Академический Документы

Профессиональный Документы

Культура Документы

1.1. - Conga Capex Final Reconciliation - Stage 2-3.RevC

Загружено:

visnupadaИсходное описание:

Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1.1. - Conga Capex Final Reconciliation - Stage 2-3.RevC

Загружено:

visnupadaАвторское право:

Доступные форматы

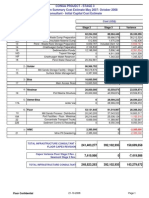

CONGA PROJECT - STAGE 3

Reconciliation Summary Cost Estimate May 2007 - October 2008

All Project Scope - Initial & Sustaining Capital Cost Estimate

Project N A3CO

Cost Analysis (US$)

Cost Estimate Review 2008: Rev. C / Cost Estimate Baseline 2007: Newmont Revision

May 2007 CAPEX

(Newmont Rev)

2008 CAPEX - Stage 3

(Fluor Rev. C)

2008 - 2007

Total Cost - Stage 2

Total Cost - Stage 3

Variance

Last change: 18-Oct-2008

Observations of Escalation, Scope Changes +/- Estimated

INITIAL CAPITAL COSTS

Direct Cost

Mining

Mining Equipment

85,172,700

271,887,297

Pre-Strip Development

15,400,000

53,601,716

Dispatch & Magazine

2,124,424

17,053,003

Mine Inpit Power

Capex Variance Fluor Stage 2

Rev (Feb 2007) - Newmont Stage

2 Rev (May 2007)

Total Mine

1,400,000

1,764,866

11,782,645

115,879,769

344,306,882

2006 Amec Study considered 30 units of mine equipment. The 2008 study consider 78 equipment items.

Revise Mine Plan in 2008

186,714,597 Haul truck unit price increased by US$MM 2.78 to 4.81. market condition and escalation factors.

2008 Capex included spare and tools for mining equipments.

One pit stage 2 versus open two pits simultaneous on stage 3.

2006 Bog Removal was estimated in Golder Scope. Unit prices and quantities increases for pre/stripping and haul

38,201,716

roads.

14,928,579

Steaming & emulsion plant add to 2008 scope.

2007 scope for explosive & nitrate storage was platform only with out buildings. Bigger platforms for Stage 3 design.

364,866 Same scope: mining power and mobile substations.

-11,782,645 Undocumented changes from Feb 2007 to May 2007.

228,427,113

Concentrator Plant & Mine Facilities

1

Civil and Earthworks

34,515,388

56,341,590

In-Plant Roads

17,527,516

26,865,214

Concrete

28,449,729

70,450,160

Structural Steel

18,879,158

42,070,160

Architectural

56,776,228

51,258,761

Mechanical

214,981,899

339,375,031

Piping

40,382,096

50,135,717

Electrical

65,430,102

84,317,308

Instrumentation

13,027,521

20,363,681

2,514,073

9A

Z

Insulation & Painting

Capex Variance Baseline Feb

2007 to Apr 2007

Total Concentrator Plant

Mto Qty: 2007: 5,791,000 m3 / 2008: 4,888,000 m3 (cut and fill).

Unit Price: 2007: 5.96 US$/m3 (3% rock excavation) / 2008: 10.96 US$/m3 (35% rock excavation & 5 Km haul

21,826,202

borrow material area due to revised lay out).

Different location for the Process Plant in Stage 3.

Mto Qty: 2007: 3,580,000 m3 (14 Roads) / 2008: 2,096,000 m3 (22 Roads).

9,337,698 Unit Price: 2007: 4.89 US$/m3 (3.5% rock excavation) / 2008: 11.68 US$/m3 (38% rock excavation & 5 Km haul

borrow material area due to revised lay out).

Mto Qty: 2007: 45,419 m3 / 2008: 95,085 m3.

Obs: 2007 non-process building were estimated by m2. Not concrete quantities for these buildings. Additional scope

42,000,431

due to plant capacity increased from 85,000 to 92,000. Major equipment size increased.

Unit Price: 2007: 626.3 US$/m3 / 2008: 740.9 US$/m3 (rebar and concrete price increase).

Mto Qty: 2007: 4,800 Ton / 2008: 9,036 Ton.

