Академический Документы

Профессиональный Документы

Культура Документы

Health Safety Guide - Bitumen

Загружено:

braackwОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Health Safety Guide - Bitumen

Загружено:

braackwАвторское право:

Доступные форматы

For advice on which product to use to meet your specific job requirements, please contact us:

Web

www.roadsthatperform.com.au

E-mail

bpbitumenaustralia@bp.com

Technical Helpline 1800 24 88 66 (FREECALL)

National Office 55 Toll Drive, Altona North, VIC 3025

Telephone

(03) 8368 8700

Facsimile

(03) 8368 8701

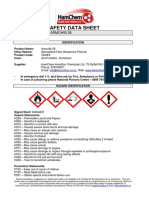

Health and safety. Safe Handling of Bitumen and Bitumen Products.

Always refer to product Material Safety Data Sheets for a full description of

hazards associated with the use of bitumen products.

Take care, stop and think about the task before handling hot bitumen products.

Hazards

Bitumen First Aid

Burns

Burns

Paving grade bitumens, including polymer modified

binders (PMB) are supplied and stored at very high

temperatures in the range 150C to 190C, making them

much hotter than boiling water. Bitumen burns may

cause severe damage to eyes and skin. Sadly, accidents

have resulted in workers requiring skin grafts. Burns

victims may also suffer from shock. Keep them warm

and rested. Do not give them food or fluids.

It is important that everyone working with hot bitumen

be familiar with the recommended first aid treatment of

bitumen burns. Notes for guidance of first aid and medical

personnel are provided in the form of a Bitumen Burns

Card available from the Australian Asphalt Pavement

Association.

Fumes

Hot bitumen products may give off irritating fumes

resulting in eye, nose and throat soreness. Bitumens may

also contain hydrogen sulphide (H2S) gas, also known

as rotten egg gas. H2S may accumulate in confined

spaces and reach hazardous levels. Exposure to H2S may

cause eye, nose and throat irritation, nausea, headaches

and, in extreme cases, may be fatal.

Cool the affected area with cold running water for as

long as possible, preferably until medical assistance is

obtained this is very important. Ensure that bitumen

splashed in difficult areas, such as the back of legs, is

also cooled with water. Body hypothermia must be avoided.

Do not attempt to remove bitumen adhering to the

skin as it forms a sterile protective layer.

Boil-Overs

Take immediately to hospital or medical centre with

the approved Bitumen Burns Card and advise medical

staff of the nature of the burn.

Violent boil-over of tanks can occur if water or bitumen

emulsion is present when loading hot bitumen products.

Fumes

Pyrophoric Deposits

Move person to fresh air and seek medical assistance if

respiratory irritation persists.

Deposits of complex chemicals may develop in bitumen

storage tanks and these may self-ignite when exposed to air.

Safety Precautions

Full skin protection is required to avoid accidental burns

when transferring or handling hot bitumen. Always wear

long-sleeved shirts or overalls that are buttoned up at the

wrist, long trousers (legs worn over boots, not tucked in),

gauntlet heat-resistant gloves, safety shoes, face shield

with clear visor, and balaclava or flaps to cover the head.

Check the contents of the previous load before loading

bitumen into tankers and follow procedures to avoid a boil-over.

Do not use steam to empty pipelines or hoses as this

will allow water to enter the system and may cause a

boil-over.

Avoid exposure to fumes which may be released on

the initial opening of the hatch on a road or rail tanker or

storage tank a vapour plume of hot bitumen fumes and

H2S may be released. Avoid exposure to these fumes by

standing back on the gantry or upwind until the vapours

have dispersed.

Minimise bitumen fume by heating bitumen and asphalt

products to the recommended temperatures do not

overheat them.

Minimise the use of diesel when cleaning equipment as

this contributes to the bitumen fume.

Bitumen Fire

Call the emergency services immediately dial 000 or

call the Fire Brigade.

Attempt to extinguish the fire using foam, dry chemical

powder, inert gas extinguishers or water sprays never

use water jets to fight the fire.

Switch off heaters and pumps and close valves if safe

to do so.

Bitumen Spills

Call the emergency services immediately dial 000 or

call the Fire Brigade.

