Академический Документы

Профессиональный Документы

Культура Документы

Alum 6xxx Pwps

Загружено:

Abu ZahidИсходное описание:

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Alum 6xxx Pwps

Загружено:

Abu ZahidАвторское право:

Доступные форматы

PT.

MITRA KARYA SARANA

Kara Industrial Estate Blok B-09

Batam Centre - Batam Island

Ph : +62778 429711 Fax : +62778 429733

PRELIMINARY WELDING PROCEDURE SPECIFICATION (PWPS)

AWS D1.2/D1.2M:2008

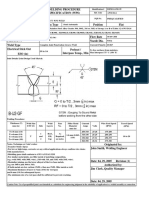

JOINTS

Joint Design

Single V Butt

Backing

Not applicable

Backing Material (Type)

No

Retainer

Not applicable

60

6

2

0-2

Unless otherwise noted, WPS shall

also be applicable for repair.

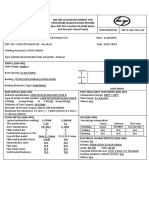

BASE METALS

M-No.

23

Specification Type & Grade

Thickness Range

Diameter

Alloy & Temper

6061-T651

Aluminium 6XXX series

3mm - 12mm

610mm.OD

Fillet: F, H

WELDING PROCEDURE

Welding Process

Layer

F-No.

AWS Spec./Electrode

Size of Filler Metals

Type of Electrode

Position of Groove

Weld Progression

Position of Fillet

Shielding Gas

Percent Composition

Flow rate

Preheat Temp.

Interpass Temp.

Initial Cleaning Oxide

Initial Cleaning oil & Dirt

Interpass Cleaning

PWHT

Welding Current (Amps)

Arc Voltage (Volts)

Travel Speed

Approx. Electrode Consumption

GMAW

Root, Hot Pass, Filler/Cap

23

AWS 5.10/ER4043

1,2mm

SuperGlaze 4043 by Lincoln

2G (F, H)

Forehand

F, H

Argon

99,99%

15 - 25 L/min

18C

50C

Brush/Grind

Brush

Brush/Grind

Not Applicable

(DC+) 110 - 300 A

19 - 29 V

7,5 - 13 mm/s

0,045 - 0,522 kg/m

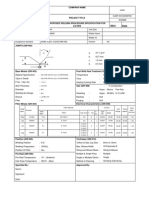

WELDING TECHNIQUE

Bead

Orifice & Gas Cup Size

Contact Tube to Work Distance

Mode of Metal Transfer

Electrode

Pass

Peening

Oscillation

Stringer and/or Weave

16 mm

10 - 15mm

Short Arc or Spray

Single

Multiple and/or Single

Not Used

Yes

Вам также может понравиться

- WPS 316 L PDFДокумент4 страницыWPS 316 L PDFIrinaОценок пока нет

- 1035 03Документ2 страницы1035 03Anuj ShahiОценок пока нет

- 163 Gmaw Zug Asme (Sri Supatmi 3g) WPQДокумент4 страницы163 Gmaw Zug Asme (Sri Supatmi 3g) WPQMuhammad Fitransyah Syamsuar PutraОценок пока нет

- Fcaw 16 THKДокумент5 страницFcaw 16 THKparesh2387Оценок пока нет

- Welding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Документ1 страницаWelding AND NDT Purposed Format: FORM QW-484 A ASME IX-Welder Performance Qualification (WPQ)Mohammad Mehdi Jafari100% (2)

- Wps 316L Gtaw R00Документ3 страницыWps 316L Gtaw R00Richard Periyanayagam100% (3)

- Wqt-Visual-Mag - BS 2Документ24 страницыWqt-Visual-Mag - BS 2KyОценок пока нет

- Wps Is 2062 GR B Butt-OkДокумент2 страницыWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- SS WPSДокумент1 страницаSS WPSMOHAMEDABBASОценок пока нет

