Академический Документы

Профессиональный Документы

Культура Документы

1007 DISQ 0 P SS 48080 Sales Gas Metering Package Specification

Загружено:

Anonymous XbmoAFtIАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

1007 DISQ 0 P SS 48080 Sales Gas Metering Package Specification

Загружено:

Anonymous XbmoAFtIАвторское право:

Доступные форматы

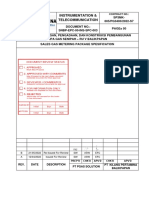

Contract

Number: 1007

File Reference

Page

1007-DISQ-0-P-SS-48080-Rev.3

1 of 43

RWE Dea

Disouq Field Development

FEED

Specification

Sales Gas Metering Package

A-5401

Document number

1007-DISQ-0-P-SS-48080

10.05.12 Issued for Design

A Saleh

A Fawzi

A Hamdan

RWE

08.02.12 Re-Issued for Approval

A Saleh

A Fawzi

A Hamdan

RWE

26.01.12 Issued for Approval

A Saleh /

A Khamisy

A Fawzi

A Hamdan

RWE

11.12.11 Issued for Client comment

A Saleh /

A Khamisy

A Fawzi

A Hamdan

RWE

Approved

By

Client

Approval

Rev

Date

Description

Issued By Checked By

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

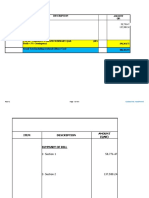

Changes List

Rev.

Date

prepared

Prepared by

Description

(DD.MM.YYYY)

26.01.12

A Saleh /

A Khamisy

Client Comments incorporated

08.02.12

A Saleh

Client Comments incorporated

10.05.12

A Saleh

GASCO requirements and client comments

incorporated

Page: 2 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Table of Contents

1

Introduction ....................................................................................................................6

1.1

Background ................................................................................................................6

1.2

Purpose of Document .................................................................................................7

Referenced Documents .................................................................................................7

2.1

Project Documentation ...............................................................................................7

2.2

International Codes and Standards ............................................................................9

2.3

Order of Precedence ................................................................................................13

Package Components ..................................................................................................14

3.1

Inlet / Outlet Pipe Spools and Interconnecting Piping ...............................................15

3.2

Sales Gas Filter ........................................................................................................15

3.3

Metering Module .......................................................................................................16

3.3.1

3.4

Ultrasonic Meter ....................................................................................................16

Metering System ......................................................................................................18

3.4.1

Multi-stream Flow Computer .................................................................................19

3.4.2

Supervisory Computer ..........................................................................................19

3.4.3

Operator Work Station ..........................................................................................19

3.4.4

Instrumentation Panel ...........................................................................................20

3.4.5

Secondary Devices ...............................................................................................20

Extent of Supply ...........................................................................................................21

4.1

Inclusions .................................................................................................................21

4.2

Exclusions ................................................................................................................22

4.3

Battery Limits............................................................................................................22

Design Requirements...................................................................................................24

5.1

Basic Design Data ....................................................................................................24

5.2

Piping, Flanges, Gaskets and Bolts ..........................................................................26

5.3

Painting ....................................................................................................................26

5.4

Skid Assembly ..........................................................................................................27

5.5

Metering System Design Requirements....................................................................27

5.5.1

Transient, Static and RFI Protection......................................................................27

5.5.2

Cabinet Design .....................................................................................................28

5.6

System Software Design Requirement .....................................................................28

5.7

Noise Limitations ......................................................................................................29

Page: 3 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

5.8

Utilities......................................................................................................................29

5.9

Material Certificate to Conformance (C&C)& Traceability .........................................29

5.10

Name plates .............................................................................................................29

5.11

Climate Condition .....................................................................................................30

Electrical Requirements ...............................................................................................30

6.1

General ....................................................................................................................30

6.2

Power Supply Voltages ............................................................................................30

6.3

Hazardous Area Requirements.................................................................................30

6.4

Certifying Authorities ................................................................................................30

6.5

Ingress Protection for Electrical Equipment ..............................................................30

6.6

Cabling .....................................................................................................................31

6.7

Equipment Earthing & Bonding .................................................................................31

Installation, Operation and Maintenance ......................................................................32

7.1

Installation, Pre-commissioning and Commissioning ................................................32

7.1.1

Start-Up, Pre-commissioning and Commissioning Services ..................................32

7.2

Maintainability...........................................................................................................32

7.3

Calibration ................................................................................................................33

7.3.1

Ultrasonic Meters Calibration ................................................................................33

7.3.2

Secondary Devices ...............................................................................................33

7.4

Special Tools ............................................................................................................33

7.5

Spare Parts ..............................................................................................................33

7.6

Training ....................................................................................................................34

7.6.1

Training Philosophy ..............................................................................................34

7.6.2

Training Course Documentation ............................................................................34

7.6.3

Operator Training Course .....................................................................................34

7.6.4

Maintenance Training Course ...............................................................................34

7.6.5

System Configuration Course ...............................................................................34

7.6.6

Training Aids .........................................................................................................34

Preparation for Shipment .............................................................................................35

Quality Assurance & Health, Safety and Environment ..................................................35

9.1

QC Factory Acceptance Test (FAT) ..........................................................................35

9.2

QC System Integration Test (SIT) .............................................................................37

9.3

QC Site Acceptance Test (SAT) ...............................................................................37

Page: 4 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

9.4

Ultrasonic Meter Inspection ......................................................................................38

10

Vendor Data Requirements ......................................................................................39

10.1

Functional and Detail Design Specification (FDS and DDS) .....................................39

List of Abbreviations ............................................................................................................41

Page: 5 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Introduction

1.1

Background

RWE Dea Egypt has discovered seven natural gas reserves in the Disouq Concession within

the onshore Nile Delta, starting in 2008, as shown on the concession map below. Further

exploration in the concession is on-going. RWE Dea Egypt is the operator of the Concession

with EGAS as a partner.

The selected development comprises a central gas treatment plant near NSG-1x, where the

gas is collected, treated by means of Low Temperature Separation utilizing the Joule Thomson

effect to achieve sales gas quality, and compressed for export. Sales gas is transferred via a

16 pipeline directly into the GASCO NTS pipeline.

The well fluids are gathered and fed to a common inlet separator at the central plant. All gases

and liquids will be separated and processed on the central treatment plant into sales gas,

stabilized condensate, and free production water.

Treatment of gas is carried out in two trains, while treatment of condensate is in a single train.

Three trains of gas compression and three metering streams shall be installed. Fuel gas for

the gas engine driven main power generators will be taken from the suction of the gas

compressors upstream of the sales gas metering package.

Page: 6 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

1.2

Purpose of Document

This Specification defines the minimum technical requirements for the design, material

specification, fabrication, assembly, QC inspection, QC testing and preparation for shipment of

a fiscal / custody transfer Sales Gas Metering Package to be installed on the Central

Treatment Plant as part of the Disouq Field Development Project.

