Академический Документы

Профессиональный Документы

Культура Документы

Fmea

Загружено:

Hani PatelОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fmea

Загружено:

Hani PatelАвторское право:

Доступные форматы

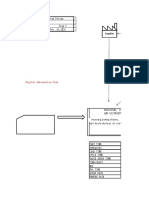

PME 640

FMECA

PROCESS FAILURE MODES EFFECTS AND CRITICALITY ANALYSIS

Process: Blending

Date:

Team Number:

6 Calibrate the equipment

150

6 Train the operator

30

Improper function of Butterfly

valve Rotation speed is not

adjusted IInadequate SOP to

how to operate blender

5 Calibrate the equipment

320

Inappropriate sampling method

Inadequatee training of operator

Rewrite the SOP for

sampling method

180

Inadequate training of operator,

3 Inadequate SOP for clening

after material discharging

Provide proper training of

the staff

45

There might be chances of mix up

and product contamination

Weighing of Raw Material

Weighing machine

Variation in the quantity of the raw

material

Uncalibrated weighing machine,

5 SOP is nor availlabe for

weighing of material

Charge the materia in to the Blender

Improper traing of the operator

Waste of the material

1 Improper traing of the operator

Blending of the Raw Material using suitable

blender

Blender

Improper blending of the raw

material

Take three samplle at the end of the blending

Operator

Can not predict the quality of the

product

Discharge final blend material

None

Waste of the material

Inadequate space for

Compounding

Notifyy the vendor

Follow SOP

Weighing

Charging

Blending

Sampling

Discharrging

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 1 of 3

Risk is easily detectable and

mix up can be avoided by

proving enough space for

compounding

I f there is less variation in

quantity of materials due to

weighing defects then there

is less chance that this going

to effect patient life

The waste of material is not

going to effect the life of the

patient

Improper mixiing of the

material may lead to

uniuniform distribution of the

API which may affect

significantely to the patients

life

Improper sampling may

effect the quality of the

product

Untrained staff effect the

quality of the product

RPN

Inadequate space for Compounding

Description of

Risk Analysis

Detection

36

Receive the Raw Material from the supplier

Dispensing of Raw Material according to

Formulation Requirements

Current Controls

Severity

Potential Cause(s)

Occurrence

RPN

Criticality

Potential Effect(s) of

Failure

Occurrence

Potential Failure Mode

Detection

Recieving & compounding

Step Description

Severity

Process Step

9/24/2014

Provide enough space for

compounding

Krunal 10/2/2014

Keep all components

separate to avoid

mixup

36

Do proper weighing of

components

Jaynita 10/02/2014

Calibration of weighing

machine

180

Give training to Operator

Megha 10/02/2014

Provrde traning

program for Operator

30

Revallidate the equipment

Hiren10/08/2014

Calibration of weighing

machine

320

Provide traning to operator

Alpa 10/02/2014

Revise a new SOP

27

None

Jahin10/02/2014

Provrde traning

program for Operato

45

Recommended

Action

Assigned To

and Target

Date

Quantitative

Post Action

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PME 640

FMECA

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 2 of 3

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PME 640

FMECA

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Page 3 of 3

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

Вам также может понравиться

- Basic Life Science Methods: A Laboratory Manual for Students and ResearchersОт EverandBasic Life Science Methods: A Laboratory Manual for Students and ResearchersОценок пока нет

- Crystallizer Methods of TestДокумент15 страницCrystallizer Methods of TestRegan Roldan RolaОценок пока нет

- PNS BAFS PAES 189 - 2018 Coffee Grinder Methods of TestДокумент25 страницPNS BAFS PAES 189 - 2018 Coffee Grinder Methods of TestAlfredo CondeОценок пока нет

- MunerДокумент8 страницMunermueen khanОценок пока нет

- UCM397228 Pharmaceutical Microbiology ManualДокумент91 страницаUCM397228 Pharmaceutical Microbiology Manualnsk79in@gmail.com100% (1)

