

249.90

99.95

99.89

150

249.72

99.88

99.87

150

249.67

99.86

99.91

200

299.73

99.90

99.98

200

299.94

99.97

99.85

200

299.55

99.84

Table-1.12(B): Statistical data for accuracy determination

Level of % Recovery

Total amount found

(mean)

Standard deviation

% RSD

50%

199.82

0.0808

0.0404

100%

249.76

0.1209

0.0484

150%

299.74

0.1951

0.0650

Table 1.13: Robustness with Change in Column Lot

Flow rate

Same column

Sample

Diff column

% Assay

Test solution

99.95

100.53

Average assay result from method precision

100.28

100.28

Mean

100.12

100.41

Standard Deviation ()

0.23

0.18

(%) Relative Standard Deviation

0.23

0.18

Table -1.14: Results for change in flow rate

Flow rate

1.8mL/minute

Sample

2.2 mL/minute

% Assay

Test solution

99.96

101.09

Average assay result from method precision

100.28

100.28

Mean

100.12

100.69

Standard Deviation ()

0.23

0.57

(%) Relative Standard Deviation

0.23

0.57

67

Determination of Chloramphenicol in Bulk

Table -1.15: Results for change in wavelength

Wavelength

270 nm

Sample

274 nm

% Assay

Test solution

100.03

99.95

Average assay result from method precision

100.28

100.28

Mean

100.16

100.12

Standard Deviation ()

0.18

0.23

(%) Relative Standard Deviation

0.18

0.23

Table 1.16: Robustness with Change in pH of mobile phase

pH

4.6

Sample

5.0

%Assay

Test solution

98.81

98.27

Average assay result from

method precision

98.09

98.09

Mean

98.45

98.68

Standard Deviation()

0.58

0.84

(%) Relative Standard

Deviation

0.56

0.83

Table -1.17: Results for solution stability

% Assay results calculated against the freshly prepared system suitability standard

Sample

% Assay of Chloramphenicol

0th hr

99.94

12th hr

100.12

24 hr

100.66

36 hr

100.58

48 hr

100.02

Mean

100.26

Standard Deviation ()

0.33

(%) Relative Standard Deviation

0.33

RESULTS AND DISCUSSIONS

The appropriate wavelength in UV region has been selected for the measuring of active ingredient in

the proposed method. This method was validated by linear fit curve and all the parameters were calculated.

68

Determination of Chloramphenicol in Bulk

Parameters Fixation: In developing methods, systematic study of the effects of various parameters was

undertaken by varying one parameter at a time controlling all other parameters. The following studies were

conducted for this purpose.

a) Mobile phase characteristics

In order to get sharp peaks and baseline separation of the components, carried out number of experiments

by varying different components like percentage of organic phase in the mobile phase, total pH of the selected

mobile phase and flow rate by changing one at a time and keeping all other parameters constant. The optimum

conditions obtained were included in the procedure proposed.

b) Detection Characteristics

To test whether Chloramphenicol had been linearly eluted from the column, different amounts of

Chloramphenicol were taken and analyzed by the above mentioned procedures. The peak area ratios of

component areas were calculated and the values are graphically represented in Fig 2. The linear fit of the

system was illustrated graphically. Least square regression analysis for the method was carried out for the slope,

Intercepts and correlation coefficient. The results were presented in Table -1.2.

c)

Performance Calculations

To ascertain the system suitability for the proposed method, a number of statistical values have been

calculated with the observed readings and the results were recorded in Table-1.2.

d) Method validations

The UV absorption maximum for Chloramphenicol was fixed at 272 nm respectively. As the final detection

was made by the UV absorption spectrum, each method was validated by linear fit curve.

e)

Precision

The precision of the method was ascertained separately from the peak area ratios obtained by actual

determination of a fixed amount of drug. The percent of relative standard deviation was calculated for

Chloramphenicol and were presented in Table-1.8, 1.9. 1.10 & 1.11. The precision of the assays was also

determined in terms of intra and inter-day variation in the peak areas for a set of drug solution was calculated in

terms of coefficient of variation (CV)

f)

Accuracy

To determine the accuracy of the proposed methods, different technical grade samples of Chloramphenicol

within the linearity limits were taken and analyzed by the proposed methods. The results (percent error) were

recorded n Table-1.12.

g) Interference Studies

The effect of wide range of excipients and other additives usually present in the formulations of