The Sales Gas Metering Package shall be designed and supplied as a single skid mounted

package if technically feasible with three Ultrasonic Meter Streams and metering room

equipment to be located in the Equipment room of the central room building. The arrangement

of the package and skids to be determined by Vendor. The package shall comprise all

necessary equipment including a minimum of 2 Multi-stream flow computers (with nonresettable flow totalizers), one supervisory computer, one online gas chromatograph to be

located on the skid, sales gas filters, shutdown valve, blow down valve, pressure control

valves, manual valves, field instrumentation and pipe work and fittings as per P&ID Metering

Skid no 1007-DISQ-O-P-DW-48059 and Sales Gas Metering Package Process Data Sheet

document number 1007-DISQ-0-P-DP-48131.

Compliance with this specification shall not relieve the Vendor of his responsibility to provide a

fully completed and safe equipment design including all auxiliary elements necessary to

ensure reliable and efficient operation under the specified operating conditions.

Referenced Documents

The design, construction, fabrication, QC inspection, QC testing, calibration and supply of the

Sales Gas Metering Package shall be in accordance with the latest revisions of the following

specifications, data sheets, codes and standards.

2.1

Project Documentation

NUMBER

1007-DISQ-0-M-RT-42015

1007-DISQ-0-P-DW-48059

1007-DISQ-0-L-DW-39000

1007-DISQ-0-P-SS-48079

1007-DISQ-0-P-DP-48131

1007-DISQ-0-G-MA-30092

1007-DISQ-0-G-DW-30036

1007-DISQ-0-J-SS-33010

1007-DISQ-0-J-SS-33030

1007-DISQ-0-J-SS-33033

1007-DISQ-0-J-SS-33055

1007-DISQ-0-L-SS-39010

1007-DISQ-0-F-DW-10012

1007-DISQ-0-O-CF-48065

1007-DISQ-0-E-SS-27023

1007-DISQ-0-G-MA-30088

1007-DISQ-0-L-SS-39004

1007-DISQ-0-F-G-SP-10014

1007-DISQ-0-F-SS-10018

DESCRIPTION

Environmental Data and Units of Measurement

P&ID Metering Skid

Plot Plan - CTP

Specification for Integrated Control and Safety System

(ICSS)

Sales Gas Metering Package Process Data Sheet

Control System Philosophy

Control System Architecture Central Treatment Plant

Field Instrumentation General Specifications and Testing

Requirements

Control Valve Specification

Shutdown Valve Specification

Safety Relief Valves Specification

Specification for Piping Material

Hazardous Area Classification Layout

Cause & Effect Diagram

Electrical Specifications for Packaged Equipment

Electrical System Design Philosophy

Specification for Painting and Protective Coatings

F&G Requirement Specification

Specification for Equipment Noise Control

Page: 7 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

1007-DISQ-0-M-SS-42003

1007-DISQ-00-QP-1008

1007-DISQ-00-F-QA-1007

Article 5 (2 pages of GSA)

GASCO Vendor list

Package Equipment Specification

Project Quality Plan

QA Plan

Measurements and Tests, Para 5.1 to 5.6

PNM /2011 Reducing and Metering Gas Stations

Page: 8 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

2.2 International Codes and Standards

NUMBER

DESCRIPTION

AGA Eng. Tech.

Note M-96-2-3

Ultrasonic Flow Measurement for Natural Gas Applications

AGA Rep. No.3

Orifice Metering of Natural Gas and Other related Hydrocarbons Fluids

AGA Rep. No.7

Measurement of Gas by Turbine Meters

AGA Rep. No.8

Compressibility Factors of Natural Gas and Other Related

Hydrocarbon Gases

AGA Rep. No.9

Measurement of Gas by Multipath Ultrasonic Meters, second edition

2007

AGA Rep. No. 10

Speed of Sound in Natural Gas and Other Related Hydrocarbons

ANSI B2.1

Pipe Threads (Except Dry seal) Specifications, Dimensions, and

Gauging for Taper and Straight Pipe Threads Including Certain Special

Applications

ANSI B16.20

Ring-Joint Gaskets and Grooves for Steel Pipe Flanges

ANSI B 16.47

Large Diameter Steel Flanges NPS 26 Thru NPS 60

ANSI B16.5

Pipe Flanges and Flanged Fittings

ANSI B 16.9

Factory Made Wrought Steel Butt welding Fittings

ANSI B 16.11

Forged Steel Fittings, Socket Welding and Threaded

ANSI B 31.1

Power Piping Code

ANSI B 31.3

Chemical Plant and Petroleum Refinery Piping

ANSI B 31.4

Liquid Transportation Systems for Hydrocarbons, Liquid Petroleum

Gas, Anhydrous Ammonia, and Alcohols

ANSI B 31.8

Gas Transmission and Distribution Piping Systems

ANSI B16.34

Valves - Flanged and Butt welding End Steel, Nickel Alloy and Other

Special Alloys

ANSI B16.104

Valve Leakage Classifications

ANSI B 36.10M

Welded and Seamless Wrought Steel Pipe

ANSI C 37.96

IEEE Guide for AC Motor Protection

API 1104

Standard for Welding of Pipelines and Related Facilities

API 2B

Specification for Fabricated Structural Steel Pipes

API 500

Recommended practice for classification of locations for electrical

installations at petroleum facilities classified as Class 1, Division 1 and

Division 2

Page: 9 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

API RP 520

Sizing, Selection and Installation Of Pressure-Relieving Devices in

Refineries

API RP 550

Manual on Installation of Refinery Instruments and Control Systems,

Part 1 - Process Instrumentation and Control, Section 6 - Control

Valves and Accessories

API 551

Process Measurement Instrumentation

API 552

Transmission Systems

API RP 553

Refinery Control Valves

API SPEC 6FA

Specification for fire test for valves

API RP 14C

Recommended Practice for Analysis, Design, Installation and Testing of

Basic Surface Safety Systems for Offshore Production Platforms

API 554

Process Control and Instrumentation

API SPEC 6D

Specifications for Pipeline Valves, End Closures, Connectors and

Swivels

ASME B31.3

Chemical Plant & Petroleum Refinery Piping

ASME B16.5

Pipe Flanges and Flanged Fittings

ASME PTC

Temperature Measurement

ASME Section II

Material Specifications

ASME Section IX

Welding and Brazing Qualifications

ASTM A193/A193M

Standard Specification for Alloy Steel and Stainless Steel Bolting

Materials for High Temperature Service

ASTM A194

Standard Specification for Carbon and Alloy Steel Nuts for Bolts for

High pressure / High-Temperature Service

ASTM A234

Specification for Piping fittings of Wrought Carbon Steel and Alloy Steel

for Moderate and Elevated Temperatures

ASTM A269

Standard Specification for Seamless and Welded Austenitic

Stainless Steel Tubing for General Service

ASTM A269

Specification for Seamless and Welded Austenitic Stainless Steel

Tubing for General Service

ASTM A320

Specification for Alloy Steel Bolting Materials for Low Temperature

Service

ASTM A325

High Strength Bolts for Structural Joints, including Suitable Nuts and

Plain Hardened Washers

ASTM A370

Methods and Definitions for Mechanical Testing of Steel Products.

ASTM A403

Standard Specification for Wrought Austenitic Stainless Steel Piping

Fittings

Page: 10 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

ASTM A450/450M

Specification for General Requirements for Carbon Steel, Ferritic Alloy,

and Austenitic Alloy Steel Tubes

ATEX 95 (Directive

94/9/EC)

Directive on Equipment and Protective Systems Intended for use in

Potentially Explosive Atmospheres

BS EN ISO 10204

2004

Metallic Products - Types of Inspection Documents

DIN EN 10204

Metallic Products - Types of Inspection Documents

DIN 50049

Metallic Products - Types of Inspection Documents

EI15

Energy Institute Model Code of Safe Practice Part 15 Area

Classification Code for Installation Handling Flammable Fluids (3rd

Edition).

