Академический Документы

Профессиональный Документы

Культура Документы

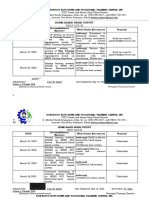

Operation Instructions Gear Boxes 2

Загружено:

Ninad MonparaАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Operation Instructions Gear Boxes 2

Загружено:

Ninad MonparaАвторское право:

Доступные форматы

THE POWER OF [E]MOTION

Operating, lubrication

and maintenance

instructions for

gearboxes and motors

Walther Flender Gruppe

Index of contents

Page 02

Page

General notes

Worm gears

Helical bevel gears, Type BH / MBH

Coaxial helical gears

Angular gears, light version

12

Angular gears, heavy version

13

Speed variators

14

Electronic motors

15

Troubleshooting Guide

21

Detailed informations about our products can also be found at

www.walther-flender-gruppe.com

Note: All information in this catalogue is provided without guarantee.

Technical details subject to change. Errors excepted.

Walther Flender Gruppe

Page 03

General notes

I. Assembly instructions

These instructions contain general notes applicable to all

types of gearing and power transmissions. Carefully observing these notes is essential to ideal running and a long service

life.

1. The drive unit shall without exception be installed in the

attitude specified in the order, since the lubrication concept

is set up for this arrangement.

2. All mating surfaces are to be carefully cleaned before

assembly; apply a cost of rust-protection grease to the

machinery and gearbox shafts.

3. When installing the gearing in close quarters it is necessary

to ensure that air flow to the surface of the case is not

restricted and the oil drain plug is accessible.

4. The mounting surfaces on the machine must be rigid,

absolutely flat and exactly at right angles to the center of

the shaft in order to avoid vibrations, tensions and bearing

damage.

5. Where bottom flange connections are used with direct

power transfer between the machine and the drive unit,

an elastic coupling should if at all possible be used in order

to compensate for any misalignment; otherwise particular

care will have to be paid to alignment in all planes. The

bolts for the bottom flange connectors may be tightened

down only after alignment is complete.

6. Where severe loading peaks are expected, with the hazard

of blocking, safety slip couplings (either frictional or oneway) or electronic overload and protective devices should

be installed.

II. Motor installation

The motor is to be connected in accordance with the diagram

found inside the terminal box cover or with the help of the

enclosed operating instructions. The motor overload protector is set for the rated motor current (see type plate). Make

sure that local voltage and frequency are identical with the

specifications given on the type plate.

III. Lubrication and maintenance

The instructions for gearbox lubrication and maintenance,

specific to the design employed, are to be observed. The

following general notes apply as well:

1. Before putting the gearbox into service, check to make

sure that there is sufficient lubricant for the intended

installation position. The installation position is specified

in the order. Please contact our technical office if this is

ever changed. It is necessary to keep the lubrication level

up to oil level screw.

Manufacturer

Environment

temperature

Lubricant

Load

IP

ESSO

AGIP

MOBIL

SHELL

BP

TEXACO

TOTAL

KLBER

-10C to +50C

Petroleum based oil

Medium

Mellana Oil 320

Spartan EP 320

Blasiaa 320

Mobilgear 632

Omala EP 320

Energol GR-XP 320

Meropa 320

Carter EP 320

Synthetic oil

Heavy

Mellana Oil 460

Spartan EP 460

Blasia 460

Mobilgear 634

Omala EP 460

Energol GR-XP 460

Meropa 460

Carter EP 460

2. Gearboxes which were not filled with lubricant at the factory will have to be filled with a lubricant suitable for the

gearbox design, as indicated in the table below

3. The oil fill volumes given for any particular installation attitude are only guideline values; the oil level shown in the

sight glass is authoritative.

4. Never mix up different sorts of lubricants or rather lubricants

of different manufacturers.

5. Petroleum based lubricants as synthetic lubricants are not

allowed to be mixed up; if gearboxes which had already

been run with petroleum-based lubricants are to be filled

with a synthetic product, then it will be necessary to flush

the inside of the gearbox beforehand in order to avoid

saponification.

6. The oil change intervals for the various gearbox designs

and sizes are to be observed (see the table on General oil

change intervals).

7. The oil should be warm when it is drained; flush the gearbox

before installing new oil.

8. The flanks of the toothing in a new gearbox will run in during the first few hours in service. This creates microscopic

particles which will contaminate the lubricant. That is why

we recommend changing the lubricant after the first 500

hours in service and flushing the gearbox before installing

new lubricant.

Storage

If longer periods out of service or in storage (particularly

outdoors, in salty air or in rooms with high humidity, wide

temperature fluctuations or corrosive vapors) are to be

expected, then a preservative agent will have to be applied to

the gearing and the motors and renewed at regular intervals.

In addition, the gearboxes will have to be filled completely

with lubricant and operated every two to three months or

the shafts will have to be turned through a few revolutions. It

will also be necessary to start the motors and braking motors

briefly several times at the same intervals.

The oil will have to be lowered to the prescribed level before

returning the system back to service.

General oil change intervals

Oil temperature

< 60 C

> 60 C

-30C to +100C

Operating mode

Continuous

Intermittent

Continuous

Intermittent

-40C to +120C

Synthetic grease

Medium and Heavy

Telesia Oil 150

S 220

Blasia 5

Glycoil 30

Tivela Oil WB

Energol SG-XP 220

Synoil CLP-220

Syntheso D220

Syntheso HT 220

Hours in operation

5000 h

8000 h

2500 h

5000 h

-10C to +60C

Medium and Heavy

Telesia Compound A

EGL 3818 A

Glycoil Grease 00

Tivela Compound A

Energrease G-SF

Glissando GF 1064

Structovis P Liquid

Walther Flender Gruppe

Worm gears

Page 04

Worm gears

Lifetime lubrication

Recommended synthetic lubricants

All worm gears and worm gear motors through to and

including size 90 are shipped with a lifetime lubricant fill

and thus are maintenance-free. Gearboxes as of size 110 will

have to be filled with oil before they are put into service.