Chloramphenicol in the determinations under optimum conditions were investigated. The common excipients

such as colloidal Silicon dioxide, ethyl cellulose, hydroxyl propyl methyl cellulose, magnesium state,

microcrystalline cellulose provide have been added to the sample solutions and injected. They have not

disturbed the elution or quantification of drug. In fact many have no absorption at this UV maximum.

h) Analysis of Formulation

To find out the stability of the proposed methods for the assay of formulations containing Chloramphenicol

was analyzed by the proposed and reference methods. The proposed method does not differ significantly in

precision and accuracy from reference method. The results were recorded in Table-5.42.

i)

Ruggedness and Robustness

Ruggedness of the proposed method was determined by carrying out the analysis by two different analysts

using similar operational i.e. Robustness with Change in Column Lot, change in flow rate, change in wavelength

and change in pH of the mobile phase . The results were indicated by % CV in Table -1.13, 1.14, 1.15 & 1.16.

Robustness of the method was determined by carrying out the analysis at two different wavelengths i.e. at 270

nm and 274 nm and the results were indicated by % CV in Table 1.15.

j)

Recovery Studies

Recovery studies were conducted by analyzing each formulation in the first instance for the active

ingredient by the proposed methods known amounts of pure drug was then added to each of the previously

analyzed formulations and the total amount of the drug was once again determined by the proposed methods

69

Determination of Chloramphenicol in Bulk

after bringing the active ingredient concentration within the linearity limits. The results were recorded in Table 1.12.

h) Solution Stability

The stability of the solutions under study was established by keeping the solution at room temperature for

48 h. The results indicate no significant change in assay values that indicates stability of drug in the solvent used

during analysis. The results were recorded in Table -1.17.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

L. Ag, A. Guzmn, P. Yez-Sedeo, and J. M. Pingarrn, Anal. Chim. Acta, 2002, 461, 65. S.

B. K. Neuhaus, J. A. Hurlbut, and W. Hammack, Lab. Inform. Bull., 2002, 4290.

A. Pfenning, S. Turnipseed, J. Roybal, C. Burns, M. Madson, J. Storey, and R. Lee, Laboratory Information Bulletin, 2002, 4284.

Impens, W. Reybroeck, J. Vercammen, D. Courtheyn, S. Ooghe, K. De Wasch, W. Smedts, and H. De Brabander, Anal. Chim. Acta,

2003, 483, 153.

P. Mottier, V. Parisod, E. Gremaud, P. A. Guy, and R. H. Stadler, J. Chromatogr., A, 2003, 994, 75.

M. Ramos, P. Muoz, A. Aranda, I. Rodriguez, R. Diaz, and J. Blanca, J. Chromatogr., B, 2003, 791, 31.

J. Storey, A. Pfenning, S. Turnipseed, G. Nandrea, R. Lee, C. Burns, and M. Madson, Lab. Inform. Bull., 2003, 4306.

P. A. Guya, D. Royerb, P. Mottiera, E. Gremauda, A. Perisseta, and R. H. Stadlerc, J. Chromatogr., A, 2004, 1054, 365.

D. A. Skoog, D. M. West, F. J. Holler, and S. R. Crouch,Fundamentals of Analytical Chemistry, 8th ed., 2004, Thomson

Learning, Belmont, 694.

H. Y. Shen and H. L. Jiang, Anal. Chim. Acta, 2005, 535, 33.

G. Scortichini, L. Annunziata, M. N. Haouet, F. Benedetti, I. Krusteva, and R. Galarini, Anal. Chim. Acta, 2005, 535, 43

P. Vias, N. Balsalobre, and M. Hernndez-Crdoba, Anal Chim. Acta, 2006, 558, 1

R. J. Shakila, S. A. Vyla, R. S. Kumar, G. Jeyasekaran, and G. I. Jasmine, Food Microbiology, 2006, 23, 47.

A. Preechaworapun, S. Chuanuwatanakul, Y. Einaga, K. Grudpan, S. Motomizu, and O. Chailapakul, Talanta, 2006, 68, 1726.

P. Ngamukot, T. Charoenraks, O. Chailapakul, S.Motomizu, and S. Chuanuwatanakul, Anal. Sci., 2006, 22, 111.

70

Вам также может понравиться

- Methods of Analysis For FluconazoleДокумент6 страницMethods of Analysis For FluconazoleJuan PerezОценок пока нет