IEC 664

Insulation co-ordination within low-voltage systems including

clearances and creep age distances for equipment

IEC 60059

IEC Standards Current Ratings

IEC 60079

Electrical Apparatus for Explosive Gas Atmospheres

Part 0: General requirements

Part 1: Flameproof enclosures d

Part 2: Pressurized enclosures p"

Part 4: Method of test for ignition temperature

Part 7: Increased safety "e"

Part 10: Classification of hazardous areas

Part 11: Intrinsic safety I

Part 12: Classification of mixtures of gases or vapours with air

Part 13: Construction and use of rooms or buildings protected by

pressurization

Part 14: Electrical installations in hazardous areas (other than mines)

Part 16: Artificial ventilation for the protection of analyser house

Part 18: Encapsulation m( why this gap here?)according to their

maximum experimental safe gaps and minimum

igniting currents

IEC 60085

Thermal Evaluation and Classification of Electrical Insulation

IEC 60228

Test for electric cables under fire conditions Circuit integrity

IEC 60331

Degrees of protection provided by enclosures (IP Code)

IEC 60529

Industrial Process Control Valves Inspection & Routine Testing

IEC 60751

Industrial Platinum Resistance Thermometer Sensors

Page: 11 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

IEC 61000

Electro-magnetic compatibility Generic emissions standard

ISA 5.1

Instrument Symbols and Identification

ISA 5.4

Instrument loop diagrams

ISA 18.1

Annunciator Sequences and Specifications

ISA 20

Specifications forms for process measurement and control instruments

primary elements and control valves

ISA 50.1

Compatibility of analogue signals for electronic industrial process

Instruments

ISA 51.1

Process Instrumentation Terminology

ISA S75.01

Control Valve Sizing Equations

ISA S75.02

Control Valve Capacity Test Procedures

ISA S75.03

Uniform Face-to-face Dimensions for Flanged Globe Style Control

Valve Bodies

ISA S75.04

Face-to-face Dimensions of Flangeless Control Valves

ISO 1000

SI units and recommendations for use of their multiples and of

certain other units

ISO 4406

Hydraulic fluid power Fluids Method for coding the level of

contamination by solid particles

ISO 6551

Petroleum Liquids and Gases Fidelity and Security of Dynamic

Measurement Cabled Transmission of Electric and/or Electric

Pulsed Data

ISO 14617-1:2005

Graphical symbols for diagrams

ISO 9001:2008

Quality Management System Requirements

ISO 15408

Common Criteria for Information Technology Security Evaluation

ISO14001:2004/2009 Environment Management System- requirements

OHSAS18001:2007

Occupational health and safety system- requirements

ISO 17089

Measurement of Gas by Ultrasonic Meters

ISO 5167-1.

Measurement of fluid flow by means of pressure differential devices

inserted in circular cross-section conduits running full -- Part 1: General

principles and requirements

ISO 6976

Calculation of calorific value, density and relative density

ISO 5167

Measurement of fluid flow by means of pressure differential devices

inserted in circular cross-section conduits running full.

ISO 5168

Methods of measurement of fluid flow, estimation of Uncertainty of a

flow rate measurement.

Page: 12 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

MSS SP 61

Pressures Testing of Steel Valves

NFPA 72E-4

National Fire Alarm and Signalling Code - Automatic Fire

Detectors

NFPA 90A

Standard for the Installation of Air Conditioning and

Ventilation Systems

SI 1994 3260

The Electrical Equipment (Safety) Regulations

SI 1992 2372

The Electromagnetic Compatibility Regulations

2.3 Order of Precedence

In case of discrepancies among the various documents, the following order of precedence shall

be applied:

1. Purchase Order and amendments thereto

2. Data Sheets

3. This Package Specification

4. Other Referenced Project Specifications

5. Egyptian National/Local Codes and Standards

6. International Codes and Standards

7. Egyptian environment law 4 /2011

Page: 13 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Package Components

The Sales Gas Metering Package shall be used as a fiscal sales gas metering system for the

sales gas of the Disouq Field Development Project to be transferred from the Central

Treatment Plant into the sales gas pipeline. The Sales Gas Metering Package shall

compensate the flow readings for the online pressure and temperature readings as well as gas

composition through one online gas chromatograph and calculate instantaneous flow rate

based on the sales gas composition. The system shall use an ultrasonic meter as the primary

method of flow metering method. Other flow terms such as volumetric or energy flow rate and

flow tantalization shall be calculated in multi stream flow computers. Non resettable flow

totalization shall be recorded in the flow computer, supervisory computer and the ICSS.

The sales gas metering package shall consist of all mechanical, electrical and instrumentation

equipment such as rigid base frame, piping, gas filters, three ultrasonic flow meters,

instrumentation, one online gas chromatograph, cabling and the metering system. The

metering system shall be located in the equipment room of the control room building and shall

include the metering cabinet with marshalling cabinet ex interfaces/barriers, 2 multi stream

flow computer for handling of four ultrasonic meter streams in minimum, supervisory computer,

printer and operator workstation c/w keyboard, mouse and LCD display or touch screen, two

communication interfaces with the ICSS, two communication interfaces for the communication

with the SCADA system of the Gas Grid Operations Company shall be provided and a junction

box or terminal strip with four hardwired signals (IS type) for the hardwired transfer of these

signals to the Gas Grid Operation Company.

The Gas Grid Operations Company will be responsible for the pick-up and transfer of all

signals and communications from the metering cabinet inside the equipment room of the

control room building on the CTP to the location of the SCADA system of the Gas Grid

Operations Company.

Each multi-stream flow computer function shall calculate, record, report the corrected sales

gas volumetric flow rate (in MMSCF/d and in MMSCM/d), energy flow rates (in BTU and

kWh/MWh) and associated total quantities of ultrasonic flow meters as required. The

Supervisory computer shall manage, compare and report the flow computer results and

validity of measurements where the operator workstation shall provide the GUI for the operator

to interface with the system and provide access for printing and reporting.

The Sales Gas Metering Package inlet gas composition, pressure, temperature, flow rate and

sales gas outlet pressure is detailed within the Sales Gas Metering Process Data Sheet

number 1007-DISQ-0-P-DP-48131.

The Vendor is required to confirm the necessary technology and equipment required to meet

the specification. As a minimum, the package will consist of inlet/outlet headers,

interconnecting piping, gas filters, ultrasonic meter runs (US Meter Streams), pressure control

valves, shutdown valve, blow down valve, relief valves, ultrasonic flow meter, field

instrumentation, two multi stream Flow Computer in minimum, supervisory computer,

instrumentation panels and metering cabinets, skids and supports, electrical and instrument

wiring and junction boxes as shown in figure 1 below.

Page: 14 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Figure 1

The following is a description of the minimum Sales Gas Package Process Components as

per P&ID No:

- 1007-DISQ-0-P-DW-48059

P&ID Metering Skid

3.1

Inlet / Outlet Pipe Spools and Interconnecting Piping

The main inlet / outlet piping, metering runs and header shall be designed for 100% of the

maximum flow rate and shall be equipped with the required instrumentation as shown in the

P&ID- Metering Skid 1007-DISQ-0-P-DW-48059.