Isolate the source by switching off pumps and closing

valves if safe to do so.

In the event of spillage of cutback bitumen or bitumen

emulsion, or when heavy rainfall occurs after spraying:

It is important to ensure that entry to waterways is

prevented dam the product if necessary to stop it

entering the waterway. Place a boom or barrier to stop

any contamination travelling downstream. Remove

bitumen residues that remain in the vegetation on the

sides of the waterway.

If there is any concern or query regarding the health

and safety aspects of SBS-based PMBs, please seek

advice and guidance.

Recommended Handling and Application Temperatures

for BP SBS-based PMBs:

Storage

Pumping

Mixing/

Sealing

Compaction

140C - 160C

Contact local authorities and/or emergency services.

Asphalt

185C maximum 160C minimum

Grades

155C - 175C

Check for any affected wildlife coated or otherwise

affected by the spilt bitumen products and contact the

EPA for assistance if necessary.

Sealing

185C maximum 150C - 170C

Grades

175C - 190C

Safe handling of SBS-modified

Polymer Modified Binders

Polymer modified binders incorporating SBS polymer require

close attention to their handling and application to avoid

degradation of the binder and exposure to irritant fumes.

Avoid fumes by:

Storing and handling products at the recommended

temperatures.

Not overheating products.

Minimising the use of diesel for cleaning tools and

equipment.

Excessive fumes may:

Irritate the eyes, nose and throat.

Cause nausea, headaches and a general feeling of

being unwell.

If a worker suffers from any of the above symptoms:

Report it to a supervisor immediately.

Seek medical advice.

Complete any necessary incident reports.

Important points to remember:

Know the product being handled.

Know the recommended storage and handling

temperatures.

SBS-based PMBs have their own unique odour

however they are safe to use when stored and handled

according to recommendations.

Material Safety Data Sheets

Further detailed information on the health and safety

aspects of BP Bitumen products is available in the product

Material Safety Data Sheets available on our website:

www.msds.bp.com.au

Recommended references:

Austroads

AP-G41/08 Austroads Bitumen Sealing Safety Guide

Australian Asphalt Pavement Association

HSE Guide Intro: Introduction to health and safety in the flexible

pavement industry,

HSE Guide 1: Guide to good practice in asphalt and bitumen laboratories

HSE Guide 6: Safe Working In Heat

HSE Guide 7: Updated guide to the safe use of bitumen transfer hoses

HSE Guide 8: Guide For Environmental Management When Spraying

Bituminous Materials

Advisory Note 7: Guide to the Selection, Heating and Storage of

Binders for Sprayed Sealing and Asphalt Manufacture

Advisory Note 10: Loading Hot Bitumen Products

Advisory Note 14: Summary of SBS Bitumen Fume Monitoring Project

For advice on which product to use to meet your specific job requirements,

please call the BP Bitumen technical helpline 1800 24 88 66 (freecall)

or contact the BP Bitumen Sales Manager in your region.

Eliminate nearby ignition sources.

Contain the product by using dirt or sandbags.

Make sure all drains are blocked to stop access to

waterways.

Allow the spilt bitumen to cool before scraping it up.

Appropriately dispose of spilt bitumen to an approved

landfill site.

The health and safety and environmental information provided in this document may not be appropriate for all individuals and/or situations. It is the users obligation to evaluate and use products safely and to comply

with all applicable laws and regulations The BP Group of Companies will not be responsible for any damage or injury resulting from any information contained in this document or from any abnormal use of the

material, from any failure to adhere to product recommendations or from any hazards inherent in the nature of the material. 2011 BP Australia Pty Ltd ABN 53 004 085 616, 717 Bourke Street, Melbourne, Victoria.