Obs: 2007 non-process building were estimated by m2. Not structural steel quantities for these buildings were

23,191,002 considered. Additional scope due to plant capacity increased from 85,000 to 92,000. Major equipment size

increased.

Unit Price: 2007: 3,933 US$/Ton / 2008: 4,655 US$/Ton (steel price increase).

Mto Qty: 2007: 46,700 m2 / 2008: 47,900 m2.

Obs: 2007 truck shop and other mine facilities were estimated by m2. Concrete and steel prices were included in

-5,517,467 these account for May 2007. Non process building significally increased in Stage 3 (the Stage 2 included truck shop

and mine facilities). A building list reconciliation will be developed .

Unit Price: 2007: 1,215 US$/m2 / 2008: 1,070 US$/m2.

Great increase in equipment prices (quotation). Some prices increased due to equipment specification & capacity

124,393,132

changes. Ref. equipment list reconciliation.

Mto Qty: 2007: 128,700 m / 2008: 85,900 m. Additional water pipe for Flotation circuit. Piping in concentrator area

9,753,621 changed, due to revised lay out.

Unit Price: 2007: 313.7 US$/m / 2008: 583.6 US$/m (increase price of steel)

Mto Qty: 2007: 223,000 m / 2008: 498,000 m (Includes lighting, power & control cable to junction boxes). Verify if

total qty of control cable was included in Stage 2 estimate and separate power & control cables for Stage 3

18,887,206 estimate. Also verify the power increase from 80 MW to 140 MW.

Obs: Variance explanation: US$MM 10 equipment escalation, US$MM 5 additional elec. equipment and US$MM

4 additional quantities of cable.

Mto Qty: 2007: 1,300 ea / 2008: 960 ea (instruments). May 2007 quantities included 242 pull cords, rip switches

and becon and horns.

7,336,160

Obs: mayor equipment increased its quotation. Previous study did not included mine slope detection system and

early storm detection system.

No insulation is included in the scope. Painting is considered in field fabricated tanks, structural steel and piping

-2,514,073

accounts.

-39,830,620

452,653,090

741,177,622

288,524,532

39,830,620 Undocumented changes from Feb 2007 to May 2007.

20,243,205

37,043,522

16,800,317

Mill Sands/Dumps/Port - Consultant

10

Mill Sands Process / Distribution

11

Mill Sands Storage Facility / Stage

1

14

Perol Waste Dump Preparation &

Bog Removal

Mine Unsuitable Material Dump

Perol - Waste Rock Storage

Preparation

Chailhuagon Dump Preparation

15

Surface Water Management

16

Sedimentation Ponds

16D

12

12A

13

80,578,876

100,332,108

20,474,050

58,686,579

512,800

1,675,236

6,659,787

Included (Item 12)

Thickening mechanism, structural and civil price increased due to escalation.

One more thickener was added in stage 3.

Dams Fill Placement (Initial)

Qty: 2007: 3,970,000 m3 / 2008: 4,878,000 m3.

19,753,232 Unit Price: 2006: 11.99 US$/m3 / 2008: 11.86 US$/m3.

Obs: The 2007 study was a conceptual design, in the 2008 study the Earthwork embankment volume increase due

to better geotechnical interpretation, also the unit pricing for the liners was under estimated in May 2007 study.

Dump foundation redesign including membrane liner over karst, contouring to support lining requirements and

complete under drain system.

1,162,436 Scope change occasioned by change in the Bog disposal methodology.

38,212,529

-6,659,787 2008 cost now included in Perol waste dump preparation (see Item 12 and 12A).

2,106,832

3,538,301

17,691,006

33,364,320

894,900

3,806,146

Topsoil Storage

4,911,508

1,431,469 Design criteria change for Chailhuagon Dump resulting in increased quantities in base preparation.

Water management changed from a concept to a design and included additional diversion channels in interim

locations.

Under estimated the size and complexity of the required dams. Chailhuagon sediment control was necessitated by

2,911,246

the addition of Chailhuagon reservoir in the stage 3 study

4,911,508 Stage 2 cost estimate did not include topsoil storage.