- Fmea PosДокумент8 страницFmea PosGeovin Dexter Uy100% (1)

- Validation of Dry Powder MixerДокумент21 страницаValidation of Dry Powder Mixerdr3azzam60% (5)

- As-200 服务手册 v1.0 en PDFДокумент6 страницAs-200 服务手册 v1.0 en PDF袁崇山Оценок пока нет

- Haccp Yang YoghurtДокумент82 страницыHaccp Yang YoghurtLailatulMunawaroh50% (2)

- MB 15 04 PDFДокумент20 страницMB 15 04 PDFDeiiviid SoriaОценок пока нет

- MB 15 04 PDFДокумент20 страницMB 15 04 PDFDeiiviid SoriaОценок пока нет

- SMS LabДокумент64 страницыSMS LabDivya DiyaОценок пока нет

- Summary Report Listeria MonoДокумент29 страницSummary Report Listeria MonoGaraGeGameSОценок пока нет

- Safety Compliance Facility Information: August 15, 2018Документ23 страницыSafety Compliance Facility Information: August 15, 2018X69hotdogОценок пока нет

- Method 5b PDFДокумент4 страницыMethod 5b PDFMichael StevenОценок пока нет

- 2017LR75 - SUMMARY REPORT Final 03052020Документ130 страниц2017LR75 - SUMMARY REPORT Final 03052020Dung PhamОценок пока нет

- Fertilizer Applicator - Methods of Test PDFДокумент20 страницFertilizer Applicator - Methods of Test PDFEdsel Jay RaperОценок пока нет

- B PT Standards and Guidelines For The Statistical Treatement of PT DataДокумент7 страницB PT Standards and Guidelines For The Statistical Treatement of PT Datacarina.pintuxaОценок пока нет

- Oos Out of SpecificationДокумент12 страницOos Out of SpecificationShumaila Iftikhar100% (1)

- Print DurabilityДокумент3 страницыPrint DurabilityDoulat Ram100% (2)

- PAES 247 - Corn Dryer (MT)Документ21 страницаPAES 247 - Corn Dryer (MT)darrelОценок пока нет

- 2017LR66 - Compact Dry PA - Summary ReportДокумент29 страниц2017LR66 - Compact Dry PA - Summary Reportusaha online100% (1)

- Philippine National Standard: PNS/PAES 243:2010 (PAES Published 2010) ICS 65.060.01Документ23 страницыPhilippine National Standard: PNS/PAES 243:2010 (PAES Published 2010) ICS 65.060.01Felizardo GuiananОценок пока нет

- TC 005Документ17 страницTC 005Valya RusevaОценок пока нет

- Audit Checklist SOPДокумент43 страницыAudit Checklist SOPthemba100% (4)

- Pharmacuetical Microbiology Manual 2014 PDFДокумент86 страницPharmacuetical Microbiology Manual 2014 PDFteaОценок пока нет

- Lab. QAДокумент205 страницLab. QAMai HanyОценок пока нет

- Summary of Changes NSF 42 2012 2013 PDFДокумент6 страницSummary of Changes NSF 42 2012 2013 PDFNermeen ElmelegaeОценок пока нет

- SITHCCC001 - Written AssessmentДокумент22 страницыSITHCCC001 - Written Assessmentsantiagodsl1405Оценок пока нет

- SAC-SINGLAS 002 (JUNE 2018) : Guidelines For The Application of ISO/IEC 17025: 2017Документ8 страницSAC-SINGLAS 002 (JUNE 2018) : Guidelines For The Application of ISO/IEC 17025: 2017Michael AngОценок пока нет

- 3.6.7 Strongly Basic Rev 4Документ7 страниц3.6.7 Strongly Basic Rev 4Mark ReinhardtОценок пока нет

- PAES 227 - Micromill - TestДокумент22 страницыPAES 227 - Micromill - Testshuvatheduva123123123Оценок пока нет

- Protocol No 5 QC-guideline 2011-10-11 PDFДокумент23 страницыProtocol No 5 QC-guideline 2011-10-11 PDFcamila65Оценок пока нет