JANUARY 2014

Вам также может понравиться

- SHIPPING TERMSДокумент1 страницаSHIPPING TERMSGung Mayura100% (1)

- Infineum D3426 MSDSДокумент9 страницInfineum D3426 MSDSahmetОценок пока нет

- SQL-Problems Solutions PDFДокумент11 страницSQL-Problems Solutions PDFManpreet Singh100% (1)

- CP 601S CP 601S: Elastomeric Firestop SealantДокумент4 страницыCP 601S CP 601S: Elastomeric Firestop Sealantrichard_qrОценок пока нет

- Ultimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsОт EverandUltimate Guide to Home Repair and Improvement, Updated Edition: Proven Money-Saving Projects; 3,400 Photos & IllustrationsРейтинг: 3 из 5 звезд3/5 (8)

- Pipe Jack Design GuideДокумент81 страницаPipe Jack Design GuidebraackwОценок пока нет

- FC Bayern Munich Marketing PlanДокумент12 страницFC Bayern Munich Marketing PlanMateo Herrera VanegasОценок пока нет

- Fall Protection ANSIДокумент5 страницFall Protection ANSIsejudavisОценок пока нет

- Nynas K1-60 GB EN SDSДокумент6 страницNynas K1-60 GB EN SDSNakkolopОценок пока нет

- Bitumen MSDSДокумент7 страницBitumen MSDSsonn1729Оценок пока нет

- RBA Training Bitumen HSE 20may2003Документ33 страницыRBA Training Bitumen HSE 20may2003Pedro ValverdeОценок пока нет

- OLIN - Curing Agent Easy-Fit AДокумент9 страницOLIN - Curing Agent Easy-Fit ABoyet BaldeОценок пока нет

- ASPHALT CUTBACK MC30, 70, 250, 500, 800, 3000: Safety Data SheetДокумент11 страницASPHALT CUTBACK MC30, 70, 250, 500, 800, 3000: Safety Data SheetTk SubhashОценок пока нет

- Vigon SDS US EnglishДокумент14 страницVigon SDS US EnglishFahad MaqsoodОценок пока нет

- Bitumen Ref 4360 BP Bitumen Class 600Документ7 страницBitumen Ref 4360 BP Bitumen Class 600Goran StamenkovicОценок пока нет

- RS Potting Compound Safety Data Sheets PDFДокумент25 страницRS Potting Compound Safety Data Sheets PDFAchira Chanaka PeirisОценок пока нет

- R1802-1 System DescriptionДокумент3 страницыR1802-1 System DescriptionJun DeeОценок пока нет

- Sds Paint Marker Sl.250 PmucДокумент5 страницSds Paint Marker Sl.250 Pmucfakename4bugmenotОценок пока нет

- PM-700 Polyisocyanate ProductДокумент4 страницыPM-700 Polyisocyanate ProductAmr RagabОценок пока нет

- MSDS Summary: Quartz 5000 SN 15W-50 Motor OilДокумент6 страницMSDS Summary: Quartz 5000 SN 15W-50 Motor OilAlkinson CecilОценок пока нет

- Armohib 28 Safety Data SheetДокумент6 страницArmohib 28 Safety Data SheetnbagarОценок пока нет

- Msds Sigma Phenguard 930 (Sigma Phenguard Primer) BaseДокумент7 страницMsds Sigma Phenguard 930 (Sigma Phenguard Primer) BasekumarОценок пока нет

- Msds Sigma Vikote 56 (Sigma Topacryl Finish) (Chrome)Документ8 страницMsds Sigma Vikote 56 (Sigma Topacryl Finish) (Chrome)kumarОценок пока нет

- Msds Sigma Alphagen 20 SeriesДокумент8 страницMsds Sigma Alphagen 20 SerieskumarОценок пока нет

- Msds Sigma Phenguard 930-935-940 (Sigma Phenguard) HardenerДокумент8 страницMsds Sigma Phenguard 930-935-940 (Sigma Phenguard) HardenerkumarОценок пока нет

- Gasoline 95 Ron 97 RonДокумент7 страницGasoline 95 Ron 97 RonGeal Geol PentolОценок пока нет

- Msds Sigms Alphagen 650Документ8 страницMsds Sigms Alphagen 650kumarОценок пока нет

- Msds Sigma Phenguard 935 (Sigma Phenguard Coating) BaseДокумент7 страницMsds Sigma Phenguard 935 (Sigma Phenguard Coating) BasekumarОценок пока нет

- Propane Safety Data SheetДокумент8 страницPropane Safety Data SheetRon PrattОценок пока нет

