Академический Документы

Профессиональный Документы

Культура Документы

2010 V15 Se1 6

Загружено:

Jessica HessОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

2010 V15 Se1 6

Загружено:

Jessica HessАвторское право:

Доступные форматы

Thammasat Int. J. Sc. Tech., Vol.

15, Special Edition, September 2010

The Effect of Storage Degradation of

Palm- Stearin Biodiesel on Engine

Performance and Exhaust Emission

Sureerat Ngamjaroen1, Watit Pakdee2 and Cattaleeya Pattamaprom1,*

1

Department of Chemical Engineering, Faculty of Engineering, Thammasat University,

Department of Mechanical Engineering, Faculty of Engineering, Thammasat University,

Khlong Luang, Pathumthani, Thailand, 12120

*

E-mail: cattalee@engr.tu.ac.th

Abstract

The main objective of this experimental study is to determine the effects of biodiesel

degradation on the fuel properties, the engine performance and exhaust emissions of a diesel

engine by keeping biodiesel in closed containers at room temperature for different storage

times. In this work, the biodiesel derived from palm stearin was investigated. The study was

conducted for a period of 6 months. At the beginning of the study and at end of every month,

the stored biodiesel was analyzed for changes in acid value (AV), iodine value (IV), peroxide

value (PV), viscosity and methyl ester content. Results showed that AV and PV increased,

while methyl ester content decreased with storage time upto 6 months. Viscosity changes

were not significant within the 6-month storage time. The engine performance and exhaust

emission results indicated that, the brake power of petroleum diesel was comparable to those

of fresh and stored biodiesels, while the fuel consumption of biodiesel was higher than

petroleum diesel by about 5 % and this trend increased slightly as the biodiesel degraded.

Furthermore, the fuel conversion efficiency of degraded biodiesel continually decreased with

storage time. In terms of emission, fresh biodiesel produced half the CO pollution compared

to petroleum diesel and, as the biodiesel storage time increased, the emission of CO was even

lower. On the other hand, the NOx emission increased with longer biodiesel storage time.

Keywords: Degraded biodiesel, Chemical properties, Engine Performance, Emission, Storage

time

easily oxidized, such as methyl linoleate

(C18:2) and methyl linolenate (C18:3). The

formation of degraded products of biodiesel

includes insoluble gums, organic acids and

aldehydes. These products are claimed to

not only degrade the properties of biodiesel,

but also build problems in engine operation

[1].

As the degree of degradation

increases with biodiesel age, some of the

degraded products of biodiesel may cause

negative effects to engine performance.

Therefore, the main objective of this

1. Introduction

Nowadays, biodiesel is one of the most

popular alternatives derived from transesterification of vegetable oils or animal

fats. The chemical structure of biodiesel is

composed of saturated and unsaturated

long-chain fatty acid alkyl esters. Thus,

biodiesel is biodegradable, non-toxic and

has low emission compared to petroleum

diesel. However, the weak point of

biodiesel for engine fuel is that it is

sensitive to degradation because it contains

unsaturated methyl esters, which can be

32

Thammasat Int. J. Sc. Tech., Vol. 15, Special Edition, September 2010

was tested with temperature program

ranging from 160 C up to 240 C to detect

the full length of fatty acid methyl ester.

The acid value was determined by titration

method according to ASTM D 664.

Viscosities of biodiesels were tested using

Cannon Fensky Routine No.75 P 573

viscometer at 40 C according to ASTM D

445. The peroxide and iodine values were

approximated by titrating with sodium

thiosulfate solution following ISO 3960 and

EN 14111 standards, respectively.

2.3 Engine performance and exhaust

emission testing

The short term engine test was

carried out in a 4-cylinder, 4-stroke, direct

injection Nissan diesel engine. The main

specifications of the engine are given in

Table 1. The engine performance test was

measured by Eddy current dynamometer. In

this work, the tests of diesel and biodiesel

fuels were performed at variable loads and

engine speeds. The engine was tested at

speeds between 1,800 and 4,000 rpm. The

performance parameters obtained from the

engine test included brake power (P), brake

specific fuel consumption (bsfc) and brake

fuel conversion efficiency ( bf ). The

experimental study was to determine the

effects of biodiesel storage degradation on

the fuel properties as well as the engine

performance and exhaust emissions. So far,

there have been several reports on storage

degradation of biodiesel [2-4]. However,

there has been only one study on the effect

of storage degradation on engine

performance of biodiesel [19]. Besides, the

report was for rapeseed biodiesel, not the

palm-stearin one. In this work, the biodiesel

produced from palm stearin was chosen for

our investigation because palm stearin has

become more and more popular as raw

material for biodiesel production in

Thailand.