Following consultation with the manufacturer, a lifetime

grease fill may be installed (see table at the right).

The Tivela SC 320 synthetic lubricant made by Shell is used

for gearboxes up to size I90.

Similar synthetic oils listed in the table may also be used.

Thanks to their excellent lubricant properties, these oils are

extremely dependable and will extend the service life of the

gearing.

Manufacturer

Operating temperature

Environment temperature

Lubricant

Type of loading

IP

- 40C + 130C

- 30C + 50C

Synthetic oil

Medium and heavy

Teliuml VSF

ESSO

Clycoil Liberange 220

FINA

Giran S 320

SHELL

Tivela Oil SC 320

KLBER

Syntheso D 220 EP

Oil quantity for worm gears

Gearbox size

I 30

I 40

I 50

I 60

I 70

I 80

I 90

I 110

I 130

I 150

I 175

Oil/Liters

0,03

0,095

0,163

0,384

0,44

1,05

1,4

2,5

Version

B3

V5

B8

V6

B6

B7

B51

B53

B52

V1

V3

Standard

A

Standard

B

Standard

V

Version

B5

F

FR

FBR

Standard

FP

Fill/vent screw

Oil level indicator

Drain screw

Walther Flender Gruppe

Worm gears

Page 05

Operating temperature

The operating temperature of the worm gear unit depends

on many factors, e.g. the mode of operation, lubricant, input

speed, power output and the ambient temperature at the

installation site.

After commissioning, the temperature of the housing may

be higher during the initial operating phase (ca. 300 hours)

of worm gear units.

Therefore it is recommended to apply a load of only 50-70%

during the break-in period of the worm gear units.

The operating temperature at the housing of a worm gear

unit can be as high as 50-60C without damage to the

housing.

The maximum internal temperature of a standard worm

gear unit can be as high as 80C. It is important to ensure

that the maximum permissible operating temperature is not

exceeded.

Higher temperatures can destroy the shaft seal rings and

impair the lubricating properties of the lubricant.

The standard seals used are NBR seals designed for temperatures between -40 and 100C.

Component overview I - MI 30

No.

1

2

3

4

5

6

7

8

Designation

housing

worm

worm gear (hollow shaft)

feather key

ball bearing (input)

ball bearing (output)

shaft seal (input)

shaft seal (output)

No.

9

10

12

15

16

17

20

21

Designation

circlip (input)

circlip (output)

bearing cover

motor flange

circlip (input M)

ball bearing (input M)

hexagon head screw

motor

Walther Flender Gruppe

Worm gears

Page 06

Component overview I 40 - I 70

No.

1

2

3

4

5

6

7

8

9

10

Designation

circlip

base plate

paper gasket

ball bearing

rear sealing cap

snap ring

ball bearing

worm wheel

housing

OR ring

No.

11

12

13

14

15

16

17

18

19

20

21

Designation

hexagon nut

motor flange

hexagon head screw

circlip

hexagon head screw

hexagon head screw

paper gasket

worm

Flange FP

feather key

ball bearing

Walther Flender Gruppe

Worm gears

Page 07

Component overview I 80 bis I 175

A (B or V)

No.

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

16C

17

18

19

20

21

22

23

24

26

FBR

Designation

Output flanges connection srew

Output shaft seal

Output ball bearing

Wormwheel on the hollow shaft

Plug gasket

Oil discharge plug

Level plug

Closed cover (worm rear side)

Fixing screws for worm covers

Output cover

Solid output shaft (optional)

Key on the shaft extension

Key on the internal side

Lockwasher (for cover screws)

Front worm bearing

Rear worm bearing

Oil loading plug

Housing

Worm (I version)

Worm key (I version)

Input cover (I version)

Input shaft seal

Worm (version PAM)

Motor connection flange

(vers. PAM)

Foot

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

16C

17

18

19

20

21

22

23

24

FP

Designation

Output flanges connection srew

Output flange

Output shaft seal

Output ball bearing

Wormwheel on the hollow shaft

Plug gasket

Oil discharge plug

Level plug

Closed cover (worm rear side)

Fixing screws for worm covers

Output cover

Solid output shaft (optional)

Key on the shaft extension

Key on the internal side

Lockwasher (for cover screws)

Front worm bearing

Rear worm bearing

Oil loading plug

Housing

Worm (I version)

Worm key (I version)

Input cover (I version)

Input shaft seal

Worm (version PAM)

Motor connection flange

(vers. PAM)

No.

1

3

4

5

6

7

8

9

10

11

12

13

14

15

16

16C

17

18

19

20

21

22

23

24

25

Designation

Output flanges connection srew

Output shaft seal

Output ball bearing

Wormwheel on the hollow shaft

Plug gasket

Oil discharge plug

Level plug

Closed cover (worm rear side)

Fixing screws for worm covers

Output cover

Solid output shaft (optional)

Key on the shaft extension

Key on the internal side

Lockwasher (for cover screws)

Front worm bearing

Rear worm bearing

Oil loading plug

Housing

Worm (I version)

Worm key (I version)

Input cover (I version)

Input shaft seal

Worm (version PAM)

Motor connection flange

(vers. PAM)

Flat flange

Walther Flender Gruppe

Helical bevel gears

Page 08

Helical bevel gears, Type BH / MBH

The helical bevel gear units are delivered without oil,

but can be filled with synthetic oil at the request of the

customer.

Select the oil grade according to the lubricant chart; the oil

quantity depends on the size and type of the gear unit and

the installation position.