- ClosantelДокумент6 страницClosantelLaOde AdinОценок пока нет

- Jurnal CiproloxacinДокумент5 страницJurnal Ciproloxacinfebriyanm98Оценок пока нет

- 86 PDFДокумент3 страницы86 PDFDian Raeza DitamiОценок пока нет

- Validated RP-HPLC Method For The Determination of Nelaribine in Bulk and Tablet Dosage FormДокумент10 страницValidated RP-HPLC Method For The Determination of Nelaribine in Bulk and Tablet Dosage FormEditor IJTSRDОценок пока нет

- Validarea Aspirinei Prin CromatografieДокумент11 страницValidarea Aspirinei Prin CromatografieStefaniaОценок пока нет

- Ampicilina Capsula HPLCДокумент10 страницAmpicilina Capsula HPLCcarbouОценок пока нет

- Validated Spectrophotometric Method For The Determination of Chloramphenicol in Pure and in Its Dosage FormДокумент6 страницValidated Spectrophotometric Method For The Determination of Chloramphenicol in Pure and in Its Dosage FormNin TiyasОценок пока нет

- 265-270 JPTCP+March+0016Документ6 страниц265-270 JPTCP+March+0016lifehaxus8426Оценок пока нет

- Cephalexine Spectro VisДокумент0 страницCephalexine Spectro VisVictor Purnama Agung FanggidaeОценок пока нет

- Pirol 2011Документ6 страницPirol 2011adolfo olmosОценок пока нет

- Validated RP-HPLC Method For Analysis of Aripiprazole in A FormulationДокумент6 страницValidated RP-HPLC Method For Analysis of Aripiprazole in A Formulationblashyrkh_79Оценок пока нет

- STABILITY INDICATING ASSAY METHOD DEVELOPMENT AND VALIDATION OF PREGABALIN IN PHARMACEUTICAL DOSAGE FORMS BY RP-HPLC P.Sneha, Prathima SrinivasДокумент10 страницSTABILITY INDICATING ASSAY METHOD DEVELOPMENT AND VALIDATION OF PREGABALIN IN PHARMACEUTICAL DOSAGE FORMS BY RP-HPLC P.Sneha, Prathima SrinivasiajpsОценок пока нет

- Research Journal of Pharmaceutical, Biological and Chemical SciencesДокумент11 страницResearch Journal of Pharmaceutical, Biological and Chemical Sciencesyuna yulianaОценок пока нет

- Analisa Jurnal Spektrofluorometri AnfiskimДокумент21 страницаAnalisa Jurnal Spektrofluorometri AnfiskimMulkyОценок пока нет

- Estimation of Nebivolol Hydro Chloride by Using RPДокумент5 страницEstimation of Nebivolol Hydro Chloride by Using RPkarthik613Оценок пока нет

- 97 FullДокумент4 страницы97 FullSerpentarius_05Оценок пока нет

- Development and Validation of HPLC Method For The Estimation of Lapatinib in Bulk Drugs and Pharmaceutical FormulationsДокумент8 страницDevelopment and Validation of HPLC Method For The Estimation of Lapatinib in Bulk Drugs and Pharmaceutical FormulationspalkybdОценок пока нет

- Simultaneous Estimation of Sulfamethoxazole and Pyrimethamine in Bulk and Combined Tablet Dosage FormДокумент10 страницSimultaneous Estimation of Sulfamethoxazole and Pyrimethamine in Bulk and Combined Tablet Dosage FormSaravanan RamОценок пока нет

- A Comparative Study For The Quantitative Determination of Paracetamol in Tablets Using UVДокумент7 страницA Comparative Study For The Quantitative Determination of Paracetamol in Tablets Using UVRizqita Atikah SОценок пока нет

- International Journal of Innovative Pharmaceutical ResearchДокумент8 страницInternational Journal of Innovative Pharmaceutical ResearchDavid GuzmanОценок пока нет

- Analytical Method Development and Validation of Caffeine in Tablet Dosage Form by Using UV-SpectrosДокумент5 страницAnalytical Method Development and Validation of Caffeine in Tablet Dosage Form by Using UV-SpectrosKrisna Raditya PОценок пока нет