- Welding Proposed Pwps For Our Jubail WorkДокумент2 страницыWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test CertificateДокумент3 страницыWelding Procedure Qualification Records (WPQR) (EN / ISO 15614-1:2017) Welding Procedure Qualification-Test Certificateramesh rajaОценок пока нет

- WPS-PQR (Er309l Mo)Документ4 страницыWPS-PQR (Er309l Mo)Hamza Nouman0% (1)

- PQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpДокумент1 страницаPQR / WPQ Witness Report: Weld Layer (S) Welding Process Electrode Current Voltag e Travel Speed Dia. Class Polarity AmpSatish KeskarОценок пока нет

- Wps Aws d1.1 NEWДокумент2 страницыWps Aws d1.1 NEWIkhy Tohepaly100% (1)

- N0200003 - NEW-F201-0 - Inspection & Test PlanДокумент3 страницыN0200003 - NEW-F201-0 - Inspection & Test PlanAfiq RamliОценок пока нет

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Документ5 страницWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- 004 Gtaw P5aДокумент16 страниц004 Gtaw P5aMuhammad Fitransyah Syamsuar Putra100% (1)

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Документ2 страницыWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajОценок пока нет

- PQR Is7307Документ1 страницаPQR Is7307Tridib Dey100% (1)

- Gtaw Smaw 6 Inch 6G CSДокумент1 страницаGtaw Smaw 6 Inch 6G CSKentDemeterio100% (1)

- QW-484A (WPQ) GTAW 4MM FilletДокумент2 страницыQW-484A (WPQ) GTAW 4MM FilletBalkishan Dyavanapelly100% (1)

- Welding Procedure Specification For GTAW & GMAWДокумент4 страницыWelding Procedure Specification For GTAW & GMAWanh thoОценок пока нет

- WPS FormatДокумент2 страницыWPS FormatAmit SarkarОценок пока нет

- Welding Procedure Specification (WPS) : N.A N.AДокумент1 страницаWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiОценок пока нет

- Wps Mma PipeДокумент2 страницыWps Mma PipeDimitris NikouОценок пока нет

- 19403955-WPS M.S. Is 2062Документ10 страниц19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- (Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2Документ2 страницы(Applicable Code: ASME Section IX Edition 2019) : Page 1 of 2amit singh100% (2)

- WPS Pipe 08'' SHD 40 SMAW REV02Документ2 страницыWPS Pipe 08'' SHD 40 SMAW REV02Amine MaalejОценок пока нет

- Iqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlДокумент1 страницаIqtsz DK Uke% Vkwijs'Ku % Iqtkz La ( K% Ekmy % Vkwijs'Ku U %: Quality Check Points XQ - Kork PSD IokbzavlAjayОценок пока нет

- Gmaw Complete Aws d1.6Документ1 страницаGmaw Complete Aws d1.6Silvia CardenasОценок пока нет

- WPS ListДокумент2 страницыWPS ListAdeel OmerОценок пока нет

- PQR With-PwhtДокумент2 страницыPQR With-PwhtKarthikОценок пока нет

- Aws 001Документ1 страницаAws 001akshay sarfareОценок пока нет

- Proposed WPSДокумент2 страницыProposed WPSChisom Ikengwu100% (2)

- Inter Office Memo: Sr. No. Material Specification Test Piece Size Welding ProcessДокумент1 страницаInter Office Memo: Sr. No. Material Specification Test Piece Size Welding Processg_sanchetiОценок пока нет

- WPS PQR A36.20Документ5 страницWPS PQR A36.20gchaves504100% (2)

- Welding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Документ2 страницыWelding Procedure Specification (PWPS) Asme Sec Ix, Asme Boiler & Pressure Vessel Code Contract: STP-Ph1Karam Fta Al-andalusОценок пока нет

- Welding Procedure Specification For Storage Tank & Piping SystemДокумент3 страницыWelding Procedure Specification For Storage Tank & Piping SystemAhmad MohammadОценок пока нет

- WPS Sitelca S002Документ2 страницыWPS Sitelca S002Jose Antonio GomezОценок пока нет