Synthetic oils are especially suitable for long-term lubrication with longer inspection intervals. Depending on the

load classification and operating temperature, inspection

intervals of six months to one year are recommended. Noise

and temperature must be checked during operation and the

oil level must be checked when the gear unit is stopped.

Heavy accumulation of dirt prevents heat dissipation and

therefore must be removed. If oil leaks on the seal faces,

replace the seals or, in the case of flange seals, tighten the

flanges.

At operating temperatures above 85C, shaft seal rings

made of fluoroplastic are required.

Installation positions

Oil quantity (litres)

Installation

positions

B3

B6

B7

B8

V5

V6

BH

63

1,8

2,8

3,0

2,0

1,8

1,9

80

3,6

4,8

4,1

3,6

2,7

2,9

100

7,1

9,3

8,5

5,9

5,0

5,7

125

11,0

15,0

13,0

8,5

7,8

9,0

140

20,4

24,4

23,0

15,0

15,0

16,2

160

31,0

40,0

32,0

15,5

14,0

16,5

Walther Flender Gruppe

Helical gears

Page 09

Helical gears Type MNHL

Lubrication

Recommended lubricants

Lubrication is forced by the rotary movements and by oil

vapours which are formed inside the gear unit.

The oil quantity depends on the installation position and

can be checked at the oil level sight gauge.

Since proper lubrication is necessary to ensure high efficiency and a long service life, you should always follow the

recommendations when choosing a lubricant.

Mineral oils

Since some impurities of the lubricant occur during the

initial operation of newer gear units, it is recommended to

change the lubricant after the first 500 hours of operation

and to flush the gear unit before refilling it. The following

intervals are recommended for changing the oil:

Oil temperature

< 60C

> 60C

Mode

of operation

continuous

intermittent

continuous

intermittent

Hours of

operation

5000 h

8000 h

2500 h

5000 h

Mineral oils

Oil type

IP

SHELL

MOBIL

ESSO

MELLANA OIL 220

OMALA OIL 220

MOBILGEAR 630

SPARTAN EP 220

Ambient temperature:

Operating temperature:

-5C / +35C

-5C / +80C

Comment:

Never mix synthetic oil with mineral oil; also, synthetic oil

is not compatible with nitrocellulose paints and natural

rubber seals.

The oil quantity depends on the installation position and

can be checked at the oil level sight gauge.

Synthetic oils

Manufacturer

Oil type

IP

SHELL

Klber

TELIUM OIL 320

TIVELA OIL 320

SYTHESO D 320 EP

Ambient temperature:

Operating temperature:

-30C / +50C

-40C / +130C

Installation

position

Size

20/2

25/2 25/3

30/2 30/3

35/2 35/3

40/2 40/3

B3

B5

B6

B7, B8

V1, V3

V5, V6

0,4

1,3

2,0

1,9

2,0

0,5

1,2

1,9

1,8

2,0

0,7

1,3

2,2

2,0

2,2

Weights in kg

20/2

25/2

30/2

35/2

40/2

4,5

15,5

26

28

35

25/3

30/3

35/3

40/3

14,5

25,5

27,5

34

Walther Flender Gruppe

Helical gears

Helical gears

General installation positions

Page 10

Walther Flender Gruppe

Helical gears

Page 11

Installation positions

Only for type MNHL 20, 25 and 30-35

Only for MNHL 20

Only for MNHL 25

Only for MNHL 30-35

Walther Flender Gruppe

Angular Gears

Page 12

WF angular gears light version

All WF angular gears are delivered from the factory with

lubricant installed. Size DZ 1 is lifetime-lubricated with

AGIP GR SLL synthetic grease; all other sizes are filled with a

petroleum-based oil (AGIP BLASIA 100).

There is positive lubrication due to the rotation of the components. It is advisable to replace the lubricating oil after the

first 500 hours in service and to flush the gearbox.

It is recommended that the oil be changed every 3,000

hours in service thereafter. It is absolutely necessary to flush

the inside of the gearbox before installing a synthetic oil in

order to avoid saponification.

Important: Never mix up different sorts of lubricants or

rather lubrications of different manufactures.

Lubrication chart

Gearbox size

Lubricant type

Ambienttemperature

DZ 1

DZ 2 bis DZ 5

Synthetic grease Petrolium-based oil

-10 C + 60 C

-10 C + 50 C

Lubricant selection

GR SLL

Blasia 100

EGL 3818 A

Spartan EP 100

Tivela Compound A

Omala 100

Glycoil Grease 00

Mobilgear 627

Structovis liquid Lamora Gear oil 100

AGIP

ESSO

SHELL

MOBIL

KLBER

Lubricant quantity

Gearbox sizes

Fill quantity

DZ 1

15 g

DZ 2

30 ml

DZ 3

DZ 4

DZ 5

150 ml 180 ml 200 ml

Walther Flender Gruppe

Angular Gears

Page 13

WF angular gears heavy version

The bevel gears will be delivered with grease lubrication for

input speeds of up to 1,000 rpm.

Lubricant quantity / Gearbox weights

In all other cases (please indicate when ordering), oil

lubrication will be provided. The bevel gears in this case

will be delivered with an oil filler plug, vent screw, oil level

screw and drain screw. This makes it necessary to specify the

installation attitude.

Implementing positive lubrication is recommended at high

input speeds.

Size

BG 12

BG 19

BG 24

BG 32

BG 38

BG 42

BG 55

BG 75

Grease

(Liters)

0,15

0,22

0,35

0,90

1,70

3,50

5,50

14,00

Oil

(Liters)

0,10

0,15

0,22

0,60

1,10

2,20

3,60

9,00

Weight

(kg)

2,5

6,0

12,0

22,0

37,0

57,0

87,0

255,0

Since the lubricant will be contaminated to a certain extent

during initial service, we recommend replacing the lubricant

after the first 500 hours in service and to flush the gearbox

before installing new lubricant.