- 821 826 PDFДокумент6 страниц821 826 PDFराजन पाण्डेयОценок пока нет

- A Validated RP-HPLC Method For The Determination of Celecoxib in Bulk and Pharmaceutical Dosage FormДокумент5 страницA Validated RP-HPLC Method For The Determination of Celecoxib in Bulk and Pharmaceutical Dosage FormOskar LazaroОценок пока нет

- 07 Chapter 3Документ52 страницы07 Chapter 3hieuОценок пока нет

- Analisa Jurnal Spektrofluorometri - AnfiskimДокумент13 страницAnalisa Jurnal Spektrofluorometri - AnfiskimWira Wahyudi NandayasaОценок пока нет

- Development of HPLC Method For The Determination of Zinc Carnosine in Bulk and Dosage FormsДокумент5 страницDevelopment of HPLC Method For The Determination of Zinc Carnosine in Bulk and Dosage FormsSouheila MniОценок пока нет

- Method Development and Validation For The Simultaneous Estimation of Azilsartan and Chlorthalidone by RP-HPLC in Pharmaceutical Dosage FormДокумент6 страницMethod Development and Validation For The Simultaneous Estimation of Azilsartan and Chlorthalidone by RP-HPLC in Pharmaceutical Dosage FormsadafОценок пока нет

- 26537-Article Text-147230-1-10-20190103 PDFДокумент4 страницы26537-Article Text-147230-1-10-20190103 PDFSoheil JafariОценок пока нет

- 26537-Article Text-147230-1-10-20190103 PDFДокумент4 страницы26537-Article Text-147230-1-10-20190103 PDFSoheil JafariОценок пока нет

- Jurnal UtamaДокумент4 страницыJurnal UtamaAmaluddinОценок пока нет

- Martins 2019Документ7 страницMartins 2019Hasna NoerОценок пока нет

- Procedure Jurnal AtenololДокумент3 страницыProcedure Jurnal AtenololNining KurniasihОценок пока нет

- Ambroxol DegradationsДокумент4 страницыAmbroxol DegradationsHector PirirОценок пока нет

- A New RP-HPLC Method Development and Validation of Orlistat in Bulk and Pharmaceutical Dosage FormsДокумент7 страницA New RP-HPLC Method Development and Validation of Orlistat in Bulk and Pharmaceutical Dosage FormsEduardo BarreraОценок пока нет

- 143 150 (Ajpr)Документ8 страниц143 150 (Ajpr)SandraОценок пока нет

- Templete Research PaperДокумент23 страницыTemplete Research Paperlalit4u78Оценок пока нет

- Determination of Enalapril Maleate From Tablets Using A New HPLC MethodДокумент6 страницDetermination of Enalapril Maleate From Tablets Using A New HPLC MethodAlinaDianaОценок пока нет

- PoloДокумент3 страницыPoloRaja AbhilashОценок пока нет

- Quantitative Analysis and Purity Evaluation of Medroxyprogesterone Acetate by HPLCДокумент12 страницQuantitative Analysis and Purity Evaluation of Medroxyprogesterone Acetate by HPLCLeonardo GiraldoОценок пока нет

- A C A D e M I C S C I e N C e SДокумент5 страницA C A D e M I C S C I e N C e SUmasankar KulandaiveluОценок пока нет

- 논문 - A stability-indicating HPLC method for the determination of glucosamine in pharmaceutical formulationsДокумент7 страниц논문 - A stability-indicating HPLC method for the determination of glucosamine in pharmaceutical formulationsjs_kim5781Оценок пока нет

- SdarticleДокумент9 страницSdarticleaveryОценок пока нет

- Development & Validation of HPLC Analytical Assay For Mefenamic Acid.Документ11 страницDevelopment & Validation of HPLC Analytical Assay For Mefenamic Acid.Anonymous SDUIPeqXОценок пока нет

- Simultaneous Determination of Aceclofenac, Paracetamol, and Chlorzoxazone by RP-HPLC in Pharmaceutical Dosage FormДокумент4 страницыSimultaneous Determination of Aceclofenac, Paracetamol, and Chlorzoxazone by RP-HPLC in Pharmaceutical Dosage FormMihaela GrigorescuОценок пока нет

- Development and Validation of A ReversedДокумент14 страницDevelopment and Validation of A ReversedKarina Guadarrama HernándezОценок пока нет