2. Experimental

2.1 Raw Materials and methods

The biodiesel produced from palm

stearin used in this study was kindly

supplied by Prathum Vegetable Oil Co.,

Ltd. (Thailand). The petroleum-base diesel

fuel used as a reference fuel was purchased

from PTT Public company Ltd. (Thailand).

In the experiment, the biodiesel was stored

in closed containers at room temperature

(temperature variation between 25 30 C)

during the whole experiment. The period of

biodiesel storage was 6 months, during

which the chemical properties of biodiesel

was analyzed every month. The biodiesel

was also tested for the engine performance

and exhaust emissions initially and after 3,

4, 5 and 6 months, respectively.

2.2 Analysis of chemical properties

The biodiesel was characterized for

methyl ester content, acid value, viscosity,

peroxide value, iodine value and high

heating value. The purity of biodiesel was

determined using Fisons GC 8000 series

gas chromatography equipped with flame

ionization detector. The capillary column

was a DA-WAX column with a length of 30

m., a film thickness of 0.25 m and an

internal diameter of 0.32 mm. Methyl

heptadecanoate was introduced as an

internal standard. The methyl ester sample

exhaust emissions of engine were measured

by Madur GA-40T Plus fuel gas analyzer.

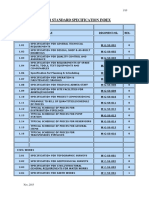

Table 1: Engine specifications

Engine model

Nissan BD-30

Engine type

4 cylinder, 4 stroke,

in - line

Displaced volume

2,953 cc.

Bore

96 mm

Stroke

102 mm

Compression ratio

18.5 :1

Maximum power

70.8 kW (95 HP)

3. Results and Discussion

The results will be discussed in 3

parts including chemical characteristics,

engine performance and exhaust emissions.

The changes in several chemical properties

33

Thammasat Int. J. Sc. Tech., Vol. 15, Special Edition, September 2010

over time were analyzed and correlated with

engine performance and exhaust emissions.

3.1 Chemical characteristics

In this experiment, the degradations

of biodiesel at various storage time up to 6

months were indicated by the changes in

several properties including acid value,

kinematic viscosity, iodine value, peroxide

value, methyl ester content and high heating

value.

3.1.1 Change in acid value

The acid value is a measure of the

amount of acidic substances in fuel. Fig. 1

shows the acid values of biodiesel derived

from palm stearin at all storage periods. As

can be seen, the acid values of biodiesel

derived from palm stearin increased with

storage time from 0.14 to 0.59 mg KOH/g

within 6 months. One reason for the

increase in acid value is the hydrolysis of

methyl ester by the reaction of moisture in

the ambient air with methyl ester [5].

Another reason is that, as the biodiesel is

kept for a long time without antioxidant, the

biodiesel undergoes oxidation by the

reaction of ambient oxygen with double

bonds of biodiesel causing it to form

peroxides as the first product. These

peroxides then undergo complex reactions

including a split into more reactive

aldehydes, which further oxidize into acids,

leading to an increase in acid value [3-5].

3.1.2 Changes in viscosity

Another

possible

degradation

pathway is to form a larger molecule like

polymers or gums. This type of degraded

products can be indicated by changes in

kinematic viscosity. Kinematic viscosity is

an important property of fuel as it indicates

the ability of fuel to atomize into small

droplets in the combustion chamber. Fig. 2

indicated that the changes in the fuel

viscosity were not significant within the 6 month storage time. This means that

degradation of palm stearin biodiesel into

polymer products was not significant in the

period of this study.

Fig. 1 Acid values of degraded biodiesels at

various stored periods.

Fig. 2 Kinematic viscosities of degraded

biodiesels at various stored periods.