Recommended lubricants

The following table lists the recommended lubricant quantities, referenced to the gearbox size and input speed. These

specifications are valid for ambient temperatures of from 0 to +35C.

BG 12

BG 19

BG 24

BG 32

BG 38

BG 42

BG 55

BG 75

0 to 100

Grease

Grease / B / 2

Grease / B / 2

Grease / B / 2

Grease / B / 2

Grease / A / 1

A/1

A/1

100 to 400

Grease

Grease / C / 3

Grease / B / 2

Grease / B / 2

Grease / B / 2

Grease / B / 2

A/1

A/1

Speed (rpm)

400 to 700

Grease

Grease / C / 3

Grease / C / 3

Grease / C / 3

Grease / B / 2

Grease / B / 2

B/1

B/1

700 to 1000

Grease

Grease / C / 3

Grease / C / 3

Grease / C / 3

Grease / C / 3

Grease / C / 3

B/2

B/2

1000 to 1500

1500 to 3000

Grease

Grease

Grease / D / 4

Grease / D / 4

Grease / D / 4

D/4

Grease / C / 3

D/4

C/3

C/3

C/3

C/3

B/2

*)

*)

*)

*) Not suited for these speeds.

Quality

A

B

C

D

ISO VG at 40C

320

220

150

68

Mobil

Mobilgear 632

Mobilgear 630

Mobilgear 629

Mobilgear 626

Petrolium-based oil

Shell

Omala Oil 320

Omala Oil 220

Omala Oil 150

Omala Oil 68

IP

Mellana 320

Mellana 220

Mellana 150

Mellana 68

Esso

Spartan EP320

Spartan EP220

Spartan EP150

Spartan EP 68

Quality

1

2

3

4

ISO VG bei 40C

320

220

150

68

IP

Enersyn EPX 320

Enersyn EPX 220

Enersyn EPX 150

Tribol

1510/320

1510/220

Grease

Quality

Mobil

Petroleum-based Mobilux EP 004

Synthetic

Gligoyle Grese 00

Synthetic Oil

Mobil

Shell

SHC-632

SHC-630

Tivela Oil WB

SHC-629

Tivela Oil WA

SHC-626

Esso

Beacon EP 2

1510/68

Tribol

1100/320

1100/220

1100/68

Walther Flender Gruppe

Speed variators

Page 14

Speed variators

The oil in speed variators will have to be replaced after the

first 100 hours in service and every 1,000 operating hours

thereafter. Here it is always necessary to check ensure that

the fill level comes to the middle of the sight glass.

All downline gearboxes in the R1 Series (single-stage), the

R2 Series (two-stage) and the R3 Series (three-stage), in sizes

40, 50 and 63, are filled with a long-life lubricant and thus

have only oil filler and drain screws and no sight glass.

The R2 and R3 Series gearboxes in sizes 80, 100 and 125 are

delivered filled with oil and will require an oil change after a

run-in period of between 500 and 1,000 hours in operation.

The inside of the gear case will have to be cleaned thoroughly before installing new oil. Subsequent oil changes are

required every 4,000 hours in service.

The gear cases are fitted with one each oil filler, drain and

vent screw. To avoid oil losses during shipping the vent

opening is closed with a blind screw. This will have to be

removed and replaced with the supplied vent screw (see

Installation attitude illustration) before putting the unit

into service.

Lubricant quantity, dependent on the installation guide

SC-SF-ST

03

05

10

20

30/50

100

B3-B5-B6-B8

0,150

0,210

0,360

0,600

1,200

2,000

Installation guide

V1-V5

0,210

0,330

0,680

1,070

2,150

3,580

Recommended lubricants

V3-V6

0,225

0,330

0,360

0,600

2,150

3,840

DEXRON FLUID II 1)

A.T.F. DEXRON FLUID

A.T.F. 220

A.T.F. DEXRON

BP AUTRAN DX

A.T.F. DEXRON

A.T.F. DEXRON

A.T.F. DEXRON

IP 1)

SHELL

MOBIL

FINA

BP

ESSO

CHEVRON

AGIP

1) Lubricant

installed at the factory

Lubricant quantity for downline coaxial gears

R1 gearing

SRT

SRF-SRM

Oil quantity

03/1 - 40

05/1 - 50

10/1 - 63

20/1 - 80

30/50/1-100

100/1-125

0,100

0,38

0,650

1,000

1,400

1,800

Oil type

R2-R3 gearing

Manufacturer

ATINA

GREASE 0

IP

SRT-SRF

2-40

3-40

2-50

3-50

2-63

3-63

2-80

3-80

2-100

3-100

2-125

3-125

Oil quantity

Oil type

Manufacturer

0,300

0,800

TELESIA

COMPOUND A

1,300

IP

2,100

4,200

MELLANA

OILS

6,300

Installation position

B3

B6-D

B5-S

B5

V1

V5

V6

V3

Vent screw

Oil fill screw

Drain screw

Sight glass

B8

Walther Flender Gruppe

electric motors

Page 15

electric motors

Electrical connection Star/delta circuit

Star-Delta connection

Before connecting to the line supply, ensure that the line

voltage is identical with the specifications on the motors

data plate.

The motor shall be properly wired at the terminal box

and in accordance with the schematic shown for 3-phase

AC motors.

If the direction of rotation is not correct then it can be

reversed by interchanging two hot wires..

Voltage/Frequency

Unless stated otherwise with the order, three-phase current motors are wound for a voltage of 230/400 V, 50 cycles

10 %, as standard. Threephase current motors wound for

the 50 Cycles mains frequency can also be connected to a

60 cycles mains network.

This exludes brake motors, explosion-protected motors

and single-phase motors.

The tables below give the data, taking into account the

voltage or frequency change.