- Development and Validation of An RP-HPLC Method For Determination of Empagliflozin in Empagliflozin TabletДокумент8 страницDevelopment and Validation of An RP-HPLC Method For Determination of Empagliflozin in Empagliflozin TabletInternational Journal of Innovative Science and Research TechnologyОценок пока нет

- Development and Validation of Stability Indicating HPTLC Method For Estimation of Swertiamarin in Bulk and Dosage FormДокумент5 страницDevelopment and Validation of Stability Indicating HPTLC Method For Estimation of Swertiamarin in Bulk and Dosage Formshraddha5jОценок пока нет

- RP HPLC Method Development and Validation For The Estimation of Fenoverine in Bulk Drug and Dosage FormДокумент9 страницRP HPLC Method Development and Validation For The Estimation of Fenoverine in Bulk Drug and Dosage FormQuty Papa KannaОценок пока нет

- RP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormДокумент8 страницRP-HPLC Method Development and Validation of Alogliptin Bulk and Tablet Dosage FormBaru Chandrasekhar RaoОценок пока нет

- Xantan GumДокумент5 страницXantan Gumjulie_lindaОценок пока нет

- Spectrophotometric Determination of Isoxsuprine in Pure and Pharmaceutical FormsДокумент7 страницSpectrophotometric Determination of Isoxsuprine in Pure and Pharmaceutical FormsIOSRjournalОценок пока нет

- Analytical Method Development and Validation For Simultaneous Estimation of Lercandipine and Atenolol Tablet Dosage Form by RP-HPLCДокумент10 страницAnalytical Method Development and Validation For Simultaneous Estimation of Lercandipine and Atenolol Tablet Dosage Form by RP-HPLCSriram NagarajanОценок пока нет

- Jurnal NipaginДокумент6 страницJurnal NipaginNadya ViraОценок пока нет

- Chromsci bmt113 FullДокумент6 страницChromsci bmt113 FullEman ShawkyОценок пока нет

- 14 Ac18Документ12 страниц14 Ac18Cristian MeneguzziОценок пока нет

- 176 186 (Ijpsr)Документ11 страниц176 186 (Ijpsr)arunyaОценок пока нет

- Amoxicillin 1 PDFДокумент7 страницAmoxicillin 1 PDFLira Windriawati ListriyaniОценок пока нет

- Jurnal CTMДокумент10 страницJurnal CTMFahrul ComisterОценок пока нет

- Experimental approaches to Biopharmaceutics and PharmacokineticsОт EverandExperimental approaches to Biopharmaceutics and PharmacokineticsОценок пока нет

- Sulphasalazine Induced Toxic Epidermal Necrolysis A Case ReportДокумент3 страницыSulphasalazine Induced Toxic Epidermal Necrolysis A Case ReportIOSR Journal of PharmacyОценок пока нет

- A Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantДокумент5 страницA Case of Allergy and Food Sensitivity: The Nasunin, Natural Color of EggplantIOSR Journal of PharmacyОценок пока нет

- A Review On Step-by-Step Analytical Method ValidationДокумент13 страницA Review On Step-by-Step Analytical Method ValidationIOSR Journal of Pharmacy100% (1)

- A Review On Step-by-Step Analytical Method ValidationДокумент13 страницA Review On Step-by-Step Analytical Method ValidationIOSR Journal of Pharmacy100% (1)

- Treatment of Uthiravatha Suronitham (Rheumatoid Arthritis) With A Siddha Compound Formulation - A Case Study.Документ3 страницыTreatment of Uthiravatha Suronitham (Rheumatoid Arthritis) With A Siddha Compound Formulation - A Case Study.IOSR Journal of Pharmacy100% (1)

- Phytochemical Screening and Antioxidant Activity of Clove Mistletoe Leaf Extracts (Dendrophthoe Pentandra (L.) Miq)Документ6 страницPhytochemical Screening and Antioxidant Activity of Clove Mistletoe Leaf Extracts (Dendrophthoe Pentandra (L.) Miq)IOSR Journal of PharmacyОценок пока нет

- Summary of Infant Formula Test Results - Dr. SeidlerДокумент4 страницыSummary of Infant Formula Test Results - Dr. SeidlerStatesman Journal100% (1)

- Bio 101 Chapter 1 NotesДокумент3 страницыBio 101 Chapter 1 NotesAndrewОценок пока нет