3.1.3 Changes in iodine and peroxide values

Iodine value is a measure of the

quantity of double bonds in biodiesel,

whereas peroxide value indicates the

amount of peroxide in biodiesel. Fig. 3

shows the iodine values of biodiesel

obtained from palm stearin during long term

storage. The iodine values of biodiesel

continued to decrease with storage time to

the end of month 6 from 32.99 to 21.89 g /

100 g oil. The decrease in iodine value

indicated the reduction of double bonds in

biodiesel molecules by the degradation

process. The decrease in double bonds was

consistent with increase in peroxide values

as illustrated in figure 4, implying that the

reduction in the double bonds was due to

oxidation. As a result of oxidation, double

bonds of biodiesel broke apart and reacted

with oxygen to form hydro- peroxides. The

peroxide value parameter helps to indicate

the initial oxidation step of oil. Hydro

peroxides are unstable and easily form a

variety of secondary oxidation products

which can further undergo two major types

of degradation, which are fission to give

shorter-chain compounds and polymeri34

Thammasat Int. J. Sc. Tech., Vol. 15, Special Edition, September 2010

zation [6-10]. Although peroxide value is

not specified in the biodiesel fuel standard,

this parameter influences cetane number, a

parameter that is specified in the fuel

standard. Increasing peroxide value

increases cetane number, an effect that may

reduce ignition delay time [11].

reduction in the biodiesels heating values,

as shown in fig. 6.

Fig. 6 High heating values of degraded

biodiesel under the stored periods.

3.2 Performance characteristics

The engine performances of the

fresh and stored biodiesels were evaluated

based on brake power, brake specific fuel

consumption and brake fuel conversion

efficiency by comparing with petroleum

diesel. All tests were performed at various

engine speeds ranging from 1,800 to 4,000

rpm.

3.2.1 The effect on brake power

The brake power of the test engine

when using petroleum diesel were

compared to those using up to 6-month-old

biodiesels. The variations of brake power

with engine speed for all types of fuels are

shown in figure 7. As can be seen, all types

of fuels provided the maximum brake

power at the engine speed of 3,600 rpm.

The average values of brake power over the

range of speeds from 1,800 to 3,900 rpm in

figure 8 indicates that the brake power of

biodiesel increased slightly with storage

time up to the end of month 6. The result is

consistent with the decrease in the amount

of double bonds, as indicated by iodine

value in figure 4. The reduction in double

bonds, led to higher cetane number, thus

reducing ignition delay [12, 16 and 17].

3.2.2 Effect

on

brake

fuel

conversion efficiency

The brake fuel conversion efficiency ( bf ) indicates the engines ability to

Fig. 3 Iodine values of degraded biodiesel

at various stored periods.

Fig. 4 Peroxide values of degraded biodiesel at various stored periods.

Fig. 5 Methyl ester content of degraded

biodiesel at various stored periods.

3.1.4 Changes in methyl ester

content and heating value

The methyl ester content in fig. 5

indicates that the purity of biodiesel

continued to decrease with storage time.

This result is consistent with the change in

peroxide value and acid value, implying that

the methyl ester continued to convert to

peroxides and acids. We found that these

degraded products also contributed to the

convert chemical energy of fuel into

mechanical power. Fig. 9 shows the average

brake fuel conversion efficiency values for

35

Thammasat Int. J. Sc. Tech., Vol. 15, Special Edition, September 2010

all types of fuels. As can be seen, the brake

fuel conversion efficiency of all types of

biodiesel was higher than that of petroleum

diesel. However, the fuel conversion

efficiency decreased slightly for degraded

biodiesel.

Fig. 9 The average values of the brake fuel

conversion efficiency ( bf )

Fig. 7 The variation of brake power with

engine speed for petroleum diesel (Diesel),

fresh biodiesel (BS0), and biodiesels kept

for 3 months (BS3), 4 months (BS4), 5

months (BS5) and 6 months (BS6).

Fig. 10 The average values of the brake

specific fuel consumption (bfsc)

3.3 Exhaust emission

The emission tests were carried out

at a constant engine speed of 3,600 rpm and

various loads ranging from 0 to 30 kg.