16F

Chailhuagon Water Reservoir

1,343,323

1,343,323

17

17A

18

Main Access Road

Anillo Vial

Perol Water Reservoir

16,665,500

0

20,302,881

16,152,967

28,589,233

14,623,353

-512,533 Similar access road for both studies.

28,589,233 Stage 2 did not consider this ring road as part of the study scope.

-5,679,528 Reservoir capacity reduced from 2008 this is now a small dam at reduced cost.

19

Port Marine Structure

20,000,000

43,559,874

23,559,874 The stage 2 study was a conceptual ROM estimate and did not include dredging costs of approx 30.0 million dollars.

Port Facilities - Fluor / Westmar

26,219,440

25,036,124

-1,183,316

Concentrate Transport Trucks

6,669,000

11,389,997

Mine Pit Dewatering - WMC

Sediment Control & Reseeding

Capex Variance Fluor Stage 2

Rev (Feb 2007) - Newmont Stage

2 Rev (May 2007)

Total Infrastructure

2,385,000

0

0

8,050,344

7,419,986

248,823,263

392,102,935

143,279,672

817,356,122

1,477,587,439

660,231,317

19A

22

21

22B

Z

TOTAL DIRECT COST

Fluor Confidential

15,673,314

Stage 2 cost estimate did not include Chailhuagon water reservoir. Addition information gather from the community

after the stage 2 study identified social needs for a reservoir and sediment control structures a Chailhuagon.

The scope of the Port facilities are similar for both studies. The 2008 estimate for shore facilities are likely

understated a trend is being initiated to re evaluate the port facilities scope and estimates.

The truck fleet increased in quantity by 39,under estimated in stage 2, the current fleet has been increased to 71

4,720,997

trucks. In addition the 2008 estimate includes service facilities for drivers.

-2,385,000 No Initial capital cost is reported in this line item. All costs are reported as sustaining capital.

8,050,344 Sediment control & reseeding were not considered on Stage 2.

-7,419,986 Undocumented changes from Feb 2007 to May 2007.

27-10-2008

Page 1

CONGA PROJECT - STAGE 3

Reconciliation Summary Cost Estimate May 2007 - October 2008

All Project Scope - Initial & Sustaining Capital Cost Estimate

Project N A3CO

Cost Analysis (US$)

Cost Estimate Review 2008: Rev. C / Cost Estimate Baseline 2007: Newmont Revision

May 2007 CAPEX

(Newmont Rev)

2008 CAPEX - Stage 3

(Fluor Rev. C)

2008 - 2007

Total Cost - Stage 2

Total Cost - Stage 3

Variance

Last change: 18-Oct-2008

Observations of Escalation, Scope Changes +/- Estimated

Indirect, Owner, Escalation & Contingency Cost

Indirect Cost

27

EP Services

34,527,379

152,411,444

27A

CM Services

79,784,300

92,752,769

27B

CM Gross Up

Original estimate (Stage 2) significantly under stated. Stage 3 estimate includes two bridge periods (4 months

117,884,065 Stage 3/4 and 7 months Stage 4/5). Longer engineering schedule from (15 to 24 months for the Optimized

schedule). May 2007 cost was factored compare to detailed calculation Sept. 2008.

Man-Hours for both studies are similar (1,295,000 aprox) but US$/MH is higher on Stage 3. Original estimate (Stage

12,968,469

2) significantly under stated. May 2007 cost was factored compare to detailed calculation Sept. 2008.

12,996,506 Cost not considered on Stage 2 study. Original estimate (Stage 2) significantly under stated.

Part of Third Party Construction Facilities were moved to this account. Original estimate (Stage 2) significantly

52,285,155

under stated.

Requirement: 2007: 23,600 m2; 3,600 p. cap. / 2008: 40,686 m2; 5,936 p. cap.

28,885,539 Unit Price: 2007: 936 US$/m2 / 2008: 1,270 US$/m2.

Obs: Direct man-hours increased from 10,860,000 to 18,800,000.

27,868,106 Increased direct and indirect total hours.

-6,577,133 Less foreign materials and equipment considered in this study.

Duties in Stage 2 Study were calculated at 12%. Now for Stage 3 study duties are 19% for all CIF imported good

104,945,890

from other country. Original estimate calculation (Stage 2) significantly under stated.