- Qualified Welder List Valid Until - 03-12-2019Документ2 страницыQualified Welder List Valid Until - 03-12-2019csolanki6586100% (1)

- PQR - PipeДокумент3 страницыPQR - PipeAdvanced Quality Centre AQC100% (1)

- For Fillet Weld Joint Project:Production ManifoldДокумент1 страницаFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- WPQT CertificateДокумент104 страницыWPQT CertificateMaged Lotfy Abdel-aal100% (2)

- WPS Format For AWS D1.1 - WPS - FCAWДокумент1 страницаWPS Format For AWS D1.1 - WPS - FCAWThe Welding Inspections CommunityОценок пока нет

- WPQ-1083 3G PDFДокумент2 страницыWPQ-1083 3G PDFduendex360100% (1)

- A 36 WPSДокумент2 страницыA 36 WPSNaqqash Sajid100% (1)

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Документ2 страницыASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPSДокумент1 страницаWPSNidhinkorothОценок пока нет

- Pwps Jo Wps Asme 016 Rev.001Документ2 страницыPwps Jo Wps Asme 016 Rev.001Bagandi ManurungОценок пока нет

- VLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmДокумент3 страницыVLG02 NGUYEN QUANG TUAN - 6G Duplex, T 18.26mmTuTuy AnОценок пока нет

- WPS PQR-03Документ12 страницWPS PQR-03Ranjan KumarОценок пока нет

- QW 483Документ2 страницыQW 483delta lab sangliОценок пока нет

- Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Документ8 страницQw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Muhammad HannanОценок пока нет

- Page No: 01: SA 240 GR 304 SA 240 GR 304Документ5 страницPage No: 01: SA 240 GR 304 SA 240 GR 304jobertОценок пока нет

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationДокумент2 страницыASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaОценок пока нет

- VP16 PDFДокумент13 страницVP16 PDFKara WhiteОценок пока нет

- Manual Structural WeldingДокумент12 страницManual Structural WeldingwalitedisonОценок пока нет

- Welding Procedure Specification: Page 1 of 1Документ2 страницыWelding Procedure Specification: Page 1 of 1Harshad100% (1)

- WPS FormatДокумент1 страницаWPS FormatAbdullah AnsariОценок пока нет

- Manual Overlay WeldingДокумент8 страницManual Overlay Weldingcarlmac6183% (6)

- Material Purchase Matl Qty Weight (KG) Cost (SGD) Unit Total Unit TotalДокумент2 страницыMaterial Purchase Matl Qty Weight (KG) Cost (SGD) Unit Total Unit TotalAbu ZahidОценок пока нет

- Air Pipe Line ProgressДокумент1 страницаAir Pipe Line ProgressAbu ZahidОценок пока нет

- Risk Assessment FormДокумент9 страницRisk Assessment FormAbu ZahidОценок пока нет

- BOM Phosphate TankДокумент1 страницаBOM Phosphate TankAbu ZahidОценок пока нет

- High Temp Fabric Expansion JointДокумент1 страницаHigh Temp Fabric Expansion JointAbu ZahidОценок пока нет

- Webforge Alum GratingДокумент2 страницыWebforge Alum GratingAbu ZahidОценок пока нет

- Cost Estimation - MachiningДокумент12 страницCost Estimation - MachiningAbu Zahid100% (2)

- Pwps Aws Mks AluminiumДокумент2 страницыPwps Aws Mks AluminiumAbu ZahidОценок пока нет

- Mild Cert PFC200x75Документ1 страницаMild Cert PFC200x75Abu ZahidОценок пока нет

- Simplify Proof Load TestДокумент1 страницаSimplify Proof Load TestAbu ZahidОценок пока нет

- Dieset Fuel Tank T5302Документ1 страницаDieset Fuel Tank T5302Abu ZahidОценок пока нет

- AH36Документ3 страницыAH36Abu ZahidОценок пока нет

- Metric Screw Head SizesДокумент1 страницаMetric Screw Head SizesAbu ZahidОценок пока нет