Variable data depending upon mains frequency

Motorwinding

230

50 Hz

400 V

50 Hz

Motorpower

supply

230 V

V60 Hz

265 V

60 Hz

400 V

60 Hz

460 V

60 Hz

kW

n1

Nominal

torque

Acceleration

torque

100 %

120 %

100 %

83 %

83 %

115 %

120 %

100 %

100 %

100 %

100 %

120 %

100 %

83 %

83 %

115 %

120 %

100 %

100 %

100 %

Walther Flender Gruppe

electric motors

Page 16

Operating Connections for Three-Phase Motors

Windings

configuration

220/380 Y

230/400 V

380 Y

400 Y

500 Y

500

380 /660 Y

400 /690 Y

660 Y

690 Y

Operating

voltage

at 50 Hz

220

380

230

400

380

400

500

500

380

660

400

690

660

690

With squirrel

cage roto

for direct

switch on

220

380 Y

230

400 Y

380 Y

400 Y

500 Y

500

380

660 Y

400

690 Y

660 Y

690 Y

Winding configuration 230 V/400 VY

Direct switching on at operating voltages of

fr Y/

Anlauf

220

_

230

500

380

400

-

230 V

400 V

Connection

Y-Starting at

operating voltage of

230 V

The ends of the three

of the

winding legs

winding

go to a Y switch

legs

Connection

on the

terminal

board

D-Connection

Y-Connection

YD-Connection

General Bearing Information

In the standard configuration, the motors are quipped with

C3 bearing. For motors whose bearings are subjected to extremely low or extremely high temperatures, special grease

and/or special bearings must be used.

Bearing Lubrication

Closed Bearings

The motors of the construction group 56 to 160 are

equipped with closed bearing and therefore cannot be relubricated. For this reason, these bearings must be replaced

after the fatigue service life or grease service life expires

(see table). In the standard configuration, our motors are

delivered with 2Z bearing with a lubricant with a reference

temperature of 85 C. Also with regard to other factors such

as contamination and the effects of humidity, the renewal of

2Z bearings is recommended at least every four years.

Re-lubrication Intervals

The Re-lubrication intervals depend to a large degree on the

speed, the bearing loading, the environmental factors and

the mounting of the motor. For re-lubricating, the recommendations of the bearing and grease manufacturers are to

be observed. For motors with vertical mounting, the re-lubrication interval must be halved. For bearing temperatures

that are higher than the reference temperature of the grease

used, the re-lubrication interval must be halved for each 15

C of temperature increase. For lower bearing temperatures,

a longer re-lubrication period is adequate, however, should

not be longer than double the value given.

Walther Flender Gruppe

electric motors

Page 17

Electromagnetic DC injection brake Type CAR

Description

Adjustment

The electromagnetic DC injection brake brakes effectively

without electric power. The permissible deviation from the

nominal supply voltage is 10% V.

Various adjustments can be made:

Air gap adjustment

The distance of the air gap T between the solenoid (7) and

the moving armature (12) must be within 0.15 to 0.40 mm.

The distance can be adjusted by means of the threaded

bushes (11). A distance meter can be used to check whether

the air gap has been adjusted correctly.

Adjusting the braking torque

The braking torque is adjusted by means of the adjusting

nut (6). If the release lever (5) is installed, the lever travel has

to be adjusted by means of the lever mounting screws as

soon as the braking torque has been set and before releasing the lever.

(5)

(6)

(7)

(10)

(11)

(12)

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(T)

Release lever

Adjusting nut

Solenoid

Adjustable springs

Threaded bush

Moving armature

Mounting screws

Brake disk

Pusher

Dust protection ring

Stainless steel disk

Motor flange

Motor shaft

Air gap

Walther Flender Gruppe

electric motors

Page 18

Electromagnetic DC brake (three-phase brake) Type CAR

Description

Adjustment

The electromagnetic DC brake brakes effectively without

electric power. In the standard model, the supply line for the

brake coil is connected to the terminal board of the motor.

The standard voltage of the brake group is 230/400 V 10%

50 Hz. Braking takes place without voltage.

Various adjustments can be made:

Air gap adjustment

The distance of the air gap T between the solenoid (1) and

the mobile armature (2) must be within 0.30 to 0.40 mm.

The distance can be adjusted by means of the mounting

screws (10) and the mounting nuts (11). A distance meter

can be used to check whether the air gap has been adjusted

correctly.

Adjusting the braking torque

The braking torque is adjusted by means of the stud screws

(12), with a change for each 1/4 turn of the screw. If the release lever (5) is installed, the lever travel has to be by means

of the lever fastening bolts as soon as the braking torque

has been set and before releasing the lever.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(T)

Solenoid

Moving armature

Brake disk

Pusher

Release lever

Dust protection ring

O-ring

Counter spring

Spacer tube

Brake mounting screw

Blocking nut

Stud screw

Mounting screws for

the aeration lever

Compression spring

Air gap

Walther Flender Gruppe

electric motors

Page 19

Brake Group BA-CF Series

AIR GAP ADJUSTMENT

The air gap

, i.e. the distance between the 2 magnetics

cores, brake coil

and brake moving element

, must

be 2-4 tenths of a millimeter. It is unadvisable to exceed

this value in order to avoid vibrations of the brake moving

element and, probably, the burning of the brake coil. It is

advisable to check periodically the air gap, because by the

wear of the brake disc linings, it tends to increase. In order

to set the air gap back to the required value, operate on

the nut

to obtain the brake coils forward displacement

towards the brake moving element. When this operation has

been settled, the locknut

should be tightened.

BRAKING TORQUE ADJUSTMENT

The braking torque is proportional to the springs

compression, which can be varied operating on locknut

. The

compression of the three springs must be as even as possible. If the brake coil

isnt able to call the brake moving

element

back with a quick stroke and keep it attracted

without vibrations, verify the exact air gap adjustment and,

if this inconvenience still persists, loosen the locknut

of two threads and try it again until desired functioning is

obtained.