12,996,506

23

Temporary Facilities

25,854,620

78,139,775

23A

Construction Camp

23,137,693

52,023,232

25

26.0

Catering

Freight

35,107,101

60,757,403

62,975,207

54,180,270

26.1

Duties

5,299,117

110,245,007

26A

Third Party Construction Facilities

14,790,504

2,105,756

27A

Capital Spare Parts

11,368,417

35,567,488

0

16,869,591

37,404,993

5,273,656

10,239,579

19,379,020

5,125,872

5,125,872 Stage 2 not considered this cost.

4,000,000

6,855,759

2,855,759 Stage 2 was an allowance. Stage 3 was calculated in detail using staffing plan and ramp up duration was added.

33,274,759

0

33,150,000

6,998,151

-7,603,071

347,407,392

767,584,905

420,177,513

188,032,122

563,463,321

375,431,199

-8,306,016

268,798,970

429,221,465

56,172,713

361,900,000

337,036,278

53,367,444

630,698,970

875,797,900

245,098,930

1,157,832,468

2,206,846,126

1,049,013,658

552,665,033

552,665,033

0

0

0

0

0

-72,000,000

0

0

-72,000,000

-72,000,000

-72,000,000

CAPITALIZED INTEREST & PREPROD.

480,665,033

480,665,033

TOTAL INITIAL CAPITAL

COST

1,975,188,590

4,165,098,598

2,189,910,008

15,649,000

13,199,700

130,469,960

224,070,083

1,500,000

2,000,000

61,500,790

0

Increase in the mine fleet based on the revised mine plan, plus price increases for equipments due to escalation

(2007 to 2008).

60,000,790 Pre Stripping and Haul road Sustaining capital and maintenance costs. Mark Jordan

-2,000,000 Stage 3: no deferred items considered for that inpit power. This is included in item D of initial capital cost.

12,914,288

12,914,288 New pipeline for future tailing displacement (steel and hdpe).

19,979,362

43,005,635

23,026,273 Change is related to the haulage of the drainage blanket. Mark Jordan

4,195,941

8,888,971

159,262,542

132,872,138

0

0

29,475,492

48,361,808

8,094,444

32,793,045

0

55,723,149

4,693,030 Scope change. Mark Jordan

Tailings dam and tailings storage facility increase in capacity added labor and material costs. A

comparison of cost must consider the sum of items 10 and 11 from initial capital with this line item to

-26,390,404 determine the variance over the total life of mine.

Qty: 2007: 9,934,000 m3 / 2008: 3,743,000 m3.

Unit Price: 2007: 13.58 US$/m3 / 2008: 12.45.86 US$/m3.

8,094,444 More topsoil storage this study. Mark Jordan

32,793,045 This item was included in the Mine Equipment initial capital cost. Mark Jordan Double dip to initial Spares

-29,475,492 Cost not considered in stage 3. this may be a double dip.

7,361,341

33,646,000

19,892,390

-13,753,610 Considered light vehicle fleet in Stage 2 study.

-213,687,873

TOTAL SUSTAINING

CAPITAL COST

230,852,232

612,954,633

382,102,401

TOTAL PROJECT COST

2,206,040,822

4,778,053,231

2,572,012,409

27A.1 Spare & Tool - Mine Equipment

27C Initial Fill

27B

27D

26B

27E

34

Z

Vendor Representative

Insurance, Bonds, Permits &

Licenses

Pre-Commissioning,

Commissioning, Ramp Up &

Operation Manual

Consultants Indirect

Training Cost

Capex Variance Fluor Stage 2

Rev (Feb 2007) - Newmont Stage

2 Rev (May 2007)

Total Indirect Cost

Owner Cost

28

Owners Cost

Capex Variance Fluor Stage 2

Z

Rev (Feb 2007) - Newmont Stage

2 Rev (May 2007)

-12,684,748 Most of third party construction facilities were moved to temporary facilities.

Increase in the value of mechanical and electrical equipment. Original estimate calculation (Stage 2) significantly

under stated.

37,404,993 Stage 2: considered in mine equipment cost.

-11,595,935 Liners for Sag mill, Ball mills and Verti Mills transfer to operating cost in Stage 3.