The complete pipe inlet and outlet spools layout, arrangement of thermowell tap and

dimensions shall follow the recommended default installation requirements of AGA Report No.

9, Edition 2007, Section 7, for unidirectional design in minimum unless otherwise

recommended or required by the Ultrasonic meter manufacturer.

The requirements and dimensions of the piping shall be according to the Specification for

Piping Material document number 1007-DISQ-0-L-SS-39010.

The inside surface finish of the piping used with Ultrasonic meters shall be 250inch Ra or

better and machined honed. The welds shall be 100% radiographic tested.

The inlet pipe spool shall be equipped with a threadolet for bypass connection of inlet ball

valve. The outlet pipe shall be equipped with threadolets for connections of instruments and

other required equipment as specified by the relevant code.

3.2

Sales Gas Filter

Dependent on the gas analysis and quality, the gas metering skid shall be equipped with gas

filters. Gas filters shall have 100% standby capacity. The gas filter shall be able to separate

liquids from natural gas. Each gas filter shall consist of one/multi cycle separation stage,

cartridge filters and shall have required valves and instrumentation including a vent and

depressurizing connections.

For a quick and easy replacement of the filter cartridges the filter shall be equipped with full

size opening with a quick closing door. The filter shall be equipped with:

Page: 15 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

o

o

o

o

o

o

o

Inlet and outlet plug valves

Pressure Differential transmitter

Pressure Differential and Pressure Indicator

Level Indicator

Drain and vent valves

Safety relief valve

Maintenance manhole (if applicable)

The pressure drop across the clean filter shall not exceed 0.5 barg at the maximum flow.

3.3

Metering Module

The metering module shall consist of three metering runs (metering streams), and the

associated instrumentation necessary to calculate, correct, record flow rate and gas quantities

at standard conditions in MMSCF/d and MMSCM/d. The number of metering streams in

operation shall be decided based on plant production and consumer requirement although

there shall be at least one stream as a hot stand-by meter.

The change-over of the metering streams from operating stream to stand-by and vice-versa,

shall be achieved by manually operated valves. Each Metering stream (Metering Run) shall be

supplied with calibration certificate.

Metering runs or metering streams sizing shall take in consideration the maximum and

minimum flow rate as specified in the process data sheet to insure maximum accuracy within

the full flow operation range.

The minimum equipment of each metering run shall comprise:

o

o

o

o

o

o

o

o

Inlet and Outlet ball valves.

Ultrasonic flow meter.

Pressure transmitter.

Temperature transmitter.

The meter module instrumentations shall be designed and connected to the flow

computer for totalizing, correction and recording.

Each meter shall have a maximum permissible error of 0.5% over the flow range.

Repeatability of the meters must be within +/- 0.2% for the higher velocity range

The total uncertainty of the metering package shall not exceed 1% independent of the

number of streams in operation and shall be tested and verified during flow calibrations

in accordance with AGA Report No.9, Edition 2007, section 6 and the recommended

flow rates. Flow Calibrations are mandatory for fiscal metering applications.

Pressure, Temperature transmitters and instrumentation shall be supplied with high accuracy

and valid calibration test certificates.

3.3.1

Ultrasonic Meter

An ultrasonic meter shall be installed as the primary measuring device in the metering system

in compliance with AGA Report NO. 9. The ultrasonic meter shall be based on the latest

technology and shall be multi-path type (4-path in minimum) with the chords arranged such

that the flow profile can be analysed. Failure of a path shall not result in a measurement failure

Page: 16 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

but shall trigger an alarm that accuracy or measurement is affected. The meter reading shall

be corrected or compensated for the temperature and pressure effect on the measuring path.

Accuracy of Ultrasonic Meter shall be equal to or more than 99.5%. The ultrasonic meter shall

be installed in a way to minimize the accumulation of contaminants.

The ultrasonic meters shall have a large dynamic range and within this range, the following

requirements must be fulfilled:

Negligible offset error.

High repeatability.

High absolute accuracy.

Moreover, the ultrasonic meters shall be unaffected by installation effects such as:

Swirl.

Asymmetry.

Pulsations

The signal transmission of the Ultrasonic Meter shall use digital signals to avoid fluctuations in

sound velocity and to be able to check signal quality in addition to having built in diagnostics.

The Ultrasonic Meter shall have dedicated software to examine the performance of the

metering system. The performance of the metering system shall examine but not limited to the

following:

Swirl and asymmetry.

Ultrasonic meter footprint and ratio (verify the meter by checking the measured Velocity

of Sound versus the Calculated Velocity of Sound).

Performance monitoring of the meter.

The measuring device and associated transducers shall be capable of operating without

detriment of performance throughout the expected pressure and temperature range and

should not be affected by changes in ambient conditions.

The Vendor shall provide a study on how to minimize the effect of unsteady flow conditions

due to the presence of compressors upstream the Metering Package on the Ultrasonic meter

performance.

The Ultrasonic meter shall provide two types of signals:

Frequency/Pulse signal.

Serial port for a minimum distance of 300m between each meter and the flow

computer.

The body of the ultrasonic meter shall be designed, manufactured and tested in accordance

with the relevant sections of API 6 D and ASTM A-216 GR WCB or other material standards

equivalent to these.

The pipe material for the ultrasonic meter, bolts, nuts and flanges shall designed,

manufactured and tested in accordance with the Specification for Piping Material, document

number 1007-DISQ-0-L-SS-39010 and the inside surface finish shall be designed as

Page: 17 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

250inch Ra or better and machined honed. The hydrostatic test pressure of the meter body

shall be 1.5 times the design pressure.

The inside diameter of the ultrasonic meter shall have the same inside diameter as the

upstream tubes diameter and must be within 1% or better in accordance with AGA Report

No.9.

All material exposed to the gas shall be gas-resistant. The surface of the transducers shall not

be degraded in performance due to contact with natural gas. The transducers shall be

removable under pressure. Removal and reinstallation of transducers shall not affect the

calibration of the meter nor the accuracy. The vendor shall supply the retraction equipment to

remove the transducers under pressure.

Each ultrasonic meter shall be sandblast and shall be painted in accordance with the

Specification for Painting and Protective Coatings, document number 1007-DISQ-0-L-SS39004.

3.4

Metering System

The metering system shall comprise of two multi stream flow computer in minimum,

Instrumentation Panel, supervisory computer, operator work station and secondary devices.

The metering system cabinets shall be located in the equipment room of the control room

building.

The Metering System shall interface with the plant DCS System via redundant single mode

fibre links or redundant copper cable serial links (Ethernet TCP/IP) which will be confirmed

during detail design and shall be monitored from the plant HMI (OWS) that will be located in

the Central Control Room (CCR) of the control room building on the Central Treatment Plant.

Vendor to provide intrinsically safe junction box with 12 terminals (3 terminals each signal) for

3 analogue intrinsically safe signals and one digital intrinsically safe impulse signal (max. 50

Hz) as interface point for the Gas Grid Operator GASCO located outside the metering cabinet

in a junction box or inside the metering cabinet on a terminal strip as follows:

Flow rate; 4-20mA, 0-165 MMSCF/d.