- Safety Data Sheet for Sigma Vikote 15 PrimerДокумент8 страницSafety Data Sheet for Sigma Vikote 15 PrimerkumarОценок пока нет

- Material Safety Data Sheet: Section 1: Product IdentificationДокумент7 страницMaterial Safety Data Sheet: Section 1: Product Identificationcvolkan1Оценок пока нет

- International Paint Safety Data SheetДокумент9 страницInternational Paint Safety Data Sheetpanagiotis_panagio_2Оценок пока нет

- Nitric Acid 0 2n (n5) 24-9824 v2 1 1 1 23-Jul-2010 Us-English-local On Apr-29-2013Документ9 страницNitric Acid 0 2n (n5) 24-9824 v2 1 1 1 23-Jul-2010 Us-English-local On Apr-29-2013LucioMerloОценок пока нет

- Msds Sigma Vikote 14 (Sigmarine Alu Primer)Документ7 страницMsds Sigma Vikote 14 (Sigmarine Alu Primer)kumarОценок пока нет

- Msds Sigma Ecofleet 530 (Ecol Ha)Документ8 страницMsds Sigma Ecofleet 530 (Ecol Ha)kumarОценок пока нет

- Hfo Msds ShellДокумент9 страницHfo Msds ShellLiam MoylanОценок пока нет

- Msds Sigmacover 435 (Sigma CM Miocoat-Sigmacover CM Miocoat) Base Ral 6009 (Lead Containing) (EngДокумент9 страницMsds Sigmacover 435 (Sigma CM Miocoat-Sigmacover CM Miocoat) Base Ral 6009 (Lead Containing) (EngLes D ChavezОценок пока нет

- Msds Sigma Alphagen 50 SeriesДокумент8 страницMsds Sigma Alphagen 50 SerieskumarОценок пока нет

- MIRR ALMA SUPER API SL SAE 15W-40 Safety Data SheetДокумент8 страницMIRR ALMA SUPER API SL SAE 15W-40 Safety Data SheetAbdul GhafoorОценок пока нет

- Safety Data Sheet Paint Master Bituminous Aluminium: June 2011Документ3 страницыSafety Data Sheet Paint Master Bituminous Aluminium: June 2011Michael JoudalОценок пока нет

- Termiticide & Insecticide: CautionДокумент2 страницыTermiticide & Insecticide: CautionAli AliОценок пока нет

- MSDSДокумент5 страницMSDSShashiraj ShettigarОценок пока нет

- Advance Plus Combi - User ManualДокумент84 страницыAdvance Plus Combi - User ManualAllyson JohnsonОценок пока нет

- Golden Power Sae 20W-50 T SDSДокумент8 страницGolden Power Sae 20W-50 T SDSAbdul GhafoorОценок пока нет

- Safety Data Sheet: Azolla Zs 100Документ6 страницSafety Data Sheet: Azolla Zs 100AndiniPermanaОценок пока нет

- BP Turbo Oil 2380 MSDSДокумент6 страницBP Turbo Oil 2380 MSDSSkySupplyUSAОценок пока нет

- Lackpoxi N 1277 SdsДокумент7 страницLackpoxi N 1277 Sdsant29539432Оценок пока нет

- Regulation (EC) No. 1907/2006 (REACH) safety data sheetДокумент7 страницRegulation (EC) No. 1907/2006 (REACH) safety data sheetYekitaSОценок пока нет

- Asphalt Cutback Mc30, 70, 250, 500, 800, 3000 - Gibson Energy LimitedДокумент11 страницAsphalt Cutback Mc30, 70, 250, 500, 800, 3000 - Gibson Energy LimitedErick AbarientosОценок пока нет

- ACETIC ACID GLACIAL MSDSДокумент5 страницACETIC ACID GLACIAL MSDSWaqas RamayОценок пока нет

- Equation ProДокумент8 страницEquation ProproconstructОценок пока нет

- Farm Workshop Booklet WebДокумент28 страницFarm Workshop Booklet WebJoel ChifunaОценок пока нет

- SDS 54/56Документ4 страницыSDS 54/56perret.yap.weilunОценок пока нет

- Flogas Safety Data Sheet - Liquefied Butane GasДокумент10 страницFlogas Safety Data Sheet - Liquefied Butane GasMohammed NuseirОценок пока нет