Increase the value of mechanical and electrical equipment. Added Vendor Reps. Cost for wet commissioning, Ramp

9,139,441

up and mine equipment assemblies.

24,199,071

-124,759 Similar total cost.

6,998,151 Cost not considered on Stage 2.

7,603,071 Undocumented changes from Feb 2007 to May 2007.

8,306,016 Undocumented changes from Feb 2007 to May 2007.

Other Indirect Cost

29

Newmont Contingency P50

29

Newmont Schedule P50

30

Escalation

30

EPCM Fee - Fluor

Total Contingency & Esc.

TOTAL INDIRECT, OWNER &

OTHER COSTS

Original estimate calculation (Stage 2) significantly under stated. (Note, Stage 2 Estimate includes 84 millions in

undocumented adjustment between Feb and May 2007.)

Schedule risk analysis identified P50 schedule as having 3 additional month. The cost adjustment reflects 3 month

56,172,713

of additional time based cost.

-24,863,722 Cost change due to other variables than escalation and scope changes.

160,422,495

53,367,444 Stage 2 EPCM cost were factored and included Fee. Addition Fee increased are due to total EPCM cost increased.

Capitalized Interest & Pre-Production Net Income

Capitalized Interest

32

Capitalized Interest

Pre-Production

50

Pre-Production Cost

51

Pre-Production Revenue

52

Pre-Production Net Income

Total Pre-Production

SUSTAINING CAPITAL COSTS

Sustaining Capital Cost

21

Mine Pit Dewatering - WMC

Mining Equipment

B

D

14

Pre-Strip Development

Mine Inpit Power

Mill Sands Process / Distribution Fluor

Perol Waste Rock Storage

Preparation

Chailhuagon Dump Preparation

11

Mill Sands Storage Facility

10

13

16D

27A.1

27E

29

22

Z

Topsoil Storage

Spare & Tool - Mine Equipment

Consultants Indirect

Contingency P50

Light Fleet and Concentrate

Transport Trucks Replacement

Capex Variance Fluor Stage 2

Rev (Feb 2007) - Newmont Stage

2 Rev (May 2007)

Fluor Confidential

-2,449,300 Life of mine for 2007 study was 22 Years an 2008 is 13 years. Shorter mine life implies reduced sustaining costs.

93,600,123

213,687,873 Undocumented changes from Feb 2007 to May 2007.

27-10-2008

Page 2

Вам также может понравиться

- Technical Specifications For Earthworks, Geosynthetics Rev.CДокумент121 страницаTechnical Specifications For Earthworks, Geosynthetics Rev.Cvisnupada100% (1)

- TMF Sediment Ponds Rev 0 (Completo)Документ19 страницTMF Sediment Ponds Rev 0 (Completo)visnupadaОценок пока нет

- TMF Figures - TMF Tailings Deposition Q3 2014 To Q2 2016 RevBДокумент8 страницTMF Figures - TMF Tailings Deposition Q3 2014 To Q2 2016 RevBvisnupadaОценок пока нет

- 1.2. - Conga Capex Reconciliation - Mayor Area-Prime - RevcДокумент1 страница1.2. - Conga Capex Reconciliation - Mayor Area-Prime - RevcvisnupadaОценок пока нет

- Technical Specifications For Earthworks, Geosynthetics Rev.CДокумент121 страницаTechnical Specifications For Earthworks, Geosynthetics Rev.Cvisnupada100% (1)

- 1.3. - Conga Capex Reconciliation - area.RevCДокумент1 страница1.3. - Conga Capex Reconciliation - area.RevCvisnupadaОценок пока нет

- 1.4. - Conga Capex Reconciliation - Consultants.revcДокумент1 страница1.4. - Conga Capex Reconciliation - Consultants.revcvisnupadaОценок пока нет

- Presentation2 PDFДокумент1 страницаPresentation2 PDFvisnupadaОценок пока нет

- SIS User's Guide: Service Information SystemДокумент28 страницSIS User's Guide: Service Information SystemvisnupadaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Raja Guru. P: ObjectiveДокумент4 страницыRaja Guru. P: ObjectiveAnonymous 7CVuZbInUОценок пока нет