- Effect of Ethanolic Extracts of Andrographis PaniculataДокумент50 страницEffect of Ethanolic Extracts of Andrographis PaniculatajennitjuatjaОценок пока нет

- Drink Water MicrobiologyДокумент70 страницDrink Water MicrobiologyԼուսինե ՀովսեփյանОценок пока нет

- Out of SpecificationДокумент7 страницOut of SpecificationMichelle Morgan LongstrethОценок пока нет

- Pns-Paes 259-2011Документ23 страницыPns-Paes 259-2011shuvatheduva123123123Оценок пока нет

- BRC6 Global Food - Handling of Selected IssuesДокумент29 страницBRC6 Global Food - Handling of Selected IssuesJay Ar Madreliño TagiobonОценок пока нет

- SOP For Laminar Air Flow Workbench - PharmaguidelineДокумент2 страницыSOP For Laminar Air Flow Workbench - PharmaguidelineGopi NathОценок пока нет

- Body Fluid Unit Quality Control ProcedureДокумент7 страницBody Fluid Unit Quality Control ProcedureeferrarijrОценок пока нет

- ICH Quality Guidelines: An Implementation GuideОт EverandICH Quality Guidelines: An Implementation GuideAndrew TeasdaleОценок пока нет

- Cfb40503 Lab ManualДокумент21 страницаCfb40503 Lab ManualAziemah AulanОценок пока нет

- PV SDF 1 FdaДокумент111 страницPV SDF 1 FdaMelike EceoğluОценок пока нет

- SOP For Personnel Gowning QualificationДокумент3 страницыSOP For Personnel Gowning QualificationSunil Murkikar (GM - PMI Quality Operations)100% (1)

- Laboratory Skills Training HandbookДокумент166 страницLaboratory Skills Training Handbookcamable95% (21)

- Haccpfinalplan 190318173536Документ81 страницаHaccpfinalplan 190318173536sutharitessh100% (1)

- Sop Sero 01 Hiv TridotДокумент3 страницыSop Sero 01 Hiv TridotbhaveshdaveОценок пока нет

- General Topics: Related To Food Testing LaboratoriesДокумент9 страницGeneral Topics: Related To Food Testing LaboratoriessampathdtОценок пока нет

- Process Validation Sample ProtocolДокумент2 страницыProcess Validation Sample ProtocolAngel Cvetanov100% (2)

- Cyanide Spectroquant 114561 WW Method 1999 PDFДокумент20 страницCyanide Spectroquant 114561 WW Method 1999 PDFSantos Edwin Cari ApazaОценок пока нет

- SOP For Retest of Raw MaterialsДокумент3 страницыSOP For Retest of Raw MaterialsRainMan75Оценок пока нет

- PAES532 DefeatheringMachine MethodsofTestДокумент14 страницPAES532 DefeatheringMachine MethodsofTestFarouk PagsОценок пока нет

- US Environmental Protection Agency Office of Pesticide ProgramsДокумент17 страницUS Environmental Protection Agency Office of Pesticide ProgramsAngeles SuarezОценок пока нет

- Validation of Raw MaterialДокумент20 страницValidation of Raw MaterialMardiyati Alwi100% (1)

- Guideline Supplier Qualification - Dec09FINALДокумент34 страницыGuideline Supplier Qualification - Dec09FINALbach2007Оценок пока нет

- 2014 Electronic Cigarette Aerosol Parameters StudyДокумент89 страниц2014 Electronic Cigarette Aerosol Parameters StudyRigoberto CastroОценок пока нет

- Manual de Usuario GEM 3500Документ15 страницManual de Usuario GEM 3500Andrea PerezОценок пока нет

- Analysis of Food Toxins and ToxicantsОт EverandAnalysis of Food Toxins and ToxicantsYiu-Chung WongОценок пока нет

- True FalseДокумент3 страницыTrue FalseCarlo Paras100% (1)

- CIM LAB Manual-1 PDFДокумент40 страницCIM LAB Manual-1 PDFgagan100% (1)