Brake

The motors of series BA are delivered with threephase

AC brakes. On request the motors can be supplied with

DC brakes. Those differ from the AC brakes by the electromagnet and the rectifier, through which the feeding

take place.

Both types of brakes can be feeded also at motor full stop

at no time limit.

The threephase brake AC will brake fast and exactly, whilst

the DC brake is breaking steady and smooth.

The motors are delivered with the basic connection per

scheme A.

If there is desired a fast braking the connection must be

done per scheme B.

white

white

red

grey o. brown

black

white

white

red

grey o. brown

black

brake coil

brake coil

Schema A

Schema B

Wiring Diagram

Double Terminal Board

Single Terminal Board

BA

- A.C. Brake -

BA

- A.C./D.C. Brake -

BA

- D.C. Bremse -

Brake

Motor

Brake +

Motor

Brake

Rectifier

Motor

Walther Flender Gruppe

electric motors

Page 20

Spare parts list Type BA & CF (three-phase brake)

1

2

3

4

6

7

8

9

11

12

15

17

18

19

20

21

22

23

24

25

26

27

Rotor

Key

Front bearing

Front cover (B3)

Tie rod assembly

Frame

Circlip

Rear cover

Fan

Fan assembly

Rear bearing

Reat cover (brake surface)

Spring

Brake adjuster

Braking torque adjusting locknut

Air gas adjusting nut

Locknut

Brake disc

Brake moving elment

Brake coil

End cover (BA-CF)

Hexagonal rear nut

28

29

30

32

34

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Terminal board box screws

Terminal board box (single or double)

Terminal board

Cable gland

Terminal box/brake coil connection

Flange cover (B5)

Flange cover (B14)

Elastic washer

Brake disc (BAF-CFF)

Intermediate brake surface (BAF-CFF)

Intermediate brake disc (BAF-CFF)

Long brake adjuster (BAF-BAPV-CFF-CFPV)

Spacer (BAPV-CFPV)

Taper bush (BAPV-CFPV)

Flywheel (BAPV-CFPV)

Elastic washer (BAPV-CFPV)

Taper bush fixing screws (BAFV-CFPV)

Long end cover (BAF-BAPV-CFF-CFPV)

Brake release

Fulcrum hub for brake release (available on request)

"T"-key for manual shaft rotation (available on request)

Walther Flender Gruppe

Gearmotors

Page 21

Troubleshooting Guide

This chart contains malfunctions that may arise during operation. They are listed according to the individual functions

of the gearbox. The trouble, causes and part that may have

caused the fault are indicated in the chart.

Problem

Possible Causes

Remedy

The motor does

not start

a) The motors electrical wiring is faulty

b) The motor is faulty

c) Wrong size motor

a) Check the connections

b) Replace the motor

c) Replace the motor

a) Mechanical overload

a) Check the mechanical parts

driven by the geared motor

assembly

b) Replace the geared motor

assembly

The motor and gearbox

reach temperatures which

are too high

The current absorbed

and/or the temperature

of the motor are too high

The gearbox reaches

a tem perature which is

too high

Oil leaks from the shafts

Oil leaks from the seals

The gearbox is making a

banging noise

b) Wrong size geared motor assembly

a) Motor faulty

b) Wrong size motor

a) Replace the motor

b) Replace the motor

a) Gearbox faulty

b) Wrong size gearbox

c) Wrong mounting position

a) Repair or replace the gearbox

b) Replace the gearbox

c) Check that the gearbox

supplied is that ordered

d) Add lubricant until the level

d) Not enough lubricant

indicated is reached

a) Ring seals worn down or defective

b) Seal seat on the shaft worn

a) Replace the ring seals

b) Replace the ring seals and install them

in a very slightly different position or

replace the shafts

a) Flanges not tightened properly

b) Seals defective

a) Tighten the flanges

b) Replace the seals and check that the

surfaces are properly machined

a) Gear teeth defective

a) Not enough lubricant

b) Gears defective or worn down

The gearbox is whistling

c) Bearings defective or not installed

properly

a) Contact our customer service

department

a) Add lubricant until the level indicated

is reached

b) Contact our customer service

department

c) Contact our customer service

department

Walther Flender Gruppe

Postfach 13 02 80

Schwarzer Weg 100107

40593 Dsseldorf

Deutschland

Tel. : +49.(0)211.70 07-00

Fax: +49.(0)211.70 07-227

E-Mail: info@walther-flender.de

eng _bedSchmWarAnl_Dez 2010

www.walther-flender-gruppe.de

Вам также может понравиться

- Shear Modulus (With Torsiometer)Документ19 страницShear Modulus (With Torsiometer)Irvin IrawanОценок пока нет

- Activity 1.1.5b Circuit Theory: SimulationДокумент4 страницыActivity 1.1.5b Circuit Theory: SimulationParkerОценок пока нет

- Cat 307D Main Pump OperationДокумент3 страницыCat 307D Main Pump Operationkahandawala100% (1)

- Tad 722 GeДокумент2 страницыTad 722 GePaulo César Managó100% (1)

- Subsea Pipeline Design Report.Документ26 страницSubsea Pipeline Design Report.Luke6nОценок пока нет

- Couplings and ClutchesДокумент14 страницCouplings and ClutchesBhotka BhutkiОценок пока нет

- Renewable Energy Sources: Presented ByДокумент56 страницRenewable Energy Sources: Presented Byjkl417Оценок пока нет

- Gear Trains - Lecture 10Документ22 страницыGear Trains - Lecture 10priyankar007Оценок пока нет

- Dismantling and Assembly GuideДокумент44 страницыDismantling and Assembly GuideRadu Babau100% (1)