- Cost Estimating 01Документ233 страницыCost Estimating 01brunoОценок пока нет

- Lime Neutralization Treatment Plant Cost Estimate PDFДокумент9 страницLime Neutralization Treatment Plant Cost Estimate PDFWilmer JuarezОценок пока нет

- BapiДокумент72 страницыBapiSrikanth IyyankiОценок пока нет

- Project Cost Estimate - Excel SheetДокумент6 страницProject Cost Estimate - Excel SheetGishan Sanjeewa100% (3)

- ZZZM&E-TOR (Rev - May2015)Документ51 страницаZZZM&E-TOR (Rev - May2015)iqbal gaceОценок пока нет

- Product Costing Material LedgerДокумент166 страницProduct Costing Material LedgerShivinder Singh100% (1)

- Saep 72 PDFДокумент11 страницSaep 72 PDFRami ElloumiОценок пока нет

- Cost Estimating 04Документ243 страницыCost Estimating 04brunoОценок пока нет

- Project Control ProcedureДокумент21 страницаProject Control ProcedureSlamat Parulian Simamora100% (5)

- Cost Estimation TechniquesДокумент41 страницаCost Estimation TechniquessubashОценок пока нет

- 200806-Kibremengist Bulekero (Lot 1) - Completion Report (Draft)Документ26 страниц200806-Kibremengist Bulekero (Lot 1) - Completion Report (Draft)Genet100% (1)

- SAP COPA ConfigurationДокумент0 страницSAP COPA ConfigurationDeepak Gupta50% (2)

- Job Description Drilling EngineerДокумент2 страницыJob Description Drilling EngineerHendra Takalamingan100% (1)

- Método Factorial Estimación de CostosДокумент159 страницMétodo Factorial Estimación de CostosAle BernalОценок пока нет

- Diseño de LaboratoriosДокумент34 страницыDiseño de LaboratoriosDiego Blas MendozaОценок пока нет

- 2021-Impact of BIM Based Quantity Take Off For Accuracy of Cost EstimationДокумент15 страниц2021-Impact of BIM Based Quantity Take Off For Accuracy of Cost EstimationKhusnul KhotimahОценок пока нет

- Full Test 1 CO Management AccountingДокумент28 страницFull Test 1 CO Management AccountingDiana DobrescuОценок пока нет

- PCFM ProjectДокумент11 страницPCFM ProjectxsherwanОценок пока нет

- CCP-Certification Study Guide 2nd EditionДокумент265 страницCCP-Certification Study Guide 2nd EditionAlberto Jiménez Álvarez100% (11)

- Cost Management - QuestionsДокумент4 страницыCost Management - QuestionsLawzy Elsadig Seddig100% (1)

- Cve427 - Ce Laws - Week 7: Charging For Civil Engineering Services Six MethodsДокумент3 страницыCve427 - Ce Laws - Week 7: Charging For Civil Engineering Services Six MethodsDrei ServitoОценок пока нет

- Er - 1110 3 1300Документ24 страницыEr - 1110 3 1300Ahmad Ramin AbasyОценок пока нет

- RIBA Plan of Work ACU 2Документ7 страницRIBA Plan of Work ACU 2Sana SanОценок пока нет

- RISK.03 Integrated Cost and Schedule Risk AnalysisДокумент34 страницыRISK.03 Integrated Cost and Schedule Risk AnalysisWaheed ElbeihОценок пока нет

- Portfolio of Evidence For Prior Learning Assessmen - 240109 - 164434Документ72 страницыPortfolio of Evidence For Prior Learning Assessmen - 240109 - 164434KaraboОценок пока нет

- Full Thesis PDFДокумент93 страницыFull Thesis PDFgaranОценок пока нет

- Cost Implications of Architectural Design Variables PDFДокумент241 страницаCost Implications of Architectural Design Variables PDFsoleb80% (5)

- Construction Cost Estimates and Estimating Cost of Construction ProjectsДокумент7 страницConstruction Cost Estimates and Estimating Cost of Construction Projectskian hongОценок пока нет

- Preliminary Estimate Cost PredictionДокумент24 страницыPreliminary Estimate Cost PredictionChong Ys75% (4)