Pressure; 4-20mA, 0-100 barg.

Temperature; 4-20mA, 0-80 degree Celsius.

Impulse signal (max. 50 Hz, dry contact) for totalizer inside GASCO.

Above mentioned hardwired signals shall be in parallel also transferred via RS 232 interface.

Vendor shall provide active standard Serial link RS 232 port (physical DB 9 socket) in slave

mode and standard Modbus RTU.

Vendor shall provide also Ethernet connection (physical RJ45 socket), standard Modbus (for

future connection).

Gas analysis data C1 to C9 shall be transferred via serial link RS 232 and Ethernet

connection.

The Gas Grid operator GASCO shall be responsible to pick up the signals from above

mentioned interface points and transfer the signals to his premises.

Page: 18 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

3.4.1

Multi-stream Flow Computer

Multi stream flow computer shall be fully wired, furnished and configured to serve 4 streams in

minimum.

The Multi-stream flow computer convert uncorrected flow figures into corrected flow following,

the equations detailed in AGA 7 and shall compensate if required the flow readings for the

online pressure and temperature readings as well as gas composition through the online gas

chromatograph, and calculate flow rates (in MMSCF/d and in MMSCM/d) and shall be capable

to summarize at least 4 working metering streams.

One multi-stream flow computer shall be in operation and the other shall be a hot standby.

The operating flow computer shall receive the reading from the Ultrasonic Meters. As only two

out of the three meter streams are operating and the third is on standby, the flow computer

shall sum up the flow from the two meters and send the results to the supervisory computer.

3.4.2

Supervisory Computer

The Supervisory computer shall be equipped with necessary check and validation software to

confirm reading accuracy, reliability and validity. The supervisory computer shall supervise,

manage the flow computers and check flow calculation accuracy and validity. The Supervisory

Computer shall be able to change between main and standby flow computers as and when

required. The supervisory computer shall report the plant flow rate and sold quantities for

energy in BTU and kWh and volume in SCF and SCM (per shift, day, week, month, year and

total).

The Supervisory Computer software shall have the capability to check the validity, reliability,

performance and accuracy of the Ultrasonic Meters. The purpose of these checks is to

guarantee that the ultrasonic meters are performing satisfactorily within the specifications and

the initial meter calibration is still valid.

3.4.3

Operator Work Station

The Operator Work Station (OWS) shall be PC-based industrial computer type and shall be

provided with a dedicated keyboard, screen, mouse and printer.

The Operator Work Station OWS shall be provided with a proprietary software package

designed for easy, ergonomic operator interface with the Metering Package facilities.

The software package shall include a suite of Graphical User Interfaces (GUIs). The GUIs

shall be based on the Metering Skid P&ID to provide an accurate and familiar representation

of the process Arrangement.

The Operator Work Station (OWS) display pages shall give the operator an overview of all the

connected metering streams.

For each of the meter streams, the following data shall be displayed:

The volume flow rates at line conditions and at standard conditions in MMSCF/d and

MMSCM/d.

The energy flow rate in BTU and kWh/ MWh.

The mass flow rate in kg/h and metric tons/h

Page: 19 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

3.4.4

Volume-, Energy- and Mass Flow- total per shift, day, week, month, year and overall

totalizer

The pressure and temperature in barg and degree Celsius.

Detailed Information about the Ultrasonic Meter includes flow direction and data

validity.

Ultrasonic meter performance monitoring.

Signal to Noise Ratio.

Speed of Sound (SOS) Comparison as described in the AGA10 standard.

Swirl Angle Monitor.

Asymmetry Monitor.

Instrumentation Panel

Instrumentation Signals of the three metering runs shall be terminated at skid edge intrinsically

safe junction box. The layout, design of the junction box shall follow the 1007-DISQ-0-J-SS33010 Field Instrumentation General Specification and Testing Requirements and 1007DISQ-0-E-SS-27023 Electrical Specification for packaged Equipment and shall be subject to

company approval.

3.4.5

Secondary Devices

The Instrumentation for each metering run classified as "secondary devices" includes, but not

be limited, to the following:

One Electronic static pressure transmitter, 4-20mA, 2 wire, HART protocol compatible,

intrinsically safe transmitter.

One Electronic Temperature transmitter, 4-20mA, 2-wire, HART protocol compatible,

4-wire PT 100 from thermowell to head transmitter, intrinsically safe transmitter

Instrument vendors for all instruments shall be in accordance with attached vendors list. They

shall have required linearity and repeatability with negligible mounting position. It is required

that these transmitters are selected to have an accuracy of 0.1% of calibrated span and a

stability of 0.1% of URL per 60 months in minimum.

Page: 20 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Extent of Supply

4.1

Inclusions

The scope of supply shall include, but not be limited to the following:

Package Process Components:

Inlet / Outlet Pipe Spools and Interconnecting Piping.

Sales Gas Filters.

Metering Module including three Ultrasonic Meters.

Metering System

Multi-stream Flow Computer.

Instrumentation Panel.

Supervisory Computer including Software and Hardware

Operator Work Station c/w screen, keyboard, mouse and printer including

Software and Hardware

Secondary Devices as per section 3.4.5

All flow, pressure and temperature instrumentation, together with manifold valves

and enclosures.

Gas chromatograph C1 up to C9 in online operation installed on the skid with all

accessories required such as test gas and data link to the metering cabinet for

monitoring purposes and link into the flow computers etc.

System /marshalling/termination cabinet.

Cable trays / supports JBs and for Companys power and Instrument cabling.

Special system cables, including data communication connections to ICSS and Gas

Grid Operations Company interface inside or outside the metering cabinet, any

special cables and connectors required for system operation and gas chromatograph

online operation and monitoring.

Intrinsically safe and other Junction boxes as required.

Terminations and isolation facilities for maintenance.

Redundant Power supply modules.

System Input/ Output interface equipment.

System computers and processors with battery backup.

System network Interface units.

Redundant network communication system.

All operational software (including all licensed operating software and required

protocols for system interfaces), configured to meet the application requirements.

Supervisory Computer management and validation software.

System engineering and design including system architecture and all cabinet design.

Implementation of functions.

Computational algorithms, logic and sequence design.

System power supply design, internal power distribution boards and earthing design.

All necessary equipment and communication cables fully configured for plug and

play to interface with other systems.

Structural Steel Skid Base plate(s) c/w drip pan, diagonally arranged two earthing

points per skid in minimum and flanged drain connection.

Page: 21 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

4.2

On skid interconnecting piping, pipe supports, valves and fittings for process,

utilities, vents, shutdown and relief systems terminating at skid edge with flanged

connections.

Instrumentation, valves, fittings and tubing.

Skid Earthing and Bonding.

Safety devices (including alarms, shutdowns, interlocks, signs, access restrictions,

personnel protection, lightning protection, etc.).

Skid lighting if required.

Special Tools.

Fabrication and Assembly.

QC Inspection & QC Testing (including calibration of each meter run and the whole

metering package, factory, system integration and site acceptance tests including

test procedures and report).

Painting and Protective Coating.

3rd Party Certification.

Supervision of Installation.

Commissioning and start-up spare parts.

List of Two Years operational spare parts.

List of Capital Spares.

Packing, Marking and Preservation.