- Potassium HydroxideДокумент10 страницPotassium HydroxideSyahrul MtiОценок пока нет

- Golden Power 5000 API SL Sae 20w-50 SdsДокумент8 страницGolden Power 5000 API SL Sae 20w-50 SdsAbdul GhafoorОценок пока нет

- Stepan Pol Ps 2352Документ2 страницыStepan Pol Ps 2352A MahmoodОценок пока нет

- Mirr Turbo Supreme Plus Api CK-4 Sae 10W40 SDSДокумент8 страницMirr Turbo Supreme Plus Api CK-4 Sae 10W40 SDSAbdul GhafoorОценок пока нет

- MSDS PetrolДокумент6 страницMSDS PetrolridgellОценок пока нет

- MSDS Summary for CELCON LW90-F2 CD3068SP20Документ6 страницMSDS Summary for CELCON LW90-F2 CD3068SP20alkanderОценок пока нет

- Material Safety Data Sheet: 1. Indentification OF Material & Company Details Product Name: T180 EPOXY THINNERДокумент5 страницMaterial Safety Data Sheet: 1. Indentification OF Material & Company Details Product Name: T180 EPOXY THINNERLê TiếnОценок пока нет

- Original MSDS SolidifierДокумент6 страницOriginal MSDS SolidifierSaad IqbalОценок пока нет

- Safety Data Sheet: Identification of The Substance/Preparation and of The Company/Undertaking 1Документ7 страницSafety Data Sheet: Identification of The Substance/Preparation and of The Company/Undertaking 1Bao Duy NguyenОценок пока нет

- Safety Data Sheet: Section 1 - Product and Company IdentificationДокумент10 страницSafety Data Sheet: Section 1 - Product and Company IdentificationAndhie OsloОценок пока нет

- After a Disaster: Information to Help You and Your Family RecoverОт EverandAfter a Disaster: Information to Help You and Your Family RecoverОценок пока нет

- Concrete Pipe Jacking TB7 - 05Документ6 страницConcrete Pipe Jacking TB7 - 05kiwiscardОценок пока нет

- CRCP Performance and Best PracicesДокумент12 страницCRCP Performance and Best PracicesbraackwОценок пока нет

- Theoretical Maximum Spesific Gravity of Bituminous MixesДокумент22 страницыTheoretical Maximum Spesific Gravity of Bituminous MixesbraackwОценок пока нет

- RMS - Pavement Standard Drawings - Steel Fibre RCPДокумент5 страницRMS - Pavement Standard Drawings - Steel Fibre RCPbraackwОценок пока нет

- 4640 B Quick RefДокумент2 страницы4640 B Quick RefbraackwОценок пока нет

- Optimized for CRCP Construction Standard DrawingsДокумент17 страницOptimized for CRCP Construction Standard DrawingsbraackwОценок пока нет

- RMS - Pavement Standard Drawings - Bicycle Path DesignДокумент3 страницыRMS - Pavement Standard Drawings - Bicycle Path DesignbraackwОценок пока нет

- Worktips 51 - Asphalt Tack CoatingДокумент2 страницыWorktips 51 - Asphalt Tack CoatingbraackwОценок пока нет

- Design Standards For Urban Infrastructure - StormwaterДокумент130 страницDesign Standards For Urban Infrastructure - StormwaterbraackwОценок пока нет

- Marshall Mix Design ProcedureДокумент31 страницаMarshall Mix Design Procedurebraackw100% (2)

- Stormwater Management Manual For Western AustraliaДокумент755 страницStormwater Management Manual For Western AustraliabraackwОценок пока нет

- Marshall Teoria y Ejercicios PDFДокумент30 страницMarshall Teoria y Ejercicios PDFYuliana Meriño TОценок пока нет

- VMAДокумент131 страницаVMAbraackwОценок пока нет

- Design Standards For Urban Infrastructure - StormwaterДокумент130 страницDesign Standards For Urban Infrastructure - StormwaterbraackwОценок пока нет

- Conventional AC DesignДокумент42 страницыConventional AC Designabdikarim_omarОценок пока нет