3.3.1 Carbon monoxide (CO)

emission

High CO emission indicates degree

of incomplete combustion. The average

values of CO emission over the load range

of 0 to 30 kg are shown in fig 11.

Comparing use of petroleum diesel and

biodiesel as fuels, it is obvious that CO

emissions of all biodiesels were lower than

petroleum diesel. This result was expected

as the molecular structure of biodiesel

contains oxygen atoms leading to more

complete

combustion

compared

to

petroleum diesel. As the storage time of

biodiesel increased, the degree of oxidative

degradation also increased, leading to more

oxygen atoms in the fuel molecules. The

oxygen content of the degraded biodiesel

enhanced the air/fuel ratio in the

combustion chamber, leading to more

complete combustion and lower emission of

CO.

Fig. 8 The average values of brake power

for all types of fuels

3.2.3 Effect on brake specific fuel

consumption

The brake specific fuel consumption (bsfc) indicates the consumption rate of

fuel per unit power by the following

equation:

From fig. 10, the consumption of

fresh biodiesel was about 5% more than that

of petroleum diesel and became slightly

higher as the biodiesel storage time

increased. This relates directly to the

heating value of biodiesel reported in fig. 6

[12-15].

36

Thammasat Int. J. Sc. Tech., Vol. 15, Special Edition, September 2010

only reported the engine performance after

2 years.

3.3.2 Oxides of nitrogen (NOx)

emission

The average NOx emission values

for all types of fuels are shown in fig. 12.

As can be seen, the NOx emissions for all

biodiesels were higher than for petroleum

diesel. High NOx emission usually occurs

when excessive amount of oxygen is used in

the combustion engine at high temperature

[18]. Since biodiesel contains higher

oxygen content and even more in degraded

biodiesel, we found that NOx emission of

biodiesel was slightly higher than that of

petroleum diesel and continued to increase

with storage time up to the end of month 6.

4. Conclusion

In this study, the effects of biodiesel

storage degradation on engine performance

and exhaust emissions were investigated.

We found that the degradation of biodiesel

kept in a closed and dark container at

various storage times up to 6 months

occurred mainly by oxidation process into

acids, peroxides and other derivatives as

indicated by higher acid and peroxide

values, and lower methyl ester content.

However, the changes in the fuel viscosity

were not significant indicating negligible

degree of polymerization. In terms of

engine performance, we found that the

storage degradation of biodiesel led to an

increase in brake specific fuel consumption

overall mainly due to the reduction in

heating values of degraded biodiesel.

However, this degradation assisted the more

complete combustion inside the combustion

chamber and lower CO emission. Another

drawback of this degradation is that higher

oxygen amount in the degraded biodiesel

also led to higher NOx formation.

Fig. 11 CO emission of a diesel engine

when using the same fuels as in figure 7.

5. Acknowledgement

The authors are grateful to the

financial support from the national research

council of Thailand.

Fig. 12 NOx emission of a diesel engine

when using the same fuels as in figure 7.

6. References

[1]

By comparing our study with

previous researches on storage degradation

of biodiesel produced from rapeseed oil

[19], we found that, for the 6-month storage

period, the changes in acid value and

peroxide value of palm stearin biodiesel

were faster than rapeseed biodiesel,

corresponding to a greater drop in heating

value. However, we cannot compare the

changes in the engine performance since the

previous literature [19] did not report

monthly changes in engine performance but

[2]

[3]

37

Monyem A., Van Gerpen J. H., The

Effect of Biodiesel Oxidation on

Engine Performance and Emissions,

Biomass and Bioenergy, Vol. 20, pp.

317325, 2001.

Mittelbach M. and Gangl S., Long

Storage Stability of Biodiesel Made

from Rapeseed and Used Frying Oil,

JAOCS, Vol. 78, pp. 573577, 2001.

Bouaid A. et al., Long Storage

Stability of Biodiesel from Vegetable

and Used Frying Oils, Fuel, Vol. 86,

pp. 25962602, 2007.

Thammasat Int. J. Sc. Tech., Vol. 15, Special Edition, September 2010

[4]

Leung D. Y. C.et al., Degradation of

Biodiesel under Different Storage

Conditions, Bioresource Technology,

Vol. 97, pp. 250256, 2006.