QC Test Equipment required for Calibration runs, FAT, SIT, and SAT.

Documentation as detailed within VDRF and Minimum Quality Surveillance

(including installation, operation and metering maintenance manuals, validation,

factory acceptance-, system integration-, site acceptance test and calibration

procedures).

Performance and Mechanical Guarantees.

QC Calibration certificates as required for fiscal sales gas metering application.

Exclusions

The following Items are excluded:

4.3

Civil Works including foundations

E+I cabling work from Metering Skid to Metering Cabinet and ICSS inside equipment

of Central Control Room building.

Earthing connection of metering skid to plant earthing system

Battery Limits

The battery limits shall be as indicated on the relevant P&IDs (1007-DISQ-0-P-DW-48059)

For skid mounted packaged equipment the battery limits (i.e. pipe work flanges and instrument

junction boxes) shall be located at the skid base plate edge, skid base frame supports or in the

metering room as applicable. This is as further defined below:

Gas Inlet (R1).

Gas Outlet (R2).

Flare (PSV Outlet) (N-5401 A) (R3).

Flare (PSV Outlet) (N-5401 B) (R4).

Flare (BDV Outlet) (R5).

Page: 22 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Flare (PCV Outlet) (R6).

Manual Vent; Metering Run A (R7).

Manual Vent; Metering Run B (R8).

Manual Vent; Metering Run C (R9).

Instrument Air Supply connection.

Electrical supply connections.

Earthing connections.

Hardwired instrumentation interfaces (Junction Boxes on skid edge).

Interface connections for Gas Grid Operator Company.

Page: 23 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Design Requirements

5.1

Basic Design Data

The Gas Metering package shall be designed for continuous operation outdoors on the Central

Treatment Plant (CTP) of the Disouq Field Development Project located in the North Nile Delta

of Egypt environment and in accordance with the relevant data sheets, specifications, codes

and standards and other applicable documents listed in section 2. All supplied equipment and

components thereof shall be designed for a minimum design life of twenty five (25) years. In

addition, the equipment shall be designed, engineered and constructed to ensure safety,

environmental compliance, reliability, quality, efficient operation and ease of maintenance. An

overall package availability of 99.8% is required.

Measuring equipment shall be designed and operated to ensure to meet also the requirements

of Article 5 Measurements and Tests Para 5.1 till 5.6 and an overall uncertainty of the

measurements not exceeding one percent (1%) as stated explicitly in Para 5.5 ( see attached

two pages of Article 5 ).

The total uncertainty of the each stream and the different combinations of stream and the

whole metering package shall be verified with individual meter and metering package testing

and calibration in accordance with AGA Report 9, Edition 2007, Section 6.

IEC 60079 or equal International standards shall be used to classify hazardous areas. FEED

Hazardous Area Classification Layout; see document number 1007-DISQ-0-F-DW-10012.

All electrical and instrumentation equipment on the skid shall be designed, mounted, classified

and certified for zone 1 in accordance with EN 60079-10 or 2G in accordance with ATEX 95

and Gas Group II CT4 or equal.

Associated ex interfaces/barriers in the metering cabinet shall be suitable classified and

certified to match the requirements of the electrical and instrumentation equipment installed in

zone 1 in accordance with EN 60079-10 or 2G in accordance with ATEX 95 and Gas Group II

CT4.

The Vendor shall confirm quantity of hydrocarbon releases and durations for all and any flaring

cases including start up, process shut down and ESD of the package. The Vendor shall pay

particular attention in the design to minimise emissions, air pollutants or releases of toxic

waste products or any other contaminants into the environment. Details of all hazardous and

non-hazardous emissions shall be identified (See emissions limits in appendix -6, Egyptian

environment law 4 /2011).

The Gas Metering Package shall be designed to avoid any hydrocarbon emissions.

Continuous flaring during normal operation is not allowed.

Particular attention shall be paid to prevent vibration of skid mounted pipe work. Adequate

pipe supports shall be provided at suitable intervals to prevent excessive vibration during

operation.

The Vendor shall supply and install insulation and/or protective equipment where required on

all pipe work supplied as part of the package.

The Metering Runs/Streams shall be installed between inlet and outlet headers. Each

metering run shall collectively cover the 50% of the maximum plant flow rate with 10% oversize. Each metering run/stream shall be designed to give a turndown ratio in accordance with

Page: 24 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

document number 1007-DISQ-0-P-DP-48131, Sales Gas Metering Process Data Sheet. Each

metering run/stream shall comprise of one Ultrasonic flow meter (USM), static pressure

transmitter upstream the USM and temperature transmitter with 4-wire PT 100 and head

transmitter downstream the USM, all field instrumentation shall meet the Field

Instrumentations General Specifications and Testing Requirements 1007-DISQ-0-J-SS33010.

The Gas Grid Operations Company requested 73 Diameter straight lengths upstream and

downstream pipe diameter of the USM.

Vendor to submit a comprehensive study on the advantages/disadvantages of installing flow

conditioner/ straightening vanes upstream the ultrasonic meter stating his recommendations

on whether such flow conditioner/vanes should or should not be installed for this application.

Company has the full right in view of this study or based on other technical opinions to decide

whether or not these flow conditioner/straightening vanes shall be installed.

The measuring process should take place in a pipeline of circular cross-section. The duct

cross section uncertainty is a factor in the total uncertainty calculation of the system.

Vendor shall submit detailed data regarding the ultrasonic meters. This data must cover in

detail the following items:

Theory of operation

Calculation of speed of sound, noise level and flow speed covering the flow range

Determination of upstream and downstream straight lengths of flow meter based on

process connections upstream and downstream of metering package, USM

manufacturer recommendation, process connection with other equipment, piping

arrangement and uncertainty requirements

Flow simulation for the package covering the max. flow range

Uncertainty calculation per stream, for different combinations of streams and with all

streams in operation

Detailed procedure of flow calculation for the different operation scenarios.

Data sheet to clarify the material of construction and important data for each part of

the Ultrasonic meter

Detailed study showing the increase of accuracy and advantages gained when

increasing the number of USM transducers and vendor recommendation for the

number of USM transducers (minimum 4-path )

All QC Tests and QC calibration procedures for which the USM will be subject

The Ultrasonic meters shall be approved for use in hazardous area Zone 1 independent of

the Hazardous Area Classification Layout document no. 1007-DISQ-0-F-DW-10012, and

shall have the certification for operation in Sales Gas Metering Stations (SGMSs) for gas flow

measurement equipment as per custody transfer measurement requirements in accordance

with AGA Report 9, Edition 2007.

The centre line of the ultrasonic flow meter shall be within 1% of the pipe centre. The

upstream pipe section adjacent to the ultrasonic meter shall be in accordance with AGA

Report 9, Edition 2007, section 7and the requirements of the USM manufacturer.

The inside surface finish of piping upstream and downstream of the USM shall be 250inch Ra

or better and machined honed.

Page: 25 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Scope of ultrasonic Vendor shall include supply of upstream calibrated meter tubes and

downstream calibrated meter tubes, as required to guarantee fiscal metering system

uncertainty and requirements of ultrasonic vendor.

It shall be expected for the system to receive entrained liquids deposits.