- Driver Sony Vaio Vgn-cs320j Touch Sensor A - V ControlsДокумент20 страницDriver Sony Vaio Vgn-cs320j Touch Sensor A - V ControlsIvan YulyantoОценок пока нет

- Animal Biotechnology - The Advantages & Disadvantages of Animal BiotechnologyДокумент13 страницAnimal Biotechnology - The Advantages & Disadvantages of Animal Biotechnologysabatini89100% (3)

- Methods To Produce Marker-Free Transgenic Plants: ReviewДокумент8 страницMethods To Produce Marker-Free Transgenic Plants: ReviewVishwanath HebbiОценок пока нет

- Final SampleДокумент28 страницFinal SampleJoshua ArrojoОценок пока нет

- Informe Cnio 3013Документ248 страницInforme Cnio 3013espino1956Оценок пока нет

- Pseudomonas and Bacillus) As GreatДокумент3 страницыPseudomonas and Bacillus) As Greatichi senriОценок пока нет

- 1 Introduction To BiotechnologyДокумент2 страницы1 Introduction To BiotechnologyxОценок пока нет

- Soeiro/w8 RefinitiveДокумент213 страницSoeiro/w8 RefinitiveAntónio SoeiroОценок пока нет

- PCR Lab ProtocolДокумент5 страницPCR Lab Protocolhk8atema1lОценок пока нет

- Bacteria&Virus - 05-09-11Документ2 страницыBacteria&Virus - 05-09-11Jeevina Shirome RocheОценок пока нет

- Birla Institute of Technology: Mesra, Ranchi 835215, INDIAДокумент8 страницBirla Institute of Technology: Mesra, Ranchi 835215, INDIARichard DennisОценок пока нет

- Coursera BioinfoMethods-I Lab01 PDFДокумент22 страницыCoursera BioinfoMethods-I Lab01 PDFkalaharibОценок пока нет

- Bioprocessing & Microbial TechnologyДокумент14 страницBioprocessing & Microbial TechnologyKavisa GhoshОценок пока нет

- Fasta Sequence DatabaseДокумент17 страницFasta Sequence DatabaseKlevis XhyraОценок пока нет

- SAFC Biosciences - Technical Bulletin - EX-CELL™ NS0: An Animal-Component Free, Protein-Free, Chemically Defined Medium For Monoclonal Antibody ProductionДокумент4 страницыSAFC Biosciences - Technical Bulletin - EX-CELL™ NS0: An Animal-Component Free, Protein-Free, Chemically Defined Medium For Monoclonal Antibody ProductionSAFC-GlobalОценок пока нет

- Midi-And Mini-Primer Sets For Mtdna Control Region Sequence Analysis From Highly Degraded Forensic SamplesДокумент1 страницаMidi-And Mini-Primer Sets For Mtdna Control Region Sequence Analysis From Highly Degraded Forensic Samplesoday_ada76Оценок пока нет

- Bio MoleculeДокумент15 страницBio MoleculeManish GuptaОценок пока нет

- Module 2 - Genetic Engineering 1Документ20 страницModule 2 - Genetic Engineering 1Ash MiОценок пока нет

- Plasmid Cloning by Restriction Enzyme DigestДокумент3 страницыPlasmid Cloning by Restriction Enzyme DigestVempati Rahul KumarОценок пока нет

- PB News 235 May 12Документ92 страницыPB News 235 May 12Francisco FuentesОценок пока нет

- Edible VaccinesДокумент3 страницыEdible Vaccinesapi-263663768Оценок пока нет

- MannitolДокумент5 страницMannitolZinedin AzОценок пока нет

- Biochemistry Chapter 1Документ115 страницBiochemistry Chapter 1habteОценок пока нет

- Transgene: Transparent FrogДокумент3 страницыTransgene: Transparent Froggeobee emmanuelОценок пока нет

- Sales Bill Jan20Документ74 страницыSales Bill Jan20Mansoor TheenОценок пока нет

- Ethanol Fermentation Process PDFДокумент2 страницыEthanol Fermentation Process PDFTonyaОценок пока нет

- Agricultural Biotechnology SyllabusДокумент2 страницыAgricultural Biotechnology SyllabusKamlesh SahuОценок пока нет

- Extracción de Ácidos Nucleicos Viral (FavorGen)Документ2 страницыExtracción de Ácidos Nucleicos Viral (FavorGen)claudiareitterОценок пока нет