[5] Ramos M. J. et al., Influence of Fatty

Acid Composition of Raw Materials

on Biodiesel Properties, Bioresource

Technology, Vol. 100, pp. 261268,

2009.

[6] Knothe G., Structure Indices in FA

Chemistry. How Relevant Is the

Iodine Value, JAOCS, Vol. 79, No. 9,

pp. 847- 854, 2002.

[7] Moreira R. G. et.al, Deep-Fat-Frying

Fundamentals and Applications,

Aspen Publication, Inc. Gaithersburg,

Maryland, 1999.

[8] G. Knothe, Some Aspects of

Biodiesel Oxidative Stability, Fuel

Processing Technology, Vol. 88, pp.

669677, 2007.

[9] Mittelbach M. and Gangl S., Long

Storage Stability of Biodiesel Made

from Rapeseed and Used Frying Oil,

JAOCS, Vol. 78, pp. 573-577, 2001.

[10] Ferguson C. R. and Kirkpatrick A. T.,

Internal Combustion Engine, John

Wiley & Sons, Inc., 2001.

[11] Dunn R. O., Effect of Antioxidants

on the Oxidative Stability of Methyl

Soyate (Biodiesel), Fuel Processing

Technology, Vol. 86, pp. 10711085,

2005.

[12] Karabektas M. and Hosoz M.,

Performance and Emission Characteristics of a Diesel Engine Using

IsobutanolDiesel

Fuel

Blends,

Renewable Energy, pp. 16, 2009.

[13] Altun S. et al., The Comparison of

Engine Performance and Exhaust

Emission Characteristics of Sesame

OilDiesel Fuel Mixture with Diesel

Fuel in a Direct Injection Diesel,

Engine Renewable Energy, Vol. 33,

pp. 17911795, 2008.

[14] Raheman H. and Ghadge S. V.,

Performance of Compression Ignition

Engine (Madhuca Indica) Biodiesel

with Mahua, Fuel, Vol. 86, pp. 2568

2573, 2007.

[15] Sureshkumar K. et al., Performance

and Exhaust Emission Characteristics

of a CI Engine Fueled with Pongamia

Pinnata Methyl Ester (PPME) and its

Blends with Diesel, Renewable

Energy, Vol. 33, pp. 22942302,

2008.

[16] Klopfenstein W. E., J. Am. Oil.

Chem. Soc, Vol. 59, p. 531, 1982.

[17] Krisnangkura K., A Simple Method

for Estimation of Cetane Index of

Vegetable Oil Methyl Ester, JAOCS,

Vol. 63, pp. 552-553, 1986.

[18] Graboski M. S. and McCormick R.

L., Combustion of Fat and Vegetable

Oil Derived Fuels in Diesel Engines,

Progress in Energy and Combustion

Science, Vol. 24, pp. 125164, 1998.

[19] Thomsom J. C. et al., Two-year

Storage Study with Methyl and Ethyl

Esters of Rapeseed, In: Cundi J,

Editor. Liquid Fuels and Industrial

Products from Renewable Resources.

Proceedings of the Third Liquid

Fuels Conference, Nashville, TN,

September 1517, 1996.

38

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- No-Spin Application GuidelinesДокумент2 страницыNo-Spin Application GuidelinesJessica HessОценок пока нет

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- No-Spin Application GuidelinesДокумент2 страницыNo-Spin Application GuidelinesJessica HessОценок пока нет

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- SCANIA Axle Load CalculationДокумент19 страницSCANIA Axle Load CalculationGuillermo Cordero33% (3)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- NTOS Brochure Trucks EnglishДокумент2 страницыNTOS Brochure Trucks EnglishJessica HessОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- DC Machine Theory and Transformer PrinciplesДокумент32 страницыDC Machine Theory and Transformer PrinciplesPolireddi Gopala KrishnaОценок пока нет

- Programator Orar - 292555GB-03Документ16 страницProgramator Orar - 292555GB-03Daniel EneaОценок пока нет

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Makerere University Civil Engineering Assignment on Nalubaale DamДокумент8 страницMakerere University Civil Engineering Assignment on Nalubaale DamRobert WalusimbiОценок пока нет