The ultrasonic flow meters shall operate within the specified operating conditions to meet the

sales gas metering package uncertainty of less than 1% under all operating conditions and

over the whole flow range as permitted under the Gas Sales Agreement between the Seller

and Buyer of the Gas. Swirl and non-uniform velocity profile effects shall be reduced to an

insignificant level by proper installation of the meter.

Calculations necessary to calculate corrected volume, mass flow and energy flow rates shall

be performed by the flow computers and shall be in compliance with the flow equations of

AGA-7.

AGA-8 for the comparison of the meters reported SOS and AGA-10 for speed of sound

computing.

Field devices for flow metering service shall be 4-20mA, HART compatible type transmitters,

intrinsically safe. Field devices shall be wired to the flow computations via dedicated twisted

paired and individually screened and shielded cables.

The gas composition shall be determined by manual sampling and laboratory analysis at

regular intervals. The data will be manually input into the flow computer calculations and

additional online monitored with gas chromatograph from C1 up to C9.

5.2

Piping, Flanges, Gaskets and Bolts

All piping shall be contained within skid edge and shall be fabricated, assembled and secured

in position onto the skid prior to shipment. Process piping systems forming interconnections

between skid mounted equipment shall be designed in accordance with ASME B31.3.

External pipe work connections and pipe connections to all skid mounted equipment such as

gas filter, control valve and shutdown valve shall be flanged in accordance with ASME B16.5

and sized as appropriate to the service design conditions.

All Piping, Flanges, Gaskets and Bolts shall be designed in accordance to document number

1007-DISQ-0-L-SS-39010 Specifications for Piping Material.

The pipe work arrangement and connections to all equipment shall follow recommendations

stated in AGA Report 9, Edition 2007, Section 7 and the manufacturers requirements of the

USM.

Isolation and drain valves shall be provided in piping systems and around equipment in

accordance with the requirements of the applicable design code(s) where required to ensure

safe operation and/or adequate protection of equipment.

5.3

Painting

All equipment shall be painted and coated in accordance with Specification for Painting and

Protective Coatings 1007-DISQ-0-L-SS-39004.

A sufficient quantity of touch-up paint (10%) shall be supplied with the equipment to repair

minor damage to the paint finish after site installation.

Page: 26 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

5.4

Skid Assembly

As far as practical within the limits of manufacture, transportation and installation, all

equipment supplied as part of the Sales Gas Metering package shall be supplied fully

assembled and mounted on a common rigid welded steel skid base-frame calibrated and fully

pre-commissioned ex works in order to minimise site installation and hook-up.

The skid shall be completed with all equipment, interconnecting piping, pipe supports, fittings,

wiring, cabling, junction boxes, panels, metering cabinets as separated items but fully

pretested, instrumentation, control valves, blow down valves and shutdown valves as shown

on the P&ID- Metering Skid 1007-DISQ-0-P-DW-48059. All skid wiring and terminals shall be

labelled and wiring for connections shall terminate in appropriate junction boxes at the edge of

the skid.

In determining the equipment/package skid sizing, the Vendor shall take into account the

maximum permitted limits for road and rail transportation as defined within the material

requisition. The skid shall be suitable for mounting directly onto concrete foundations and the

metering cabinets on cabinet foundations in the equipment room of the control room building

(foundation details layout and dimensions and weight of metering cabinets to be handed over

to civil engineering of building designer).

Provision shall be made for venting of equipment where necessary.

The skid design and layout shall comply with project document number 1007-DISQ-0-M-SS42003, Package Equipment Specification.

5.5

Metering System Design Requirements

The Metering system shall be designed for continuous operation. Central Treatment Plant

(CTP) production will be continuous, 24 hours per day, 365 days per year.

The system shall be designed upon the philosophy of long term, trouble free operation with

minimum downtimes for maintenance only. Functionality for performance monitoring and

validation comparison of all instrumentation including flow meters, temperature and pressure

transmitters shall be included in the Metering system.

The Metering system shall contain diagnostic routines to alert the operator of component

failure, over range operation, invalid metering data and shall raise an individual alarms on the

DCS System.

5.5.1

Transient, Static and RFI Protection

Each element of the metering system shall operate normally and within the same

specifications, when subjected to an RFI test according to IEC 61000-4-3 test level/test field

strength (10 V/m) with a frequency range 26 MHz to 2000 MHz The total effects of the radio

frequency interference shall be equal or less than 0.1% of the output spans, with the

transmitter enclosure cover in place.

The vendor shall describe in his proposal the system transient immunity testing and

certifications that have been obtained.

Page: 27 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

5.5.2

Cabinet Design

The cabinet shall be Rittal type or similar. The cabinet shall include any cable marshalling and

shall be free standing, designed and constructed with sufficient strength and ruggedness to

support the equipment without flexing.

Cable entry to the cabinet shall be from the bottom, with a suitable cable clamping

arrangement and certified method for sealing the cabinet against dust and dirt entry. The

cabinet shall have front lockable doors and a suitable plinth. The cabinet shall be identified

with a nameplate on the front door.

The cabinet shall be supplied with cooling fans if necessary to maintain the cabinet interior

temperature a maximum of 10C above the maximum building environment temperature with

all internal equipment and external loads energised. Fan failures in the cabinets shall be

alarmed.

The cabinet shall be equipped with an internal light and continental 230 Volt, 50Hz, 1Ph, N, PE

outlet socket derived internally inside the metering cabinet from the main power supply input.

For the cabinet Earthing & Bonding Refer to Doc. No. 1007-DISQ-0-E-SS-27023 Electrical

specifications for packaged equipment.

The cabinet wiring shall be sized to suit the individual load requirements. All wiring shall run in

cable trays and cable ducts and transmission cables sized to provide at least 20% spare

capacity.

Adequate segregation shall be provided between the instrument analogue signals, the

instrument digital signals, NON-IS- and IS-Signals and the AC power wiring.

All terminating wiring shall be fitted with crimp tags. Terminals shall be Weidmueller SAKR or

similar knife-edge isolating terminals for incoming/outgoing low voltage/low current signals.

SAK type or similar shall be used for other signals. Fused indicating type terminals (e.g.

Weidmueller AFT or similar) shall be used for power.

The layout and identification of terminals for the field cable terminations shall be on a multicore cable basis, with all spare cores terminated.

5.6

System Software Design Requirement

The Gas Metering system software shall monitor the flow, pressure and temperature s of each

Metering Run/Stream. The software shall be able to calculate e.g. all other parameters,

convert uncorrected into corrected gas figures and shall be able to monitor and diagnose the

each meter stream and the whole system in accordance with AGA Report 9, Edition 2007

relevant sections.

The software shall be able to carry out the Performance QC test, Verification and Validation

process on a routine basis and if and when required by metering focal point of operations

company. Any changes in composition data shall be manually input into the system when

identified.

All measured, calculated and diagnostic data for each Metering Run shall be monitored by

DCS System via redundant Fibre optic cores links (FOC). The interface shall be redundant

and fully compatible with the selected DCS System.

Page: 28 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

5.7

Noise Limitations

The overall Sound Pressure Level from the package shall not exceed 80 dBA at 1 metre

distance from the skid edge. If necessary noise control measures shall be applied to the

equipment by the Vendor to ensure that these limits are adhered to. Where noise control

measures such as acoustic insulation or acoustic enclosures are required, these shall be

provided by the Vendor. These enclosures shall be easily removable without the need to

dismantle any part of the equipment or otherwise shall not obstruct operational or routine

maintenance activities.