- PDF ViscosityДокумент18 страницPDF ViscosityTobyBorlandОценок пока нет

- Parilla x30 Overhaul ManualДокумент38 страницParilla x30 Overhaul ManualCarolina MatosОценок пока нет

- Engineering Materials by McalisterДокумент17 страницEngineering Materials by McalisterHamza KhalidОценок пока нет

- 1/27/2014 Hareesha N Gowda, Asst. Prof, Dsce, Blore-78 1Документ25 страниц1/27/2014 Hareesha N Gowda, Asst. Prof, Dsce, Blore-78 1Sameer SonuОценок пока нет

- Pipe and Pipe Fittings in Hydraulic SystemДокумент11 страницPipe and Pipe Fittings in Hydraulic SystemAaryan PawarОценок пока нет

- Unit 5 Hydro Electric Power StationsДокумент18 страницUnit 5 Hydro Electric Power Stationsapi-244568835100% (1)

- Pte Mag PDFДокумент68 страницPte Mag PDFhollowОценок пока нет

- Destructive and Non-Destructive TestingДокумент17 страницDestructive and Non-Destructive TestingBhargav ChaitanyaОценок пока нет

- Common Vaillant Boiler Error CodesДокумент6 страницCommon Vaillant Boiler Error CodesAdnan DuricОценок пока нет

- Module-II 2.gear DrivesДокумент36 страницModule-II 2.gear Drivesvanishree n100% (1)

- Quality Within Higher Education 2017 Summary ReportДокумент52 страницыQuality Within Higher Education 2017 Summary ReportCentras CentrasОценок пока нет

- Beam Deflection AssignmentДокумент4 страницыBeam Deflection AssignmentTalha KhanОценок пока нет

- 4 Types of DC Motors and Their CharacteristicsДокумент5 страниц4 Types of DC Motors and Their CharacteristicsNuno HenriquesОценок пока нет

- BITS Pilani: Engineering Materials: ENGG ZC 232Документ49 страницBITS Pilani: Engineering Materials: ENGG ZC 232Amit SinghОценок пока нет

- Basics of Belt DrivesДокумент12 страницBasics of Belt DrivesSrinivasan Ravi100% (1)

- Unit V: - TurbinesДокумент56 страницUnit V: - TurbinesparthibankОценок пока нет

- Bearing IntroductionДокумент62 страницыBearing IntroductionsbkulkОценок пока нет

- FrictionДокумент9 страницFrictionjarvis007Оценок пока нет

- Coupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, SeeДокумент24 страницыCoupling: This Article Is About A Mechanical Connection Between Two Objects. For Other Uses, Seerupesh8989Оценок пока нет

- Couplings in MechatronicsДокумент23 страницыCouplings in MechatronicsRavindra MahadeokarОценок пока нет

- Eddy Current BrakesДокумент24 страницыEddy Current BrakesMd Jawed AkhtarОценок пока нет

- 2009 - Todorov, Dobrev, Massouh - Analysis of Torsional Oscillation of The Drive Train in Horizontal-Axis Wind TurbineДокумент7 страниц2009 - Todorov, Dobrev, Massouh - Analysis of Torsional Oscillation of The Drive Train in Horizontal-Axis Wind TurbineLivrosScrОценок пока нет

- Chapter 1 Pneumatic SystemДокумент95 страницChapter 1 Pneumatic SystemNazer Mangirapin BarisОценок пока нет

- National Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsДокумент24 страницыNational Skill Training Institute, Mumbai: Draughtsman Mechanical, CitsNitin B maskeОценок пока нет

- Flywheel 2Документ6 страницFlywheel 2LegendaryNОценок пока нет

- Considerations in Greasing Electric Motor Anti Friction BearingsДокумент5 страницConsiderations in Greasing Electric Motor Anti Friction BearingsSam ChengОценок пока нет

- The Pneumatics Installation Guide: Festo Worldwide WWW - FestoДокумент216 страницThe Pneumatics Installation Guide: Festo Worldwide WWW - FestorzezniccОценок пока нет

- Quality Assurance Handbook: Education CommitteeДокумент49 страницQuality Assurance Handbook: Education CommitteeEzana EzanaОценок пока нет

- BOOK 2, CHAPTER 22 - Synchronizing Cylinder MovementДокумент31 страницаBOOK 2, CHAPTER 22 - Synchronizing Cylinder MovementJuan Emanuel VenturelliОценок пока нет

- Expansion Valve and TypesДокумент36 страницExpansion Valve and Typeskaacho piece pieceОценок пока нет

- The Electrical Portal: Testing of DC MotorДокумент2 страницыThe Electrical Portal: Testing of DC MotorGayathri Devi Yadav NakanaboyinaОценок пока нет

- SKF SphericalДокумент72 страницыSKF SphericalNath BoyapatiОценок пока нет

- 6-2 Machining Processes IДокумент44 страницы6-2 Machining Processes IOmar Ahmed100% (1)

- Measurement of Screw ThreadsДокумент21 страницаMeasurement of Screw ThreadsAnthony LopesОценок пока нет

- Bearing Current in VFD Fed MotorДокумент24 страницыBearing Current in VFD Fed Motormarn-in2501Оценок пока нет

- Analysis of Fan BladeДокумент80 страницAnalysis of Fan BladeShripad PachputeОценок пока нет

- Digital Universal Hardness Tester BRV-187.5TДокумент5 страницDigital Universal Hardness Tester BRV-187.5T周记伟Оценок пока нет

- Thrust BearingДокумент8 страницThrust Bearingsonu_saurabh100% (1)

- Types of Spanners PDFДокумент14 страницTypes of Spanners PDFRohit KarhadeОценок пока нет