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Foster Wheeler Process Engineering Practices IndexДокумент86 страницFoster Wheeler Process Engineering Practices Indexchemiesm94% (16)

- Kaplan Turbine Working As A Propeller CFD InvestigДокумент11 страницKaplan Turbine Working As A Propeller CFD InvestigclaudehackerОценок пока нет

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- More power in less space with SMA SUNNY CENTRAL UPДокумент4 страницыMore power in less space with SMA SUNNY CENTRAL UPBrahadeesh Perinkolam MuraliОценок пока нет

- Introduction to Concrete Components and ClassificationДокумент29 страницIntroduction to Concrete Components and ClassificationUsama AliОценок пока нет

- Transformer REFДокумент4 страницыTransformer REFs_banerjeeОценок пока нет

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- 320, 320L Medicion de Presiones Bomba Hidraulica PDFДокумент181 страница320, 320L Medicion de Presiones Bomba Hidraulica PDFrprim100% (2)

- Fire Pump Installation GuideДокумент3 страницыFire Pump Installation GuideJeff D. AgustinОценок пока нет

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Valve Material ApplicationДокумент16 страницValve Material Applicationehab8320014413100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- 2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSДокумент47 страниц2ND YEAR PHYSICS Full Book Topical MCQS With ANSWERSArhamОценок пока нет

- Pipe Sizes and Flow Rates for Air Flush DrillingДокумент14 страницPipe Sizes and Flow Rates for Air Flush DrillingzapspazОценок пока нет

- 9.6MVA - Technical Specifications For Inverter Duty TransformerДокумент7 страниц9.6MVA - Technical Specifications For Inverter Duty Transformerarunghandwal100% (2)

- Omax Annual ReprtДокумент78 страницOmax Annual ReprtSalini RajamohanОценок пока нет

- Method of Lighting CalculationsДокумент3 страницыMethod of Lighting CalculationsSpencer Josh RegedorОценок пока нет

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Transport Phenomena: Instructor: Assistant Professor Department of Chemical Engineering, BUET, Dhaka-1000Документ21 страницаTransport Phenomena: Instructor: Assistant Professor Department of Chemical Engineering, BUET, Dhaka-1000touhidОценок пока нет

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- FMC Smith Meter 01 - Mesurement Product & SystemДокумент70 страницFMC Smith Meter 01 - Mesurement Product & SystemDucVikingОценок пока нет

- Energy Conservation Oppurtunities in Boiler SystemДокумент34 страницыEnergy Conservation Oppurtunities in Boiler SystemSiddharth Jain67% (3)

- Ground Improvement TechniquesДокумент29 страницGround Improvement TechniquesMeEr AahilОценок пока нет

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- FMM Question Set 1Документ16 страницFMM Question Set 1Abhijit KuchbhilikhtaОценок пока нет

- TERAO Presentation August 2022Документ48 страницTERAO Presentation August 2022LuatNguyenОценок пока нет

- Chapter 4 Unit 1 - Building With Nature SSДокумент28 страницChapter 4 Unit 1 - Building With Nature SSJeffreyОценок пока нет

- Quantum Mechanics 1Документ88 страницQuantum Mechanics 1Mehul GuptaОценок пока нет

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- QT-002!02!50 HZ Lister Peter - Aksa - Mitsubishi - John Deere - Perkins Engine-Alternator Couple Table 2015.02.16Документ1 страницаQT-002!02!50 HZ Lister Peter - Aksa - Mitsubishi - John Deere - Perkins Engine-Alternator Couple Table 2015.02.16Cris_eu09Оценок пока нет

- Delta Ia-Mds Vfd-Ed Um en 20150910-1Документ280 страницDelta Ia-Mds Vfd-Ed Um en 20150910-1FahadОценок пока нет

- Dose Complete CatalogueДокумент272 страницыDose Complete CatalogueBerkan OranusОценок пока нет

- Water Standard Specification Index As On Dec 2015Документ10 страницWater Standard Specification Index As On Dec 2015afp15060% (1)

- IFFCO Urea ProcesspdfДокумент3 страницыIFFCO Urea ProcesspdfBalas43Оценок пока нет

- Dual Nature of Radiation and MatterДокумент6 страницDual Nature of Radiation and Mattersub100% (1)