- Designing rural water systems with air in pipesДокумент60 страницDesigning rural water systems with air in pipeselcivilengОценок пока нет

- Troxler Model 3440 Nuclear Moisture Density Gauge FeaturesДокумент4 страницыTroxler Model 3440 Nuclear Moisture Density Gauge FeaturesbraackwОценок пока нет

- Design of Side Weirs2Документ132 страницыDesign of Side Weirs2braackwОценок пока нет

- Design of Side WeirsДокумент9 страницDesign of Side WeirsbraackwОценок пока нет

- UBI1Документ66 страницUBI1Rudra SinghОценок пока нет

- cp2021 Inf03p02Документ242 страницыcp2021 Inf03p02bahbaguruОценок пока нет

- Industry Life Cycle-Plant Based CaseДокумент3 страницыIndustry Life Cycle-Plant Based CaseRachelle BrownОценок пока нет

- Spain Price List With VatДокумент3 страницыSpain Price List With Vatsanti647Оценок пока нет

- Rejoinder To Adom Ochere's Misrepresentation - FinalДокумент3 страницыRejoinder To Adom Ochere's Misrepresentation - FinalFuaad DodooОценок пока нет

- 20220720-MODIG-Supply Chain Manager (ENG)Документ2 страницы20220720-MODIG-Supply Chain Manager (ENG)abhilОценок пока нет

- ITIL - Release and Deployment Roles and Resps PDFДокумент3 страницыITIL - Release and Deployment Roles and Resps PDFAju N G100% (1)

- JWCh06 PDFДокумент23 страницыJWCh06 PDF007featherОценок пока нет

- JRC Wind Energy Status Report 2016 EditionДокумент62 страницыJRC Wind Energy Status Report 2016 EditionByambaa BattulgaОценок пока нет

- Synopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaДокумент5 страницSynopsis: A Study On Customer Satisfaction AT Nerolac Paints LTD., KadapaAnu GraphicsОценок пока нет

- 16 BPI V FernandezДокумент1 страница16 BPI V FernandezAngelica Joyce BelenОценок пока нет

- Final Project Report: Uop, LLCДокумент165 страницFinal Project Report: Uop, LLCSiddharth KishanОценок пока нет

- Mesa de Trabajo 1Документ1 страницаMesa de Trabajo 1iamtheonionboiОценок пока нет

- (EMERSON) Loop CheckingДокумент29 страниц(EMERSON) Loop CheckingDavid Chagas80% (5)

- Examination: Subject CT5 - Contingencies Core TechnicalДокумент7 страницExamination: Subject CT5 - Contingencies Core TechnicalMadonnaОценок пока нет

- Coa - Ofx-8040a (H078K5G018)Документ2 страницыCoa - Ofx-8040a (H078K5G018)Jaleel AhmedОценок пока нет

- Research Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormДокумент13 страницResearch Grants Final/Terminal/Exit Progress Report: Instructions and Reporting FormBikaZee100% (1)

- WPB Pitch DeckДокумент20 страницWPB Pitch Deckapi-102659575Оценок пока нет

- Central BankДокумент65 страницCentral BankFarazNaseer100% (1)

- AutocadДокумент8 страницAutocadbrodyОценок пока нет

- Triblender Wet Savoury F3218Документ32 страницыTriblender Wet Savoury F3218danielagomezga_45545100% (1)

- SABIC Ethanolamines RDS Global enДокумент10 страницSABIC Ethanolamines RDS Global enmohamedmaher4ever2Оценок пока нет

- Amos Code SystemДокумент17 страницAmos Code SystemViktor KarlashevychОценок пока нет

- Laporan Mutasi Inventory GlobalДокумент61 страницаLaporan Mutasi Inventory GlobalEustas D PickОценок пока нет

- A. Readings/ Discussions Health and Safety Procedures in Wellness MassageДокумент5 страницA. Readings/ Discussions Health and Safety Procedures in Wellness MassageGrace CaluzaОценок пока нет

- MMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDДокумент6 страницMMDS Indoor/Outdoor Transmitter Manual: Chengdu Tengyue Electronics Co., LTDHenry Jose OlavarrietaОценок пока нет