- Company Profile & Clinte ListДокумент5 страницCompany Profile & Clinte ListPatel KuldeepОценок пока нет

- Chapter 7 - Operations ManagementДокумент31 страницаChapter 7 - Operations ManagementMaryjanedbn DlaminiОценок пока нет

- Sap PP Integration FlowДокумент2 страницыSap PP Integration Flowaunhavc0% (1)

- Cqi - 9Документ63 страницыCqi - 9karina medi100% (2)

- QuizДокумент33 страницыQuizHemant TejwaniОценок пока нет

- Simulation of Casting Solidification-1Документ2 страницыSimulation of Casting Solidification-1hayder1920Оценок пока нет

- Variable Costing - Lecture NotesДокумент22 страницыVariable Costing - Lecture NotesRaghavОценок пока нет

- Sol05 4eabc21133Документ73 страницыSol05 4eabc21133stillwinmsОценок пока нет

- Optimizing OEE, Productivity and ProductionДокумент14 страницOptimizing OEE, Productivity and ProductionAkbar TawaqqalОценок пока нет

- Centre Name & Number Date of Sample Eq06-01 Eqa Sampling PlannerДокумент6 страницCentre Name & Number Date of Sample Eq06-01 Eqa Sampling PlannerRajaОценок пока нет

- Using Value Stream Mapping ToДокумент12 страницUsing Value Stream Mapping ToAlexanderHFFОценок пока нет

- Managing Service and Manufacturing Operations: MGMT Chuck WilliamsДокумент11 страницManaging Service and Manufacturing Operations: MGMT Chuck WilliamsVivian_AntoОценок пока нет

- Activity Based Costing - AssignmentДокумент6 страницActivity Based Costing - Assignmentvalarrmathi0% (6)

- Advanced QFD LibreДокумент1 162 страницыAdvanced QFD LibreGermán Cárdenas AlvarezОценок пока нет

- Managerial Econ: Homework II SolutionsДокумент2 страницыManagerial Econ: Homework II SolutionsChrisОценок пока нет

- PPAPДокумент2 страницыPPAPPrasad K Nagarajaiah100% (1)

- Mathematical Programming-Based Sales and Operations Planning at Vestel Electronics (Final)Документ19 страницMathematical Programming-Based Sales and Operations Planning at Vestel Electronics (Final)adrianoooo34100% (1)

- Difference Between ISO9001 ISO29001Документ11 страницDifference Between ISO9001 ISO29001Ryan Heng100% (4)

- CS615 - Finalterm - by Dr. Tariq HanifДокумент14 страницCS615 - Finalterm - by Dr. Tariq HanifAbidОценок пока нет

- Chapter 2 Schoeder - Operations and Supply Chain StrategyДокумент19 страницChapter 2 Schoeder - Operations and Supply Chain StrategyMuhamad FuadОценок пока нет

- Supplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .Документ50 страницSupplier Assessment (F - 003 - QF-SQ-COM - 002 Rev. 02) .muthuselvanОценок пока нет

- Agile Software DevelopmentДокумент10 страницAgile Software DevelopmentrandyboyОценок пока нет

- Quality Improvement in Garments IndustryДокумент7 страницQuality Improvement in Garments IndustryGarmentLearner67% (6)

- VSM Current State MapДокумент5 страницVSM Current State MapMiljane PerdizoОценок пока нет

- Good Manufacturing PracticeДокумент5 страницGood Manufacturing PracticemadcatvamzОценок пока нет

- Manufacturing / Purchasing Information Status: Evaluasi - Supervisor - Memilih StaffДокумент4 страницыManufacturing / Purchasing Information Status: Evaluasi - Supervisor - Memilih StaffEmbun PagiОценок пока нет

- Demo of CE Technical File Document KitДокумент5 страницDemo of CE Technical File Document Kitrev2000Оценок пока нет

- Cost Accounting FinalsДокумент4 страницыCost Accounting FinalsJanine LerumОценок пока нет