- 376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enДокумент8 страниц376 IBS V09-120327 Electro-Hydraulic-Thruster DIN15430 enrajeevkumarrajeevОценок пока нет

- 1.2 Hydraulic PrinciplesДокумент48 страниц1.2 Hydraulic PrinciplesAndikaОценок пока нет

- EagleBurgmann DMS TSE E3 Brochure Mechnical Seal Technology and Selection en 22.07.2015Документ58 страницEagleBurgmann DMS TSE E3 Brochure Mechnical Seal Technology and Selection en 22.07.2015sachinumaryeОценок пока нет

- EA230 Manual Voltage RegulatorДокумент4 страницыEA230 Manual Voltage Regulatorhenryvargas238565Оценок пока нет

- ShimanoДокумент1 страницаShimanoProto Popescu VictorОценок пока нет

- Bevel Gear ManualДокумент8 страницBevel Gear ManualPiort ZelaskiОценок пока нет

- 10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersДокумент10 страниц10 Mpa Single Acting Uniform Speed Rod Action 2-Stage Telescopic CylindersĐen BáoОценок пока нет

- Strength of Materials 2016 by S K Mondal PDFДокумент472 страницыStrength of Materials 2016 by S K Mondal PDFrobinОценок пока нет

- Web Solar BrochureДокумент120 страницWeb Solar BrochureJuto SukogaОценок пока нет

- Gears, Types and ItsДокумент22 страницыGears, Types and ItsBravo VermaОценок пока нет

- Maintenance Manual: Manufacturing Number GenericДокумент64 страницыMaintenance Manual: Manufacturing Number GenericManh PhamОценок пока нет

- Caterpillar - The Impact of Generator Set Underloading - Online CommunityДокумент4 страницыCaterpillar - The Impact of Generator Set Underloading - Online Communityvictor.ciprianiОценок пока нет

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- Structural Health MonitoringОт EverandStructural Health MonitoringDaniel BalageasОценок пока нет

- Effects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamДокумент11 страницEffects of Mass Transfer On Heat and Mass Transfer Characteristics Between Water Surface and AirstreamPiterОценок пока нет

- SMES Challenges 2022Документ14 страницSMES Challenges 2022Marcelo Gustavo MolinaОценок пока нет

- NSGAFÖU 1,8/3 KV: Product InformationДокумент3 страницыNSGAFÖU 1,8/3 KV: Product InformationAttila HorvathОценок пока нет

- P&id LegendДокумент1 страницаP&id Legendkamal arabОценок пока нет

- Hns 36W 4P Se: Product DatasheetДокумент4 страницыHns 36W 4P Se: Product Datasheetaban Ibis MedicalОценок пока нет

- Rammed EarthДокумент10 страницRammed EarthAnugraha KrishnanОценок пока нет

- 10 - DME 415-435 Vol 2 Ing Sect 09 TKW Thales March 03Документ26 страниц10 - DME 415-435 Vol 2 Ing Sect 09 TKW Thales March 03Vagner AndréОценок пока нет

- Bearing MaterialsДокумент10 страницBearing MaterialsSarath Chandra100% (1)

- Food Packaging History and InnovationsДокумент4 страницыFood Packaging History and InnovationsThuy PhamОценок пока нет

- Cleaning of Pipes by Gas Discharge Back PuffingДокумент1 страницаCleaning of Pipes by Gas Discharge Back PuffingVamsi MahantiОценок пока нет

- Design HydSysДокумент1 страницаDesign HydSysManikandan RamalingamОценок пока нет

- Phase Diagram (Compatibility Mode)Документ29 страницPhase Diagram (Compatibility Mode)soonvy100% (7)

- Cho Loss Model Radial TurbineДокумент13 страницCho Loss Model Radial TurbineNicolasОценок пока нет

- 2002 Physics NQE QuestionsДокумент7 страниц2002 Physics NQE QuestionskarxriОценок пока нет

- A Brief Overview of Porous SiliconДокумент15 страницA Brief Overview of Porous SiliconFelix Lu100% (1)

- Steam Leak CalculationДокумент3 страницыSteam Leak Calculationvazzoleralex6884Оценок пока нет

- HSBTS Diagram PDFДокумент1 страницаHSBTS Diagram PDFMayurОценок пока нет

- Fluid MechanicsДокумент35 страницFluid MechanicsJohn Ely Collado Bantog0% (1)

- Deck Cranes PDFДокумент7 страницDeck Cranes PDFIndra Ranu KusumaОценок пока нет

- Ray Transfer Matrix AnalysisДокумент10 страницRay Transfer Matrix Analysisabcdefghijklmnopqrstuvwxyz12345678910Оценок пока нет

- MegaFlex - 480V UL UPS Brochure - 041720Документ9 страницMegaFlex - 480V UL UPS Brochure - 041720GeorgeОценок пока нет

- 1 Home Base Work March 19-MRCH 31Документ3 страницы1 Home Base Work March 19-MRCH 31Celso AmotoОценок пока нет

- EFuel ReportДокумент52 страницыEFuel ReportMassimiliano ZocchiОценок пока нет

- New Energy Technologies Issue 17Документ100 страницNew Energy Technologies Issue 17blameitontherain9877100% (1)

- OGAS Company ContactДокумент4 страницыOGAS Company ContactrnoordinОценок пока нет

- ELL-332 Electric Drives Lecture 3: Different Types of Load TorquesДокумент25 страницELL-332 Electric Drives Lecture 3: Different Types of Load TorquesNikhil KumarОценок пока нет

- PPC Zimbabwe Site Visit: Darryll Castle - CEO PPC Limited Kelibone Masiyane - MD PPC ZimbabweДокумент38 страницPPC Zimbabwe Site Visit: Darryll Castle - CEO PPC Limited Kelibone Masiyane - MD PPC ZimbabweBrandon ChinyanduОценок пока нет