The VDRF will require the vendor to confirm the predicted sound power level and maximum

overall sound pressure level in accordance with Noise Control Specification document number

1007-DISQ-0-F-SS-10018 and Egyptian environment law 04/2011, appendix 7.

5.8

Utilities

The design shall conform to the available site utilities and respective Utility Conditions

detailed in the process data sheets 1007-DISQ-0-P-DP-48131.

5.9

Material Certificate to Conformance (C&C)& Traceability

All field instrumentation shall be supplied with valid calibration certificates. The Vendor shall

provide (C&C) to ensure appropriate manufacturing systems and procedures are used to

ensure full traceability of materials (see Quality Assurance Plan, requirement No. 22). During

manufacture each assembled component shall be clearly and permanently marked in order

that it can be traced back to the originally supplied material certificate and its origin

determined.

5.10 Name plates

The Ultrasonic meter and all field instruments shall be equipped with a manufacturers

nameplate of 316 stainless steel permanently attached with stainless steel screws or rivets

indicating the specified data. In addition to specified data the following data shall be provided

which is a minimum:

Tag number

Serial number

Model number

Direction of flow

Flow Range

Number of Paths

Purchase Order Number

Manufacturers Name

Year of Manufacture

Other important design parameters ( e.g. medium and ambient operating temperatures )

Ingress Protection

Hazardous Area classification and certificate number

Page: 29 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

5.11 Climate Condition

The Sales Gas Metering Package shall be suitable to operate in the north delta climate

conditions as per Environmental Data and Units of Measurement, document number 1007DISQ-0-M-RT-42015.

The metering system shall be installed in the equipment room of the control room building with

the following conditions:

Normal HVAC conditions:

Temperature 22 C +/- 2 C.

Relative Humidity 40% to 60%

Design conditions:

Temperature 45 C.

Relative Humidity 80%

Electrical Requirements

6.1

General

Electrical equipment shall be provided in compliance with the codes & standards and in

accordance with Doc. No. 1007-DISQ-0-E-SS-27023 Electrical Specifications for Packaged

Equipment.

The insulating and dielectric materials used in all electrical equipment shall be non-toxic and

shall not contain components that are persistent and/or hazardous environmental

contaminants.

The design of the electrical installation and equipment shall ensure that easy and adequate

access is provided for all operational and maintenance purposes.

6.2

Power Supply Voltages

Refer to Doc. No. 1007-DISQ-0-E-SS-27023 Electrical Specifications for Packaged

Equipment.

6.3

Hazardous Area Requirements

Refer to Doc No. Document No. 1007-DISQ-0-F-DW-10012 Hazardous Area Classification

Layout.

6.4

Certifying Authorities

Refer to Doc. No. 1007-DISQ-0-E-SS-27023 Electrical Specifications for Packaged

Equipment.

6.5

Ingress Protection for Electrical Equipment

Refer to Doc. No. 1007-DISQ-0-E-SS-27023 Electrical Specifications for Packaged

Equipment.

Page: 30 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

6.6

Cabling

Refer to Doc. No. 1007-DISQ-0-E-SS-27023 Electrical Specifications for Packaged

Equipment.

6.7

Equipment Earthing & Bonding

Refer to Doc. No. 1007-DISQ-0-E-SS-27023 Electrical Specifications for Packaged

Equipment.

Page: 31 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Installation, Operation and Maintenance

7.1

Installation, Pre-commissioning and Commissioning

All installation, Pre-commissioning, commissioning and operating instructions for electrical,

instrument and mechanical equipment shall be included and indexed in the Installation, Precommissioning, Commissioning and Operating Manuals for the sales gas package in

accordance with Contract requirements as described in the Requisition.

The Vendor shall ensure that sufficient qualified personnel are at all times allocated to the

project. The Installation of the sales gas package shall be carried out with the assistance and

under supervision of the Vendor representative, any special tools required for installation, start

up, Pre-commissioning and commissioning and acceptance QC tests shall be provided by

Vendor.

7.1.1

Start-Up, Pre-commissioning and Commissioning Services

The Vendor shall provide services related to the Pre-commissioning, Commissioning and

Start-up of the Package equipment which shall include, but not be limited to, the following:

Verify proper package system components and installation

System power up

Perform diagnostics on all package components

Verify metering and control system

Verify overall integrity of the package system and the integrity with the ICSS as well

Verify proper package system operation

Submit detailed installation, start-up, Pre-commissioning, commissioning and

acceptance QC test reports for the sales gas package system and individual items as

required

All QC test and QC verification equipment shall be provided by Vendor.

7.2

Maintainability

The package shall be arranged to allow sufficient access for maintenance and operation. The

layout of the package shall reflect a compact ergonomic design with adequate spacing

between adjacent equipment and pipe work. The assembled skid shall be supplied with all

required access platforms, valves and instruments for safe operation and routine maintenance.

Adequate withdrawal space and/or removable pipe spools shall be provided, where necessary,

to permit removal and replacement of major components of the package.

Piping shall be arranged and supported so that the identified equipment maintenance items

can be removed without dismantling surrounding equipment other than removing spool pieces

adjacent to equipment connections.

All valves shall be located and arranged for operation from suitable access platforms or from

ground level.

The Vendor shall supply necessary special tools (i.e. withdrawal tools and associated cradles

as required) to enable periodic maintenance.

Page: 32 of 43

Onspec Engineering Solutions

Disouq Field Development Project

Specification

Sales Gas Metering Package

Instrumentation supplied with the equipment shall be located to permit easy access for

operation and maintenance.

7.3

Calibration

Ultrasonic Meters and Secondary Devices shall be QC calibrated as follows:

7.3.1

Ultrasonic Meters Calibration

Calibration of Ultrasonic Meter shall be calibrated at a certified High Pressure Calibration

Facility against a certified master meter with certified calibration and accuracy. The calibration

rig shall be approved by a recognized "Office for Weights and Measurements".

The Range ability of the Ultrasonic meter shall be > 100: 1.

QC Calibration shall be done in accordance with AGA Report 9, Edition 2007 and section 6 in

minimum.

The Vendor shall provide Ultrasonic meter calibration procedures and package calibration

procedures for company review and approval.

The individual meter and metering package performance and calibration curves, accuracy and

uncertainty shall be recorded. These records are an integral part of the documentation.

7.3.2

Secondary Devices

All secondary devices shall be delivered with valid calibration certificates. Adjustments to the

Pressure transmitter can be made on site but these should be limited to the zero and span

adjustments.

Temperature shall be measured by means of 4-wire PT100 which shall be connected to the

flow computer by temperature transmitter with head transmitter and two wire 4-20mA IS signal

which shall be HART compatible.

The output current of all instruments operating on a 4-20mA loop shall be checked by

measuring the output voltage across a precision resistor (+0.01%).

Analogue to digital converters are tested either by internal circuitry in the flow computer or by

measuring the voltage across a precision resistor with an applied current.

The calculation software of each flow computer must be checked and validated periodically.

The validation test software has to be supplied by the vendor.

7.4

Special Tools

All special tools, software and hardware required for the installation, adjustment, Precommissioning, commissioning, operation, validation, calibration and maintenance shall be

included in the Vendors scope of supply.